Flexible tube press for sludge cake discharge by extrusion method with multi-layer permeable panels

A technology of permeable plates and presses, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of complex technical solutions for expansion and shaking, difficulty in maintaining and replacing filter cloths, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The filter element of the present invention will be further described below with reference to the accompanying drawings.

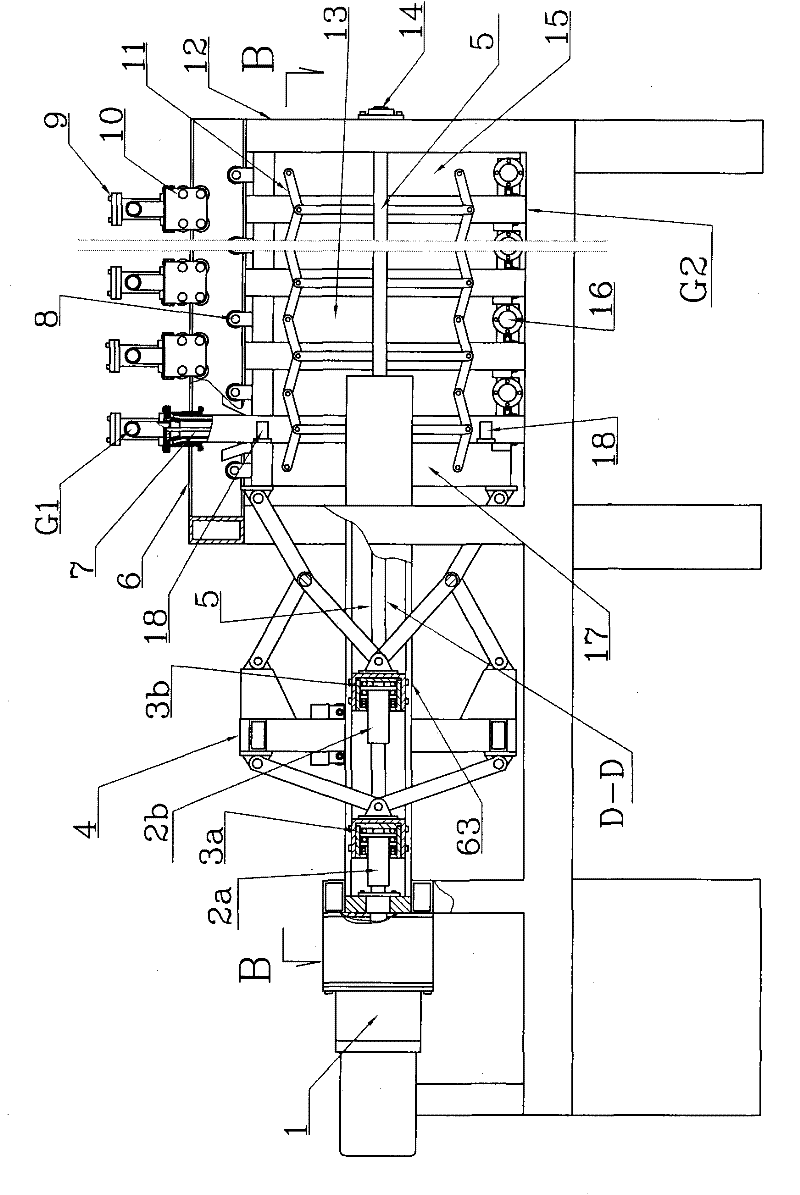

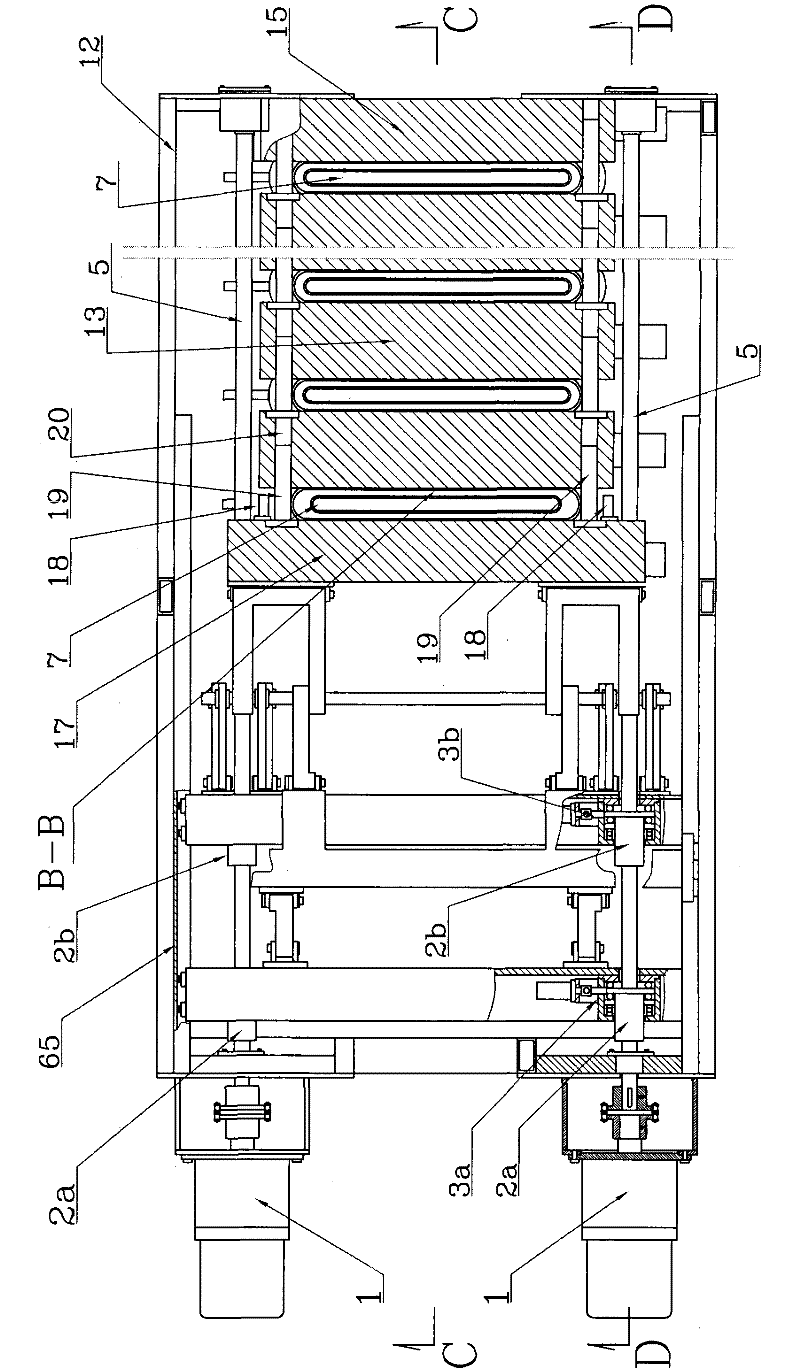

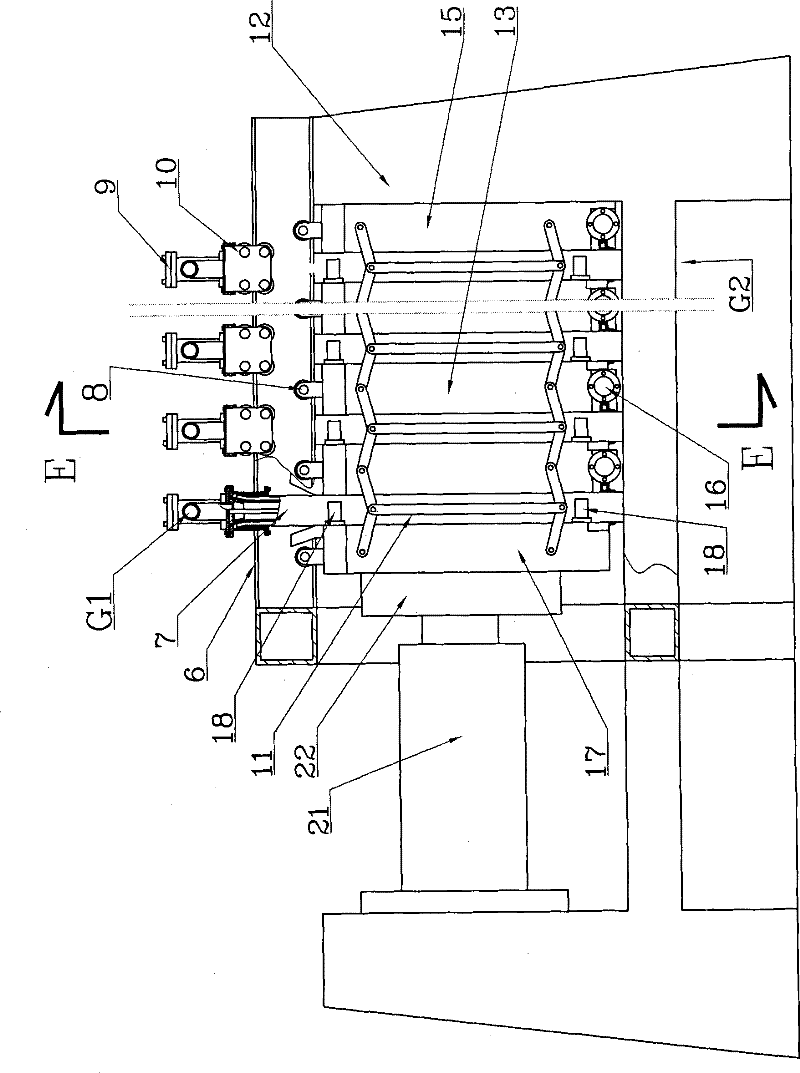

[0070] in Figure 1 to 4 In, the overall embodiment 1 of the already disclosed flexible tube press is shown. in figure 1 , 2 , 4, 5, and 8 show the filter tube unit 7a that clamps a filter element 7 between the pressure plate and the pressure plate of the pressing device along the pressing force direction 25. The filter element (such as Figure 5 (Shown) includes the upper flange, the filter tube unit 7a, the front and rear limit structure of the filter chamber, the left and right limit mechanism of the filter chamber, the horizontal filtrate collecting plate and the mechanical slag discharge assembly; the upper flange 34 includes the upper sealing structure of the filter chamber and walking The upper sealing structure of the filter chamber includes a downward pressure flange 26 and a sealing strip. The guide wheels 10 of the walking mechanism are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com