Subsurface tunnel drainage treatment method

A technology of tunnel drainage and treatment method, applied in drainage, tunnel, tunnel lining and other directions, can solve the problems of consuming man-hours, a large number of templates, and the drainage effect is not easy to achieve the expected effect, so as to facilitate later construction, ensure smoothness, and improve efflux The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

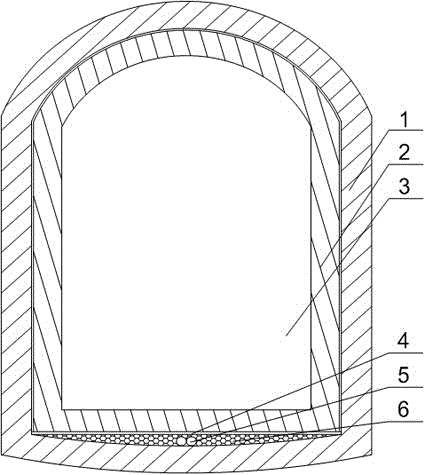

[0029] Such as figure 1 As shown, this embodiment includes the following steps carried out in sequence:

[0030] a. Set up multiple dewatering wells in the middle of the tunnel 3 first, and then carry out the initial lining 1 construction after the water level in the tunnel 3 drops to a safe position;

[0031] b. After the initial lining 1 is completed, the silt on the bottom surface is removed, and the water filter layer 6 is laid on the bottom surface of the primary lining 1;

[0032] c. Lay a plurality of drain conduits 5 extending to the sump of the shaft in the filter layer 6, and set valves at the end of the drain conduit 5;

[0033] d. Lay a waterproof layer 4 on the upper surface of the water filter layer 6, and pour C25 concrete 2 on the waterproof layer 4.

[0034]In this embodiment, the method of setting dewatering wells at the bottom of the side walls on both sides of the tunnel 3 is abandoned, and by setting the dewatering wells in the middle of the tunnel 3, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com