Automatic oil pipe length measuring device and method for oil pipe dismounting

A technology for automatic measurement and lowering of oil pipes, applied in the direction of measuring devices, instruments, etc., to achieve the effects of reducing labor intensity of workers, eliminating hidden dangers of construction quality, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

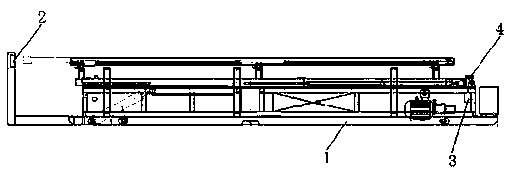

[0026] Referring to Fig. 1, it is a structural schematic diagram of Embodiment 1 of the present invention, a device for automatically measuring the length of oil pipes for lifting and lowering oil pipes, at least including a pipe rod conveyor main body 1, and also includes a proximity switch 2, a pressure regulating valve 3, a displacement sensor 4 and a control system, the front baffle of the pipe rod conveyor main body 1 is detachably connected to the proximity switch 2, the proximity switch 2 is located on the pipe rod side of the pipe rod conveyor main body 1, and the pressure regulating valve 3 is connected with the pipe rod conveying The main body 1 of the machine is connected to the hydraulic system, the displacement sensor 4 is arranged on the main body 1 of the pipe rod conveyor, and the displacement sensor 4 is located under the tailgate of the main body 1 of the pipe rod conveyor, the control system is connected with the proximity switch 2, the pressure regulating Th...

Embodiment 2

[0043] Referring to Fig. 1, a method for automatically measuring the length of the oil pipe for lowering the oil pipe includes the above-mentioned device for automatically measuring the length of the oil pipe for lifting and lowering the oil pipe, and further includes the following steps

[0044] The first step is preparation, to obtain the initial distance L between the front baffle and the rear baffle of the main body of the pipe rod conveyor 1 初 , Oil pipe effective thread length L 丝 , tubing length L 管 , put L, L 丝 and L 管 The data is entered into the control system, the oil pipe is placed on the main body 1 of the pipe and rod conveyor, and the operation of lowering the oil pipe by the main body 1 of the pipe and rod conveyor is started;

[0045] The second step is measurement. During the downward movement of the oil pipe, the displacement sensor 4 follows the movement, and the displacement sensor 4 works to obtain the downward movement length L of the displacement sen...

Embodiment 3

[0050] Referring to Fig. 1, a method for automatically measuring the length of the oil pipe when lifting the oil pipe includes the above-mentioned device for automatically measuring the length of the oil pipe when lifting and lowering the oil pipe, and further includes the following steps

[0051] The first step is preparation, to obtain the initial distance L between the front baffle and the rear baffle of the main body of the pipe rod conveyor 1 初 , Oil pipe effective thread length L 丝 , tubing length L 管 , put L, L 丝 and L 管 The data is entered into the control system, the oil pipe is placed on the main body 1 of the pipe rod conveyor, and the main body 1 of the pipe rod conveyor is started to carry out the oil pipe lifting operation;

[0052] The second step is measurement. During the hoisting process of the oil pipe, the displacement sensor 4 follows the movement, and the displacement sensor 4 works to obtain the moving length L of the displacement sensor 4. 传, At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com