Patents

Literature

75results about How to "Improve the success rate of construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

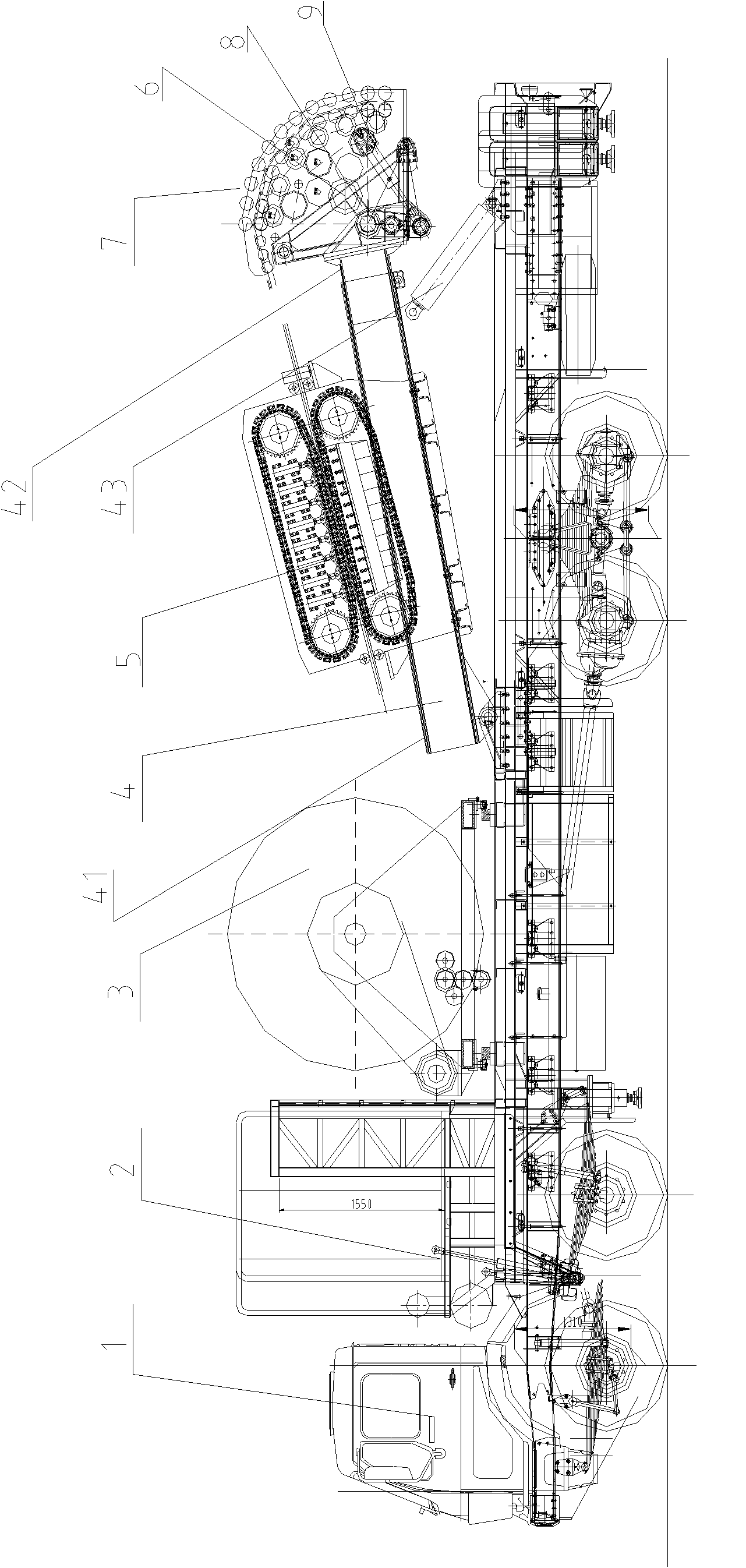

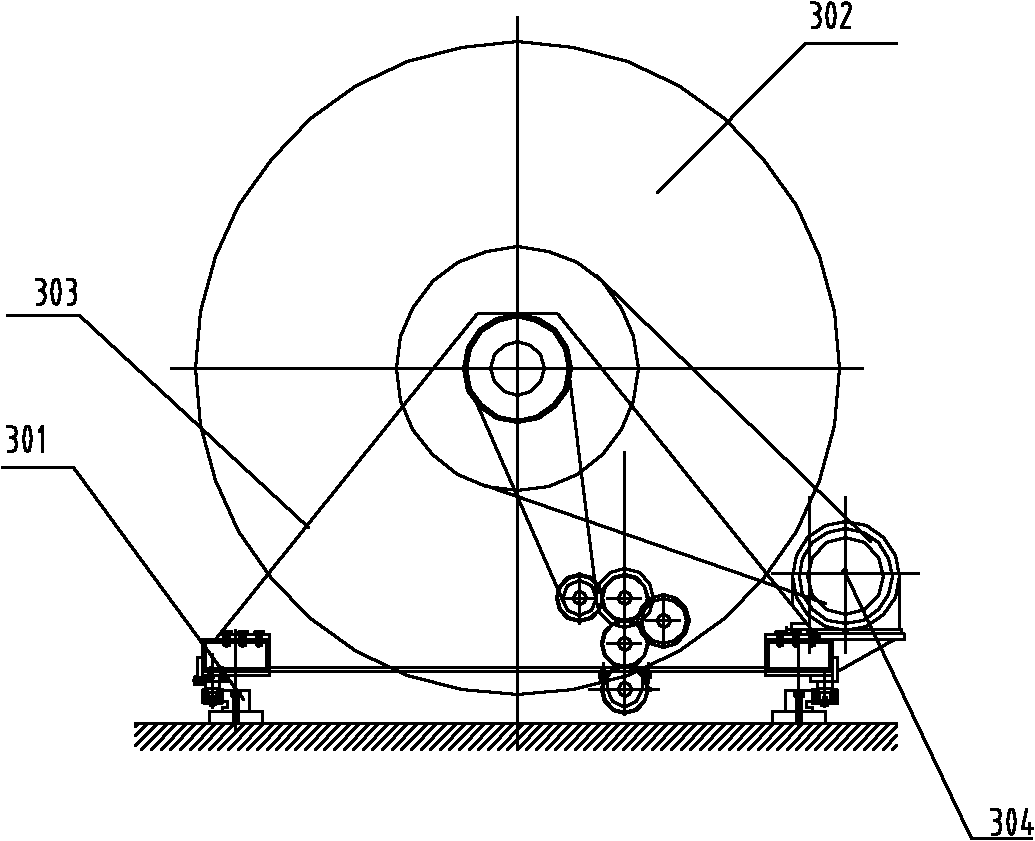

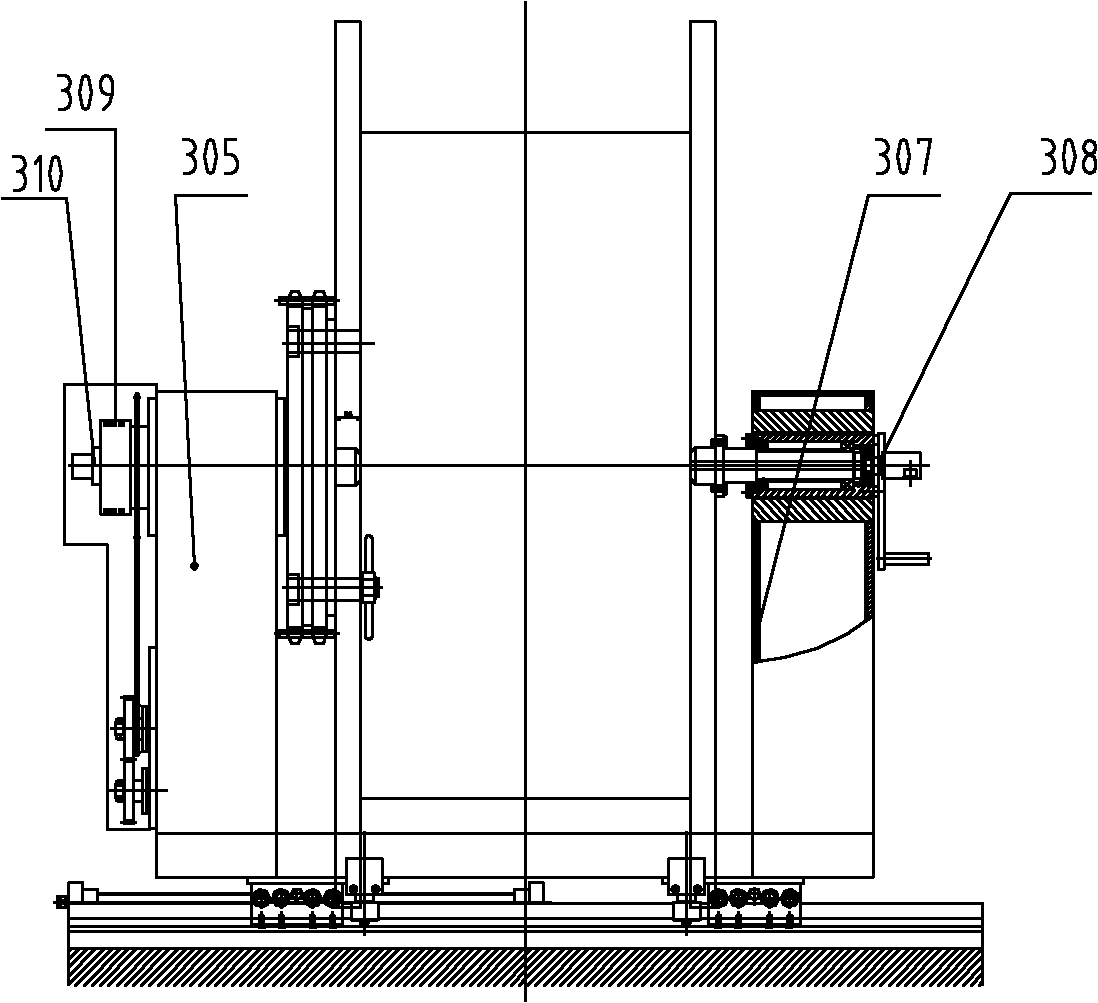

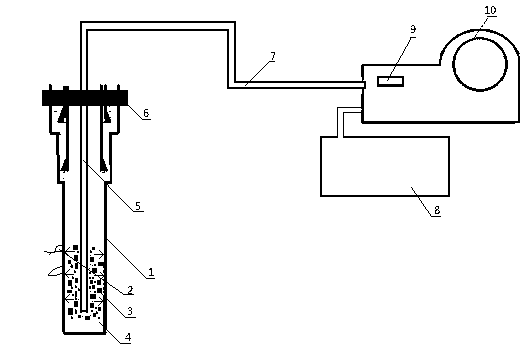

Continuous pipeline tripping device

ActiveCN102733768AQuick connectionEasy to operateDrilling rodsDrilling casingsTraction systemRotating drum

The invention discloses a continuous pipeline tripping device, comprising a rotating drum retracting, laying and releasing system, a guided injection system, a traction system, and a hydraulic power system used for supplying power for the above systems. The rotating drum retracting, laying and releasing system comprises a rotating drum, a cable laying device and a guide rail, wherein the guide rail is fixed on an underpan of a vehicle system, the rotating drum is in a sliding connection with the guide rail through a rotating drum supporting seat, the cable laying device is fixed on one side of the rotating drum, the rotating drum is driven to move along the guide rail by the cable laying device, thereby realizing the arrangement of an oil pipeline on the rotating drum. The traction system comprises a double-arm crane and a flat track frictional transmission device. When the rotating drum rotates, the oil pipeline on the rotating drum passes through the flat track frictional transmission device and a guided injection head in sequence to enter into an oil well. According to the invention, a fast connection with the mouth of the well is guaranteed, the operational process of site construction is simplified, the damage of pipelines is prevented, and the success rate of construction is increased.

Owner:PETROCHINA CO LTD

High density fracturing liquid

The invention offers high density fracturing fluid formula used inorganic salt to improve water-base fracturing fluid density. Its feature is that its weight ratio is as follows: weight additive 4-50%, vegetable gum thickener 0.3-1.0%, cross linking agent 0.1-2.0%, pH value regulator 0.5-1.0%, cracking agent 0.002-0.3%, cleanup additive 0.05-0.5%, fungicide 0.03-0.2%, and water 30-73%. The density of the high density fracturing fluid is adjustable and can exceed 1.51g / cm3. It has good high temperature resistant, shearing resistant, and so on. Thus it can supply reliable assurance for abnormal high pressure and ultra-deep well exploration test oil and exploitation.

Owner:PETROCHINA CO LTD

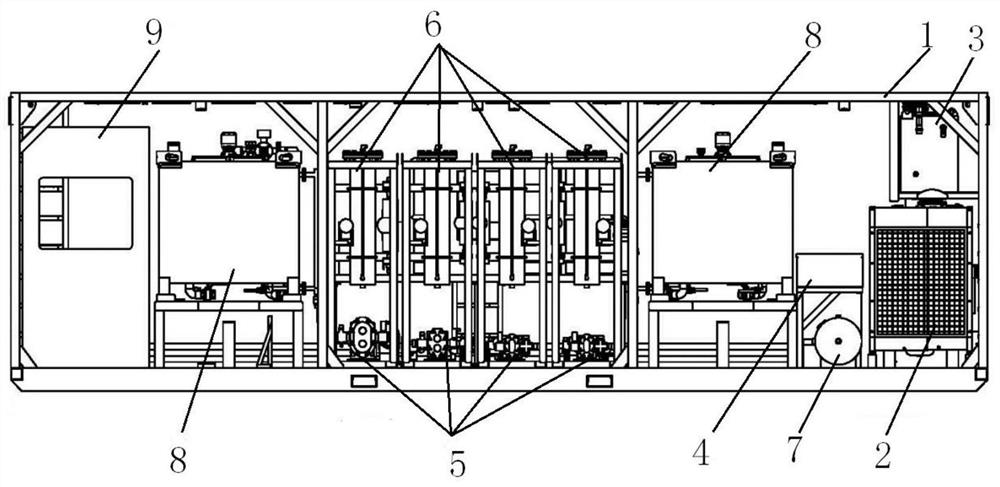

Full-automatic liquid adding device for fracturing construction and adding calibration method

PendingCN112196508AStable structureStructure, stable installationMass flow measurement devicesTransportation and packagingTransfer caseControl engineering

The invention belongs to the technical field of fracturing construction mechanization, and particularly provides a full-automatic liquid adding device for fracturing construction and an adding calibration method. The full-automatic liquid adding device comprises a prying frame, an engine, a transfer case, a hydraulic device, a liquid adding pump, a metering calibration tank, a liquid additive tank, a liquid supply pump and a control unit, wherein the input ends of the engine, the transfer case and the hydraulic device are sequentially connected; the output end of the hydraulic device is connected with the liquid supply pump and the liquid adding pump; the liquid supply pump is connected with an inlet of the liquid additive tank; an outlet of the liquid additive tank is sequentially connected with inlets of the metering calibration tank, the liquid adding pump and the liquid additive tank; the control unit is electrically connected with the engine, the transfer case, the hydraulic device, the liquid adding pump, the metering calibration tank, the liquid supply pump and the liquid additive tank; and the current situation that in the fracturing construction process, the liquid additive adding precision is large in adding difficulty and discontinuous is avoided, the mechanization and automation degree of fracturing construction is improved, meanwhile, the construction quality and potential safety hazards are effectively eliminated, and the construction success rate is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

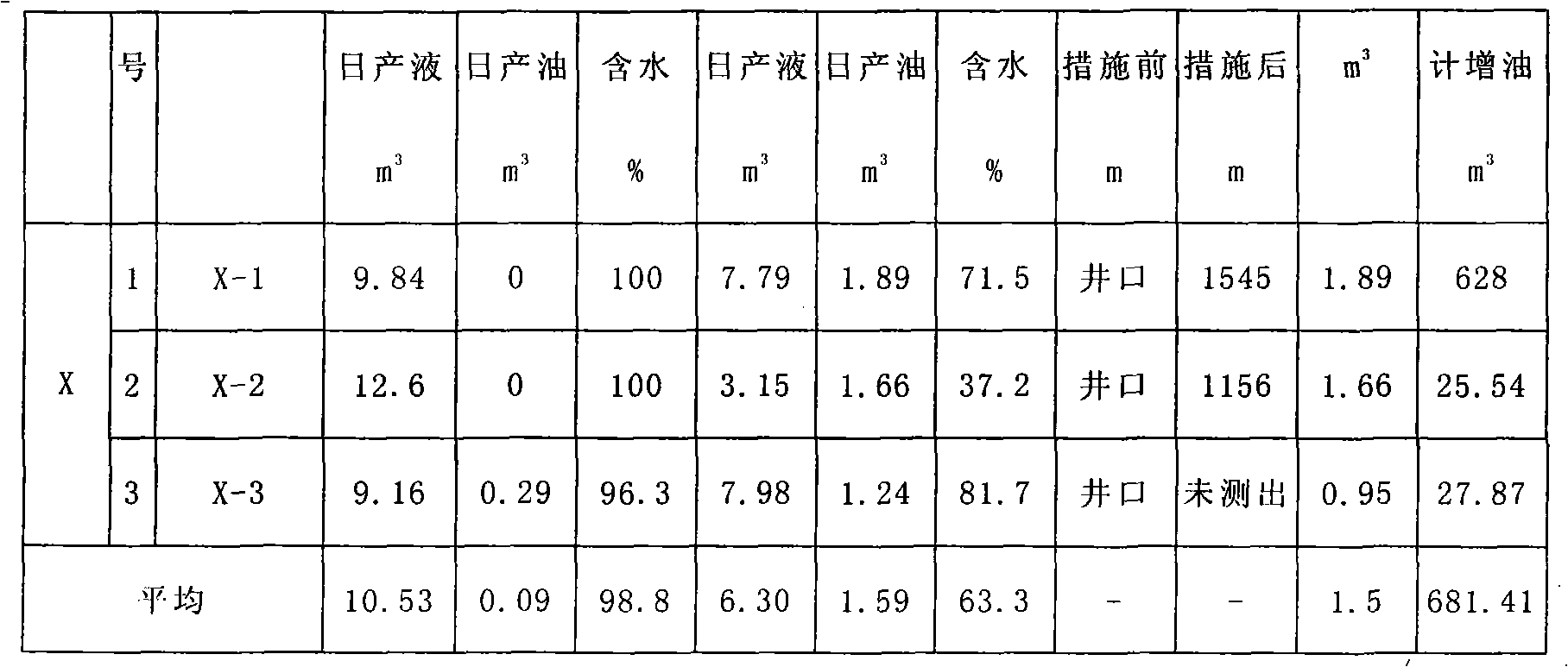

Method for plugging water from oil reservoir fractured water logging oil well developed by injecting water into low-permeable reservoir stratum

ActiveCN101787864AEffective blockingIncrease the areaDrilling compositionSealing/packingInjection pressureMicro fracture

The invention discloses a method for plugging water from an oil reservoir fractured water logging oil well developed by injecting water into a low-permeable reservoir stratum, which relates to the technical field of reform technologies for controlling water, stabilizing oil and increasing yield on the oil well in the oil exploitation process. The method comprises the following steps of: (1) preparing four plugging agents with different strengths of DQ-1, DQ-2, LDN-1 and LDN-2 on site; continuously pressing the plugging agents of DQ-1 and DQ-2 prepared in the step (1) into a natural micro fracture of the stratum by using an alternate injection process; (3) pressing the plugging agent of LDN-1 prepared in the step (1) into the natural fracture and an artificial fracture; and (4) pressing the plugging agent of LDN-2 prepared in the step (1) into the artificial fracture for sealing. The service temperatures of the four plugging agents are all 0-75 DEG C; the concentrations of the four plugging agents are 0.5-5 percent; and the pump injection pressure of a connecting truck or a fracturing truck is small than 30MPa. By using the invention, the yield increase and the stabilization of the low-permeable reservoir stratum can be effectively realized, the technical effect of the recovery rate of an oil layer can be improved and the effective plugging of the natural fracture and the artificial fracture can be realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

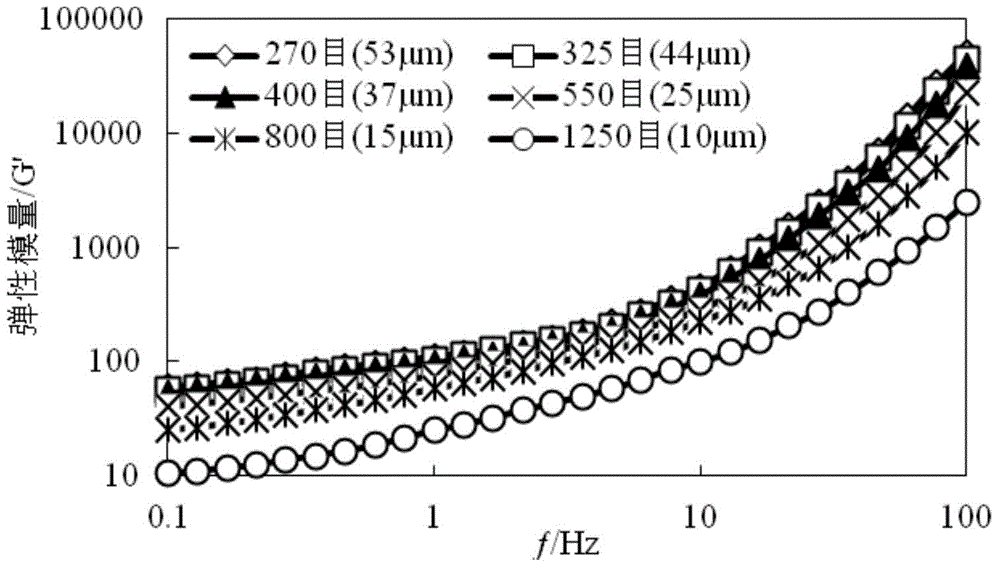

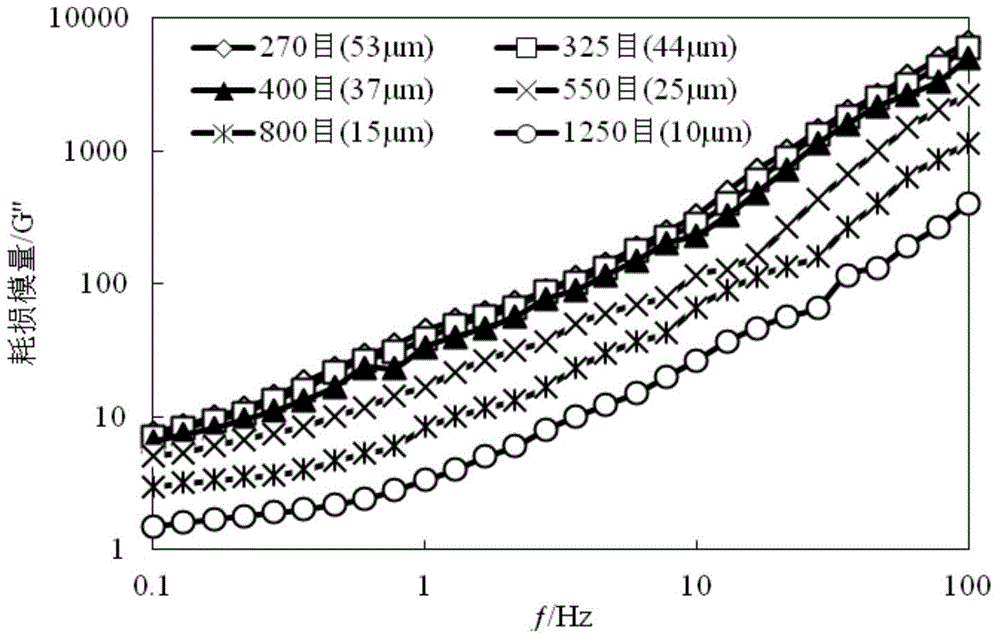

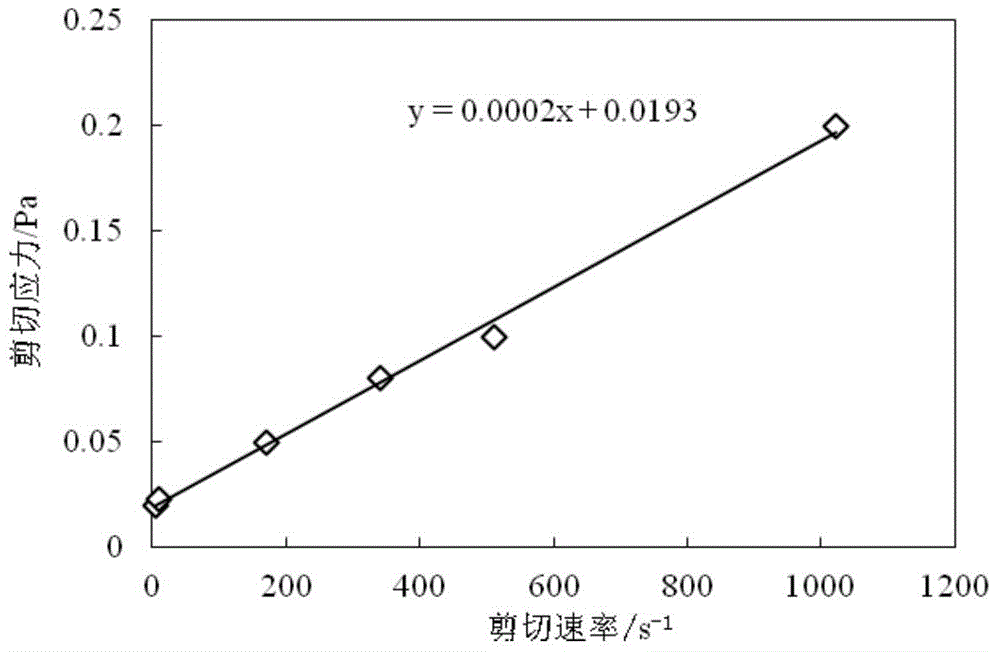

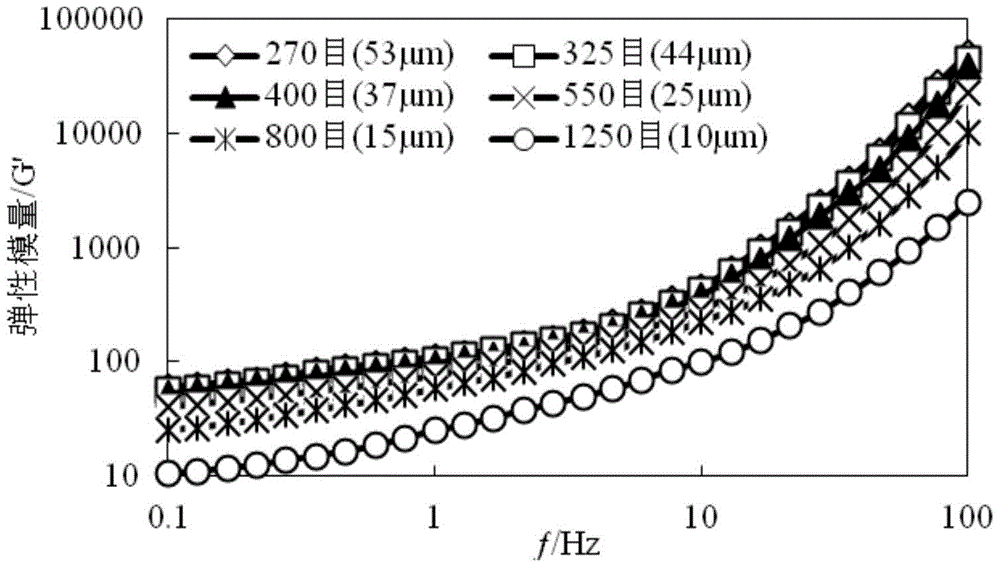

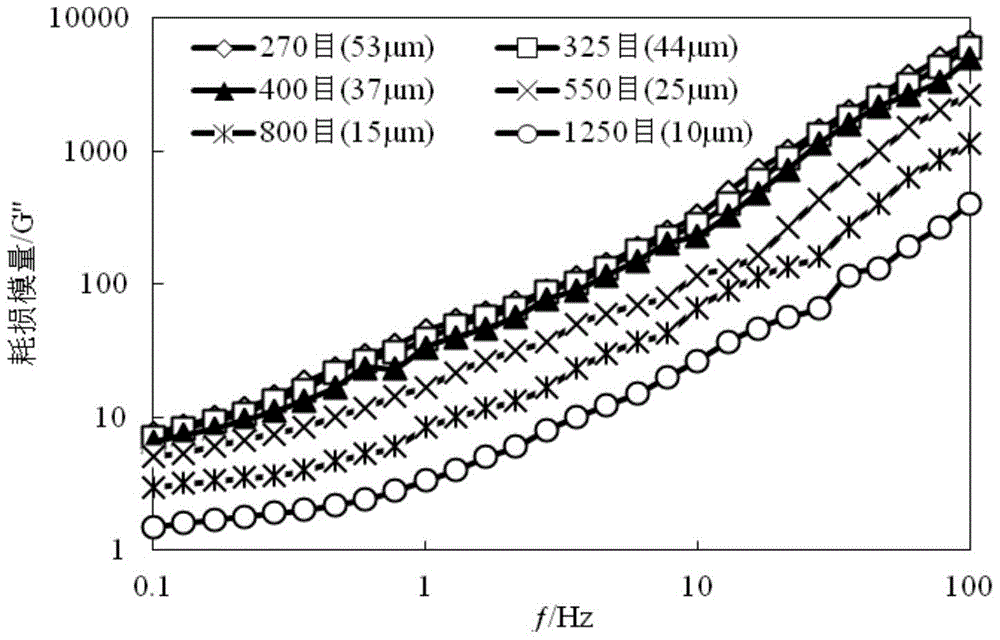

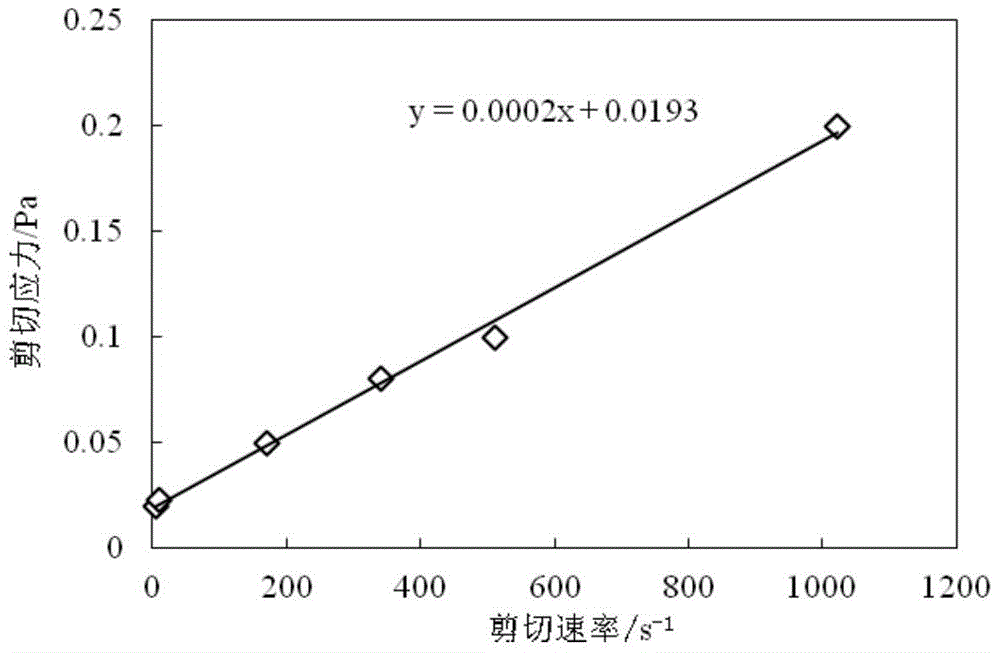

High-temperature-resistant and high-salt-resistant fine gel particle as profile control agent as well as preparation method and application of fine gel particle

The invention discloses a high-temperature-resistant and high-salt-resistant fine gel particle as a profile control agent as well as a preparation method and an application of the fine gel particle. The preparation method of the fine gel particle comprises the following steps of firstly, adding modified starch, a monomer A, a monomer B, a crosslinking agent, an initiator and an accelerant into a reaction kettle according to a certain ratio; and after finishing the polymerization reaction of the six components to form integrated water-based gel, drying, crushing, granulating, screening and performing other process steps to obtain the fine gel particle. The application method of the high-temperature-resistant and high-salt-resistant fine gel particle is as follows: a certain quantity of fine gel particles prepared by using the preparation method are added into a Bingham fluid, the gel particles can be stably suspended without settling under static and dynamic conditions, and then, the whole fluid is injected to the stratum by means of pumping pressure. By using the high-temperature-resistant and high-salt-resistant fine gel particle and the application method thereof, disclosed by the invention, the construction success rate of the gel particle can be greatly increased, and a favorable deep profile control effect can be achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

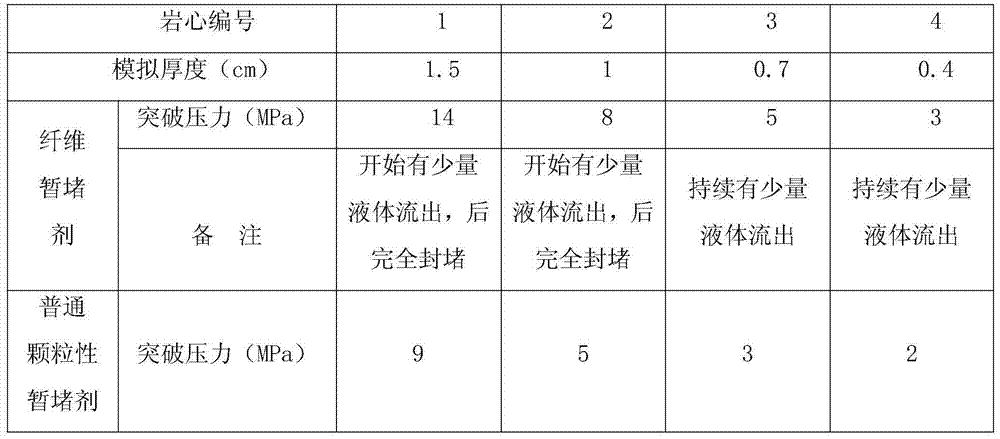

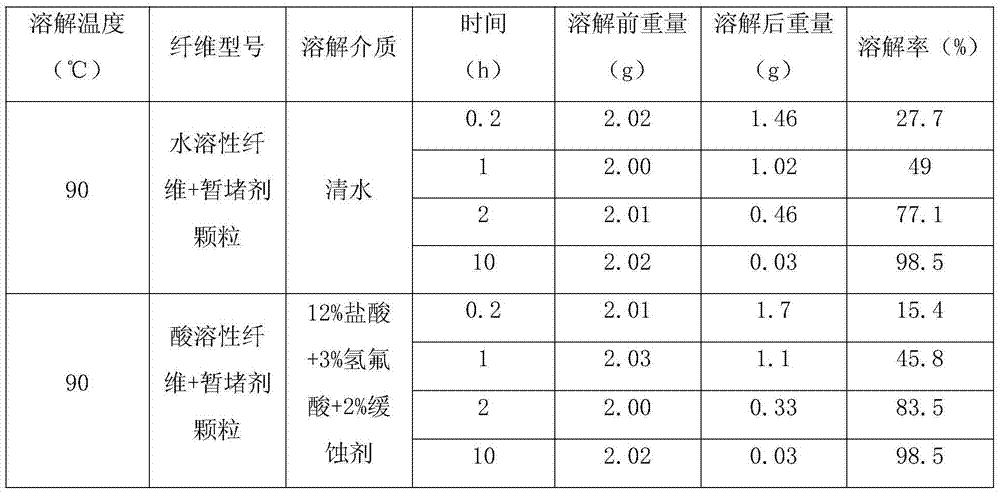

Fiber temporary plugging agent for acidizing and fracturing

The invention discloses a fiber temporary plugging agent for acidizing and fracturing. The fiber temporary plugging agent is prepared from 90-95 parts by weight of transport fluid and 0.8-2 parts by weight of temporary plugging fiber, wherein the transport fluid is prepared from the following raw materials in parts by weight: 0.2-0.6 part of guanidine gum, 0.1-0.5 part of bactericide, 0.3-0.7 part of viscosity stabilizing agent, 0.3-0.8 part of cleanup additive and 0.1-0.5 part of sodium carbonate. A dissoluble temporary plugging fiber is added to the transport fluid under a certain condition. The dissoluble fiber can form a high-density space network structure, so that the structure has strong plugging capacity. Thus, the strength of a temporary plugging layer is greatly improved. The fiber temporary plugging agent for acidizing and fracturing disclosed by the invention has the advantages of being good in plugging effect, easy to be automatically broken down after being fractured and acidized, and small in damage to a storage layer, and the success rate of construction is significantly improved.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD

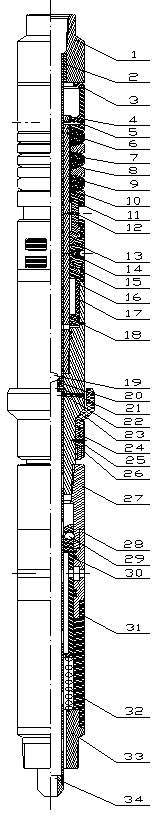

Thick oil steam flooding releasing two-way anchoring tubing anchor

ActiveCN104453757AReduce the effects of peristalsisSimple setting structureFluid removalHydraulic cylinderPulp and paper industry

The invention provides a thick oil steam flooding releasing two-way anchoring tubing anchor. The thick oil steam flooding releasing two-way anchoring tubing anchor comprises a slip, a central tube, a lower cone, a hydraulic cylinder barrel and a fixing piston. The upper end of the central tube is sleeved with the slip, the central tube is sleeved with the lower cone in a sliding mode, the upper portion of the lower cone abuts against the slip, and the slip can move upwards or downwards in the axial direction of the central tube along with the lower cone so as to achieve anchoring or releasing operation. The middle of the central tube is fixedly sleeved with the fixing piston, the fixing piston is sleeved with the hydraulic cylinder barrel in a sliding mode, the upper end of the hydraulic cylinder barrel is fixedly connected with the lower end of the lower cone in a sealed mode, a hydraulic cavity is defined by the central tube, the lower cone, the hydraulic cylinder barrel and the fixing piston, and a through hole is formed in the position, corresponding to the hydraulic cavity, of the central tube. An elastic piece is connected to the lower end of the fixing piston, a connector with which the central tube is sleeved in a sliding mode is arranged below the elastic piece, the upper end of the connector is fixedly connected with the lower end of the hydraulic cylinder barrel, and the elastic piece can be compressed by the connector. By the adoption of the thick oil steam flooding releasing two-way anchoring tubing anchor, setting operation is firm, and the reliable releasing performance is achieved.

Owner:PETROCHINA CO LTD

Process for improving bearing capacity of formation

The invention discloses a process for improving bearing capacity of a formation. The process for improving the bearing capacity of the formation comprises the following steps of: a, working out respective sizes of formation pores according to formation fracture data obtained by block coring, and preparing different sealing slurry by using gel and sealing particles of corresponding dimensions according to the respective sizes of the formation pores; b, pumping the prepared sealing slurry into a shaft, and closing a blowout preventer after the sealing slurry is full of the shaft; c, continuously pumping the sealing slurry into the shaft to enable the sealing slurry in the shaft to be extruded into the formation; and d, respectively building frameworks at the formation pores by rigid sealing particles in the manner of bridging, filling and compacting flexible sealing particles among the rigid sealing particles to fill pores near the formation of the shaft to the greatest extent so as to enable the casing pressure value of the blowout preventer to be increased continuously, therefore improving the bearing capacity of the formation. According to the process for improving the bearing capacity of the formation, bearing sealing is performed on the formation in advance, through the formation fracture data obtained by the block coring, the sealing is performed on the formation by using the chemical gel which is equivalent to formation porosity and the rigid and flexible sealing particles when drilling is performed, and therefore, the bearing capacity of the formation is artificially improved, the phenomenon that drilling fluid leaks from the formation due to the fact that drilling fluid density rises at the later stage of construction is prevented, and drilling construction can be smoothly performed.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

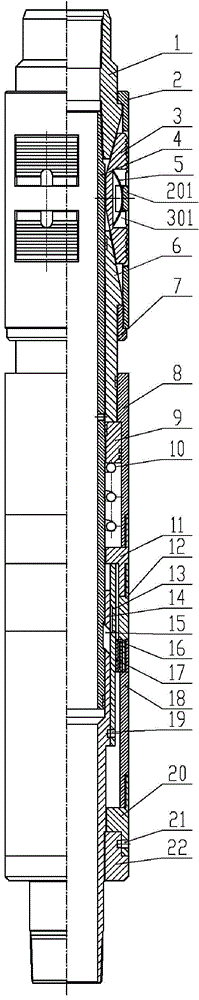

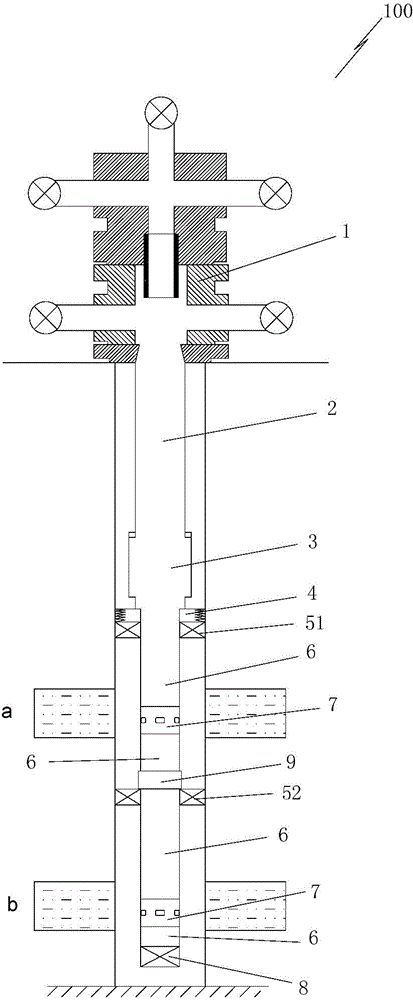

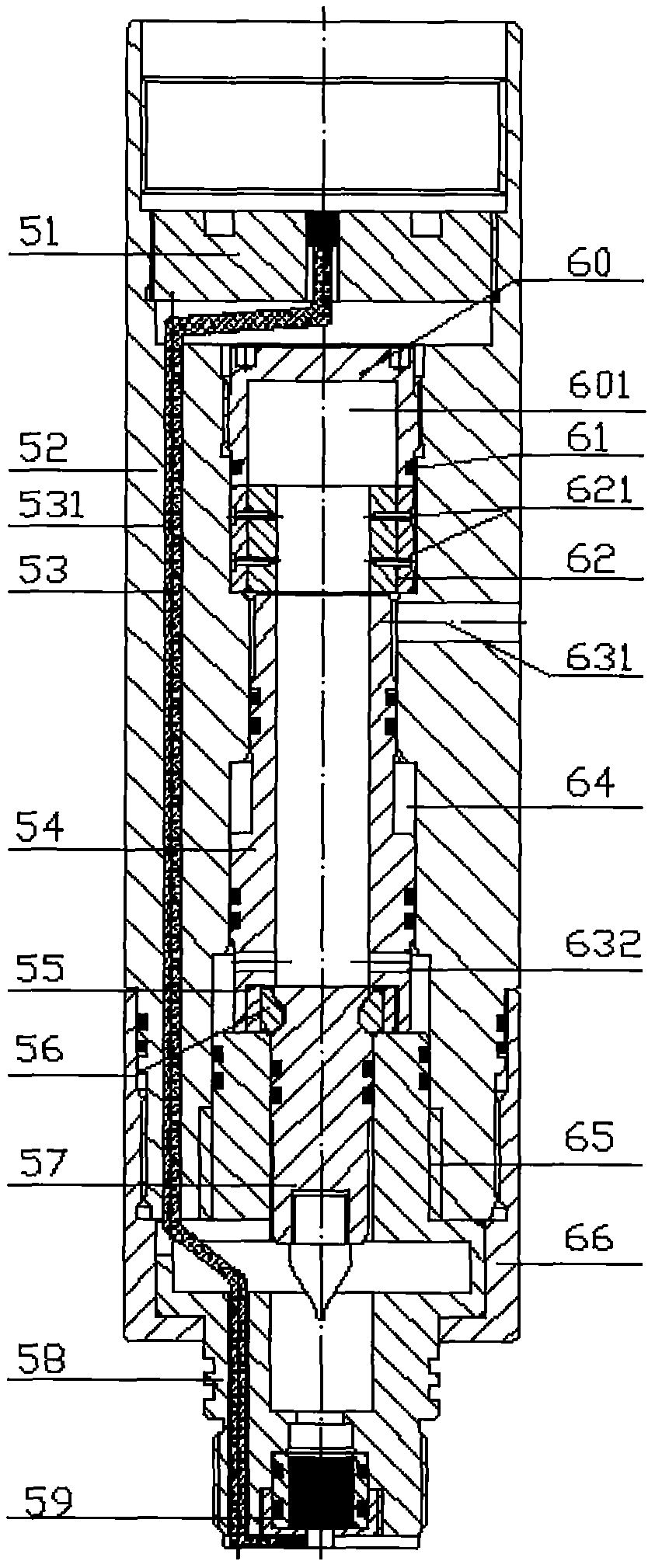

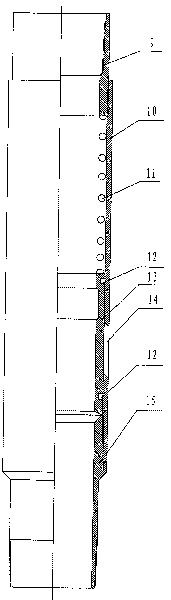

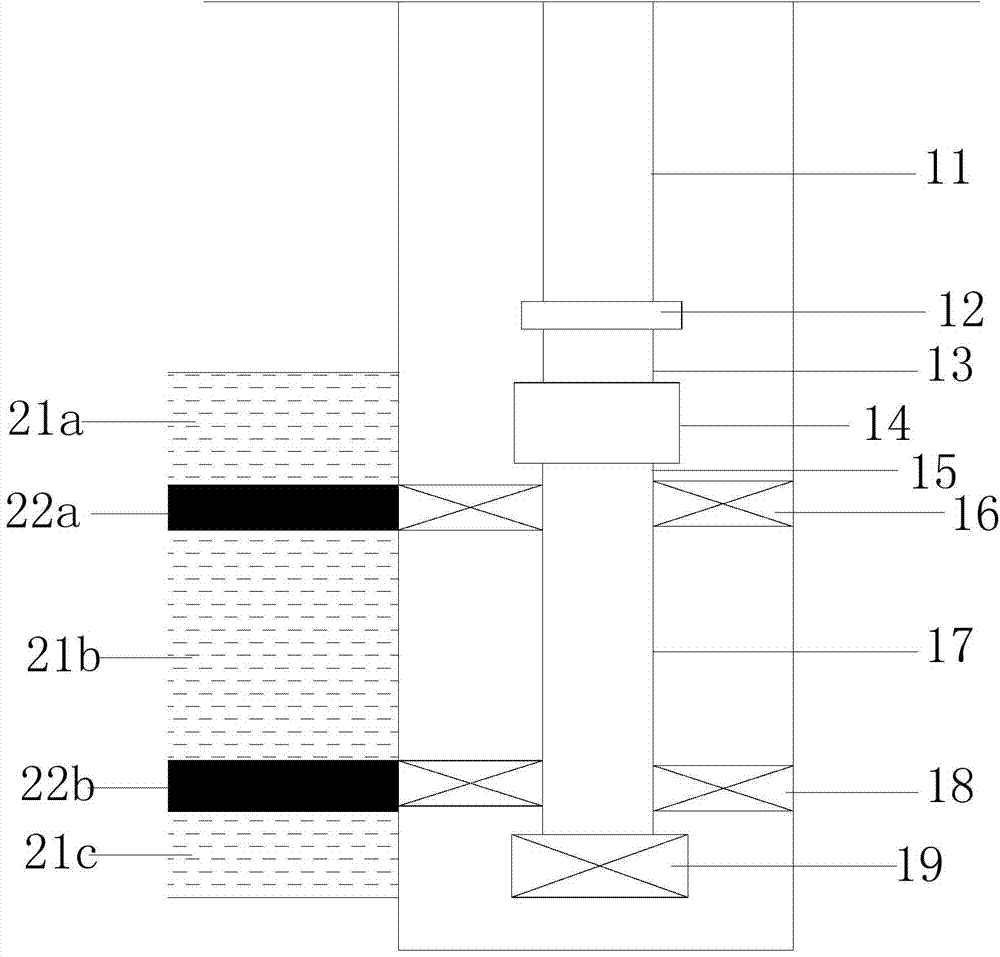

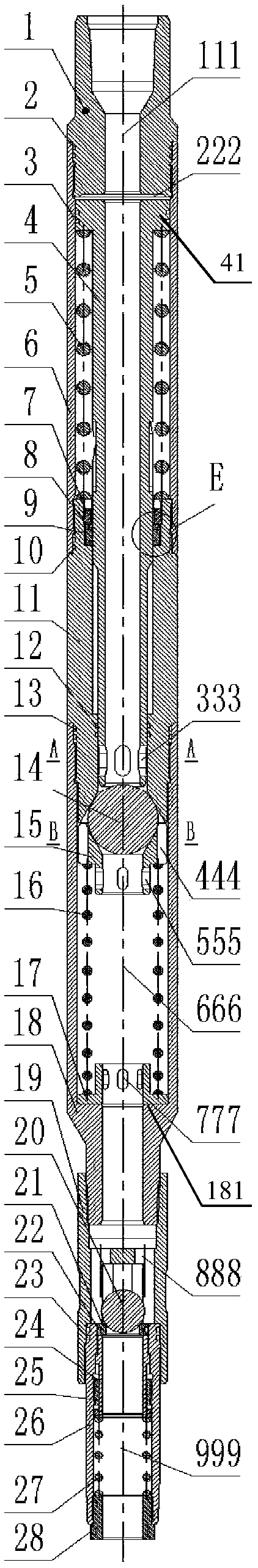

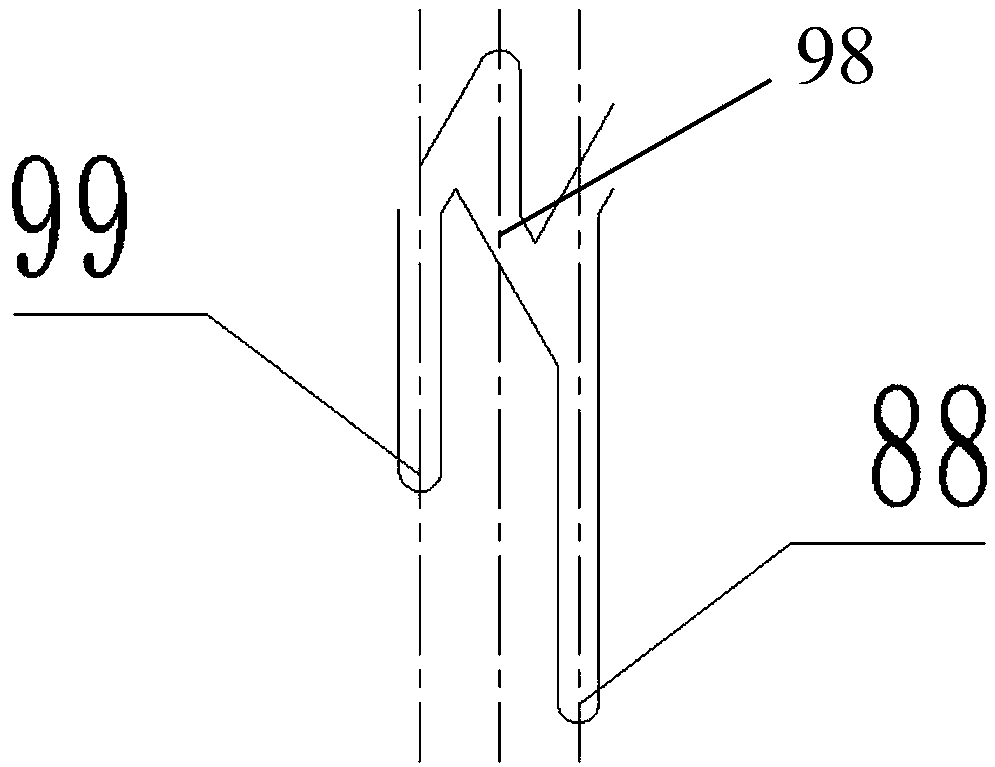

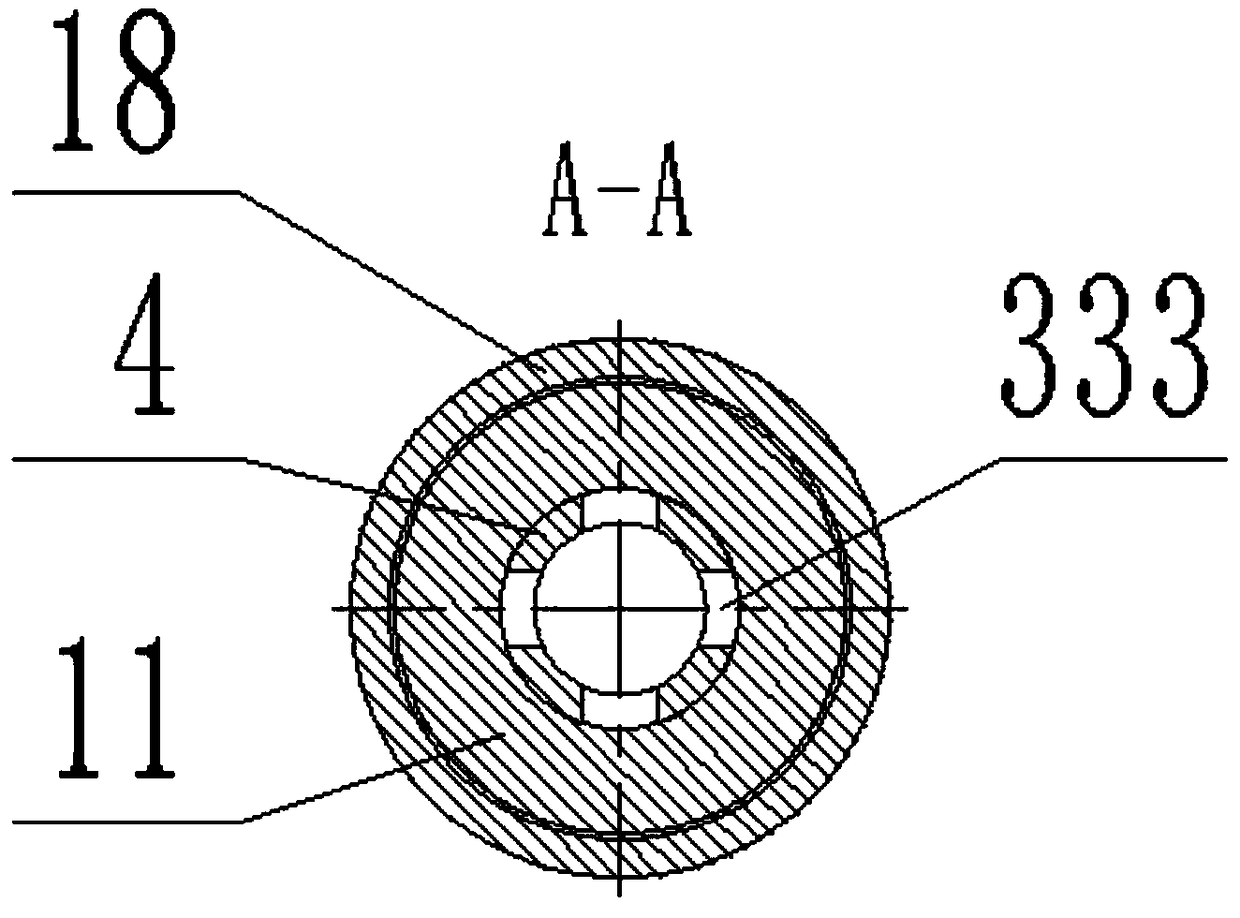

Hollow layering steam injecting system

The invention discloses a hollow layering steam injecting system. An heat preservation oil pipe is connected below a well head device; the lower end of the heat preservation oil pipe is connected with a telescopic pipe; the lower end of the telescopic pipe is connected with a steam distributing pipe column part; the steam distributing pipe column part comprises an anchor, an oil pipe, packers, an oil pipe releaser and a hollow steam injecting valve; the anchor is positioned at the uppermost end of the steam distributing pipe column part; the lower end of the telescopic pipe is connected with the anchor; in the steam distributing pipe column part, a top packer is arranged above a top oil layer, and is connected to the lower end of the anchor; a middle packer is arranged in a gap of adjacent two oil layers; the oil pipe, the hollow steam injecting valve and the oil pipe releaser are connected between adjacent two packers; and the lower end of the middle packer above a lowermost oil layer is connected with the oil pipe, the hollow steam injecting valve, the oil pipe and a plug. The hollow layering steam injecting system can preferably release thermal stress of a pipe column, is more accurate and effective in steam injecting effect, prevents the steam injecting valve from scaling to block a steam injecting channel, and increases the inner diameter of the pipe column for convenient dropping and fishing.

Owner:PETROCHINA CO LTD

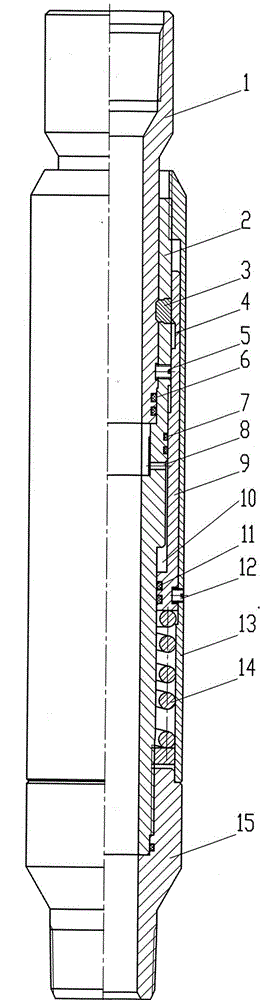

Oil well packer

InactiveCN101382053AReduce pressure requirementsSmall unsealing forceSealing/packingUpper jointEngineering

The invention relates to an oil well packer. The lower part of an upper joint is connected with the upper part of an upper inner pipe, a piston is connected with the upper joint through a seat packing pin, and a piston inner hole is matched with the upper inner pipe. A valve seat is arranged below the upper inner pipe and is connected with a lower inner pipe through a release pin, and the lower part of the lower inner pipe is connected with a lower cone. A fishing head is fixed in the lower inner pipe through an unset pin, an unset lock piece is arranged on the lower inner pipe, and the lower part of the fishing head covers the unset lock piece. A rubber tube shaft is arranged below the piston, a rubber tube is sleeved on the rubber tube shaft which is sleeved on the fishing head, a lock ring is arranged on the rubber tube shaft, a lock sleeve is sleeved on the lower inner pipe, and the lock ring and the lock sleeve can be buckled together. An upper cone is arranged below the rubber tube and is suspended onto the rubber tube shaft, and the upper cone, a slips and the lower cone are arranged inside a slips cover. During a downhole and production process, as the unset pin does not bear a force and does not require a big size, an unset force is small and an unset process is easy. The packer has low bearing requirements on an oil pipe, high execution success ratio, and low operating cost.

Owner:张永祥

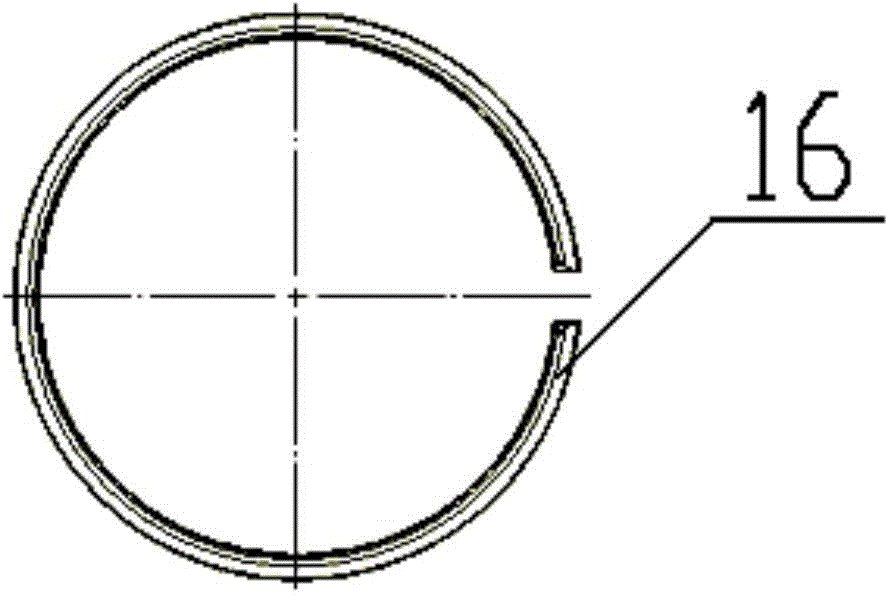

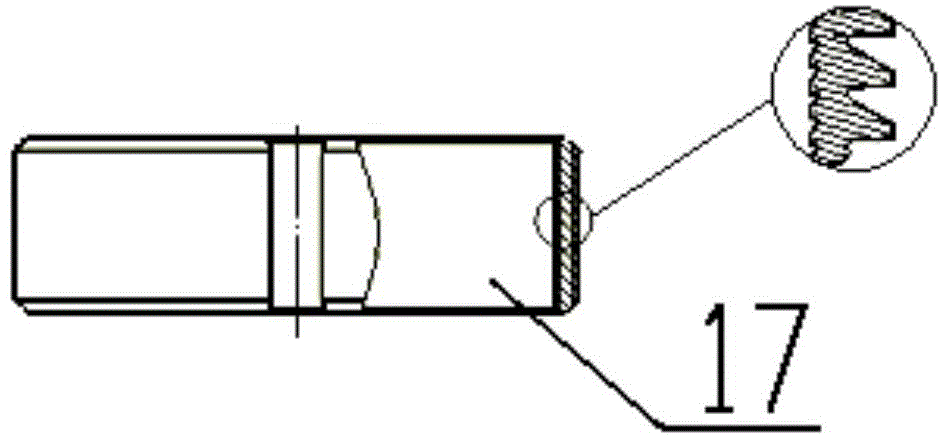

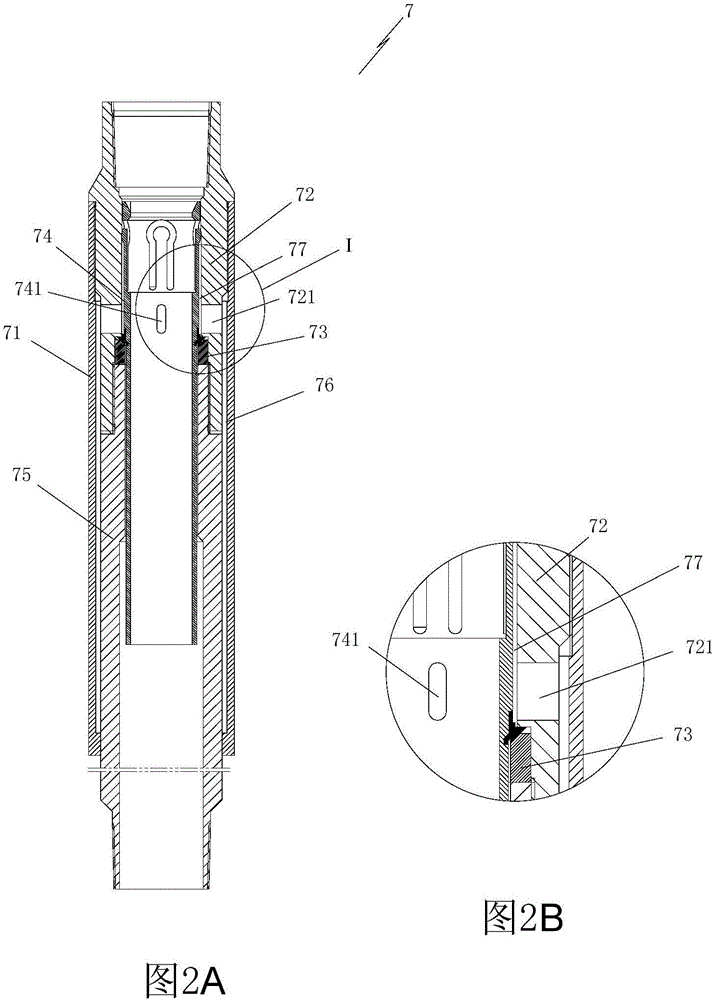

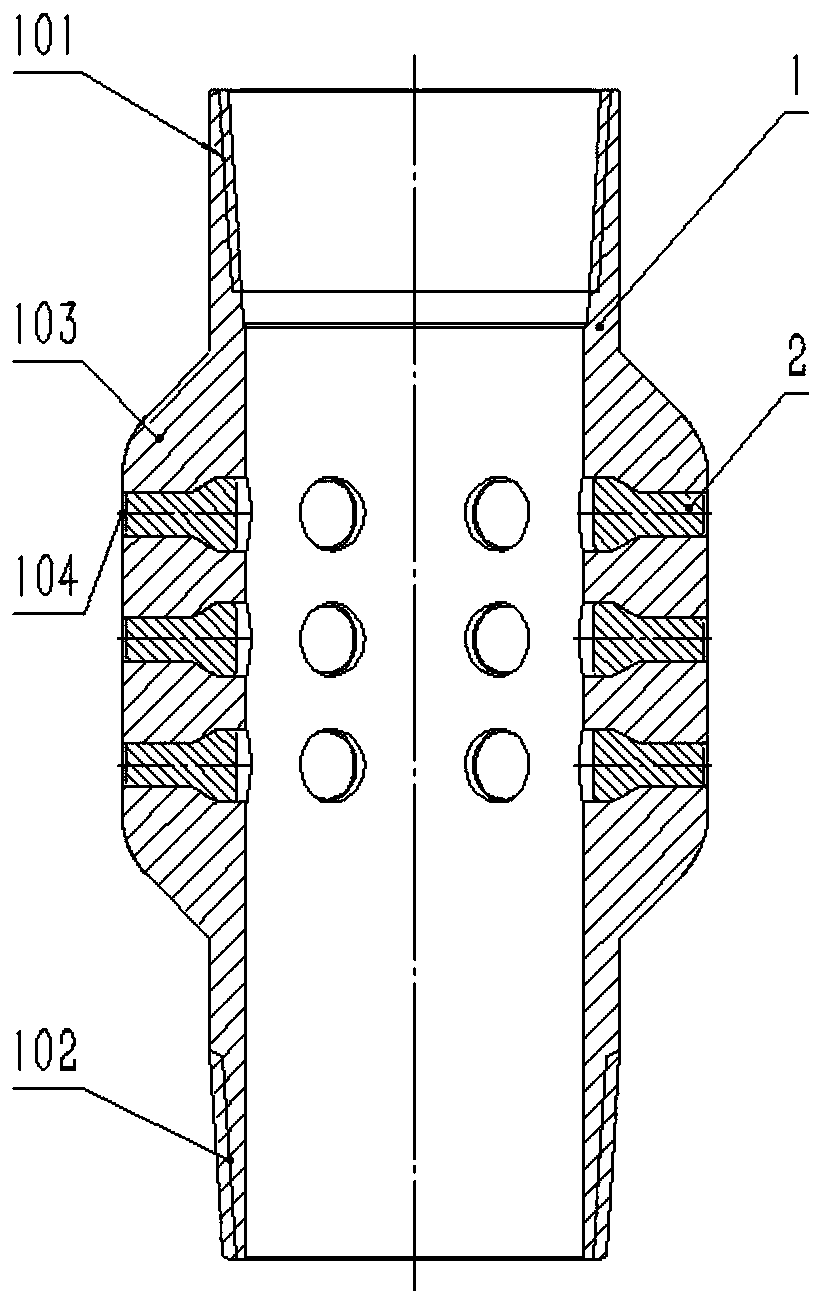

Sieve pipe self-locking switch controller

PendingCN107387037AImprove construction safetyReduce construction complexityFluid removalWell/borehole valve arrangementsEngineeringSelf locking

The invention relates to a sieve pipe self-locking switch controller. The sieve pipe self-locking switch controller is mainly composed of a conical sliding rail connector, a movable stirring block, a spring pressing cap, a reset spring and a front guiding head. Two to six dovetail grooves evenly distributed in the circumferential direction of the axis are machined in a conical structure body of the conical sliding rail connector. The movable stirring block is of a round flaw structure, and T-shaped sliding rails are machined on the bottom face, arranged in the dovetail grooves of the conical sliding rail connector and are in sliding fit. A rod head is machined at the front end of the movable stirring block, the top end of the rod head makes contact with one end of the spring pressing cap, and the spring pressing cap is arranged on a shaft outer sleeve of the front guiding head and is in sliding fit. The reset spring is arranged between the spring pressing cap and the front guiding head shoulder part. The end of the front guiding head is a conical body. The sieve pipe self-locking switch controller is used in cooperation with a sand control sieve pipe with a self-locking switch, one or more sand control sieve pipes at the assigned position under a well can be controlled according to the actual needs and can be made to put into production or quit production, and accordingly the purposes of flow adjusting, water controlling and production system optimizing are achieved.

Owner:中石化石油工程技术服务有限公司 +2

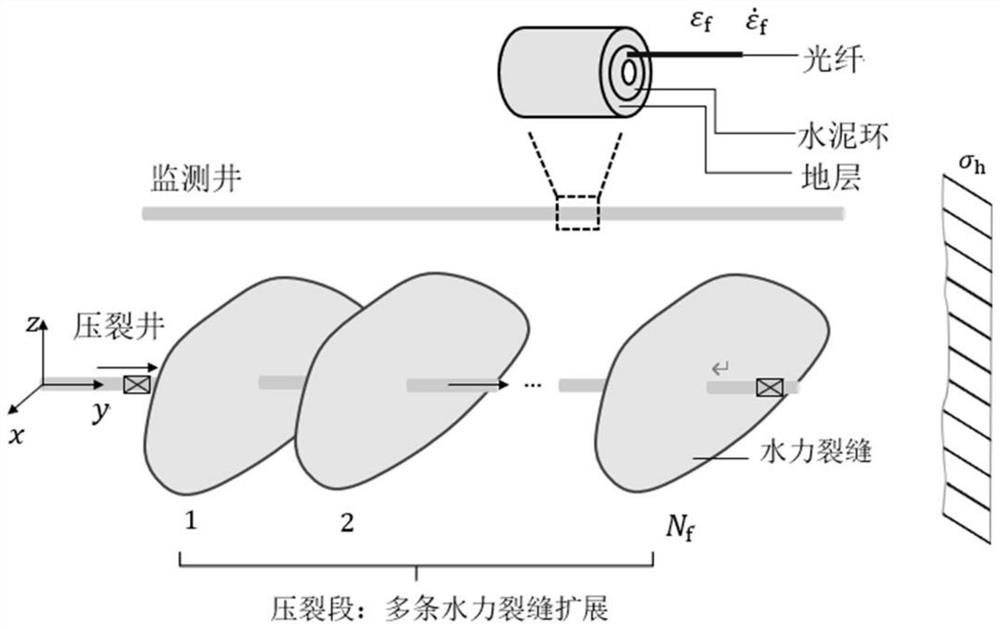

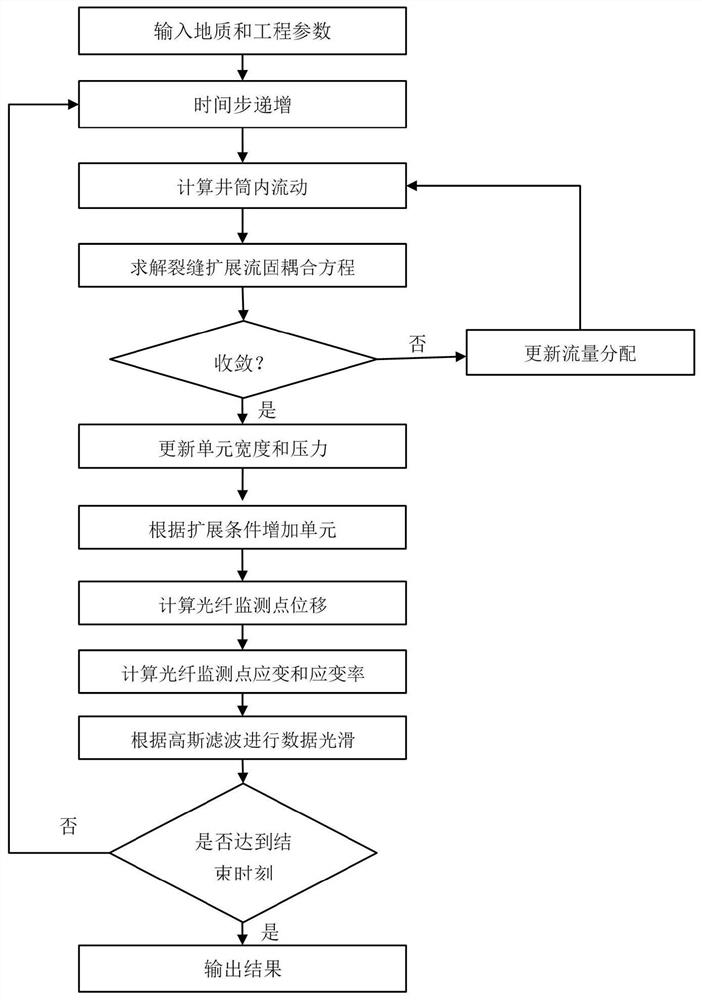

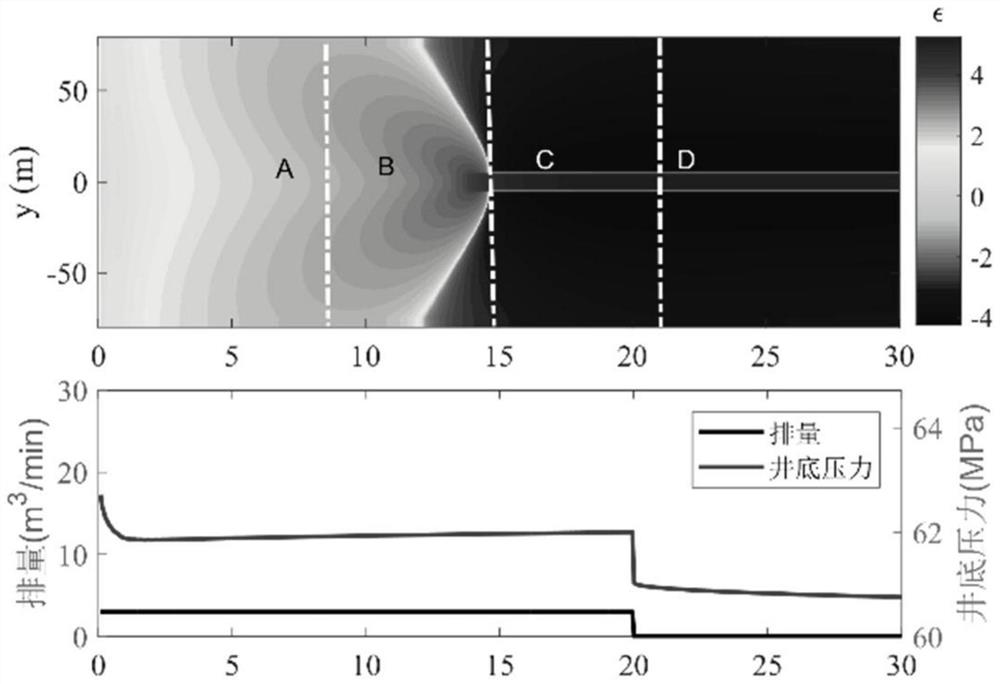

Distributed optical fiber strain monitoring method based on crack propagation simulation

ActiveCN112576245AEasy diagnosisImprove the success rate of constructionSurveyFluid removalPhysical modelEngineering

The embodiment of the invention relates to a distributed optical fiber strain monitoring method based on crack propagation simulation. The distributed optical fiber strain monitoring method comprisesthe following steps of S10, obtaining parameter information, and building a physical model of crack propagation and optical fiber strain monitoring, wherein the parameter information comprises wellbore and fracturing completion information, oil reservoir geological parameters, optical fiber positions and fracturing construction parameter information; S20, establishing a planar three-dimensional hydraulic fracturing crack propagation calculation model coupled with wellbore flow; S30, establishing an optical fiber strain and strain rate calculation model in the fracturing process; S40, smoothingdiscrete data, and drawing a cloud chart of optical fiber strain and fracturing well injection time and a cloud chart of optical fiber strain rate and fracturing well injection time; and S50, establishing a typical plate of optical fiber strain and strain rate signals and a model for judging that cracks collide with an optical fiber monitoring well, and fitting stratum parameters according to actual signals.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

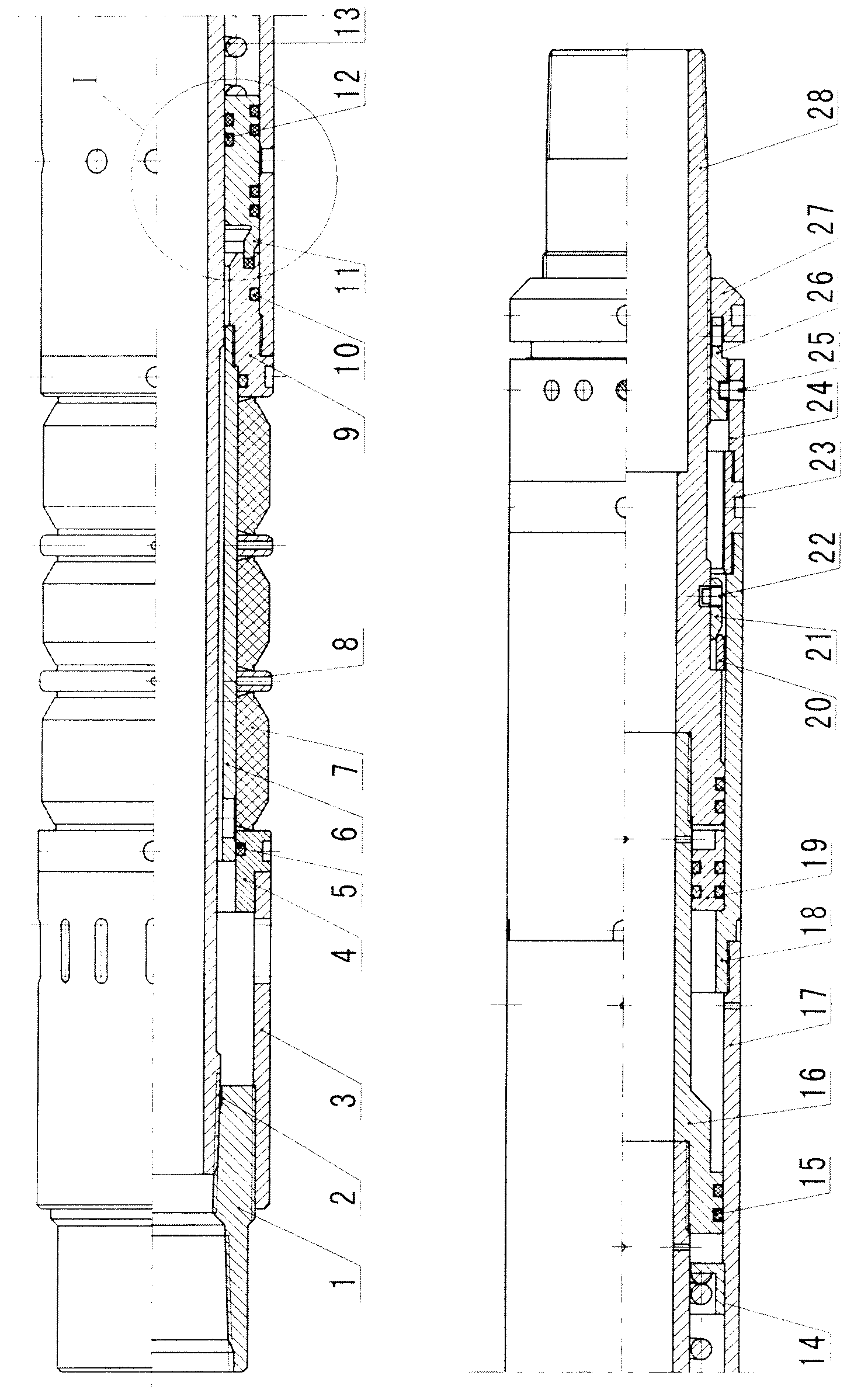

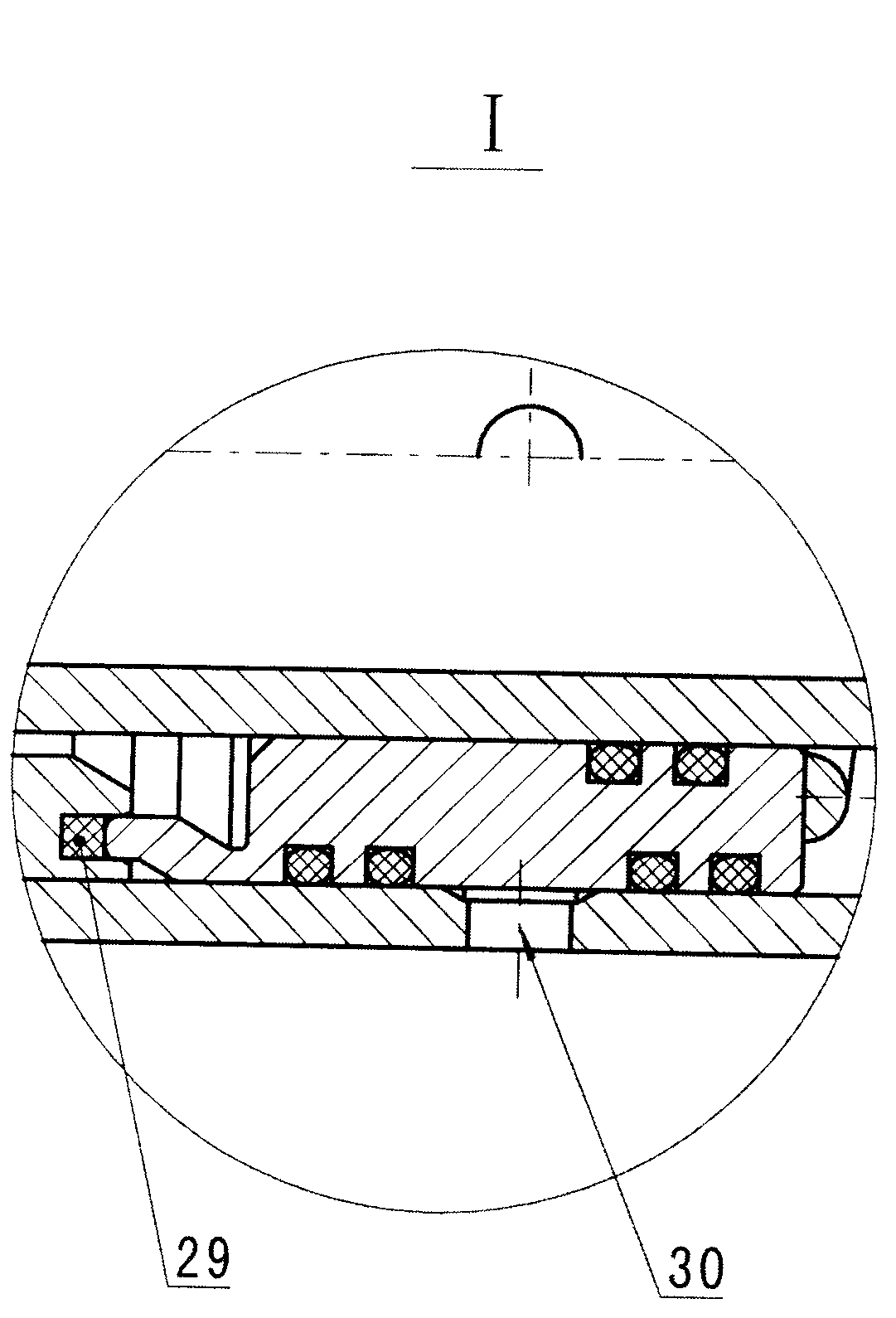

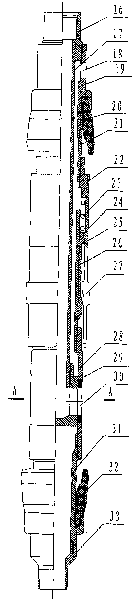

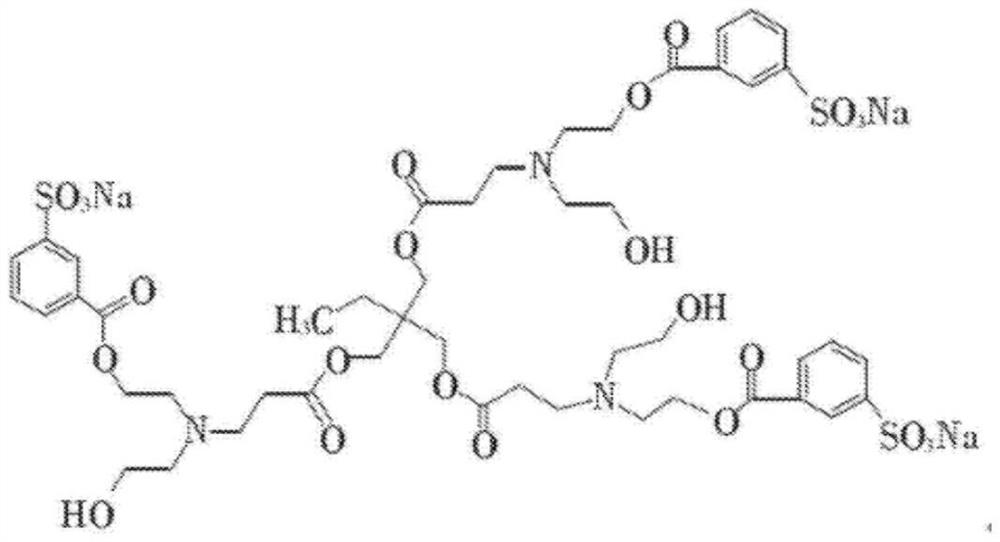

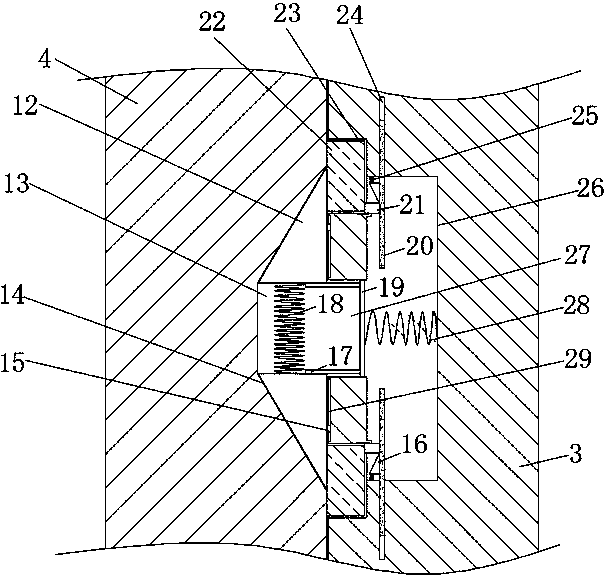

High-pressure water injection packer

InactiveCN103256017AHigh containment success rateImprove the success rate of constructionFlushingSealing/packingLocking mechanismUpper joint

A high-pressure water injection packer mainly comprises a sealing mechanism, a setting mechanism, a locking mechanism, an unblocking mechanism, a reverse well-flushing mechanism and the like. The sealing mechanism mainly comprises an outer central tube, a long rubber cylinder, a spacer ring, a short rubber cylinder and the like. The setting mechanism mainly comprises an upper central tube, a lower central tube, a setting shear pin, a piston, a lower cylinder liner, a lower reverse flushing jacket, a spring holder, a spring, a reverse flushing valve seat, an outer central tube, a pressure ring and the like. The locking mechanism mainly comprises a lock ring, a support ring, a lock loop and the like. The unblocking mechanism mainly comprises an upper joint, an upper central tube, a lower central tube, a lower joint, an unblocking shear pin and the like. The reverse well-flushing mechanism mainly comprises an upper reverse flushing jacket, a central tube, an outer central tube, a lower reverse flushing jacket, a reverse flushing valve seat, a reverse flushing piston and the like. The high-pressure water injection packer has the advantages that the defects of poor setting reliability, small packing area and low construction integration rate are overcome, the packer is especially satisfactory to high-pressure separated layer water injection, and the high-pressure water injection packer is high in packing success rate, long in effective lifetime and the like.

Owner:盐城市鑫源石化机械有限公司

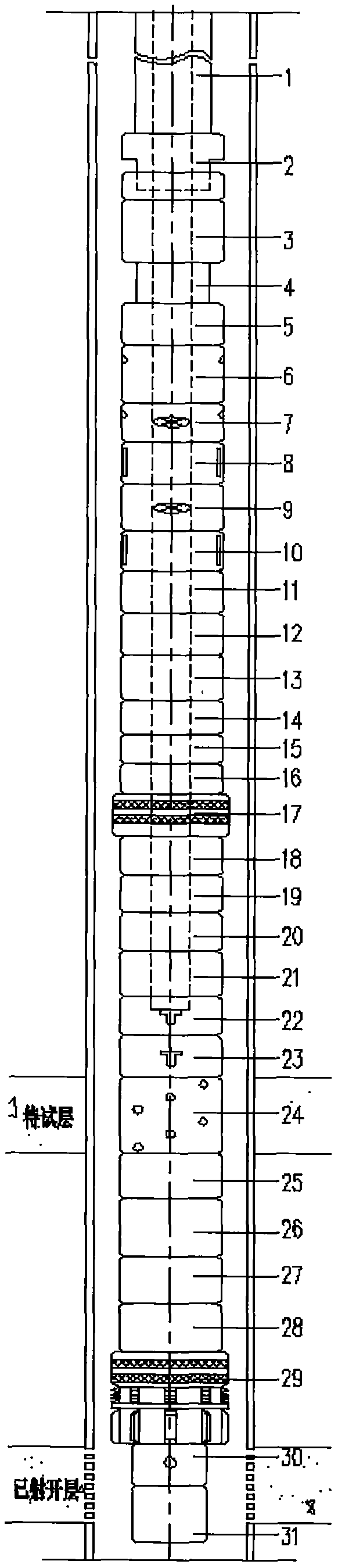

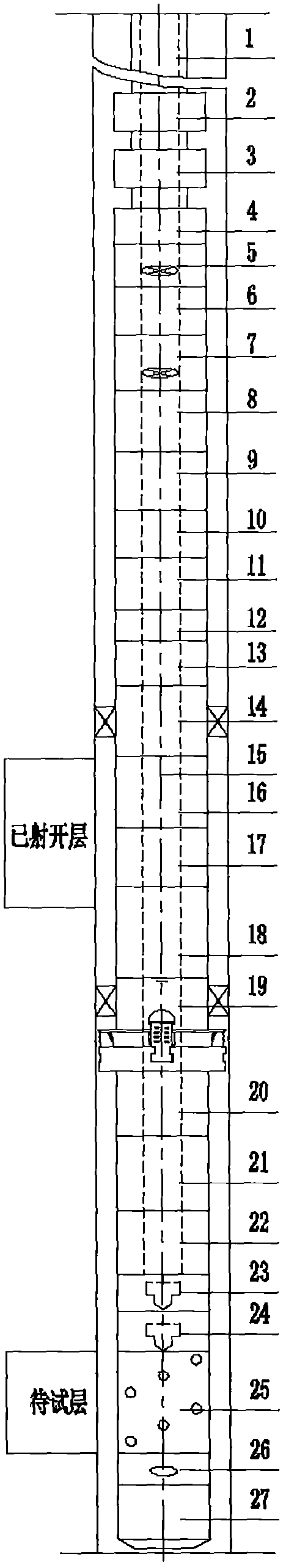

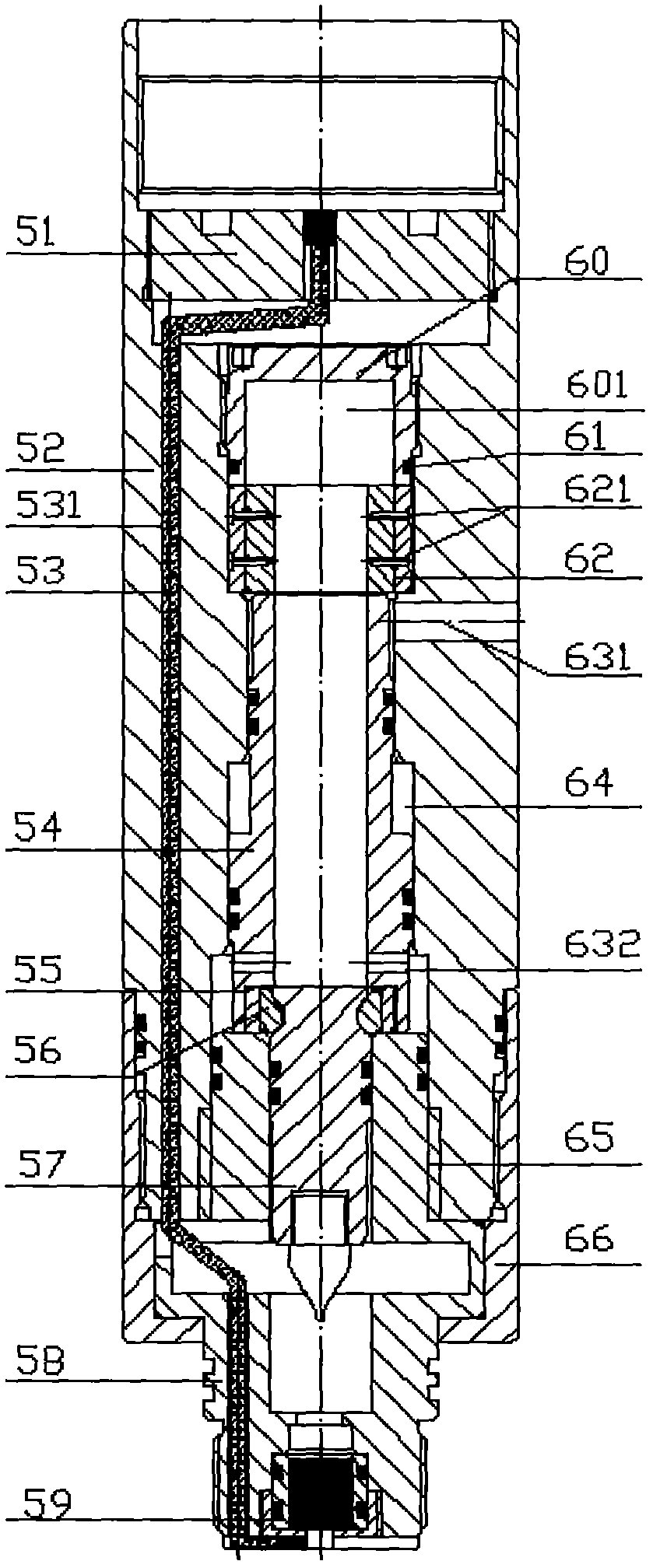

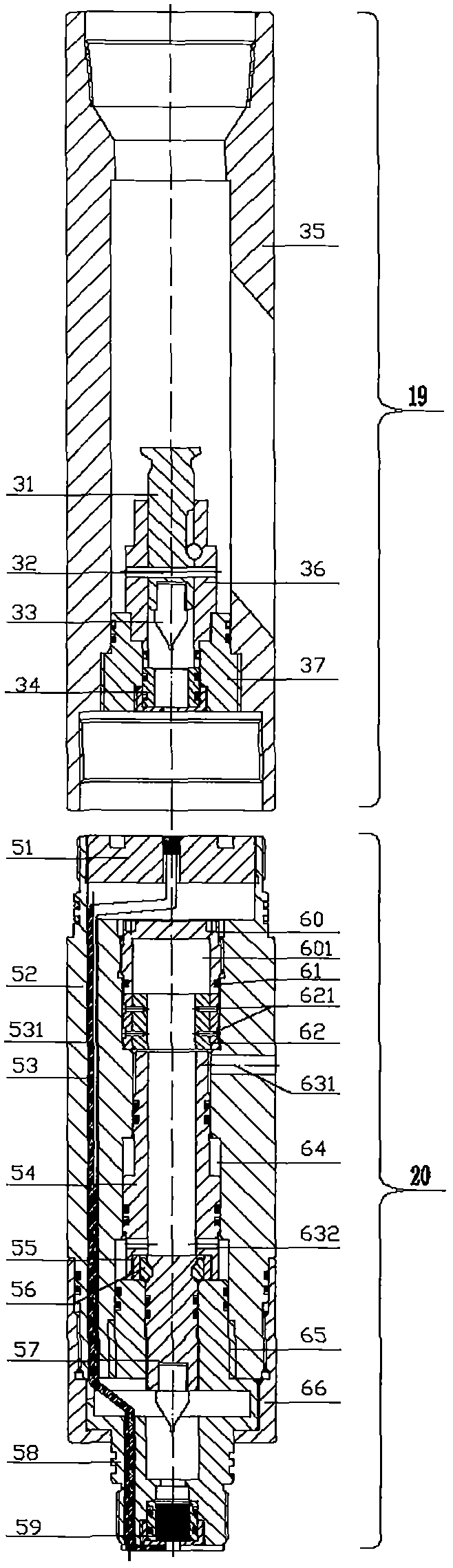

Full-bore straddling perforation-test combination tubular column and operating method thereof

ActiveCN109083625AReduced Chances of ContaminationConducive to obtaining complete and accurate formation parametersSurveyFluid removalEngineeringHigh pressure

The invention provides an efficient, reliable and multifunctional full-bore straddling perforation-test combination tubular column and an operating method thereof aiming at the situation that perforated well opening sections exist below a to-be-tested oil layer. The tubular column is provided with a full-bore straddling perforation part, a JJ-1 carrier, an RD sampler and other multiple tool systems, straddling perforation, testing, reservoir transformation, testing after transformation and other technology combinations can be conducted, testing before and after transformation, JJ-1 well testing, calculation of production volume and sampling are conducted, and stratum parameters are fully and precisely obtained; besides, on the premise that a decompression cavity is reserved, two ignition modes of bar dropping ignition and parallel explosion-propagation pressure delay ignition are simultaneously set for the tubular column above a perforating gun, the damage of instantaneous high pressure of perforations to down-hole instruments and apparatuses can also be reduced, and fishing, bar dropping and other complicated work after bar dropping ignition fails can also be avoided. By means ofthe technology, the technological process can be simplified, the labor intensity is lowered, the construction period is saved, the construction efficiency is improved, and the success rate is increased.

Owner:营口市双龙射孔器材有限公司

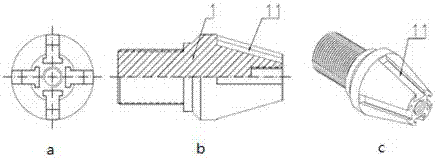

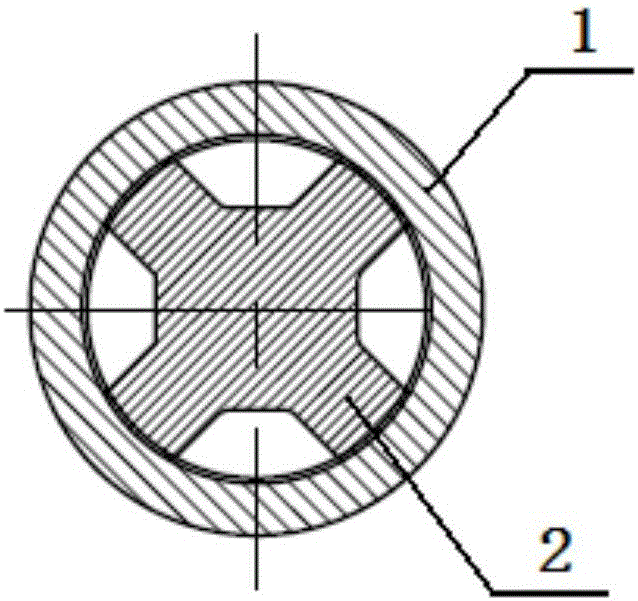

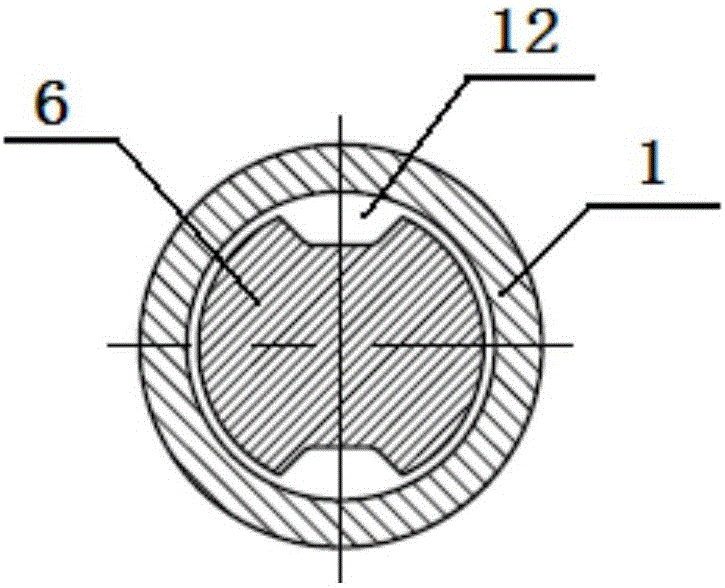

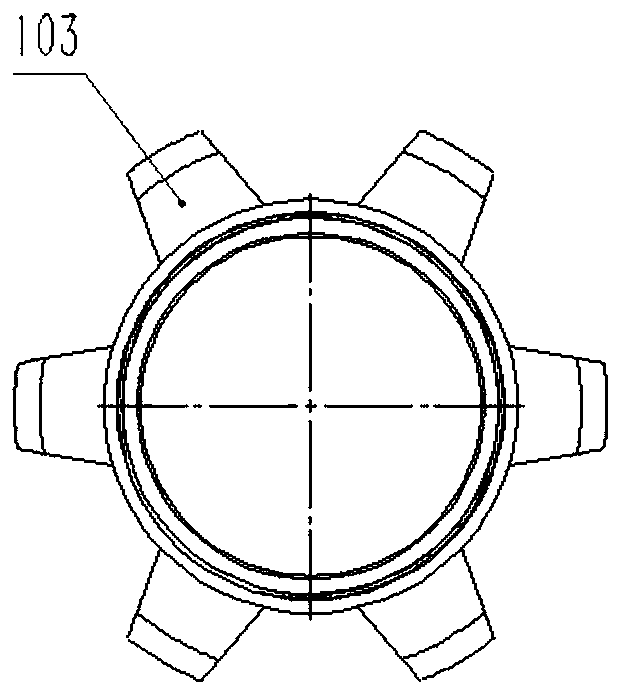

Swirl-type hydraulic ejector with screw spindle

ActiveCN106285577AExtended service lifeImprove the effect of perforation and fracturingFluid removalJet flowEngineering

The invention relates to the technical field of oil field and oil well fracturing, and more specifically relates to a swirl-type hydraulic ejector with a screw spindle. The swirl-type hydraulic ejector comprises an ejector body, and nozzles detachably connected to a sidewall of the ejector body, wherein the ejector body is provided with a hollow cavity in which a screw spindle is disposed; an annular gap for a sand-carrying fluid to flow is formed between the screw spindle and an inner wall of the hollow cavity; a spiral flow channel that presents an Achimedean twin-spiral distribution is formed in an outer surface of the screw spindle; a sand-carrying fluid inlet of each nozzle is disposed as being aligned to the spiral flow channel, while a sand-carrying fluid outlet of each nozzle communicates to an outer surface of the ejector body. The ejector has the characteristics that the screw spindle is driven by thrust / impulsive force generated by a sand-carrying fluid flowing through the spiral flow channel in the outer surface of the screw spindle, such that the sand-carrying fluid is forced to swirl in a pipe to enter into various nozzles of the ejector to generate high-speed jet flows, and therefore, the purpose of reaching equilibrium in sand concentration, flow rate and pressure between upstream and downstream ejectors and the purpose of high effective perforating and fracturing are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

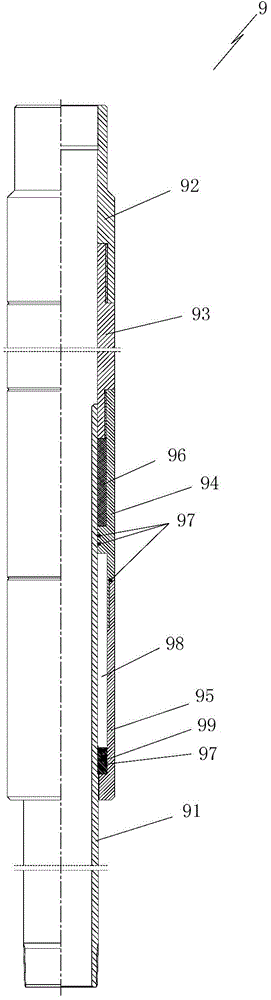

Long-effect packer for oilfield water exclusion production

ActiveCN105507845ASimple construction processImprove the success rate of constructionSealing/packingUpper jointOil field

The invention provides a long-effect packer for oilfield water exclusion production. The long-effect packer for oilfield water exclusion production comprises an upper joint, an inserting pipe, a catching sleeve, a packer rubber, a distance ring, a central pipe, a retaining-pressing sleeve, an upper cone, a locking pin, a slip, a spring, a slip sleeve, a cone, a middle joint, a start shear pin, a setting steel ball, a setting ball seat, a releasing shear pin, a packing cup, a connector, a slide sleeve outer cylinder, a locking steel ball, a slide sleeve, a central sleeve, a reset spring, a lower joint and a plug. The packer, the inserting pipe and a backward flow preventing device are integrally designed, and setting, releasing and production are completed when a string is down once, so that construction technologies are simplified greatly. The long-effect packer for oilfield water exclusion production has the advantages that the packer is specially designed for water exclusion production of oilfield casing collapse wells, normal oil production is unaffected during packing, the matched backward flow preventing device is designed integrally to achieve a backward flow preventing function during pump inspection, and a special tool is used for catching when wellbore operation is needed.

Owner:PETROCHINA CO LTD

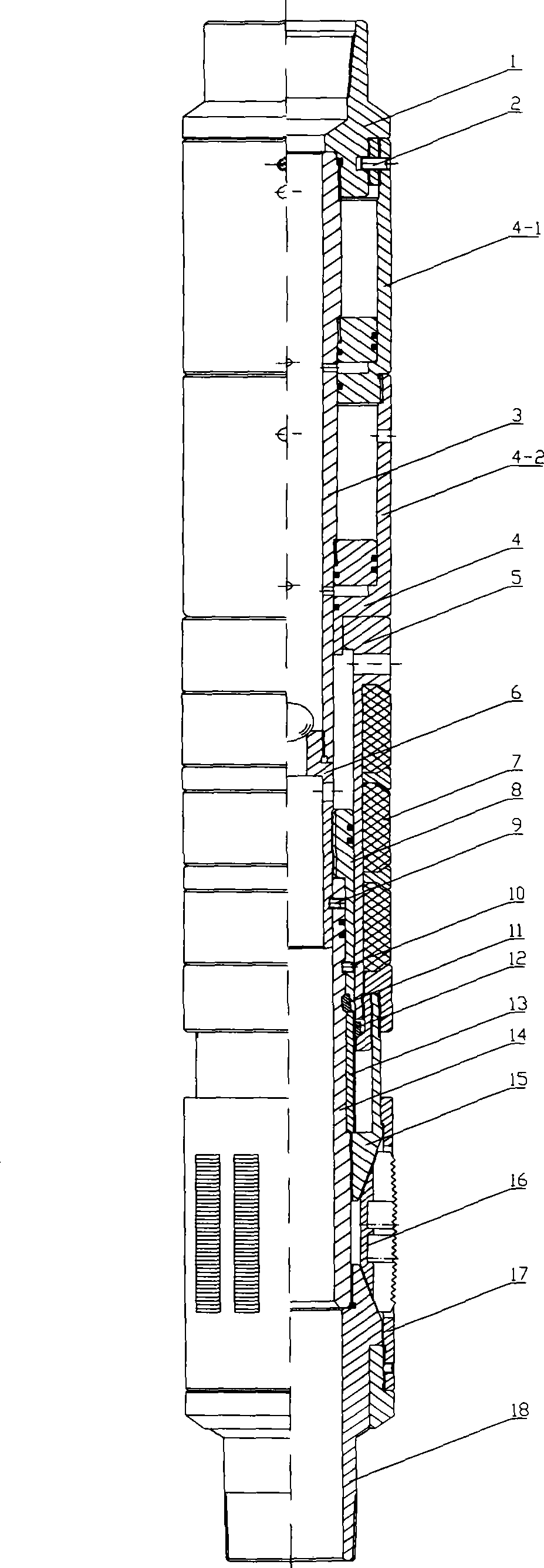

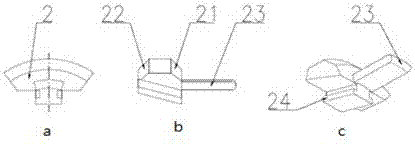

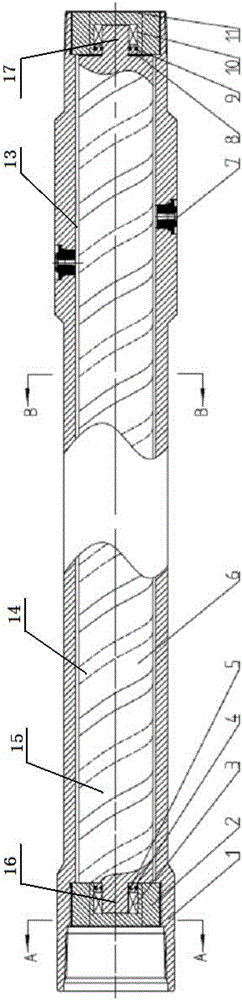

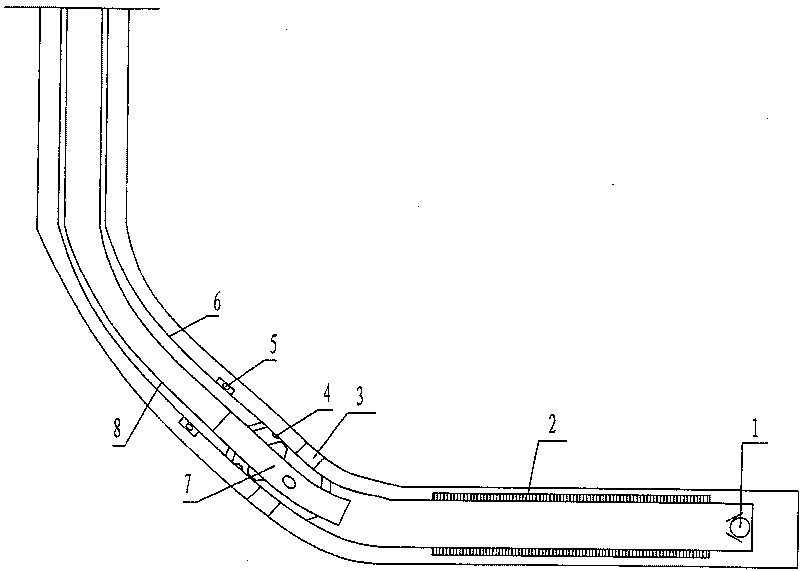

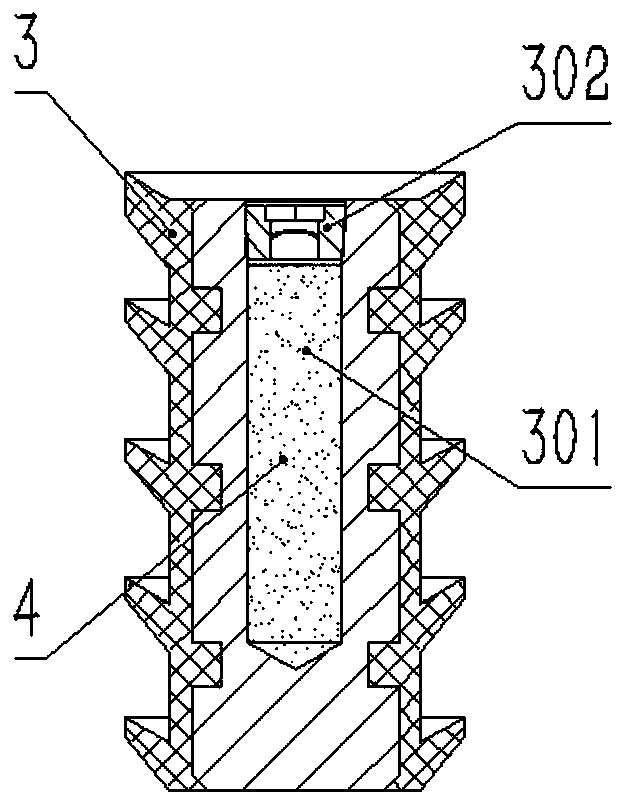

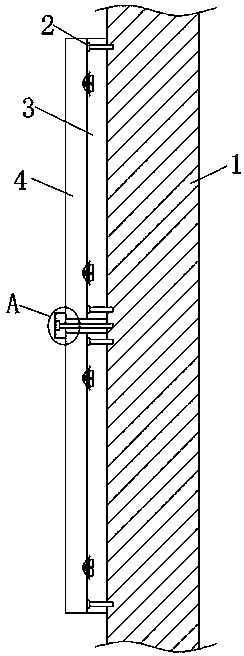

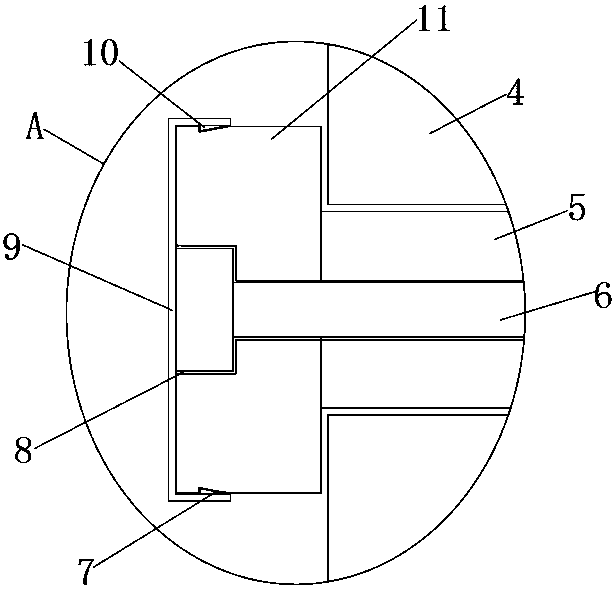

Drilling-plug free tubular column with sand control and well cementation for open-hole horizontal well

ActiveCN101701513ASimplify operating proceduresReduce operating costsFluid removalSealing/packingAcid washingUltimate tensile strength

The invention relates to a drilling-plug free tubular column with sand control and well cementation for an open-hole horizontal well, which comprises an external tubular column and an inner tubular column. The external tubular column comprises a sand control screen (2), an open-hole packer (3), an external positioning step (4), an external cementing machine (5) and a sleeve tube (6) are sequentially installed and connected on the an acid-washing filling valve (1). The inner tubular column comprises an oil tube (8) and an inner cementing machine (7) which is installed and connected on the oil tube (8). The inner tubular column is arranged in the external tubular column and the inner tubular column and the external tubular column are mutually fixed sealed. The invention can simplify operating procedures and reduce the frequency of running string, and does not need to perform drilling-plug operation free after cementing for well cementation, and also has the advantages of low operating cost, large drift diameter, regular inner wall, clean well-hole of sand control and well completion, high construction success ratio, large construction stability, low labor intensity, high oil well yield and the like, and can be widely applied to the process of sand control, well cementation and well completion of the open-hole horizontal well for oil exploration.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

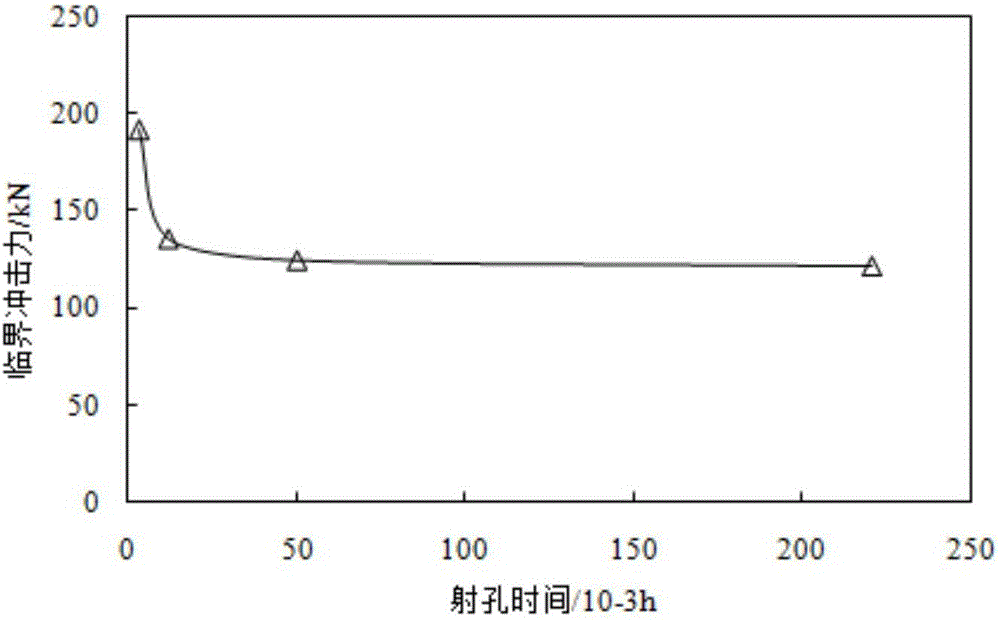

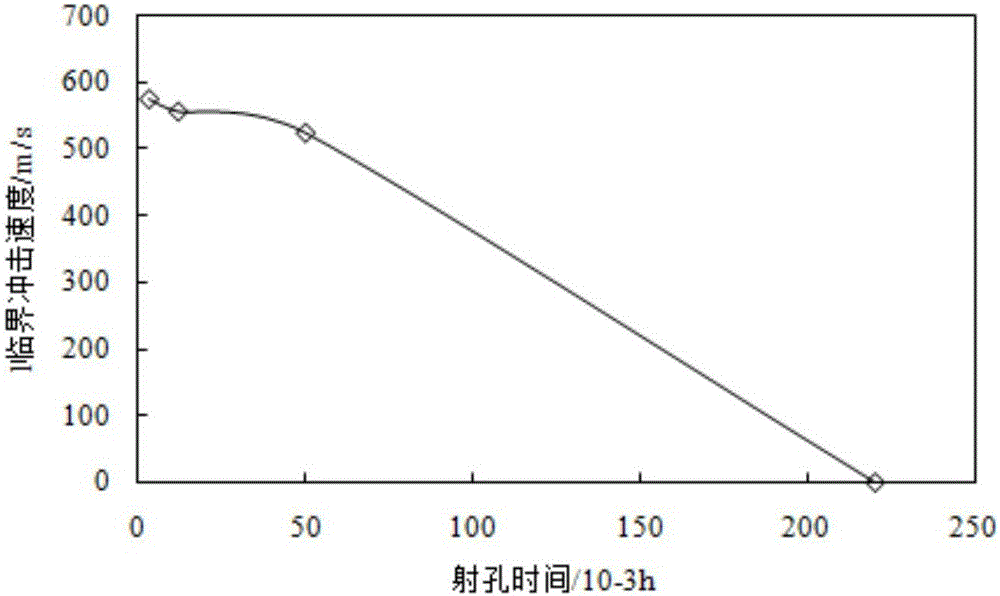

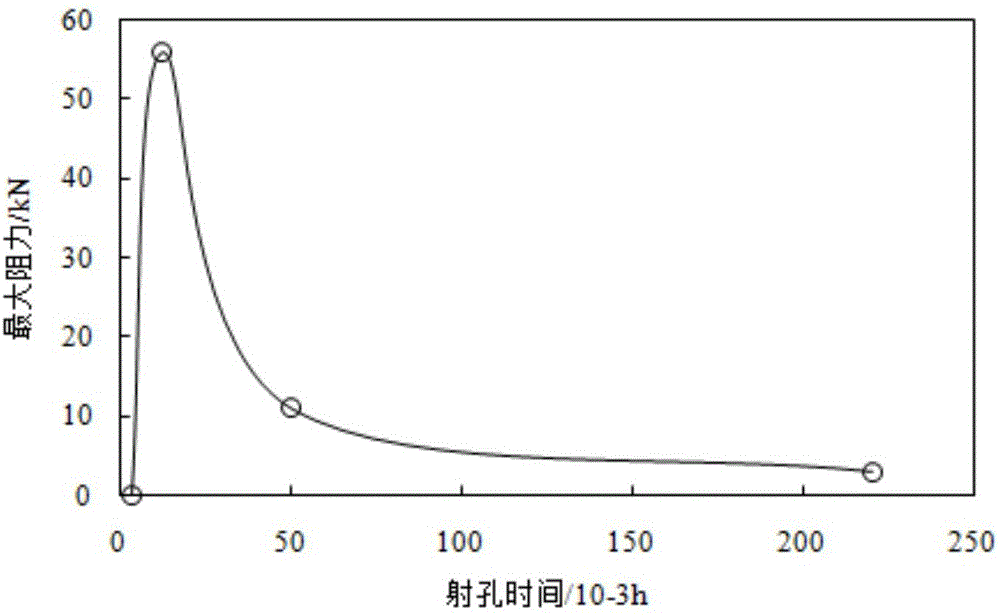

Hydraulic sandblasting fixed-point perforation mechanical parameter calculation model and application method

ActiveCN106529074AImprove calculation accuracyPracticalDesign optimisation/simulationSpecial data processing applicationsMechanical modelsConstruction design

The invention relates to the field of hydraulic sandblasting fixed-point perforation, in particular to a hydraulic sandblasting fixed-point perforation mechanical parameter calculation model. The hydraulic sandblasting fixed-point perforation mechanical parameter calculation model includes a hydraulic sandblasting fixed-point perforation casing pipe mechanical parameter calculation model, a hydraulic sandblasting fixed-point perforation cement sheath mechanical parameter calculation model, a hydraulic sandblasting fixed-point perforation formation mechanical parameter calculation model, and hydraulic sandblasting fixed-point perforation casing pipe, cement sheath and formation system energy parameter calculation models. The hydraulic sandblasting fixed-point perforation mechanical parameter calculation model has an important reference value for improving construction design efficiency and accuracy and construction success rate of hydraulic sandblasting fixed-point perforation of low-permeability reservoirs. A theoretical reference is provided for construction designers of the hydraulic sandblasting fixed-point perforation of the low-permeability reservoirs; the field application effect is good; and the mechanical model is high in calculation precision and high in practicality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High efficiency fracturing method using coiled tubing water-jet and soluble rubber plugs

InactiveCN106321050ARelieve pressureSolve the real problemFluid removalDrilling compositionTubing hangerCoiled tubing

The invention provides a high efficiency fracturing method using coiled tubing water-jet and soluble rubber plugs. The high efficiency fracturing method includes a sandblast and perforation stage, an annulus sand fracturing stage, a soluble rubber plug injection stage, a replacement stage, a curing and pressure test stage, and a blowout stage. The soluble rubber plugs are used as sealing members, the number of fracturing segments is not limited, the situation that sand blocks pipes can be avoided, gel-breaking of the rubber plugs can be controlled during construction, gel-breaking and rapid flow-back can be achieved at the same, and the construction efficiency and the successful rate can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

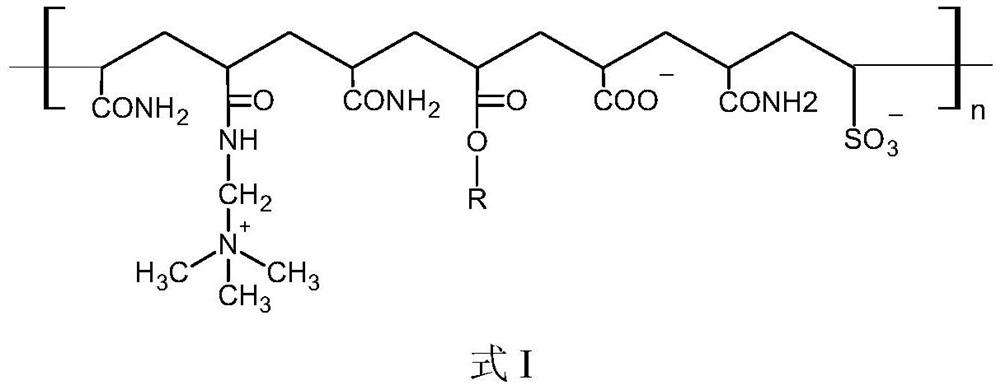

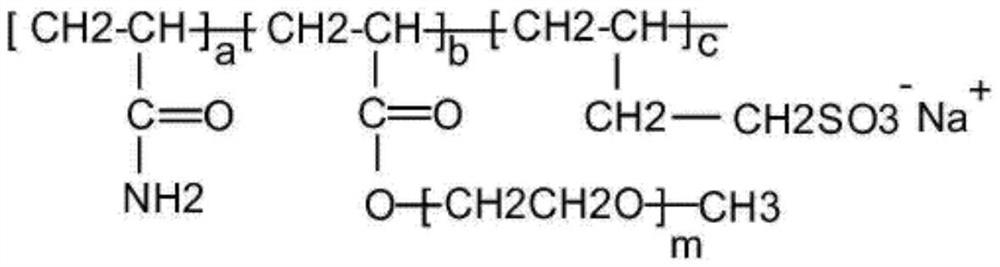

Sand-carrying fluid with effects of improving flow resistance of thickened oil and stabilizing clay

The invention relates to the field of loose sandstone development, in particular to a sand-carrying fluid with effects of improving flow resistance of thickened oil and stabilizing clay. The sand-carrying fluid comprises a sand-carrying fluid main agent and water, wherein the mole percentage ratio of the components of the sand-carrying fluid main agent, namely, the mole percentage ratio of acrylamide to quaternary ammonium salt to sulfonate to hydrophobic group is (6-8): (1-1.5): (1-1.5): (1-1.5). According to the sand-carrying fluid system, the anti-swelling function, the thickened oil flow resistance reduction function and the sand prevention function in filling sand prevention are integrated together, damage of working fluid is reduced, the stratum protection function is increased, the thickened oil recovery rate is increased, the cost is reduced, the construction process is simplified, and the sand prevention filling construction success rate is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Releasing apparatus

ActiveCN104879078AReliableImprove the success rate of constructionBorehole/well accessoriesUpper jointEngineering

Owner:山东兆鑫石油工具有限公司

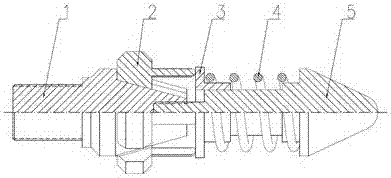

Controllable dissolution opening device for first section fracturing channel and fracturing sectional operation construction process

ActiveCN110439522ASimple structureImprove the success rate of constructionDrilling rodsFluid removalSolventWell cementing

The invention relates to a controllable dissolution opening device for a first section fracturing channel and a fracturing sectional operation construction process. The controllable dissolution opening device includes a body, a soluble plug and a well cementing rubber plug; a casing pipe female thread screw thread is arranged at the upper end of the body, a casing pipe male thread screw thread isarranged at the lower end of the body, and a centralizing edge is arranged on the outer surface of the body. The body is connected in to a casing pipe string through the casing pipe female thread screw thread and the casing pipe male thread screw thread, the centralizing edge is internally provided with a fracturing hole, and the soluble plug is installed in the fracturing hole; the well cementingrubber plug is arranged in a cavity below the body, and is in contact with a well cementing float collar, and the well cementing rubber plug is internally provided with a solvent cavity and a rupturedisk; and the solvent cavity is filled with a solution capable of dissolving the soluble plug. According to the controllable dissolution opening device, the first section fracturing channel can be opened, the construction process is simple, the construction cost is low, the running depth is not limited, and the construction of casing pipe running, well cementing and casing pipe sealing pressure tests and the like cannot be affected at all.

Owner:CHINA PETROCHEMICAL CORP +3

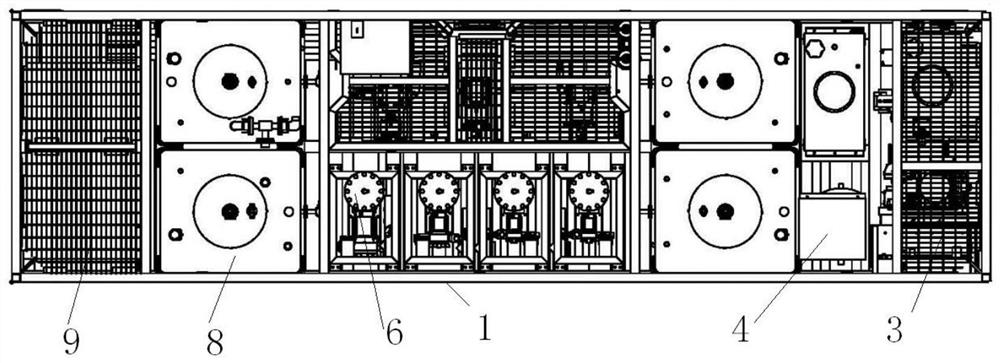

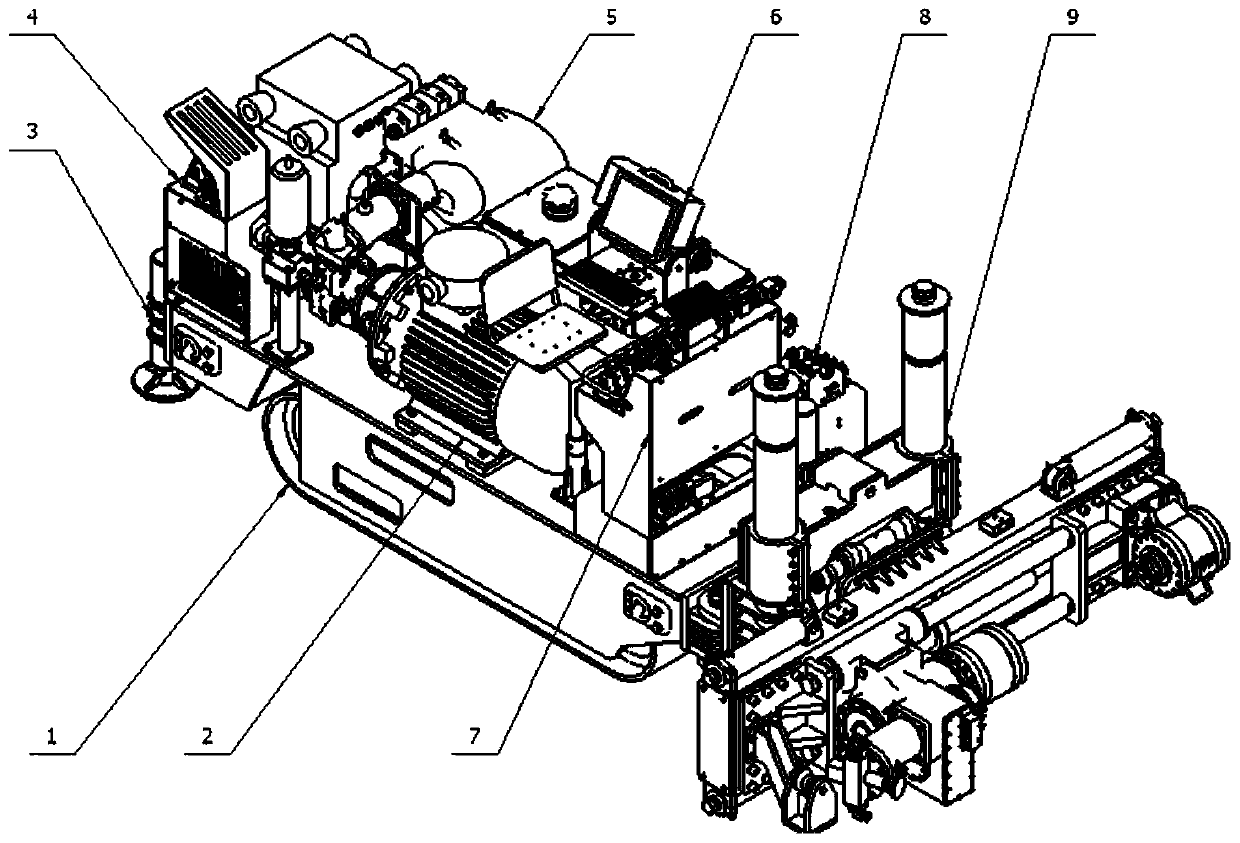

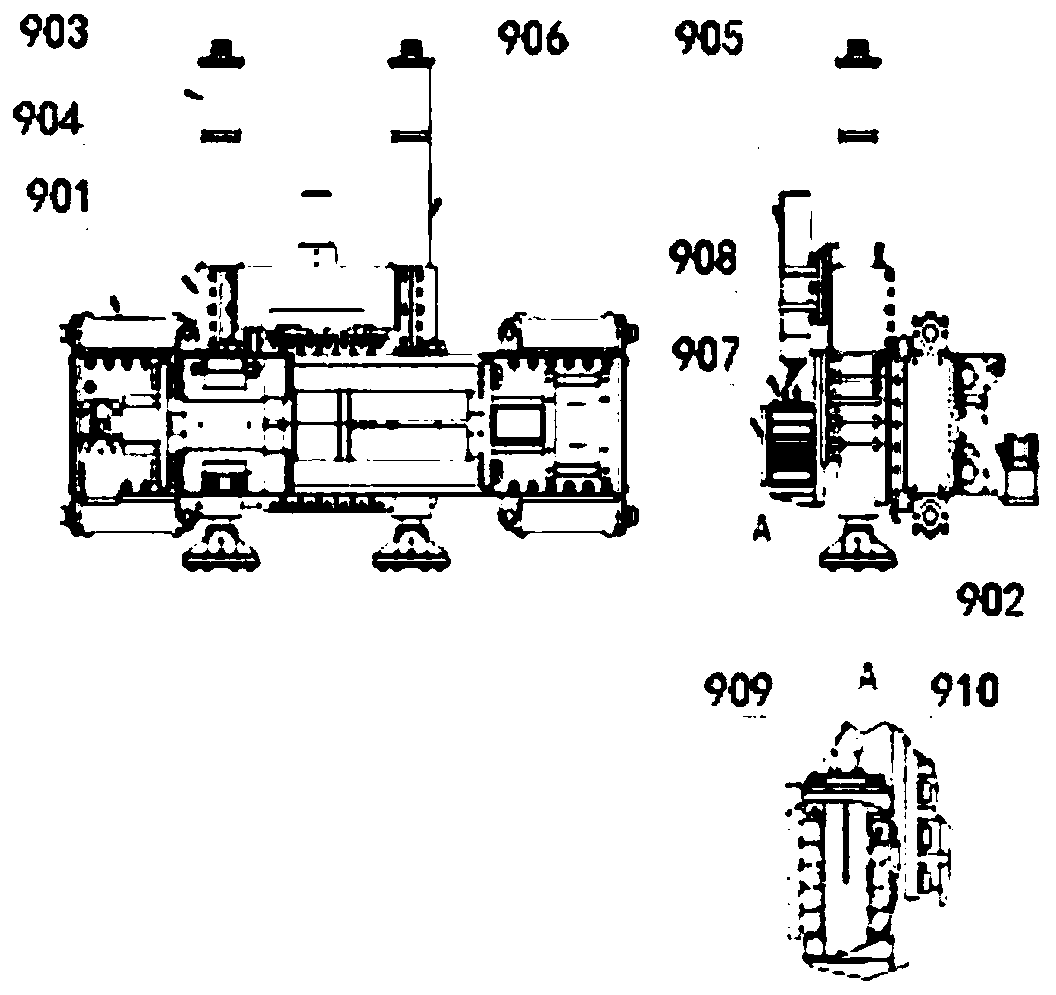

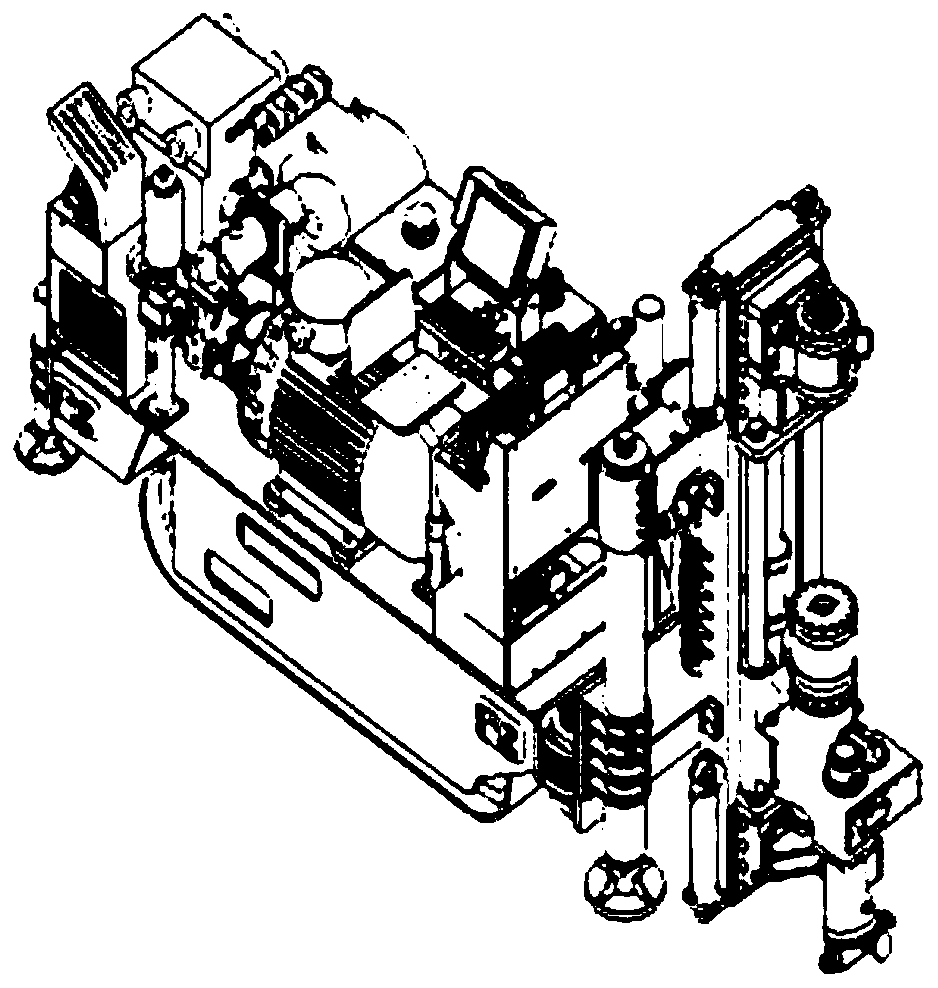

Narrow-body and all-condition directional drilling machine for coal mine

ActiveCN109763768ADiversity guaranteedGuaranteed practicalityDerricks/mastsDirectional drillingEngineeringFuselage

The invention belongs to the field of whole directional drilling machines for coal mine and particularly relates to a narrow-body and all-condition directional drilling machine for coal mine. A motorassembly, a walking anchoring operating platform assembly, a slurry pump assembly, a computer assembly, a drilling machine operating platform assembly and a multi-way valve assembly are arranged on acrawler assembly; two groups of anchoring assemblies are symmetrically arranged at the back part of the crawler assembly; and a machine frame adjusting assembly is arranged at the front part of the drilling machine and is used for adjusting the position and the dip angle of the machine frame. The whole size is more compact, and the structure of the existing main vehicle and a slurry pump vehicle double caterpillar vehicle is optimized into a single caterpillar vehicle, so the narrow-body and all-condition directional drilling machine for coal mine has applicability in the coal transportation and use process with small lane size; and the machine frame structure of the drilling machine can meet the requirements of the drilling processes with different drilling height, multiple azimuth and all condition under the condition that the hole opening height is low enough, so that the comprehensiveness and the practicability of the drilling machine on the requirements of the drilling process areguaranteed, the construction success rate of the directional branch hole is increased and the coverage range of directional drilling is guaranteed.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Anti-falling device of building elements for building construction

ActiveCN108756121ASimple construction methodImprove the success rate of constructionCovering/liningsLocking mechanismWorking environment

The invention discloses an anti-falling device of building elements for building construction. The anti-falling device of the building elements for the building construction comprises a wall body anda plurality of bases. First circular grooves are formed in the bases. First expansion screws are installed in the first circular grooves, the first expansion screws penetrate through the bases and areconnected with the wall body, the building elements are installed on the bases through a plurality of locking mechanisms, connecting plates are arranged between every two adjacent bases in a clampingmode, and the bases adjacent to the connecting plates and the side walls of the building elements abut against the connecting plates. Anti-falling plates are fixedly connected to the connecting plates. A plurality of second circular grooves are formed in the anti-falling plates, and second expansion screws are installed in the second circular grooves. The anti-falling device of the building element for the building construction has the advantages that the structure is ingenious, the use is convenient, the bonding of traditional installation is avoided, the working environment is improved, theworking difficulty is reduced, and the building elements are prevented from falling through multi-directional limiting.

Owner:宁波高新区甬港现代供应链有限公司

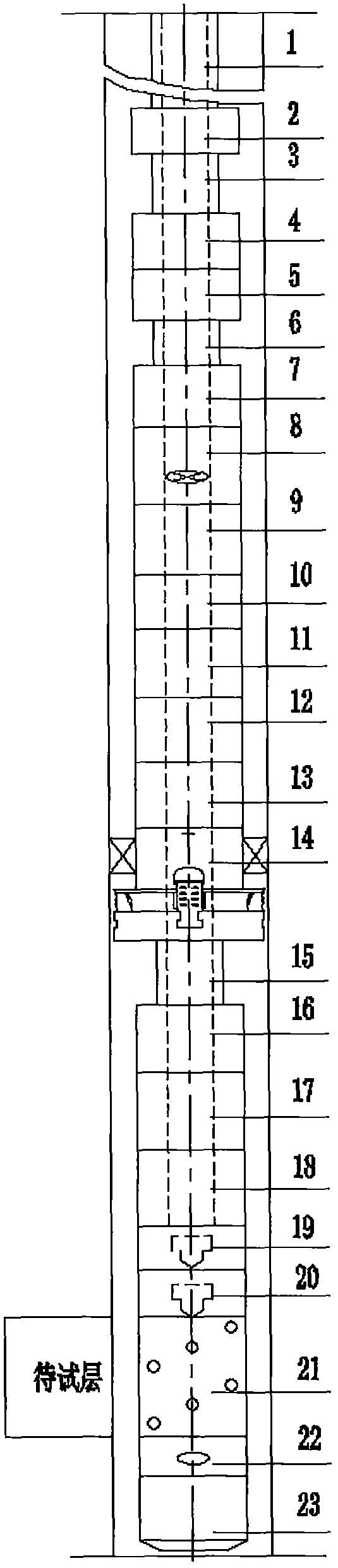

Full-bore straddled downward returning perforation-test combination pipe column and operation method thereof

The invention provides an efficient and reliable full-bore straddled downward returning perforation-test combination pipe column and an operation method thereof based on a condition that a perforatedwell section exists above an oil reservoir to be tested. In the pipe column, on the precondition of retaining a pressure relief chamber, a drop bar ignition mode and a parallel explosion propagation type pressure time delay ignition mode are simultaneously arranged above a perforating gun. When drop bar ignition is unsuccessful, pressurization ignition in the pipe column can be directly adopted, complicated operations such as drop bar salvaging after failure of drop bar ignition and the like can be eliminated, damage of in-the-pit instruments can be prevented, and perforation and test successrates can be improved; via the pipe column disclosed in the technical solution, a perforated reservoir can be straddled; integrated operation of perforating, testing, draining, and reservoir reformingof the reservoir to be tested below the perforated reservoir can be performed; construction processes can be simplified, labor intensity can be lowered, an oil test construction cycle can be shortened, and construction efficiency and success rates can be improved.

Owner:NANJING ACAD OF UNDERGROUND SPACE ENG

Perforation ignition system, perforation-test-acidification combination pipe column and usage method thereof

The invention provides a perforation ignition system comprising a drop bar ignition head and a parallel explosion propagation type pressure time delay ignition head. The perforation ignition system can be applied to a test combination pipe column of an in-the-pit perforation. On the precondition of retaining a pressure relief chamber, two ignition modes comprising a drop bar ignition mode and a pressure time delay ignition mode are set at the same time above a perforating gun. When drop bar ignition is unsuccessful, pressurization ignition in the pipe column can be directly adopted, complicated operations such as drop bar salvaging after failure of drop bar ignition can be eliminated, and pipe column vibration and damage of in-the-pit instruments can be alleviated; effects of lowering labor intensity, shortening oil test construction cycles and improving construction efficiency and success rates can be achieved; the invention also provides a perforation-test-acidification combination pipe column adopting the above ignition system and a usage method thereof; combination of perforation, a test, acidification and a post-acidification test can be realized; via comparison between the test before the acidification and the test after the acidification, acidification effects can be known accurately and directly, and accurate evaluation of a reservoir stratum can be facilitated.

Owner:陕西兴元石油科技有限公司

A high-temperature and high-salt fine gel particle profile control agent and its preparation method and application

The invention discloses a high-temperature-resistant and high-salt-resistant fine gel particle as a profile control agent as well as a preparation method and an application of the fine gel particle. The preparation method of the fine gel particle comprises the following steps of firstly, adding modified starch, a monomer A, a monomer B, a crosslinking agent, an initiator and an accelerant into a reaction kettle according to a certain ratio; and after finishing the polymerization reaction of the six components to form integrated water-based gel, drying, crushing, granulating, screening and performing other process steps to obtain the fine gel particle. The application method of the high-temperature-resistant and high-salt-resistant fine gel particle is as follows: a certain quantity of fine gel particles prepared by using the preparation method are added into a Bingham fluid, the gel particles can be stably suspended without settling under static and dynamic conditions, and then, the whole fluid is injected to the stratum by means of pumping pressure. By using the high-temperature-resistant and high-salt-resistant fine gel particle and the application method thereof, disclosed by the invention, the construction success rate of the gel particle can be greatly increased, and a favorable deep profile control effect can be achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Water plugging pipe column suitable for small partitioning layer plug bottom water well and water plugging method

The invention provides a water plugging pipe column suitable for a small partitioning layer plug bottom water well and a water plugging method. The water plugging pipe column comprises a first oil pipe, a hydraulic releasing tool, a second oil pipe, a locating short section, a third oil pipe, a hydraulic packer, a fourth oil pipe, a long rubber cylinder packer and a screwed plug which are connected in sequence. The water plugging method comprises the steps that the water plugging column goes down to an appointed position in the well, so that the position of the hydraulic packer and an upper partitioning layer correspond, the position of the long rubber cylinder packer and a lower partitioning layer correspond, the upper partitioning layer is placed between an upper oil layer and a middle oil layer, the lower partitioning layer is placed between the middle oil layer and a lower oil layer, liquid is injected into the water plugging pipe column from a well opening and is pressurized to reach a first pressure value, the hydraulic packer and the side wall of the upper partitioning layer are subjected to corresponding setting, the long rubber cylinder packer is set on the side wall of the lower partitioning layer, liquid is continuously injected into the water plugging pipe column from the well opening and is pressurized to reach a second pressure value, so that the upper portion and the lower portion of the hydraulic releasing tool are separated, the upper portion of the tool is taken from the well along with the first oil pipe, and the first pressure value is smaller than the second pressure value.

Owner:PETROCHINA CO LTD

High density fracturing liquid

The invention offers high density fracturing fluid formula used inorganic salt to improve water-base fracturing fluid density. Its feature is that its weight ratio is as follows: weight additive 4-50%, vegetable gum thickener 0.3-1.0%, cross linking agent 0.1-2.0%, pH value regulator 0.5-1.0%, cracking agent 0.002-0.3%, cleanup additive 0.05-0.5%, fungicide 0.03-0.2%, and water 30-73%. The density of the high density fracturing fluid is adjustable and can exceed 1.51g / cm3. It has good high temperature resistant, shearing resistant, and so on. Thus it can supply reliable assurance for abnormal high pressure and ultra-deep well exploration test oil and exploitation.

Owner:PETROCHINA CO LTD

Hydraulic packer communicator

PendingCN109322640AAvoid enteringRealize commutationWell/borehole valve arrangementsSealing/packingUpper jointControl engineering

The invention discloses a hydraulic packer communicator, and belongs to the technical field of oilfield exploitation. The hydraulic packer communicator comprises an upper joint, a protective sleeve, amiddle joint, a lower outer barrel, an outer pipe and a lower joint, wherein the upper joint, the protective sleeve, the middle joint, the lower outer barrel, the outer pipe and the lower joint are connected from up to down in a threaded mode in sequence, and are of a hollow structure; a reversing central pipe is arranged in the protective sleeve, and a first platform is arranged at the top of the reversing central pipe, and is in contact with the upper joint; a reversing spring is arranged on the exterior of the reversing central pipe, the top of the reversing spring is in contact with the first platform, and the bottom of the reversing spring is in contact with the top of the middle joint. According to the hydraulic packer communicator, under-pressure operation equipment is only required to be pushed down to the bottom of the packer connected with the hydraulic packer communicator to operate at one time, the production channel of the hydraulic packer communicator can be opened and closed many times, when pump inspection is carried out, the channel is closed by pressing operation of a casing pipe, dump inspection can be carried out, the operating process is simplified, the success rate of construction is improve, operating risk is reduced, and the construction period is shortened.

Owner:SHANDONG BOSAITE PETROLEUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com