Swirl-type hydraulic ejector with screw spindle

A technology of hydraulic ejector and spiral core, which is applied in the field of oil well fracturing in oil fields, can solve the problems of particle sand concentration, flow rate, and pressure unevenness, so as to solve the problem of unevenness of flushing failure, increase workload and labor intensity, and improve The effect of construction success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

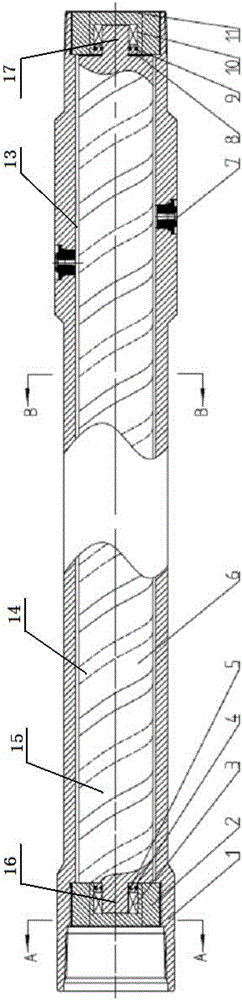

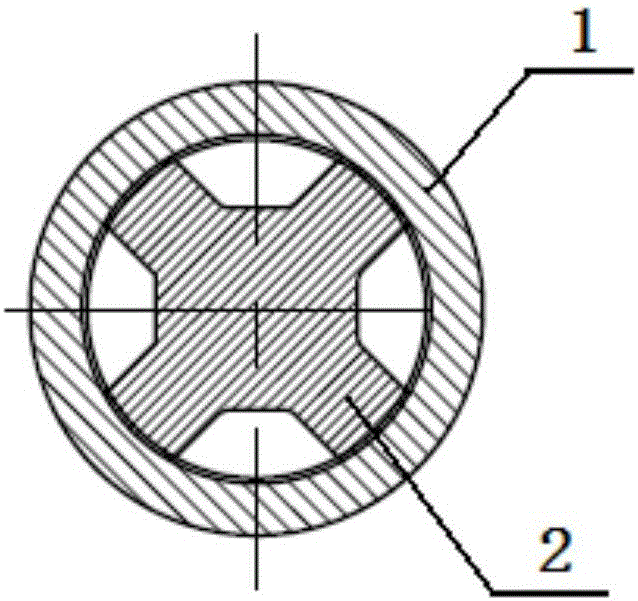

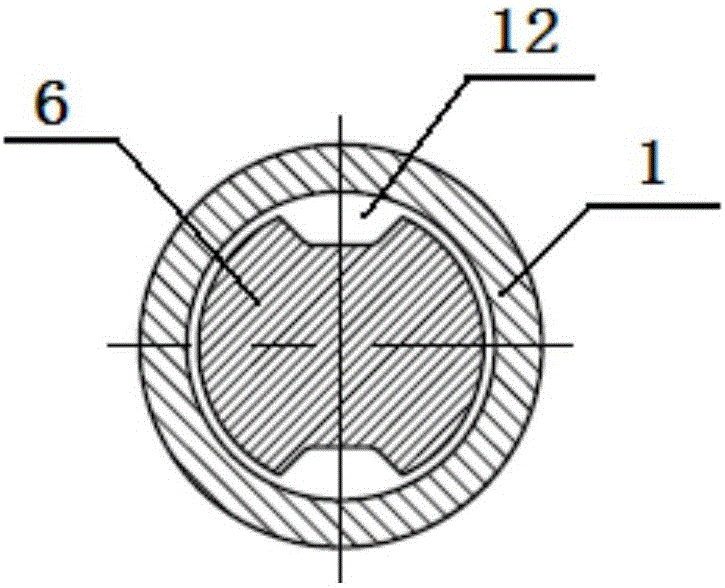

[0029] Such as figure 1 and 2 As shown, a swirling water jet with a spiral mandrel provided by the embodiment of the present invention includes a jet body 1, and a nozzle 7 detachably connected to the side wall of the jet body 1. The injector body 1 has a hollow cavity 12, and a spiral mandrel 6 is arranged inside the hollow cavity 12, and an annular gap for the flow of the sand-carrying liquid is formed between the spiral mandrel 6 and the inner wall of the hollow cavity 12 13; the outer surface of the spiral mandrel 6 is provided with a spiral channel 14 distributed in the form of an Archimedes double helix; the inlet of the sand-carrying liquid of the nozzle 7 is arranged to align with the spiral channel 14, and the nozzle The sand-carrying fluid outlet of 7 is connected to the outer surface of the injector body 1.

[0030] The working principle of the hydraulic ejector of the present invention is: when the sand-carrying liquid flows into the spiral flow channel 14 on the...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 As shown, the spiral mandrel 6 is a solid shaft made of 35CrMo and heat-treated HBW197-235.

[0033] The length of the spiral mandrel 6 is 1100mm, the outer diameter is 40mm, the length of the injector body 1 is 1300mm, the outer diameter is 100mm, and the inner diameter is 60mm, so the width of the annular gap 13 formed between the injector body 1 and the spiral mandrel 6 It is 20mm, adopting such a small width, so that the sand-carrying liquid flows into each nozzle 7 along the spiral flow channel 14 on the outer surface of the spiral mandrel 6, so as to ensure the sand concentration, The flow and pressure are uniform.

[0034] The upper and lower parts of the injector body 1 are provided with threaded screws, the type of which is 2-7 / 8"EUE, 8 threads per inch, and the taper is 1:16.

Embodiment 3

[0036] On the basis of Example 1, such as image 3 As shown, the spiral flow channel 14 is a trapezoidal groove, a triangular groove or a semicircular groove, preferably a trapezoidal groove, which is convenient for processing.

[0037] The surface of the spiral flow channel 14 is plated with a nickel-based alloy layer to prevent the local erosion of the spiral flow channel 14 caused by the change of the fluid direction.

[0038] The double helix is clockwise, the helix angle is 45°, the pitch of the double helix is 120mm, the distance between the double helix is 30mm, the length of the spiral trapezoidal groove is 120mm, the depth of the groove is 5mm, the width of the bottom of the groove is 10mm, and the trapezoidal angle is 60°. The spiral flow channel 14 not only meets the specification requirements, but also helps the sand-carrying liquid to form a more suitable outlet velocity and outlet angle of the sand-carrying liquid.

[0039] Example 3

[0040] On the basis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com