Sand-carrying fluid with effects of improving flow resistance of thickened oil and stabilizing clay

A technology of sand-carrying fluid and cross-linking agent, applied in the field of sand-carrying fluid, can solve the problems of affecting the sand control development effect of loose sandstone sensitive heavy oil reservoirs, high insoluble content, poor temperature resistance, etc. , Simplify the construction process and increase the effect of the protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

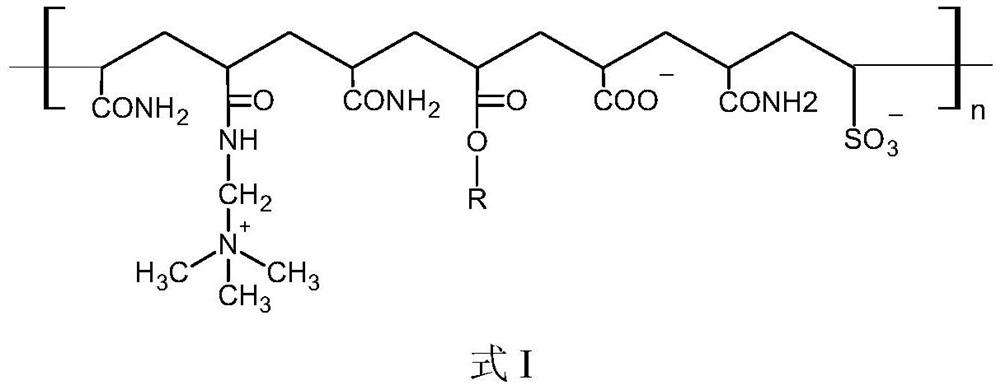

[0040] The preparation method of the sand-carrying main agent is as follows: acrylamide, quaternary ammonium salt, sulfonate and hydrophobic base compound are placed in the reaction kettle according to the above molar ratio, and the 2 Under protection, the reaction temperature is 75°C to 85°C for 8 hours to obtain a transparent gel-like sand-carrying liquid main agent.

[0041] Further, the sand-carrying liquid is composed of the following components and parts by weight: 0.3%-0.6% of the main agent of the sand-carrying liquid, and the balance is water, and the sand-carrying liquid is a thickened sand-carrying liquid. The sand-carrying liquid has obvious functions of dispersing and reducing viscosity of heavy oil, can improve the fluidity of heavy oil in the formation, and reduce flow resistance.

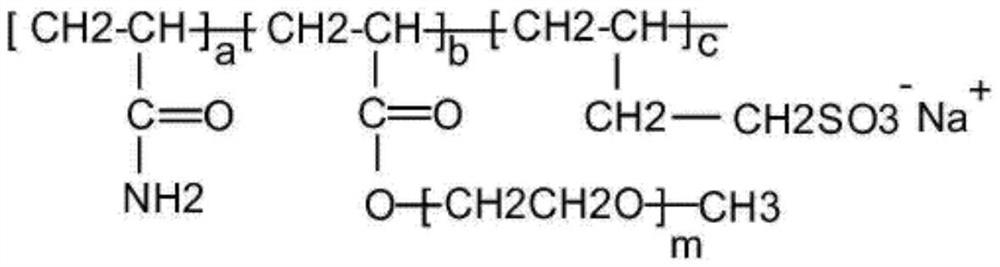

[0042] Further, the sand-carrying liquid also includes a crosslinking agent.

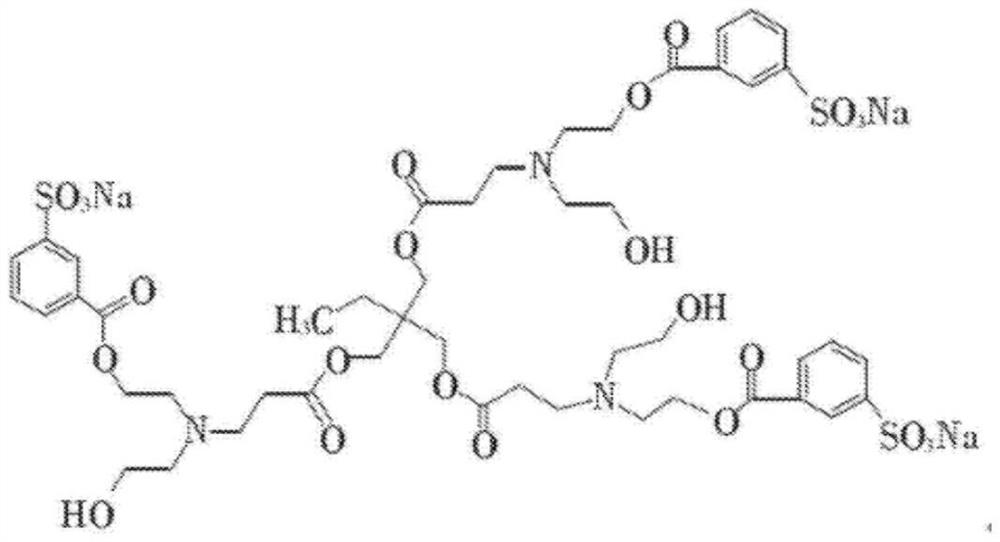

[0043] Further, the crosslinking agent is one or more of organoaluminum and organoboron.

[0044] The...

Embodiment 1

[0054] The molar ratio is acrylamide: dodecyltrimethylammonium bromide: dodecylbenzenesulfonic acid: bromododecane = 6:1:1:1, put it in the reaction kettle, under N 2Under protection, the reaction temperature is 70°C to 80°C for 5 hours to obtain a transparent gel-like sand-carrying liquid main agent.

[0055] The main agent of the sand-carrying liquid is diluted with water to 0.4% by weight to obtain a thickened sand-carrying liquid, which is measured at 30°C and 170s -1 The viscosity is 70.3mPa·s, the sedimentation velocity of single gravel is less than 0.003m / min, and the suspended sand time with 70% sand ratio is 4.76min.

[0056] Add 1‰ aluminum citrate crosslinking agent to the above-mentioned thickened sand-carrying liquid, and adjust the pH value of the system to 8-10 with sodium hydroxide solution to form gel-type sand-carrying liquid I. The jelly-type sand-carrying fluid I has outstanding temperature and shear resistance. At 90°C, after shearing for 2 hours, the vis...

Embodiment 2

[0062] The molar ratio is acrylamide: dodecyltrimethylammonium bromide: dodecylbenzenesulfonic acid: bromododecane = 7:1:1:1.5, placed in the reaction kettle, under N 2 Under protection, the reaction temperature is 75°C to 85°C for 8 hours to obtain a transparent gel-like sand-carrying liquid main agent.

[0063] The main agent of the sand-carrying liquid is diluted with water to 0.6% by weight to obtain a thickened sand-carrying liquid, which is measured at 30°C and 170s -1 The viscosity is 82.3mPa·s, the sedimentation velocity of single gravel is 0.002487m / min, and the suspended sand time with 70% sand ratio is 5.12min.

[0064] Add 0.5‰ organic boron cross-linking agent to the water-based sand-carrying liquid, and adjust the pH value of the system to 8-10 with ammonia solution to form gel-type sand-carrying liquid I. The jelly-type sand-carrying liquid I has excellent temperature and shear resistance. At 90°C, after shearing for 2 hours, the viscosity is greater than 200mP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com