Hydrophobic ceramic composite membrane and preparation method thereof

A ceramic composite membrane and ceramic membrane technology, which is applied in the field of membrane separation, can solve the problem of easy detachment of the hydrophobic layer, and achieve the effects of not being easily polluted by oil, low production cost, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

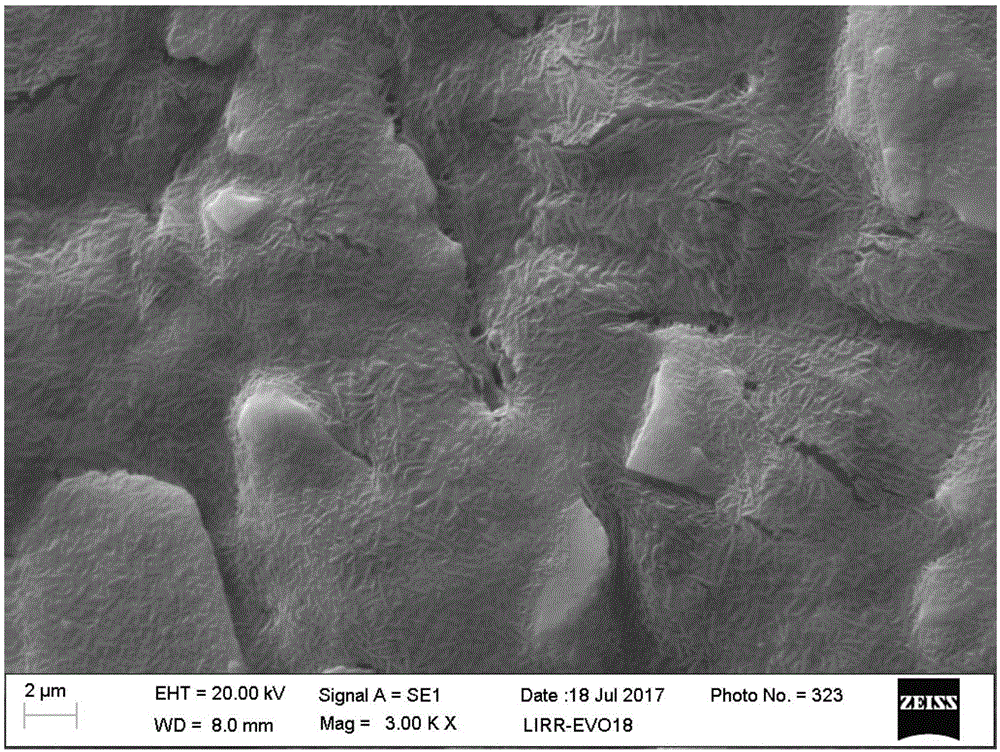

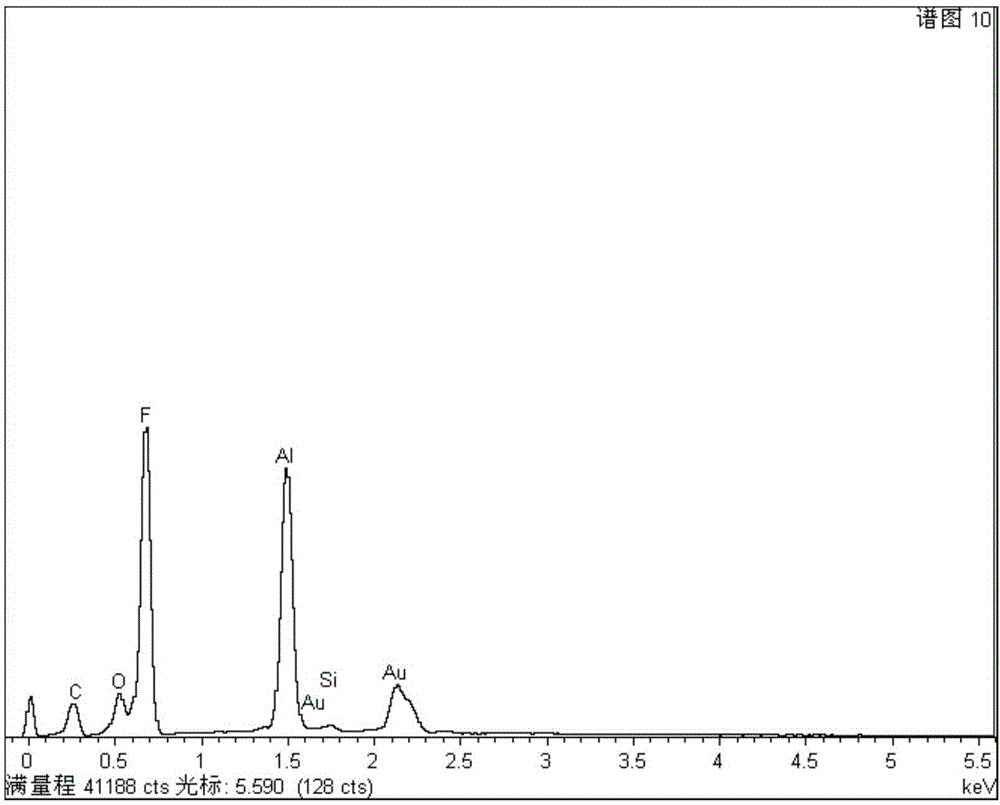

[0046] The hydrophobic ceramic composite membrane of this embodiment includes a ceramic base film, and the surface of the ceramic base film is sequentially provided with a silane coupling layer, a hydrophilic polymer layer, a binder layer, and a hydrophobic polymer layer from the inside to the outside; the ceramic base film, The mass ratio of silane coupling layer, adhesive layer, and hydrophobic polymer layer is 1:0.001:0.01:0.001:0.05; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyltrimethyl oxysilane; the hydrophilic polymer layer is polyimide; the adhesive layer is propyltrimethoxysilane coupling agent; the hydrophobic polymer layer is polytetrafluoroethylene.

[0047] The preparation method of the hydrophobic ceramic composite membrane of the present embodiment comprises the following steps:

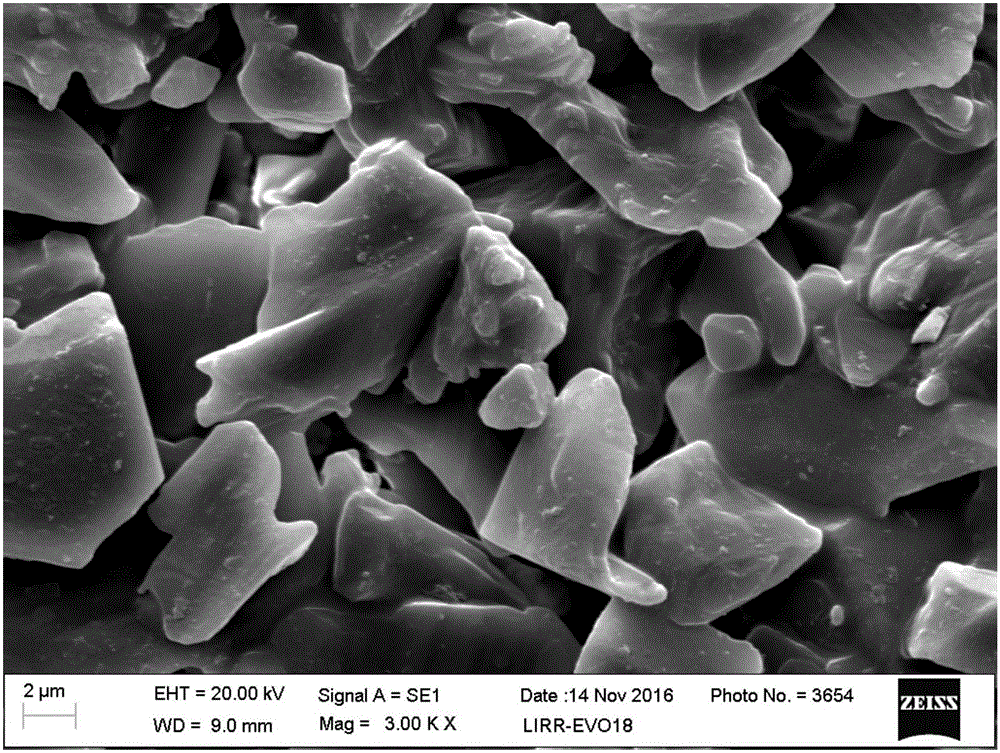

[0048] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, c...

Embodiment 2

[0052] The hydrophobic ceramic composite membrane of this embodiment includes a ceramic base film, and the surface of the ceramic base film is sequentially provided with a silane coupling layer, a hydrophilic polymer layer, a binder layer, and a hydrophobic polymer layer from the inside to the outside; the ceramic base film, The mass ratio of silane coupling layer, adhesive layer, and hydrophobic polymer layer is 1:0.005:0.05:0.006:0.1; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyltrimethyl oxysilane; the hydrophilic polymer layer is polyimide; the binder layer is stearic acid; the hydrophobic polymer layer is polytetrafluoroethylene.

[0053] The preparation method of the hydrophobic ceramic composite membrane of the present embodiment comprises the following steps:

[0054] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, clean it in an ultrasonic cle...

Embodiment 3

[0058] The hydrophobic ceramic composite membrane of this embodiment includes a ceramic base film, and the surface of the ceramic base film is sequentially provided with a silane coupling layer, a hydrophilic polymer layer, a binder layer, and a hydrophobic polymer layer from the inside to the outside; the ceramic base film, The mass ratio of silane coupling layer, adhesive layer, and hydrophobic polymer layer is 1:0.003:0.03:0.005:0.07; the ceramic base film is aluminum oxide ceramic film, and the silane coupling layer is γ-aminopropyltrimethyl Oxysilane; the hydrophilic polymer layer is polyimide; the adhesive layer is polyvinyl alcohol; the hydrophobic polymer layer is polytetrafluoroethylene.

[0059] The preparation method of the hydrophobic ceramic composite membrane of the present embodiment comprises the following steps:

[0060] 1) Put a commercial aluminum oxide ceramic membrane with a size of 1cm×1cm (mass 2g) into a beaker filled with acetone, clean it in an ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com