High-temperature-resistant and high-salt-resistant fine gel particle as profile control agent as well as preparation method and application of fine gel particle

A technology of gel particles and high temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems that the remaining oil is not well produced, easy to accumulate near the blast hole, and the construction validity period is short, etc., to achieve Good deep profile control effect, good compatibility with formation, reasonable material selection and dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

[0044] 1. Preparation of high temperature and high salt fine gel particle profile control agent

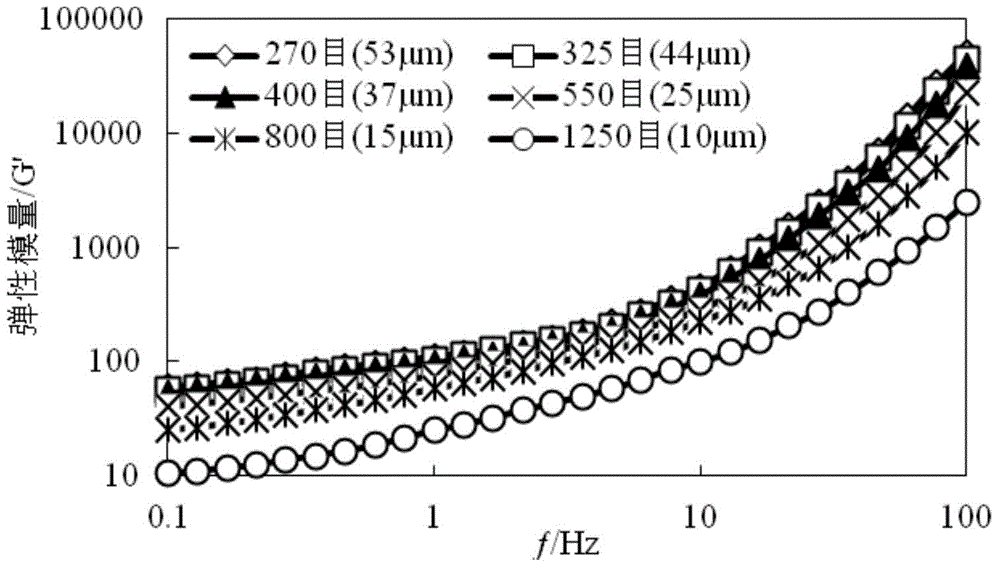

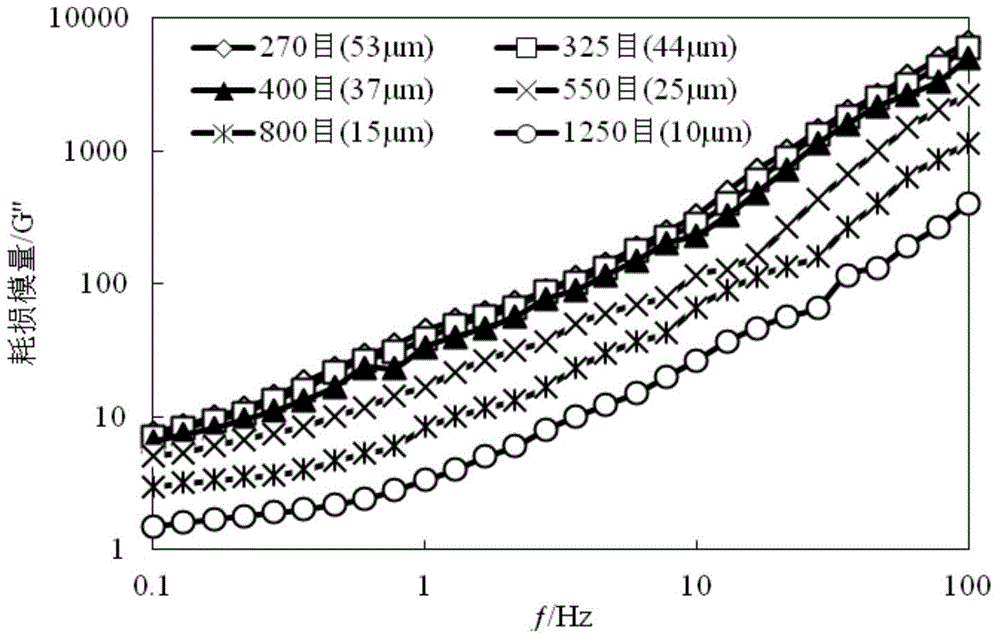

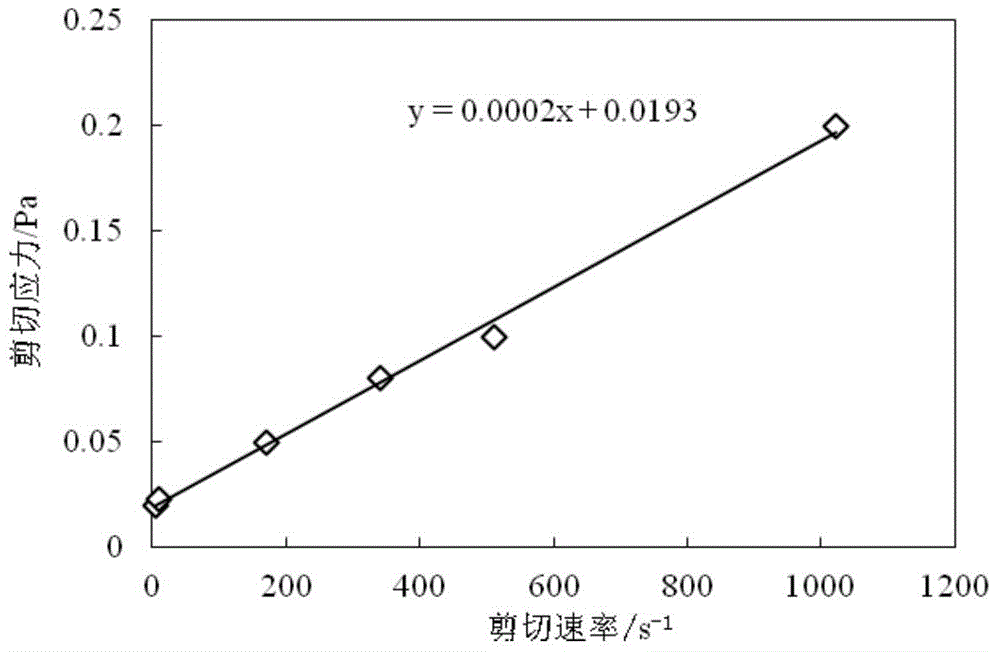

[0045] Add 50g of modified starch into 898g of water, and then add 15g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 35g of acrylamide (AM), 0.5g of N, N '—Methylenebisacrylamide, 3g of sodium hydroxide, 0.6g of potassium peroxodisulfate and 0.3g of sodium bisulfite, after the solution is fully stirred, seal it, put it in a thermostat at 40°C for 10 hours, and take it out. At this time, it has become a whole block gel. Take out the block-shaped whole gel and carry out drying, crushing, granulation and other processes to make particle sizes of 270 mesh (53 μm), 325 mesh (44 μm), 400 mesh (37 μm), 550 mesh (25 μm), 800 mesh (15 μm) ) and 1250 mesh (10μm) fine gel partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com