Water plugging pipe column suitable for small partitioning layer plug bottom water well and water plugging method

A technology of interlayer and water pipe, which is applied in the direction of earthwork drilling, sealing/isolation, wellbore/well components, etc. It can solve the problems of reducing oil well pump inspection cycle, leakage of lateral single retaining valve and failure of pressure, and failure of packer. Problems such as setting and sealing can be achieved to improve the success rate of construction, broaden application prospects and reduce the risk of well jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

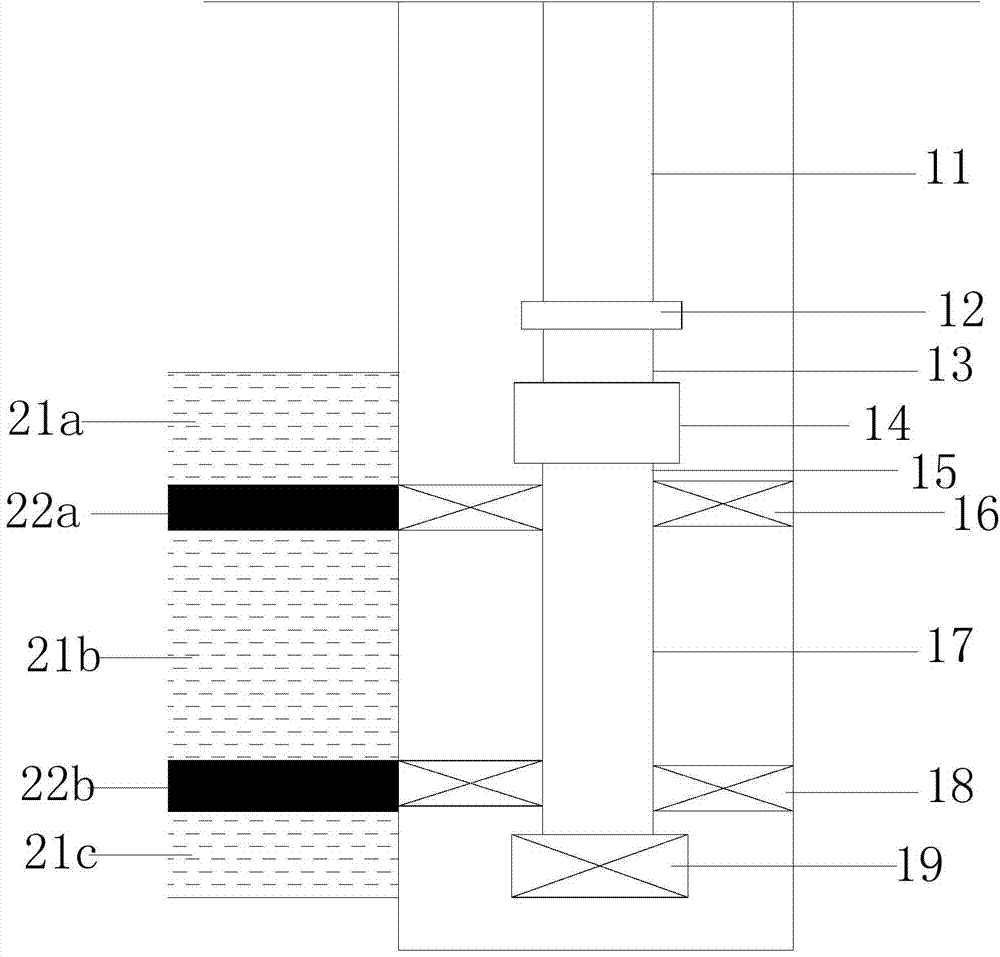

[0022] The invention provides a water plugging pipe string suitable for blocking the bottom of a water well in a small compartment, which includes a first oil pipe, a hydraulic hand-off tool, a second oil pipe, a positioning nipple, a third oil pipe, a hydraulic sealing Spacer, fourth tubing, long rubber cartridge packer and plug.

[0023] The present invention also proposes a water shutoff method using the above water shutoff string, the water shutoff method includes: lowering the water shutoff string into a designated position in the well, making the position of the hydraulic packer the same as the upper barrier in the well. Corresponding, and the position of the long rubber tube packer corresponds to the lower interlayer in the downhole, wherein the upper interlayer is located between the upper oil layer and the middle oil layer in the downhole, and the lower interlayer is located between the middle oil layer and the lower oil layer Inject fluid from the wellhead into the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com