Continuous pipeline tripping device

A technology for pipelines and oil pipelines, applied in the field of continuous pipeline lifting and lowering devices, can solve the problems of limited selection of pipeline diameter range, difficult operation at the wellhead, and difficult operation at the wellhead, so as to improve the construction success rate, avoid hard contact, reduce The effect of risk factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

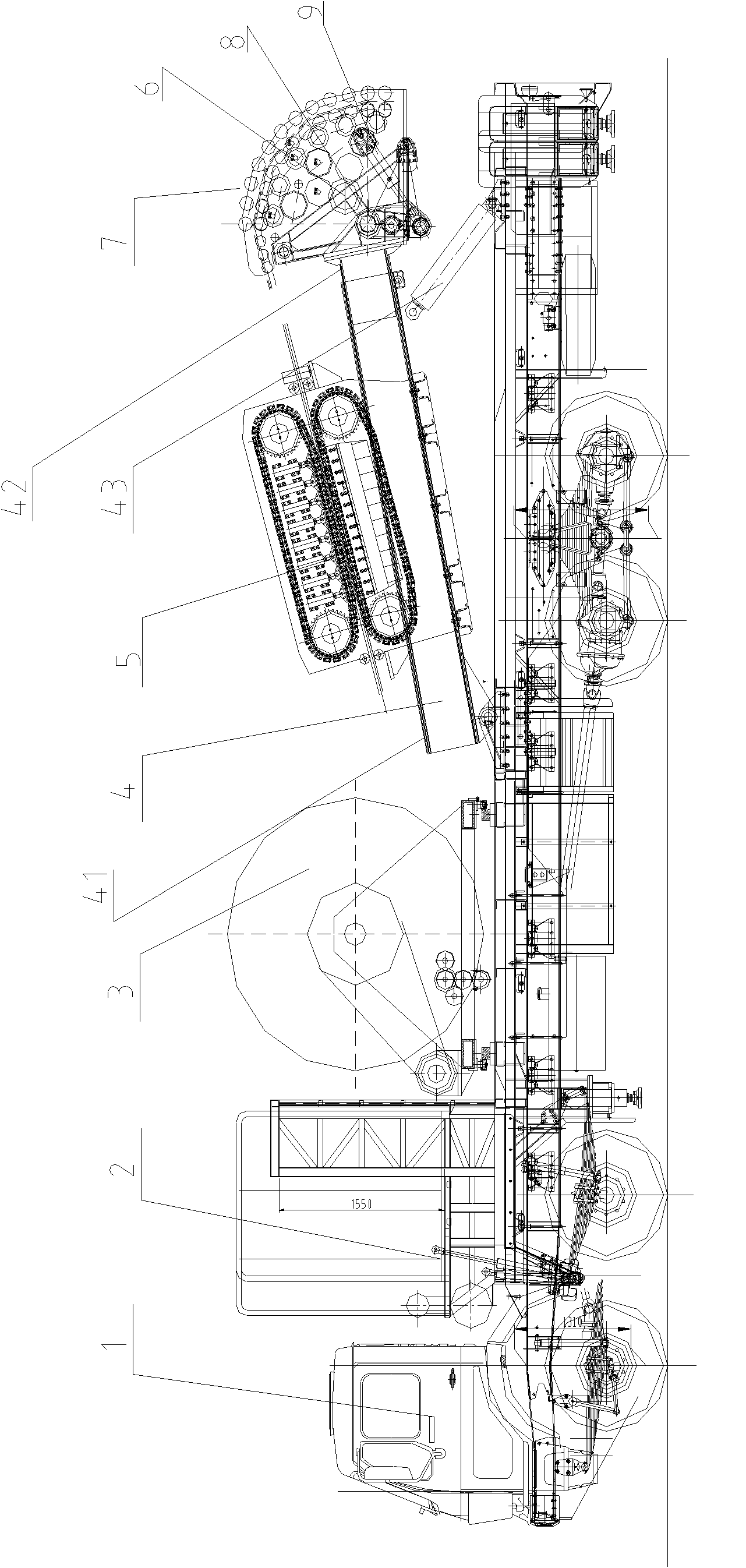

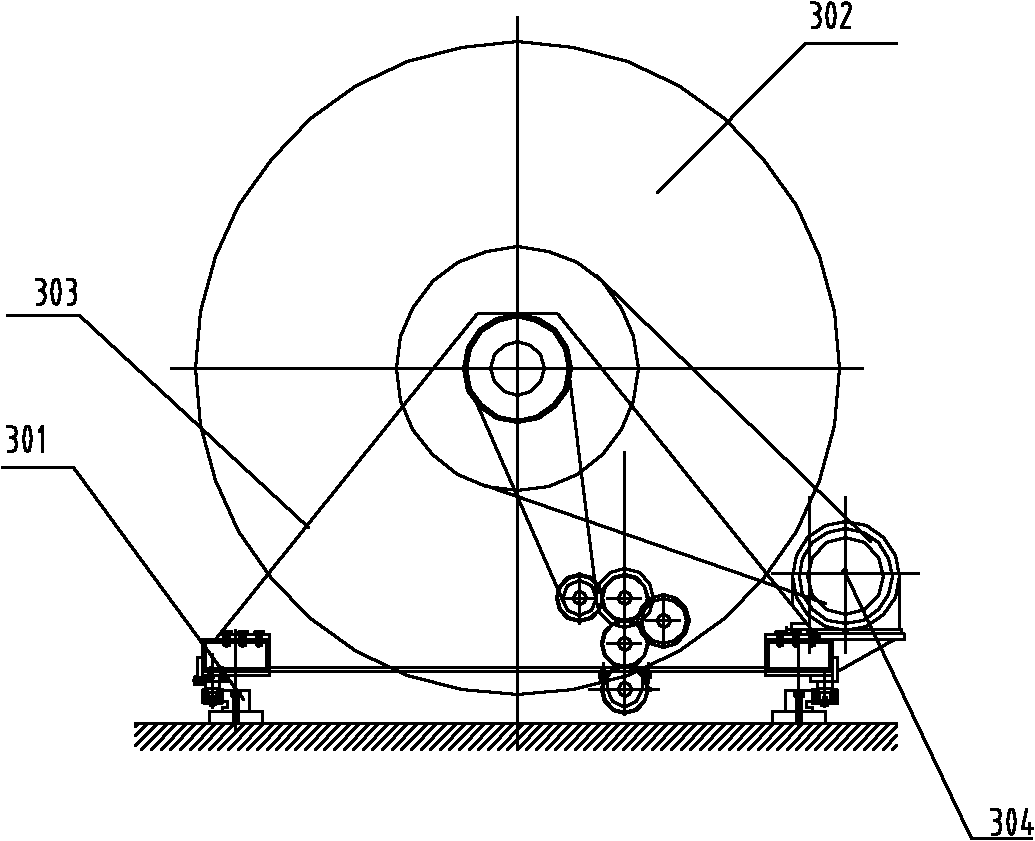

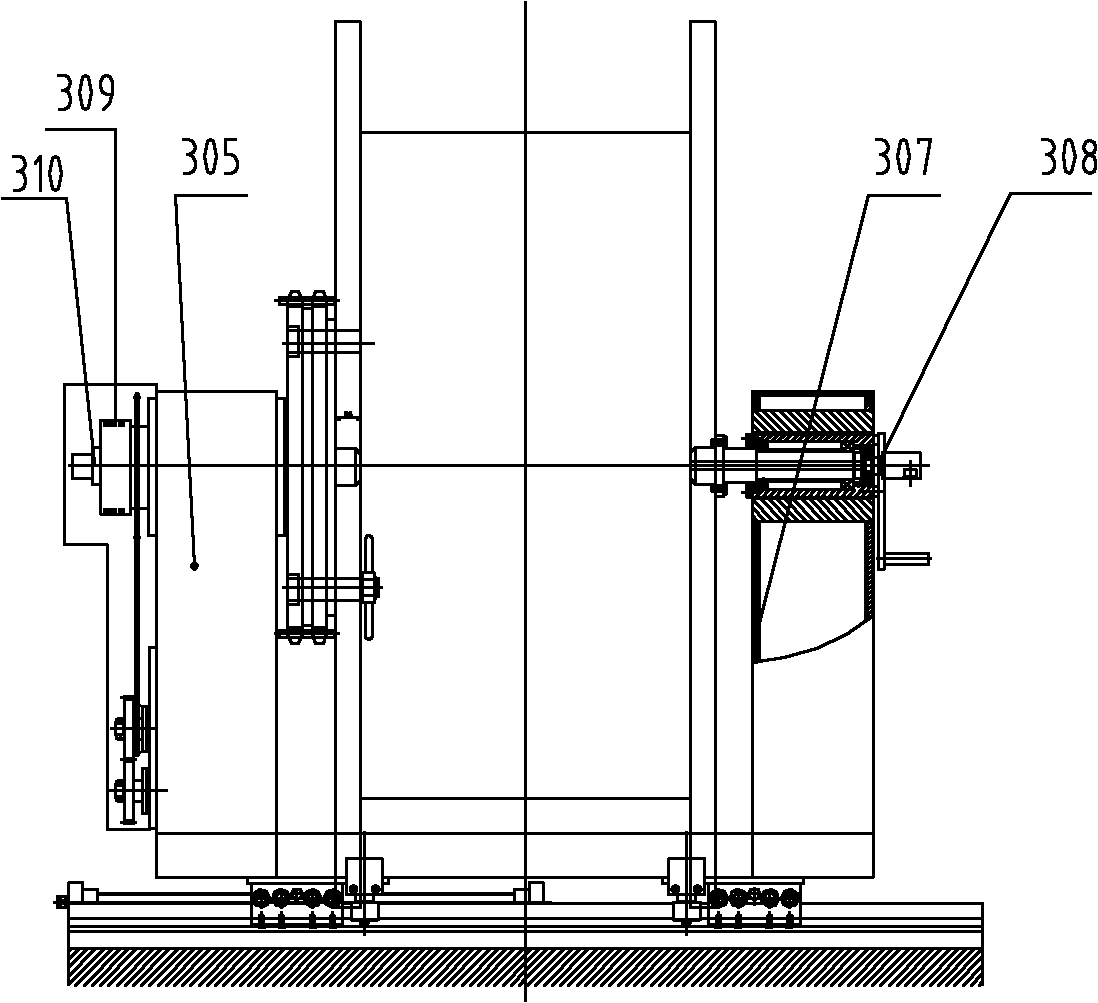

[0059] The structure of the lifting device of the present invention is as follows: figure 1 As shown, it is mainly composed of the following parts: vehicle system 1, operation control room 2, roller retraction and discharge system 3, flat traction system, guide injection system, hydraulic power system, blowout prevention system and auxiliary system, etc.

[0060] The functional and technical requirements of each component of the lifting device:

[0061] (1) Shaftless take-up and discharge system: It is mainly used for rewinding and unwinding, and makes the tubing lined up on the reel; it can assist pulling the tubing when necessary. Hydraulic drive, chain and gear drive winding and pipe arrangement, maximum rewinding force 5t, maximum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com