Long-effect packer for oilfield water exclusion production

A packer, long-term technology, used in sealing/packing, earth-moving drilling, wellbore/well components, etc., can solve the problem of shortened isolation period, complicated construction process, and extrusion deformation of packer setting section. and other problems to achieve the effect of improving the success rate of construction, simplifying the construction process and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

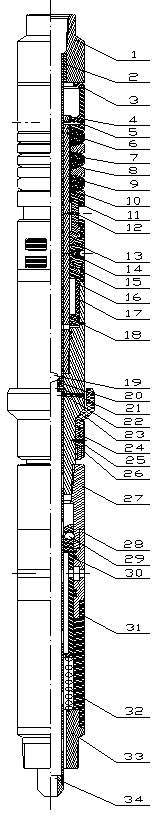

[0023] Such as figure 1 As shown, the present invention provides a long-term production isolation packer for oilfields, comprising an upper joint 1, an intubation tube 2, a fishing sleeve 3, a rubber barrel 7, a spacer ring 8, a center pipe 9, a pressure retaining sleeve 10, an upper cone Body 11, locking pin 12, slips 13, spring 14, slip sleeve 15, lower cone 16, middle joint 17, starting shear nail 18, setting steel ball 19, setting ball seat 20, throwing shear nail 21, leather cup 23, connector 27, sliding sleeve outer cylinder 28, locking steel ball 29, sliding sleeve 30, center sleeve 31, return spring 32, lower joint 33, plug 34 and other components; the upper joint 1 and The upper end of the intubation tube 2 is connected, and the upper half of the intubation tube 2 is sleeved with a central tube 9; located below the upper joint 1, the salvage sleeve 3, the rubber tube 7, the spacer ring 8 and the pressure retaining sleeve 10 are sequentially arranged from top to bottom...

Embodiment 2

[0026]On the basis of Embodiment 1, the inside of the rubber sleeve 7 , spacer ring 8 and pressure retaining sleeve 10 is provided with a rubber sleeve sleeve 4 sleeved on the central tube 9 . The upper end of the upper cone 11 is clamped between the lower end of the rubber sleeve casing 4 and the retaining sleeve 10 . A sealing gasket 6 is provided between the central tube 9 and the rubber tube 7, the lower cone 16 and the middle joint 17; Sealing rings are provided between the intermediate and middle joints 17 and the central tube 9 ; sealing rings are provided between the setting ball seat 20 and the intubation tube 2 , and between the sliding sleeve outer cylinder 28 and the sliding sleeve 30 . The fishing sleeve 3 and the central pipe 9 are fixed by the first connecting screw 5 ; the middle joint 17 and the cannula 2 are fixed by the second connecting screw 22 . Between the lower end of the cannula 2 and the plug 34, between the lower end of the middle joint 17 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com