Sieve pipe self-locking switch controller

A self-locking switch and manipulator technology, which is used in the production of fluids, wellbore/well components, and earth-moving drilling, etc., and can solve the high positioning requirements (the convex shoots must be inserted into the matching grooves to complete the opening. Closing action, large (specially running tools, and the wellhead is required to cooperate with pressure, only one sliding sleeve is controlled, etc., to achieve the effect of low downhole positioning requirements, reduced construction complexity, and improved construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

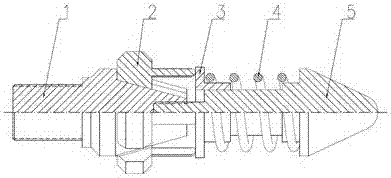

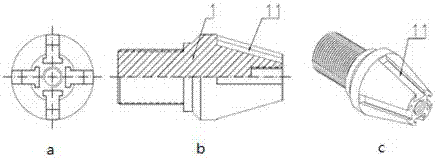

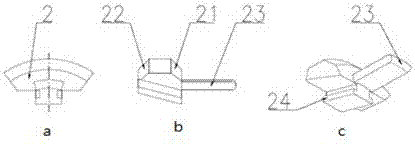

[0027] see figure 1 , a self-locking switch controller for screen tubes, including a tapered slide rail joint 1, a movable shift block 2, a spring pressing cap 3, a return spring 4, and a front guide head 5. Among them: both ends of the tapered slide rail joint 1 are threaded, and four dovetail grooves 11 are processed on the conical body, which are evenly distributed around the axis. The internal thread of the tapered slide rail joint 1 is fastened with the thread of the front leader 5, The front seeker 5 is covered with a spring pressure cap 3, and the spring pressure cap 3 and the front seeker 5 are in a sliding fit, and a return spring 4 is installed between the two. The movable shifting block 2 is a circular structure, and the bottom plane is processed. There is a T-shaped slide rail 24, and the T-shaped slide rail 24 is installed in the dovetail groove 11 of the tapered slide rail joint 1 and is in a sliding fit. Contact, the front part of the front guide head 5 is coni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com