Advance precipitation construction method of oversized-section double-side lower pilot tunnels of water-rich tunnel

A super-large cross-section, water-rich tunnel technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of slow construction progress, high construction cost and energy consumption, and low construction safety by shield tunneling and freezing methods. Achieve the effect of low allocation of machinery and labor resources, fast overall structure speed and high construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

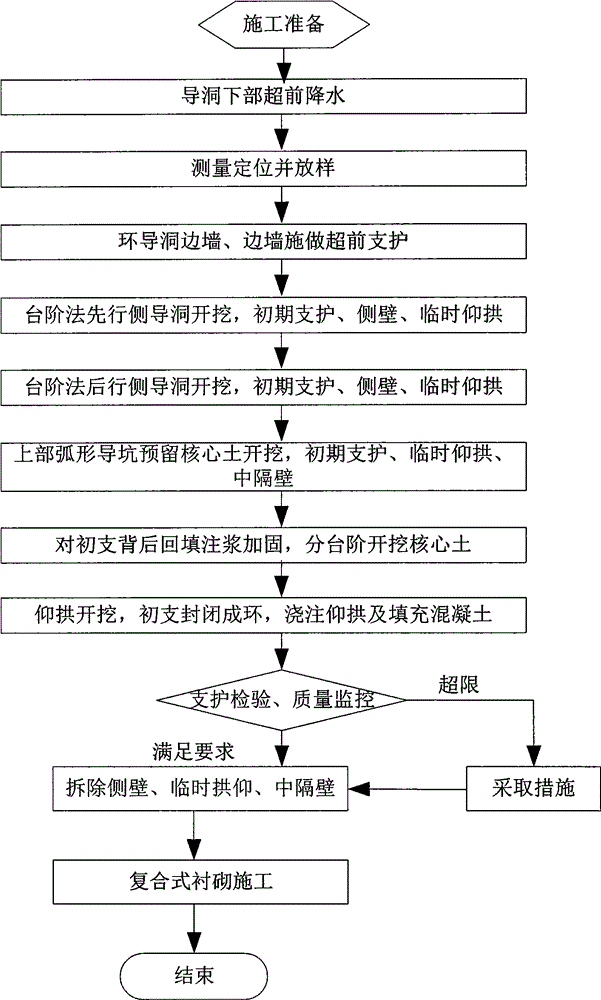

[0057] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0058] The technical principle of the advanced dewatering construction of the super large section of the water-rich tunnel of the present invention is that the double side wall guide tunnel of the lower half section of the main tunnel is advanced, and the parts are closed to form a ring, and the front tunnel is dewatered in advance and the normal The arch frame at the beginning of the hole is stable. The upper half section of the main tunnel is excavated by using the arc-shaped pilot pit to reserve the core soil method. The arch part is excavated in place at one time, and the initial steel frame at the upper part of the main tunnel is spliced in place and closed to form a ring, which reduces the disturbance of the surrounding rock caused by multiple splicing, and reduces the With small construction error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com