Thixotropic chemical sealing channeling agent

A sealing agent and thixotropic technology, applied in chemical instruments and methods, sealing/isolation, wellbore/well components, etc., can solve the problems of easy formation of pores and crevice structures, low cement extrusion pressure, and poor plugging effect and other problems, to achieve the effect of outstanding crack resistance, small formation damage and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

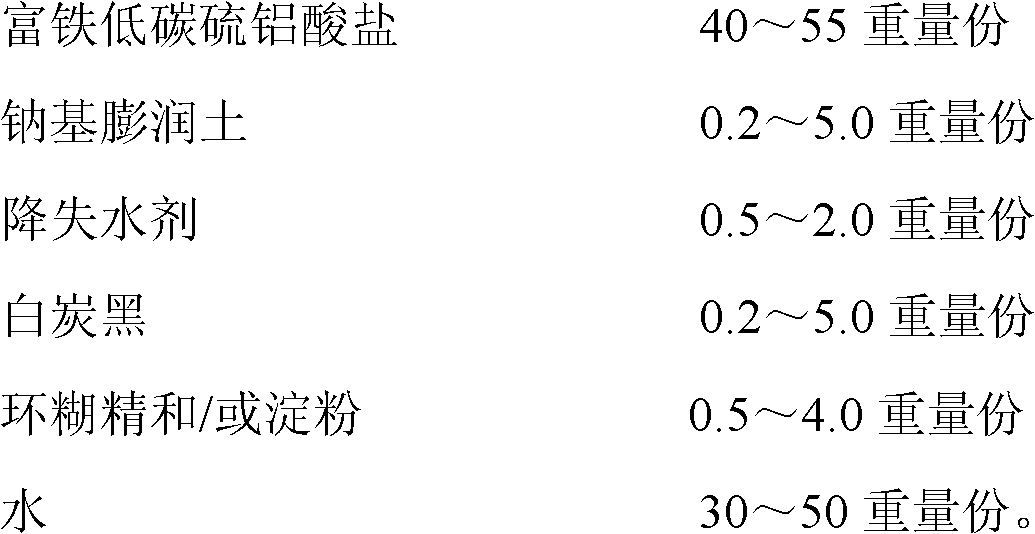

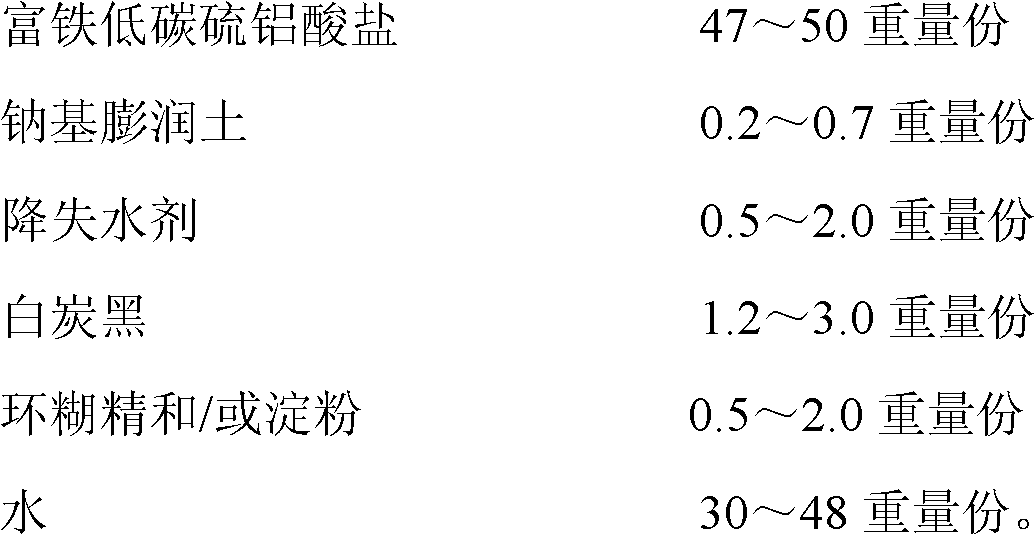

Method used

Image

Examples

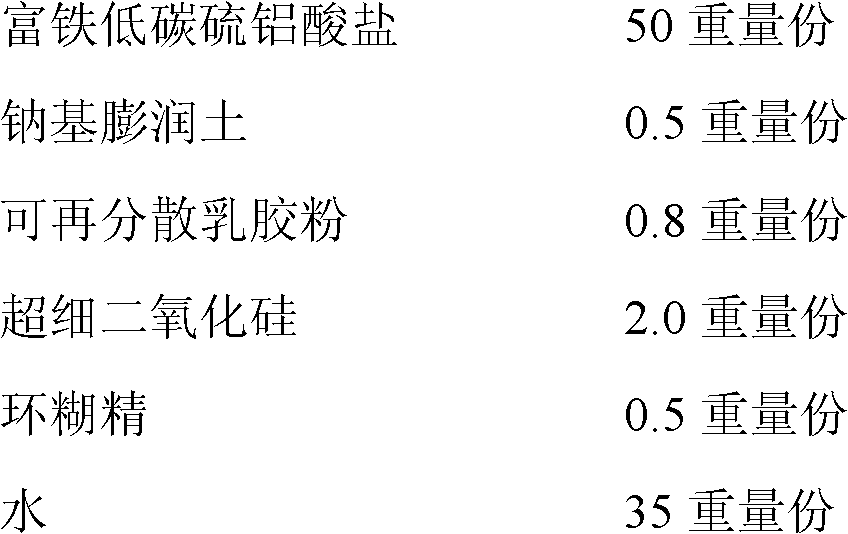

Embodiment 1

[0027]

[0028] Wherein, the iron-rich low-carbon sulfoaluminate is purchased from Anshan Angang Slag Development Company, wherein Fe 2 o 3 Content 10.5%, carbon loss on ignition 2.5%, particle size 5.5μm;

[0029] The sodium-based bentonite is purchased from Heishan Bentonite Factory, and the expansion factor is 30 times;

[0030] The redispersible latex powder is produced by Dalian Chemical Industry (Jiangsu) Co., Ltd., with a solid content of 98%, a 400 μm sieve residue of no more than 2%, and a minimum film-forming temperature of 0°C;

[0031] The BET specific surface area of the ultrafine silica is 165m 2 / g;

[0032] The cyclodextrin is alpha-cyclodextrin.

[0033] When using, prepare a piece of about 5m 3 Add water, iron-rich low-carbon sulfoaluminate, sodium bentonite, redispersible latex powder, ultra-fine silica, cyclodextrin, etc. in a proportional manner under stirring, and stir thoroughly for 5 to 10 minutes Finally, a chemical blocking agent with suita...

Embodiment 2

[0035]

[0036] Wherein, the iron-rich low-carbon sulfoaluminate is purchased from Liaoning Haicheng Mineral Powder Factory, wherein Fe 2 o 3 Content 9.5%, carbon loss on ignition 2%, particle size 4μm;

[0037] The sodium-based bentonite is purchased from Heishan Bentonite Factory, and the expansion factor is 50 times;

[0038] The redispersible latex powder is produced by Dalian Chemical Industry (Jiangsu) Co., Ltd., with a solid content of 98%, a 400 μm sieve residue of no more than 2%, and a minimum film-forming temperature of 0°C;

[0039] The BET specific surface area of the ultrafine silica is 165m 2 / g;

[0040] The cyclodextrin is beta-cyclodextrin.

[0041] When using, prepare a piece of about 3m 3 Add water, iron-rich low-carbon sulfoaluminate, sodium-based bentonite, redispersible latex powder, ultrafine silica, cyclodextrin, etc. in sequence in a stirring state, and stir thoroughly for 5 to 10 minutes Finally, a chemical blocking agent with suitable visco...

Embodiment 3

[0043]

[0044] Wherein, the iron-rich low-carbon sulfoaluminate is purchased from Liaoning Haicheng Mineral Powder Factory, wherein Fe 2 o 3 Content 9.5%, carbon loss on ignition 2%, particle size 4μm;

[0045] The sodium-based bentonite is purchased from Heishan Bentonite Factory, and the expansion factor is 50 times;

[0046] The redispersible latex powder is produced by Dalian Chemical Industry (Jiangsu) Co., Ltd., with a solid content of 98%, a 400 μm sieve residue of no more than 2%, and a minimum film-forming temperature of 0°C;

[0047] The BET specific surface area of the fumed silica is 260m 2 / g;

[0048] The starch is commercially available cornstarch.

[0049] When using, prepare a piece of about 3m 3 In a stirring tank, add water, iron-rich low-carbon sulfoaluminate, sodium bentonite, redispersible latex powder, fumed silica, starch, etc. in sequence in a stirring state, and stir thoroughly for 5 to 10 minutes to obtain It is a chemical blocking agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com