Polyhydroxy thickener, high-temperature-resistant alcohol-based fracturing fluid system and application of high-temperature-resistant alcohol-based fracturing fluid system

A thickening agent, polyhydroxyl technology, applied in the fields of mining fluids, drilling compositions, earthwork drilling, etc., can solve the problems of limited application, poor safety, and large formation damage, and achieve high flowback rate and high The effect of temperature resistance and formation damage is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In the present application, the polymerization reaction may be initiator-induced polymerization, heat-induced polymerization, photo-induced polymerization, radiation polymerization, and the like. In some preferred embodiments, the present application uses an in-situ polymerization method based on a redox reaction to obtain the polyhydroxy thickener, and the preparation method includes the following steps:

[0043] Dissolve acrylamide, N-vinylpyrrolidone and N-acrylamidopropyl-N, N, N-dimethyl hydroxyethyl ammonium chloride in water 2 to 4 times the total mass of the monomer, stir to dissolve; then add 3-5% urea and 0.01-0.05% EDTA of the total monomer mass are fully dissolved to obtain a mixed solution;

[0044] At 15-30°C, after passing nitrogen into the mixed solution for 30 minutes, add 0.001-0.01% of oxidation initiator, 0.001-0.01% of reduction initiator and 0.001-0.02% of co-initiator to the total mass of the monomers, and polymerize After reacting for 3-6 hours,...

Embodiment 1

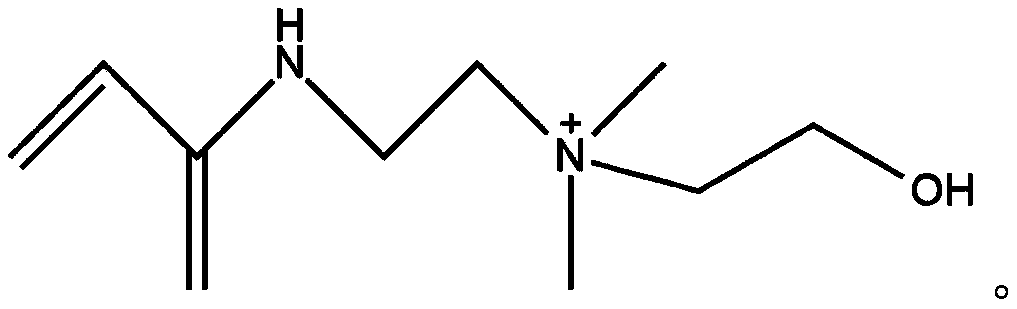

[0069] Preparation of N-acrylamidopropyl-N, N, N-dimethylhydroxyethylammonium chloride (MPP):

[0070] In a 500mL three-necked flask, add 120.0g of N,N-dimethylaminopropyl acrylamide, then add 110mL of ethanol, raise the temperature to 50°C, slowly add 68.0g of 2-chloroethanol dropwise, continue the reaction for 12h after the dropwise addition, and then vacuum The solvent ethanol is distilled off to obtain the MPP monomer.

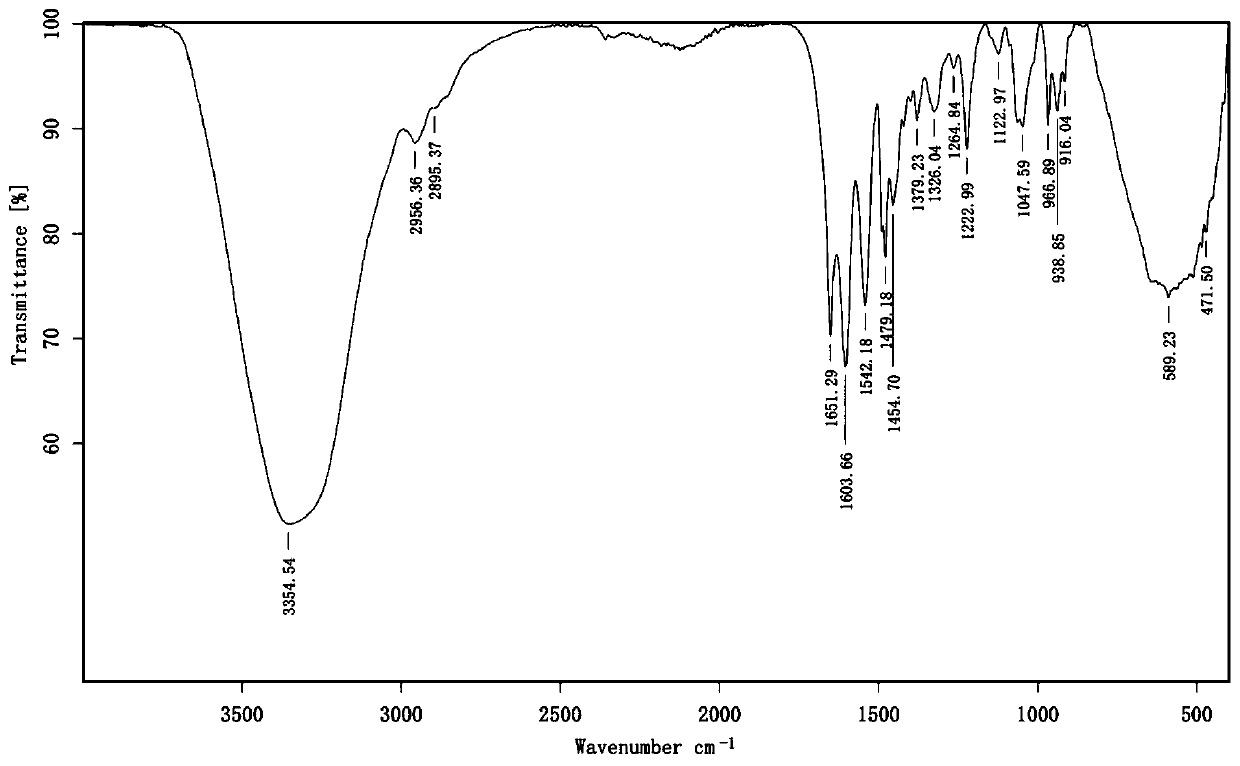

[0071] Among them, the molecular structural formula of the MPP monomer is as follows, and the infrared identification spectrum of the MPP monomer is as follows figure 1 shown.

[0072]

[0073] from figure 1 It can be seen that the FTIR spectrum of the MPP monomer is at 3354.54cm -1 exist-conh 2 In the group -NH 2 The stretching vibration absorption peak is at 1651.29cm -1 exist-conh 2 The stretching vibration absorption peak of the C=O bond in the group is at 1379.23cm -1 and 1454.70cm -1 There are characteristic peaks of methyl groups.

Embodiment 2

[0075] The preparation of polyhydroxy thickener POP-1:

[0076] In a 1L beaker, add 538.0g deionized water, add comonomer acrylamide (AM) 173.0g, N-vinylpyrrolidone (NVP) 25.2g, N-acrylamidopropyl-N, N, N-dimethylhydroxyethylammonium chloride (MPP) 11.3g, then add 8.5g of urea, 0.025gEDTA to dissolve fully; at a temperature of 18°C, then transfer the above mixed solution to a 1L polymerization bottle, pass After nitrogen gas for 30 minutes, add 2.4ml of prepared 1% potassium persulfate solution, 2.4ml of prepared 1% sodium bisulfite solution, and 4ml of prepared 1% azobisisobutylamidine hydrochloride solution , seal the polymerization bottle, wait for the reaction for 6 hours, take out the rubber block, granulate, dry, crush, and sieve to obtain the polyhydroxy thickener POP-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com