Repeated fracturing temporary plugging agent and preparation method thereof

A technology of repeated fracturing and temporary plugging agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of difficult dissolution and plugging removal, low recovery rate, unsuitable for medium and low temperature reservoirs, etc. The effect of less product, faster water absorption and expansion, and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

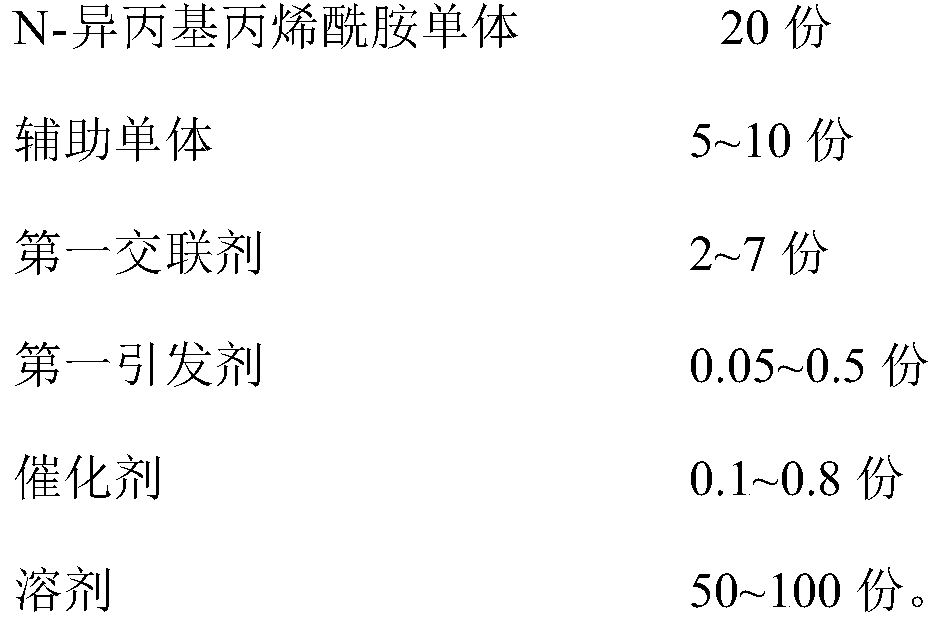

[0035] According to a preferred embodiment of the present invention, the temporary plugging agent is prepared from the following components by weight:

[0036]

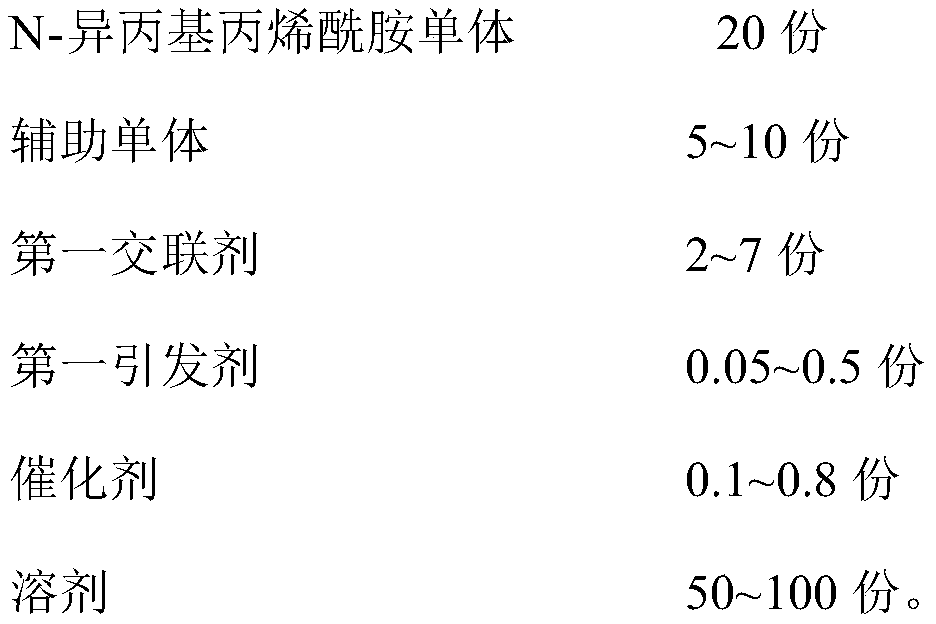

[0037] Preferably, the temporary plugging agent is prepared from the following components by weight:

[0038]

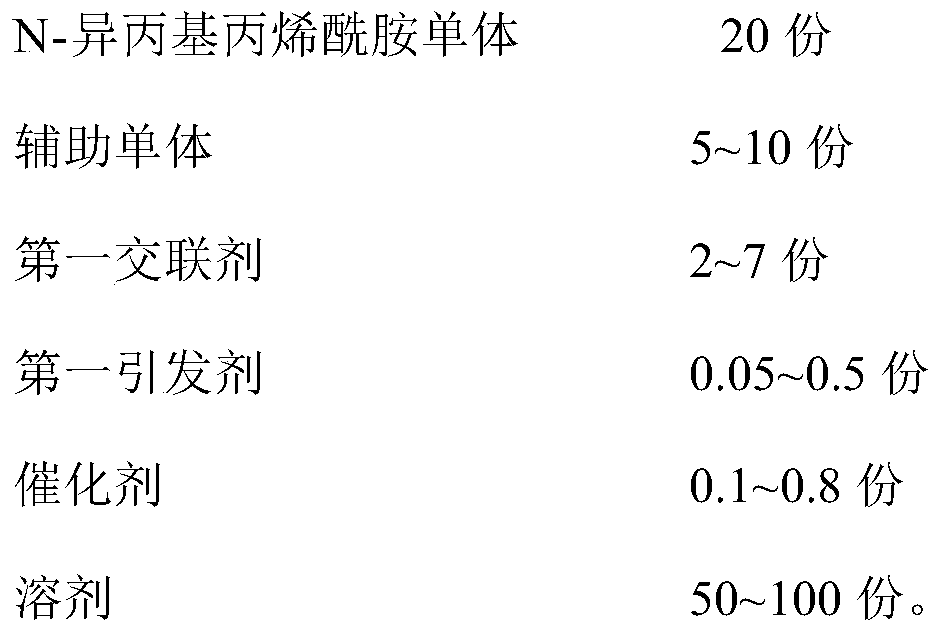

[0039] More preferably, the temporary plugging agent is prepared from the following components by weight:

[0040]

[0041] According to a preferred embodiment of the present invention, the auxiliary monomer is a monomer that can adjust the phase transition temperature of poly-N-isopropylacrylamide.

[0042] In the present invention, in order to improve the temperature sensitivity of the poly-N-isopropylacrylamide polymer, an auxiliary monomer and N-isopropylacrylamide monomer are added for cross-linking, so as to improve the response temperature of the temporary plugging agent, make it suitable for medium and low temperature reservoirs.

[0043] In a further preferred embodiment, the auxiliary mo...

Embodiment 1

[0111] In the preparation raw material of the repeated fracturing temporary plugging agent, the auxiliary monomer is acrylamide, the first crosslinking agent is polyacrylic acid microgel, the first initiator is azobisisobutyronitrile, the catalyst is ammonium sulfite, and the solvent is Deionized water. Among them, the mass of N-isopropylacrylamide monomer is 20g, acrylic monomer is 7g, polyacrylic acid microgel is 5g, azobisisobutyronitrile is 0.2g, ammonium sulfite is 0.4g, deionized water is is 75mL.

[0112] Wherein, polyacrylic acid microgel is prepared according to the following method:

[0113] Weigh 7.2g of acrylic monomer, 0.25g of 2-isopropylthioxanthone and 9.2g of N,N-methylenebisacryloyl in turn, put them in deionized water to mix, then adjust the pH to 1.3, and pass nitrogen for 15min , placed under a 250W high-pressure mercury lamp for 30 minutes, and nitrogen was continuously passed through during the reaction to obtain polyacrylic acid microgels.

[0114] T...

Embodiment 2

[0120] In the preparation raw material of the repeated fracturing temporary plugging agent, the auxiliary monomer is acrylamide, the first crosslinking agent is polyacrylic acid microgel, the first initiator is azobisisobutyronitrile, the catalyst is ammonium sulfite, and the solvent is Deionized water. Among them, the mass of N-isopropylacrylamide monomer is 20g, acrylic monomer is 7g, polyacrylic acid microgel is 5g, azobisisobutyronitrile is 0.1g, ammonium sulfite is 0.4g, deionized water is 80mL.

[0121] Wherein, polyacrylic acid microgel is prepared according to the following method:

[0122] Weigh 7.2g of acrylic monomer, 0.25g of 2-isopropylthioxanthone and 9.2g of N,N-methylenebisacryloyl in turn, put them in deionized water to mix, then adjust the pH to 1.3, and pass nitrogen for 15min , placed under a 250W high-pressure mercury lamp for 30 minutes, and nitrogen was continuously passed through during the reaction to obtain polyacrylic acid microgels.

[0123] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com