High-pressure water injection packer

A packer and high-pressure technology, which is applied in the directions of sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of low construction success rate, unreliable setting and small isolation area, etc., and achieve the goal of construction High success rate, reliable sealing and high sealing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

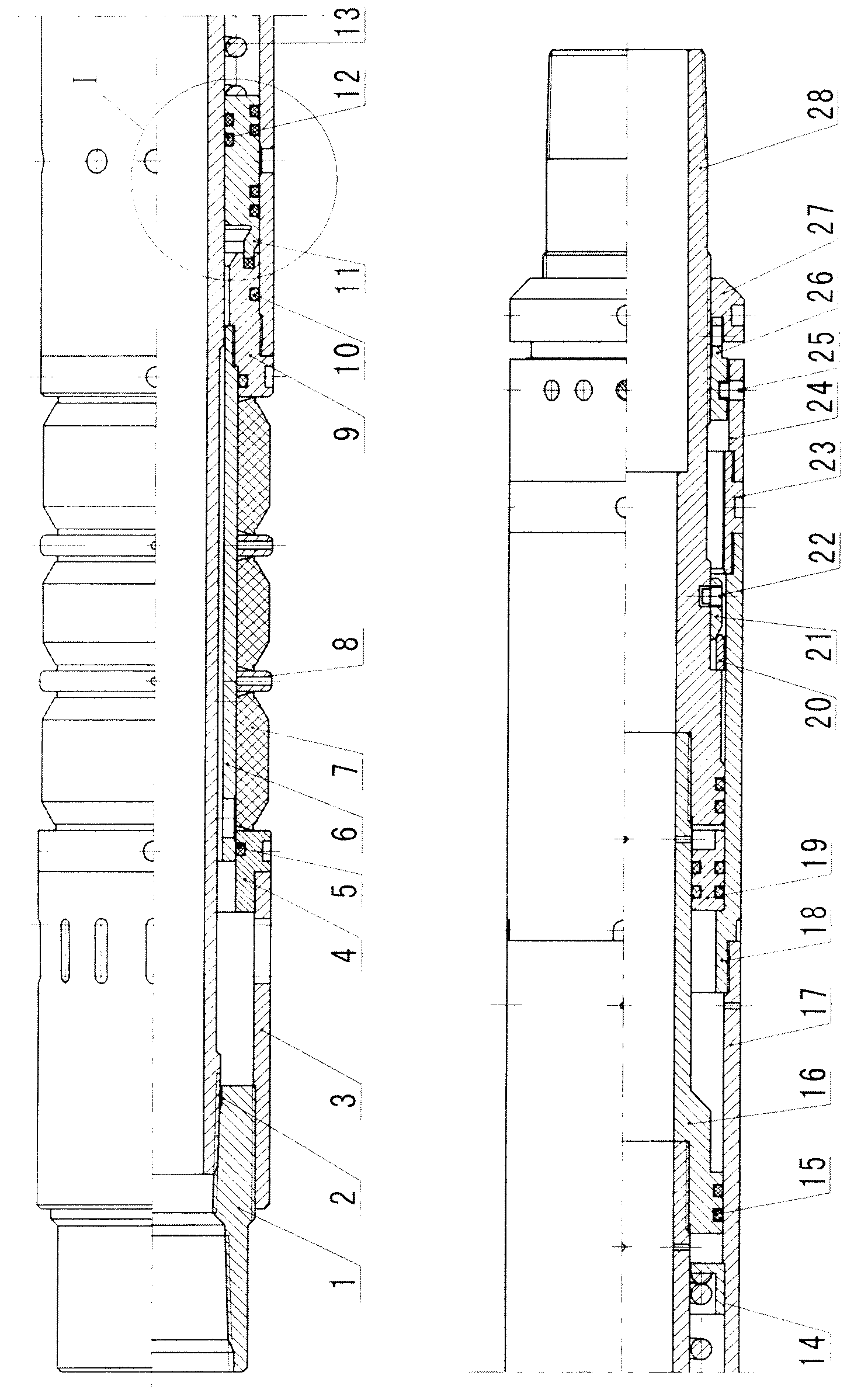

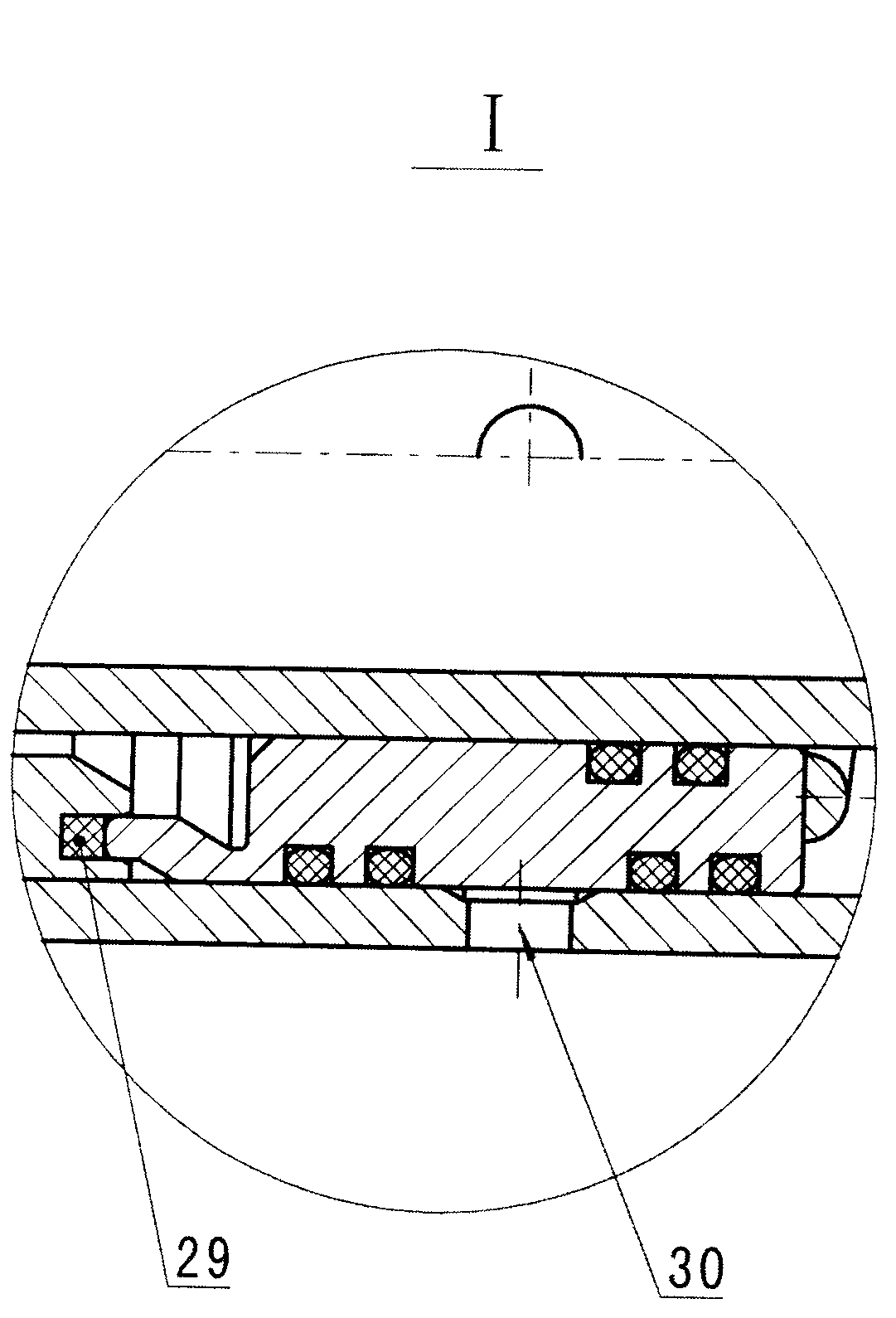

[0017] Such as figure 1 , figure 2 As shown, a high-pressure water injection packer according to the present invention includes an upper joint 1, an upper central pipe 2, an upper backwash sleeve 3, a pressure ring 4, a first sealing ring 5, an outer central pipe 6, and a rubber cylinder 7 , pressure ring 8, backwash valve seat 9, second seal ring 10, backwash piston 11, third seal ring 12, spring 13, spring seat 14, fourth seal ring 15, lower central tube 16, lower backwash sleeve 17. Lower cylinder liner 18, piston 19, lock ring 20, support ring 21, unsealing shear nail 22, lock ring sleeve 23, connecting sleeve 21, setting seal shear nail 25, joint ring 26, joint cap 27, lower joint 28. Sealing member 29, lower backwashing hole 30, characterized in that the upper joint 1 and the upper central pipe 2 are tightened through the threaded connection of the oil pipe, and the first sealing ring 5 is embedded in the sealing groove of the compression ring 4 and then connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com