Drilling-plug free tubular column with sand control and well cementation for open-hole horizontal well

A horizontal well, plug-free technology, applied in wellbore/well parts, earthwork drilling, production fluid, etc., can solve the problems of aggravated mud pollution to the formation, downhole casing loosening, affecting oil well production, etc., to achieve operating costs Low, reduce downhole pipe string, high construction reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

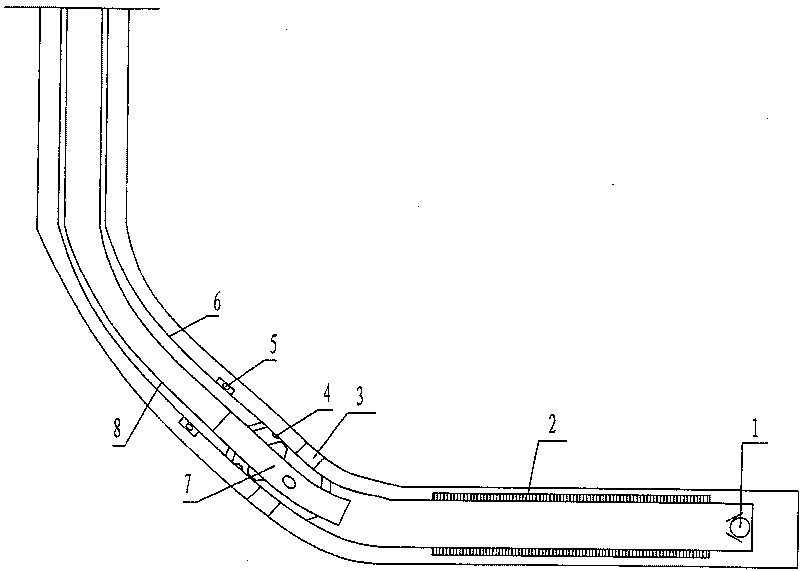

[0016] refer to Figure 1-Figure 4 , a plug-free sand control cementing string for an open-hole horizontal well, comprising an outer string and an inner string. The outer pipe string includes a sand control screen 2 , an open hole packer 3 , an outer positioning step 4 , an outer cementing device 5 and a casing 6 installed and connected in sequence on the pickling filling valve 1 . The inner pipe string includes the oil pipe 8 and the inner cementing device 7 installed on it. The inner pipe string is installed in the outer pipe string, and the inner and outer pipe strings are fixed and sealed with each other.

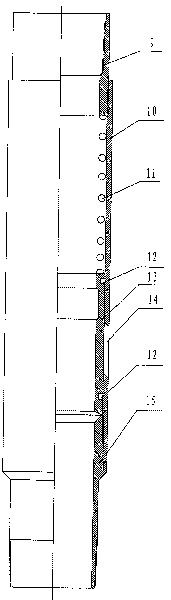

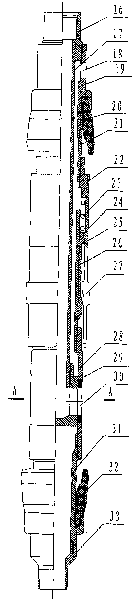

[0017] The outer cementing device 5 includes an outer sleeve 10 , a spring 11 , an inner sliding sleeve 13 and a lower joint 15 which are sequentially connected and installed on the upper joint 9 . A sealing member 12 that is sealed to the outer sleeve 10 is installed on the inner sliding sleeve 13 . The spring 11 is installed in the space between the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com