Patents

Literature

47results about How to "Improve construction reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shale gas horizontal well bridge plug separation and ball throwing segmented fracturing process

InactiveCN104989358AGood flow channelReasonable designFluid removalSealing/packingShale gasMaterial Perforation

The invention discloses a shale gas horizontal well bridge plug separation and ball throwing segmented fracturing process, which concretely comprises the following steps of: 1, draining, exploring and washing a well tube; 2, performing clustering perforation on a first segment; 3, performing fracturing construction on a first cluster; 4, throwing balls for sealing the first cluster; 5, repeatedly performing the fracturing construction, ball throwing and sealing steps in the third step and the fourth step on a second cluster, a third cluster to an N-th cluster; 6, sealing the first segment by a lower bridge plug, and performing clustering perforation on a second segment; 7, sequentially and repeatedly performing fracturing construction, ball throwing, sealing and lower bridge plug sealing steps in the third, fourth, fifth and sixth steps on the second segment to the N-th segment; and 8, performing sweeping grinding. The process method has the advantages that the design is reasonable; the construction cost is low; the optimum flowing passage of shale gas can be realized by adopting the process method; high economic return is obtained at high speed and high yield; and the fractures can be limited to the most economic positions.

Owner:中国石油化工股份有限公司华东分公司采油厂

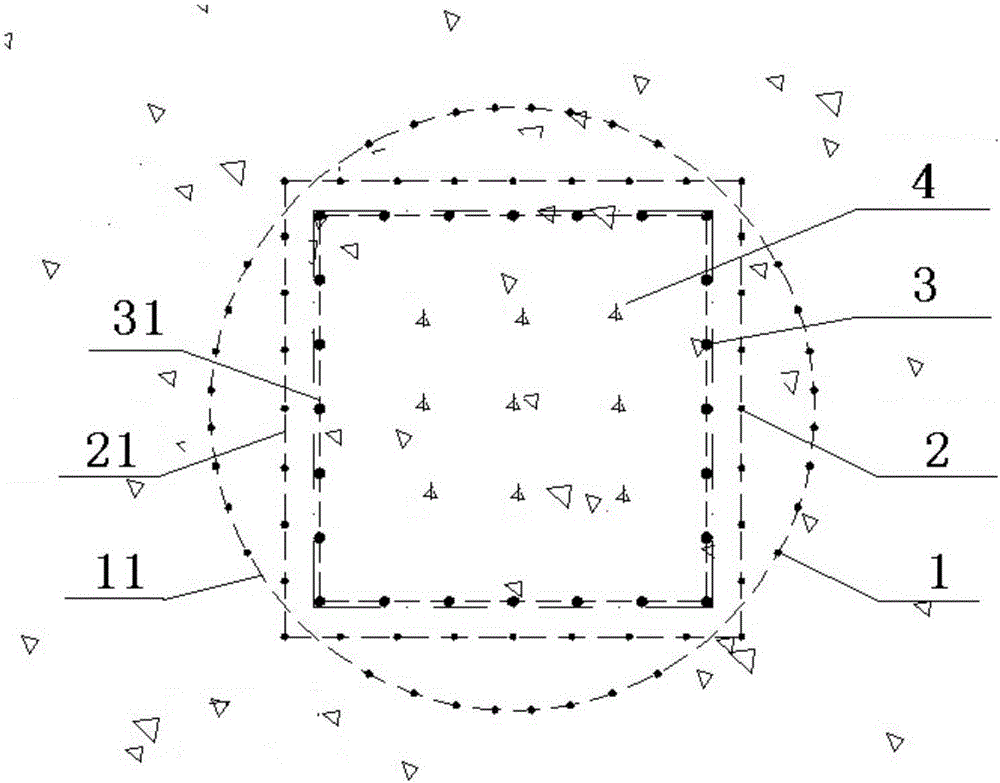

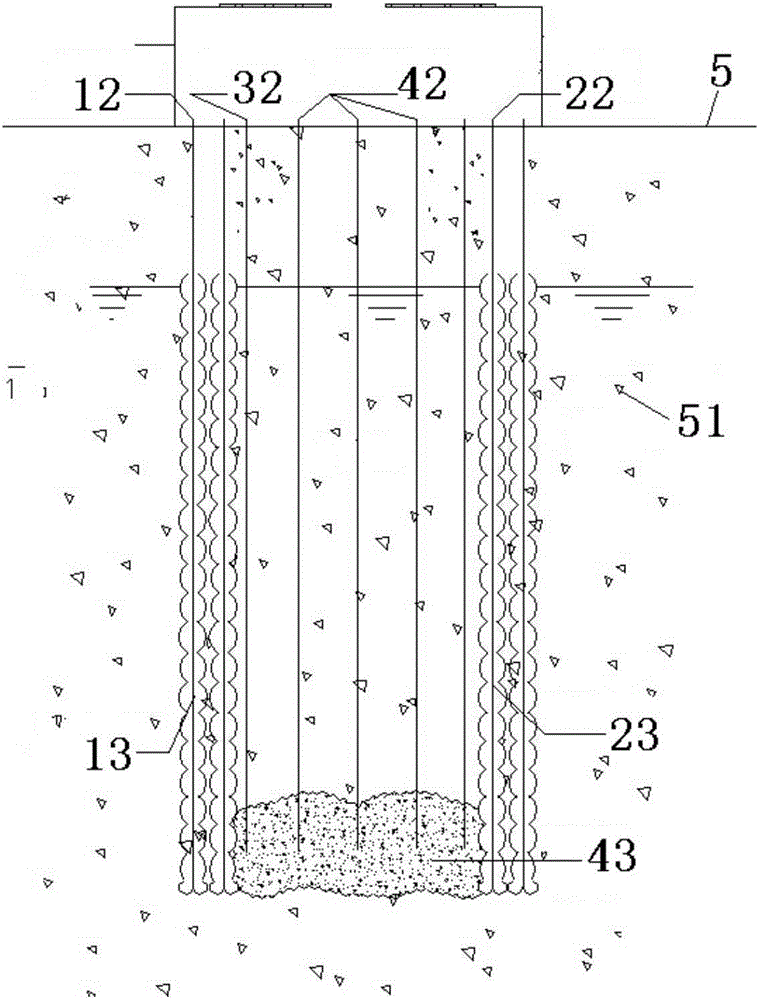

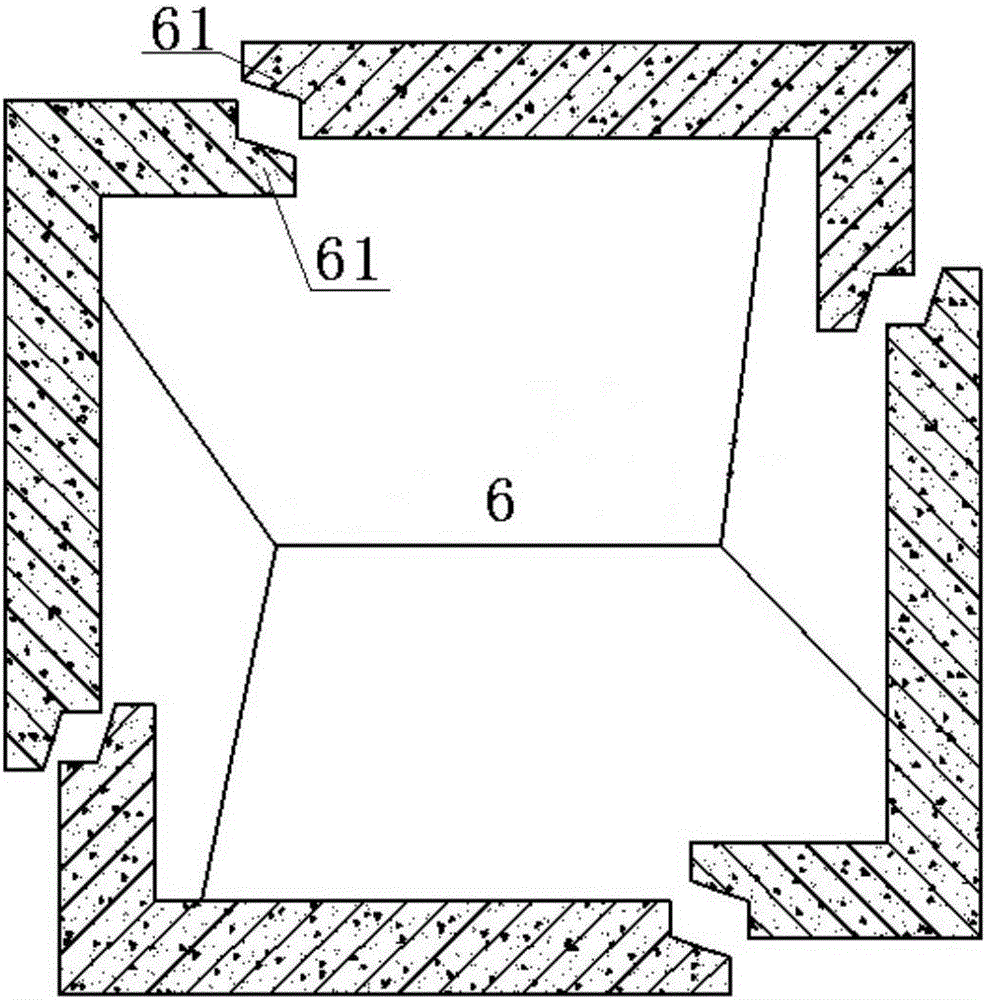

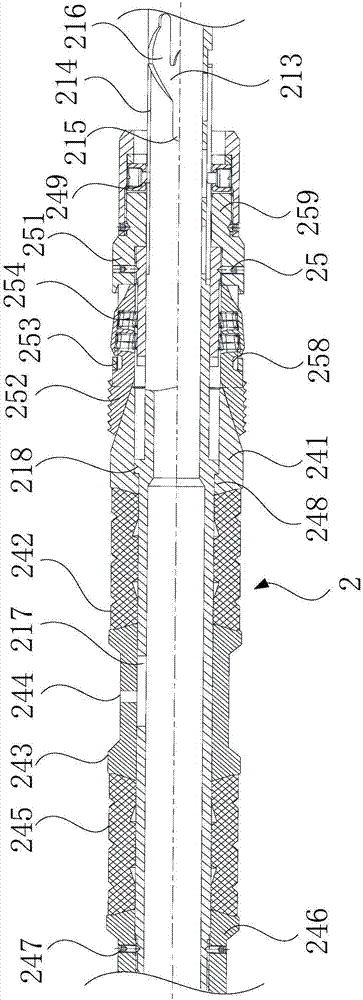

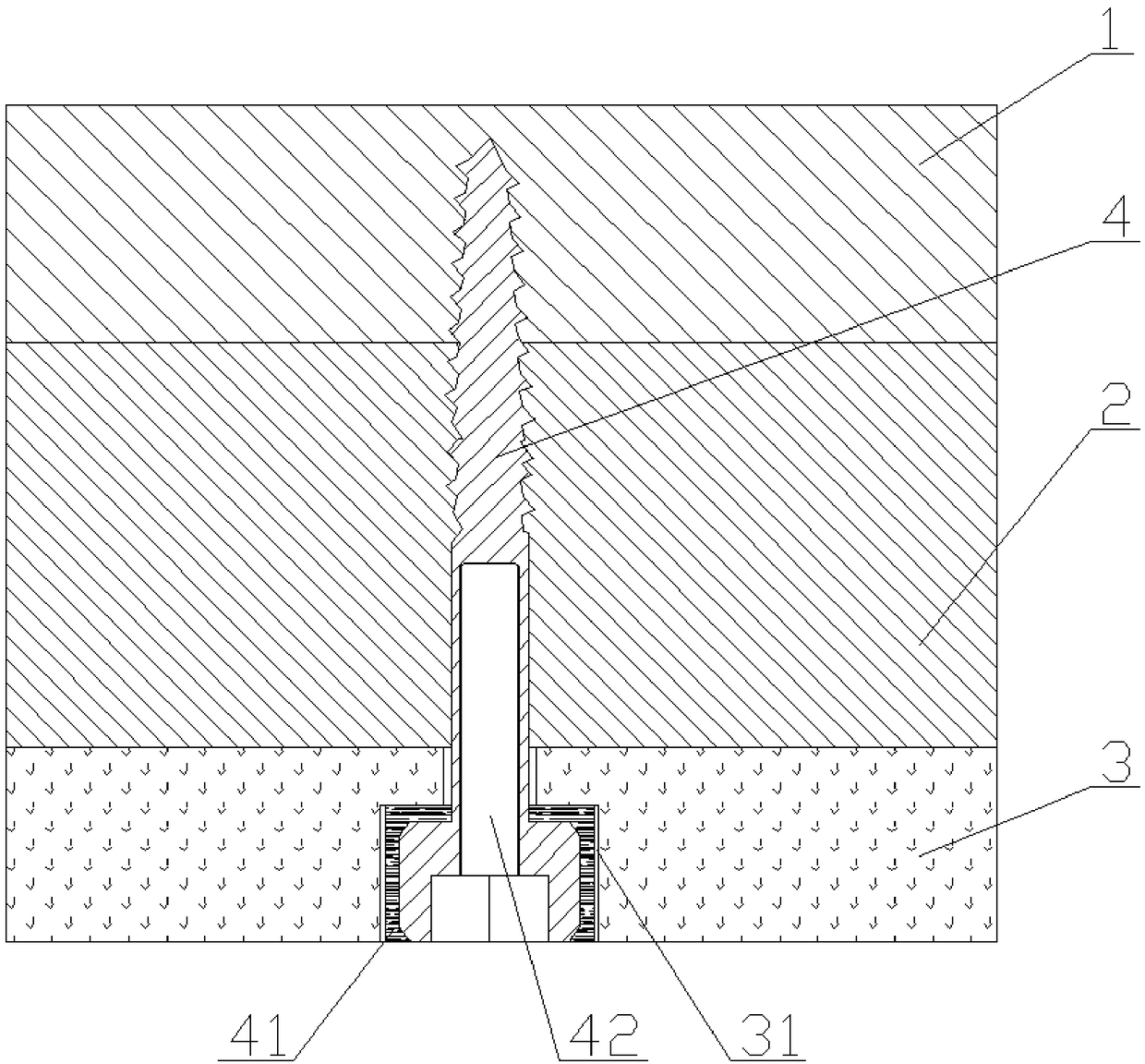

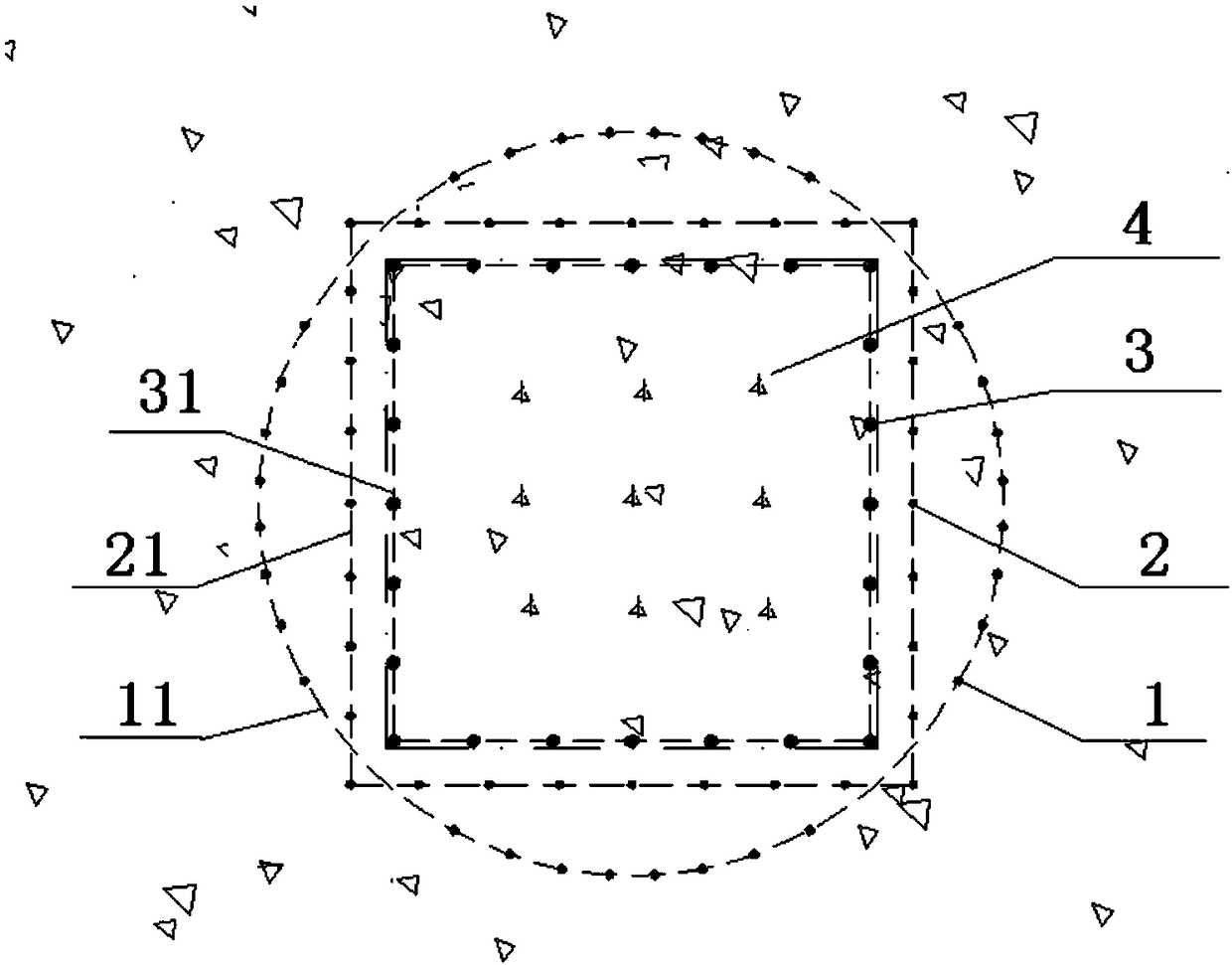

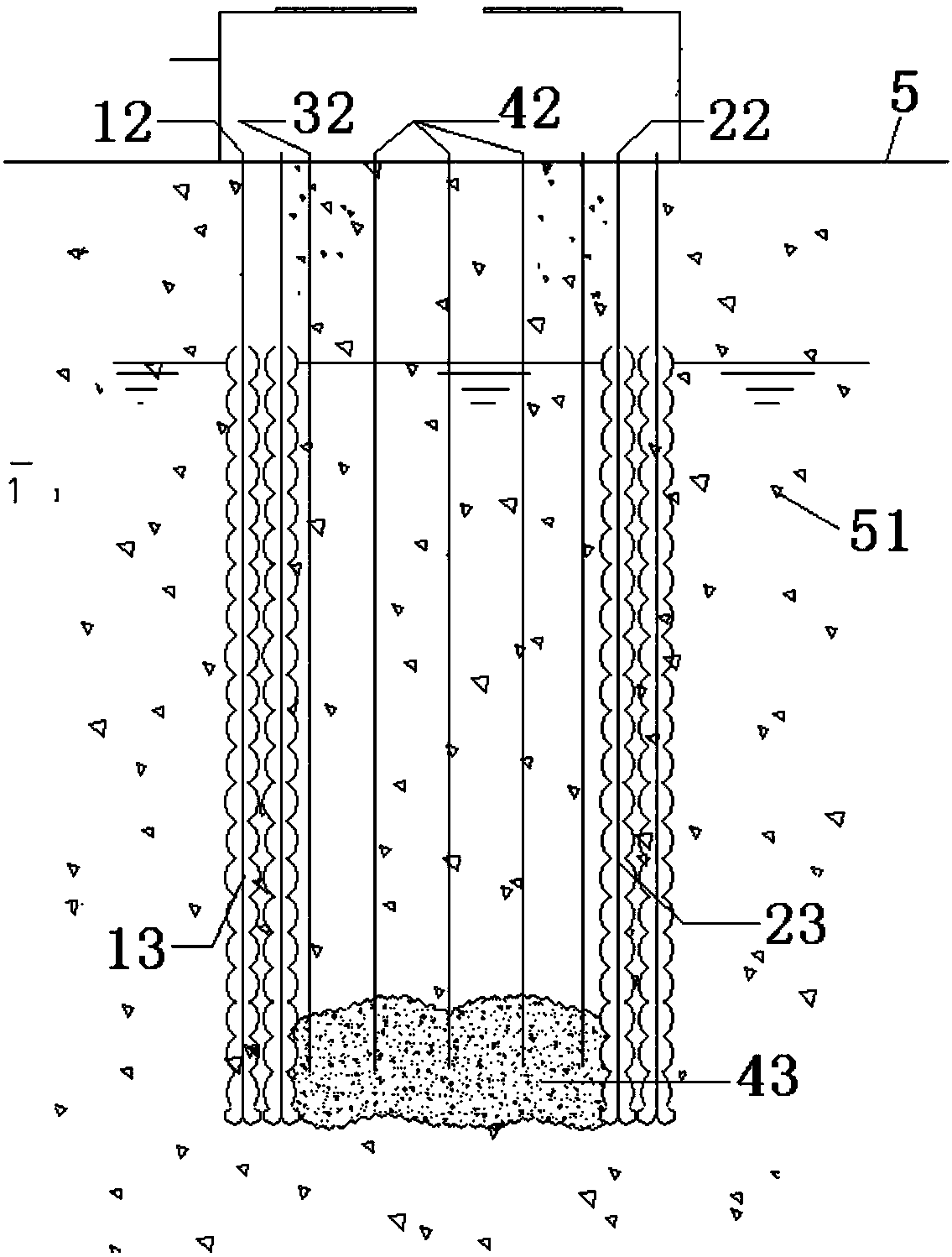

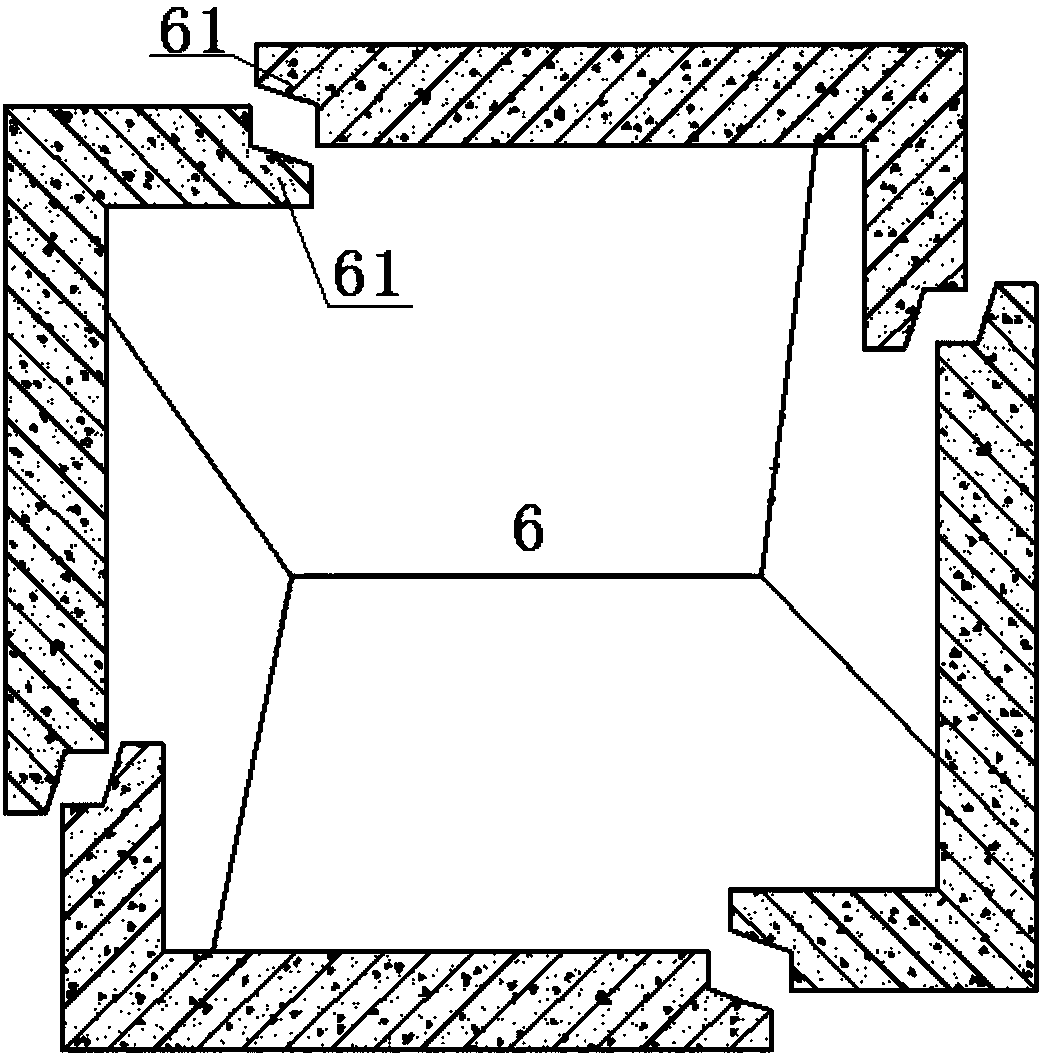

Prefabricated underground silo compound shaft construction method and silo structure

ActiveCN106088154AReduce the internal force of the rectangular sectionReduce settlementArtificial islandsUnderwater structuresEngineeringSilo

The invention relates to the field of underground silo facilities, in particular to a prefabricated underground silo compound shaft construction method and a silo structure which effectively improve the underground silo construction efficiency and greatly reduce the construction cost. The prefabricated underground silo compound shaft construction method comprises the following steps that a, paying off is firstly carried out in a silo building site to locate and arrange drill holes; b, freezing operation and bottom grouting are carried out; c, splicing assembly is carried out to form shaft structures; d, shoe leg heating pipes in shoe leg structures are used for hydrothermal circulation; e, structure shaft components are assembled step by step to form new shaft structures till the preset depth is achieved; f, bottom plates and supporting plates are mounted; g, all drill hole openings in the ground are closed; and h, debugging and running are completed, and construction is finally completed. The prefabricated underground silo compound shaft construction method and the silo structure are high in construction reliability and construction speed and especially suitable for being used in fields with the short construction period and limited construction space.

Owner:黄竟强

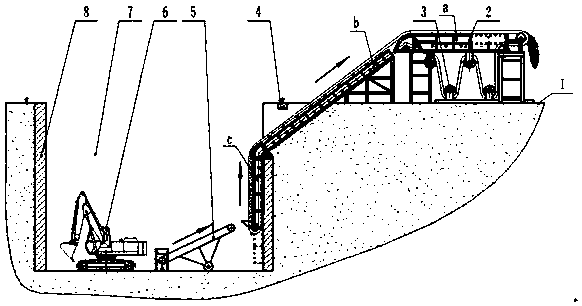

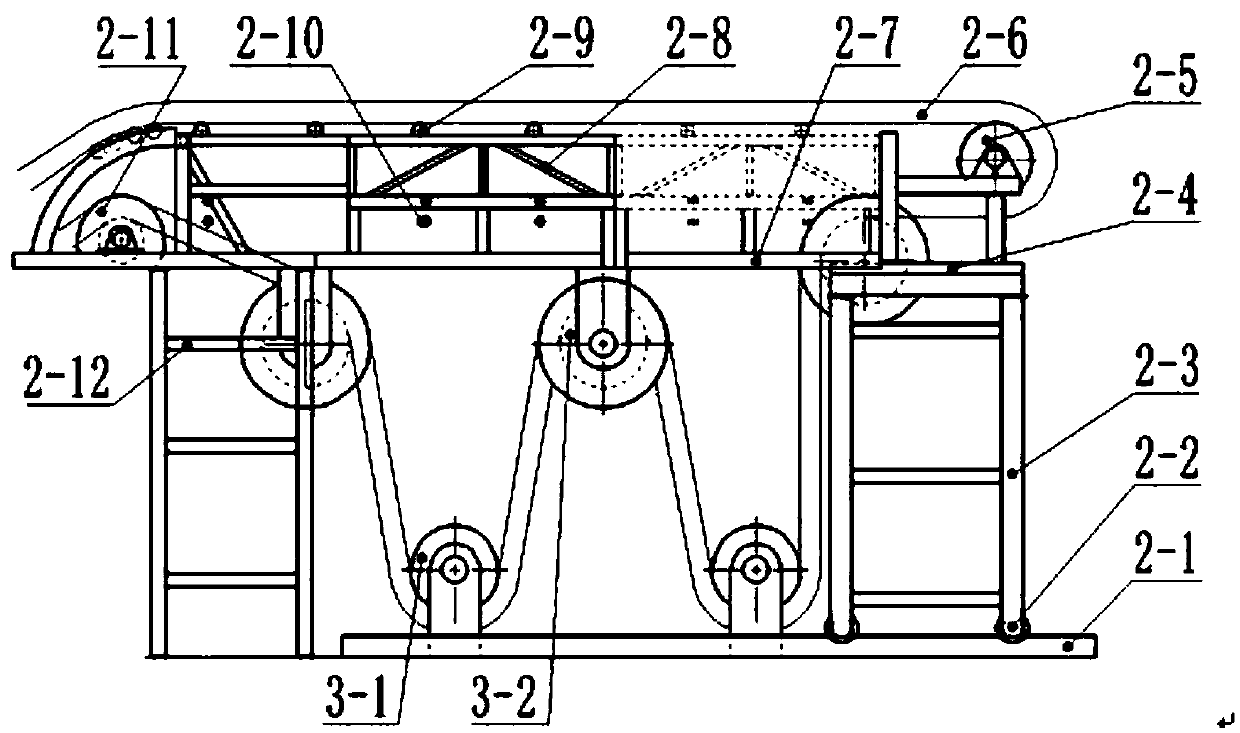

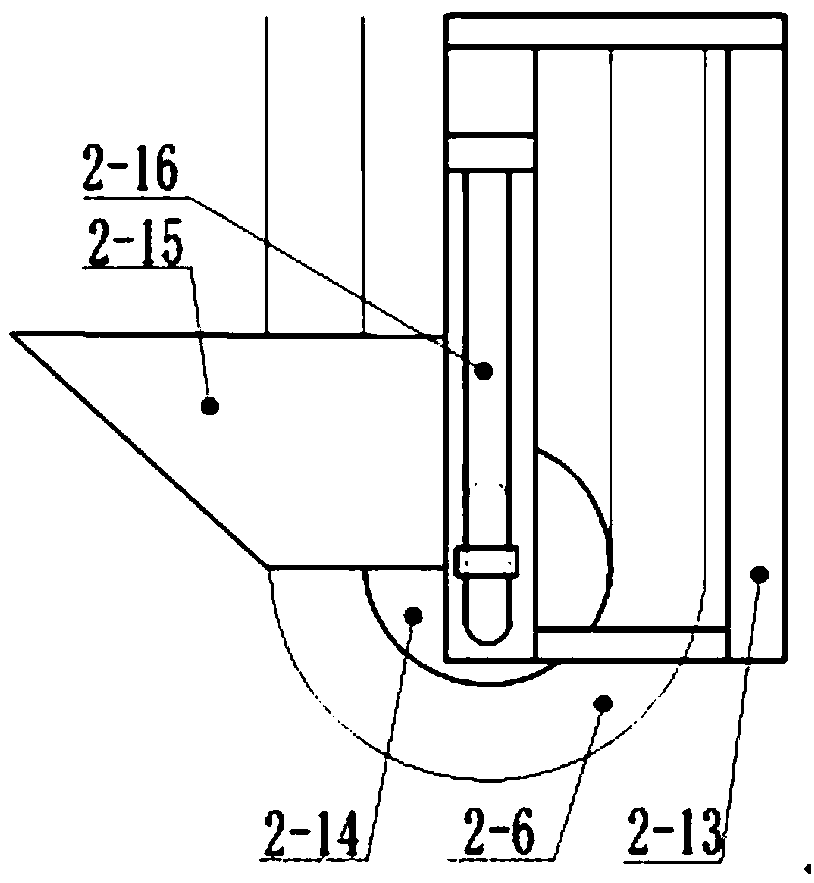

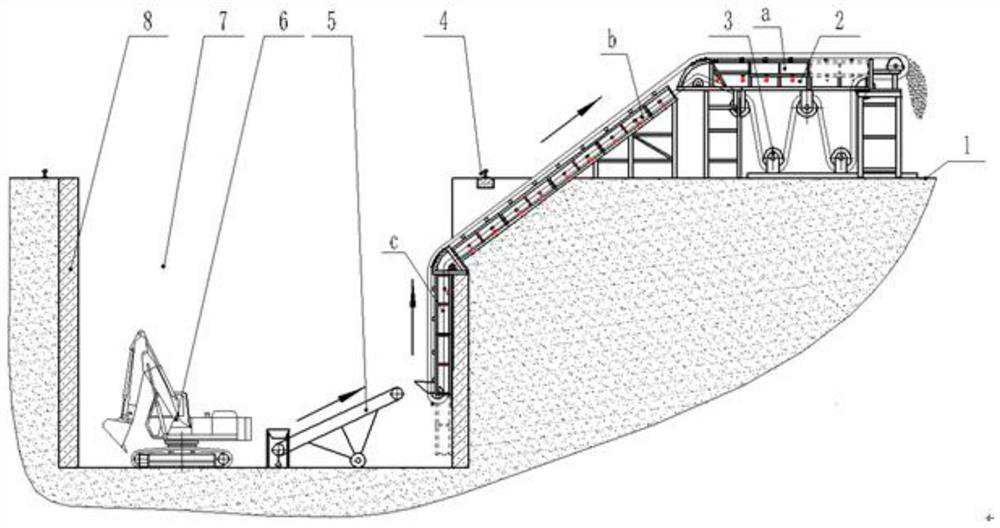

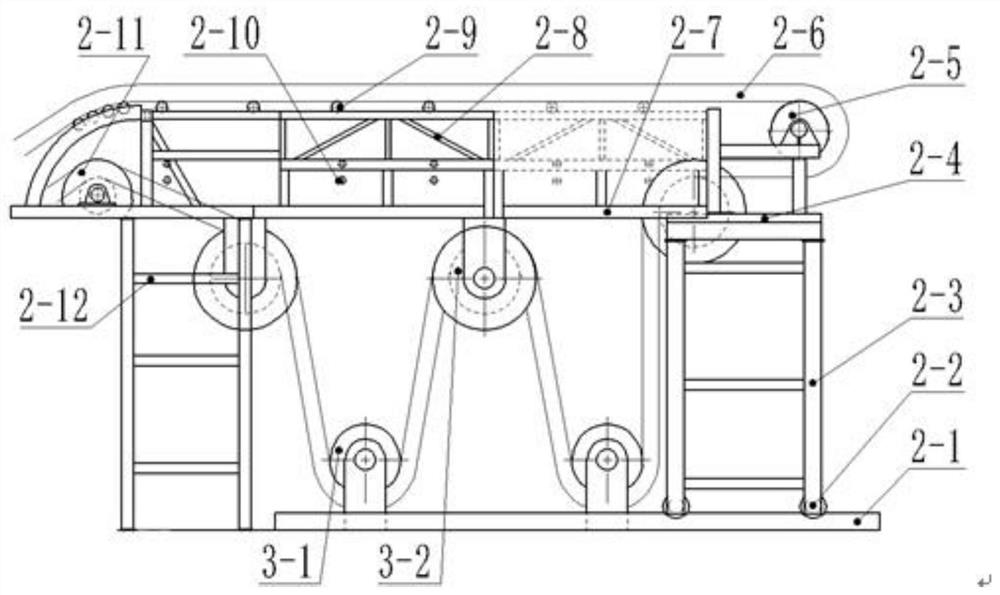

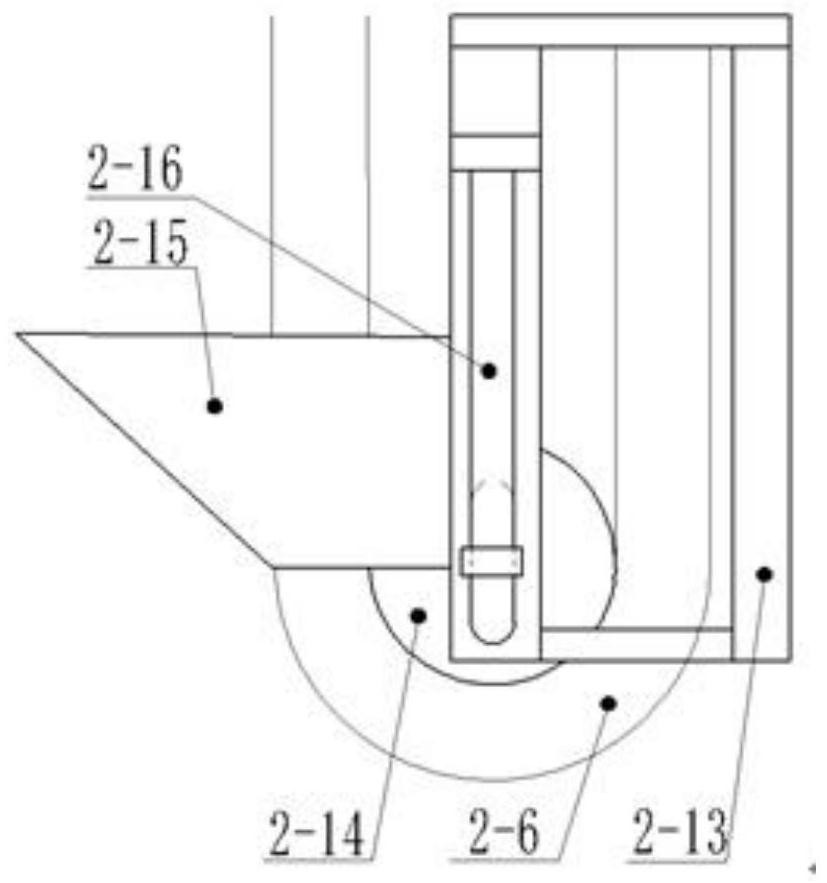

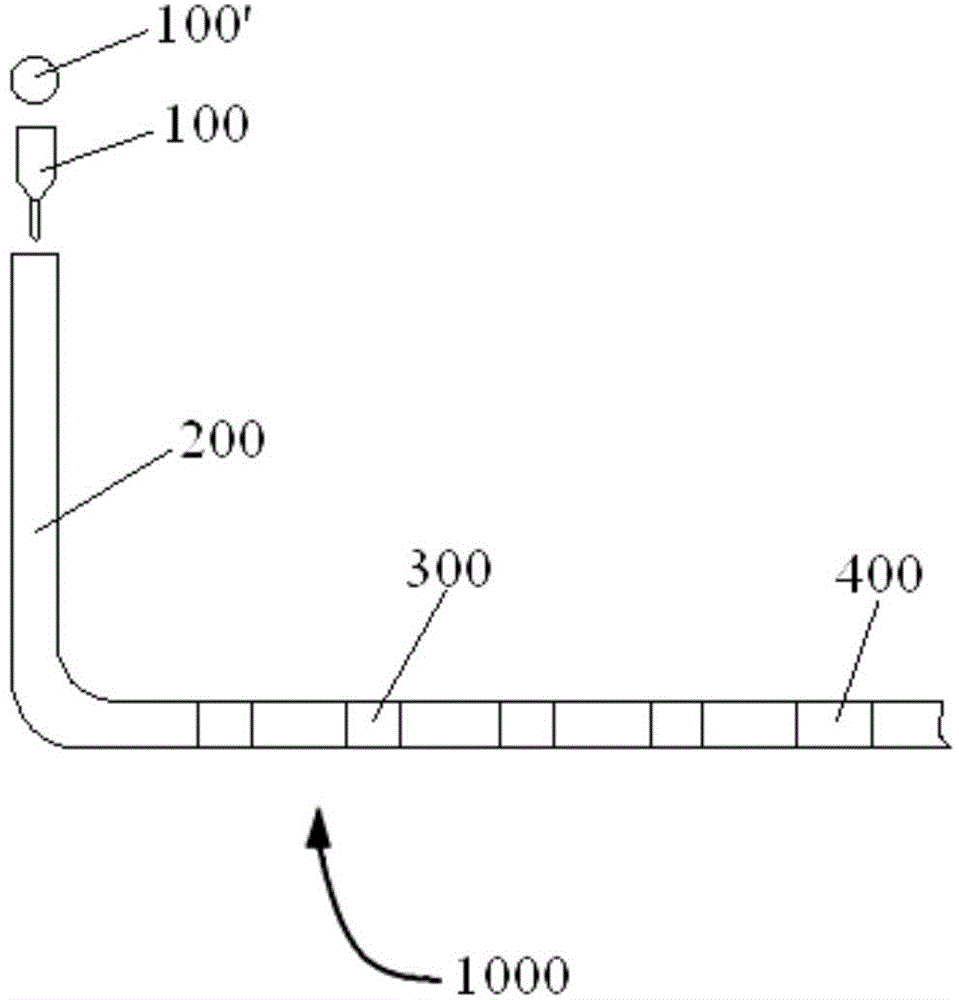

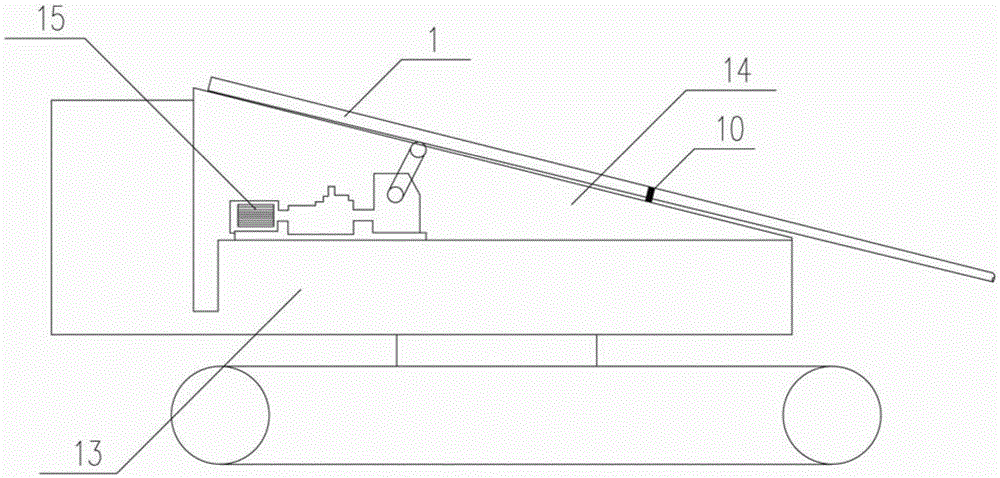

Subway station foundation pit excavation soil and waste conveying method

ActiveCN109533859AConducive to excavation construction organizationSolve the problem of construction slag transportationSupporting framesMechanical conveyorsWave shapeEngineering

The invention discloses a subway station foundation pit excavation soil and waste conveying method. A set of wave-shaped flange belt conveyor is arranged and comprises a conveyor body and a belt storage mechanism. The conveyor body is sequentially provided with a machine head horizontal section, a machine head inclined section and a machine head vertical section from the machine head end to the machine tail end. The machine head horizontal section is arranged on a ground foundation outside a foundation pit. The machine body vertical section is arranged on the side wall of a continuous wall inthe vertical direction, and the end portion of the machine body vertical section is close to the bottom of the foundation pit. As the excavation depth of the foundation pit increases, the length of awave-shaped flange conveying belt of the section of the belt storage mechanism can be reduced. When the length of the machine body vertical section needs to be extended continuously, the length of themachine head horizontal section can be shortened, and the extension to the machine body vertical section can be realized. According to the construction method, the wave-shaped flange belt conveyor isused for conveying soil and waste, so that soil and waste continuous conveying can be realized. As the depth of the foundation pit increases, the length of the wave-shaped flange belt conveyor can beprolonged. The automation degree is high. The labor intensity of workers is low. The soil and waste conveying efficiency is high.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

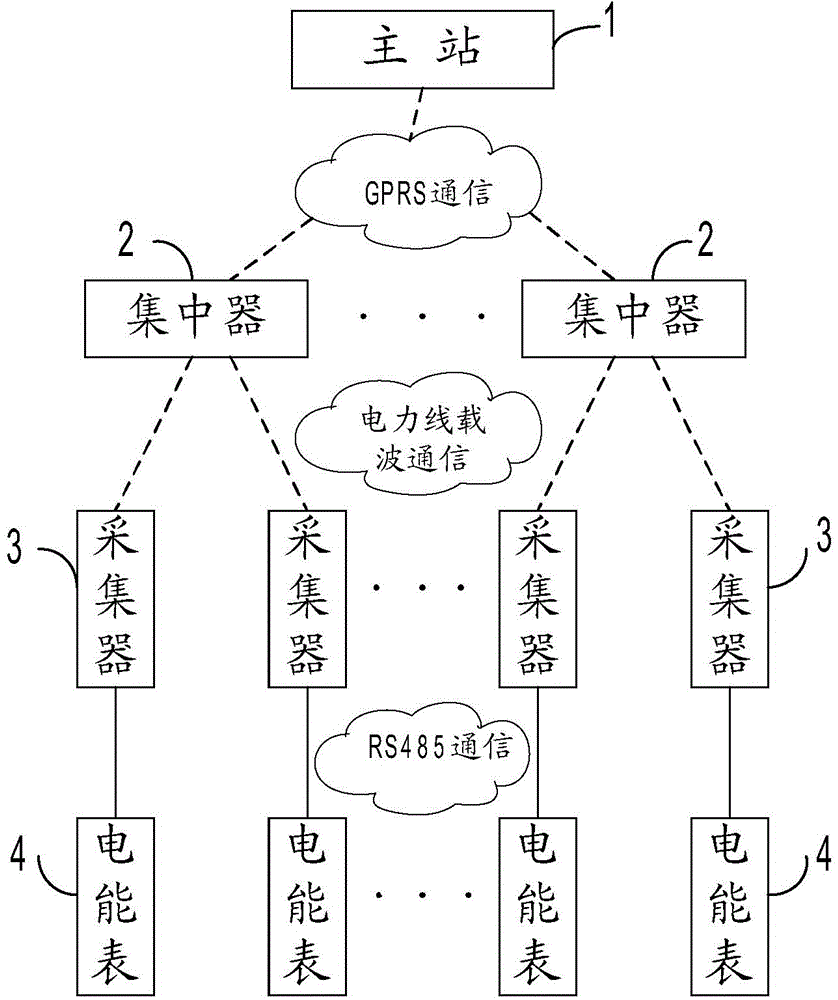

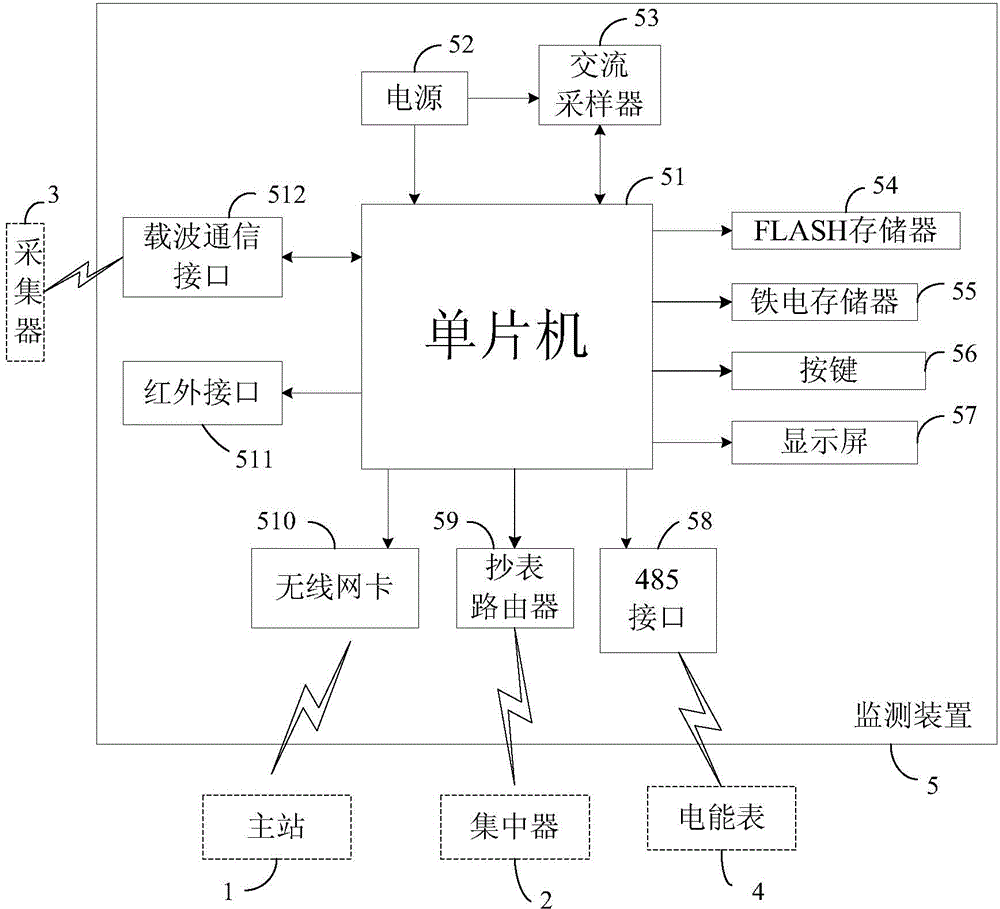

Monitoring device used for power user electric energy data acquire system

InactiveCN104901720AImprove construction reliabilityImprove securityTransmission monitoringLine-transmission monitoring/testingMicrocomputerCommunication interface

The invention discloses a monitoring device used for a power user electric energy data acquire system. The monitoring device comprises a single-chip microcomputer, a power supply, an AC sampler, a FLASH memory, a ferroelectric memory, a button, a display screen, a 485 interface, a meter reading router, a wireless network card, an infrared interface and a carrier communication interface. The single-chip microcomputer is respectively connected with the power supply, the AC sampler, the FLASH memory, the ferroelectric memory, the button, the display screen, the 485 interface, the meter reading router, the wireless network card, the infrared interface and the carrier communication interface. The power supply is connected with the AC sampler. According to the monitoring device, data transmitted by a GPRS communication channel, a power line carrier communication channel and an RS485 communication channel can be monitored simultaneously so that the state of the GPRS communication channel, the state of the power line carrier channel and the state of the RS485 link communication can be better understood.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

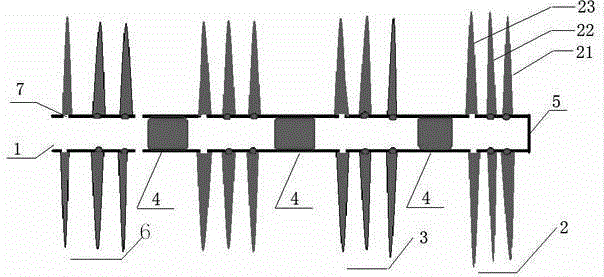

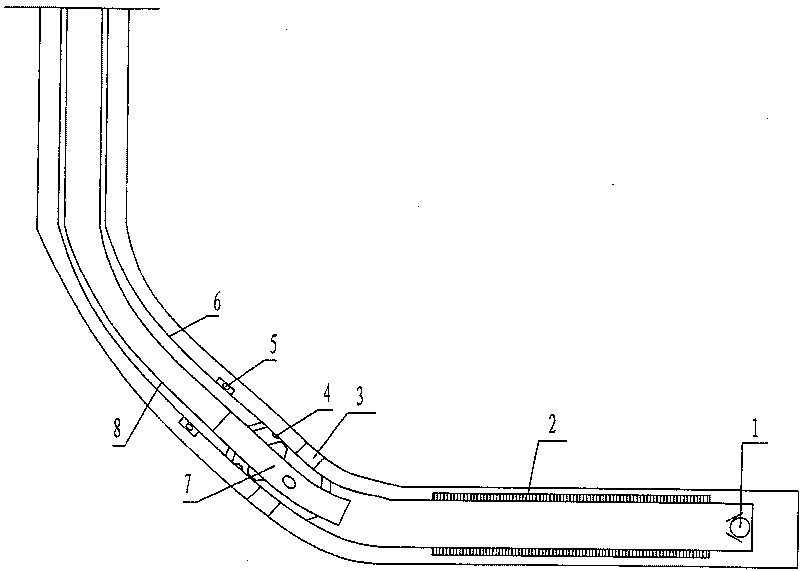

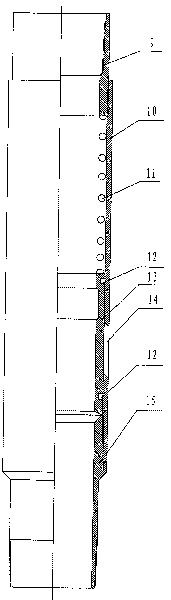

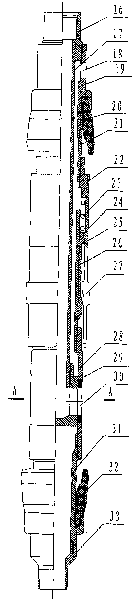

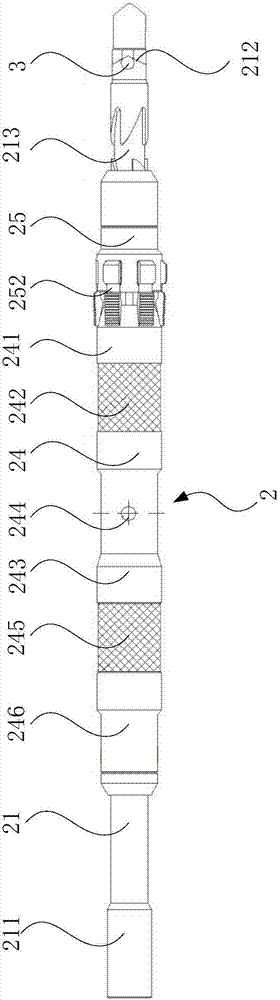

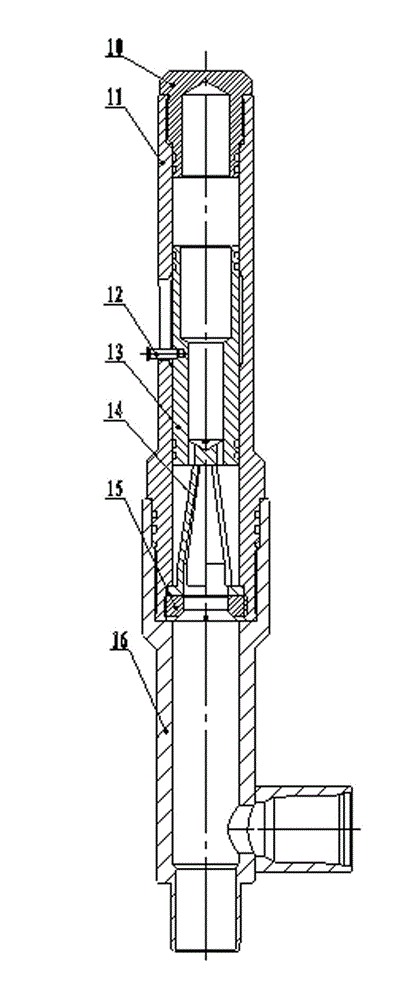

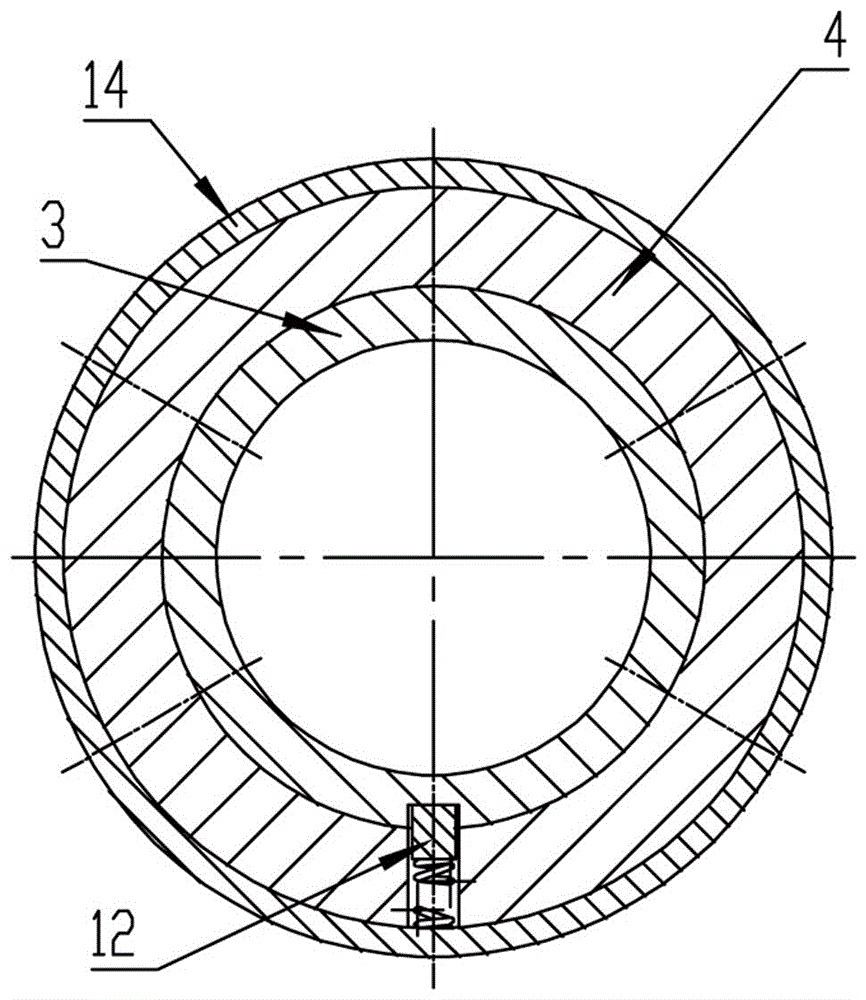

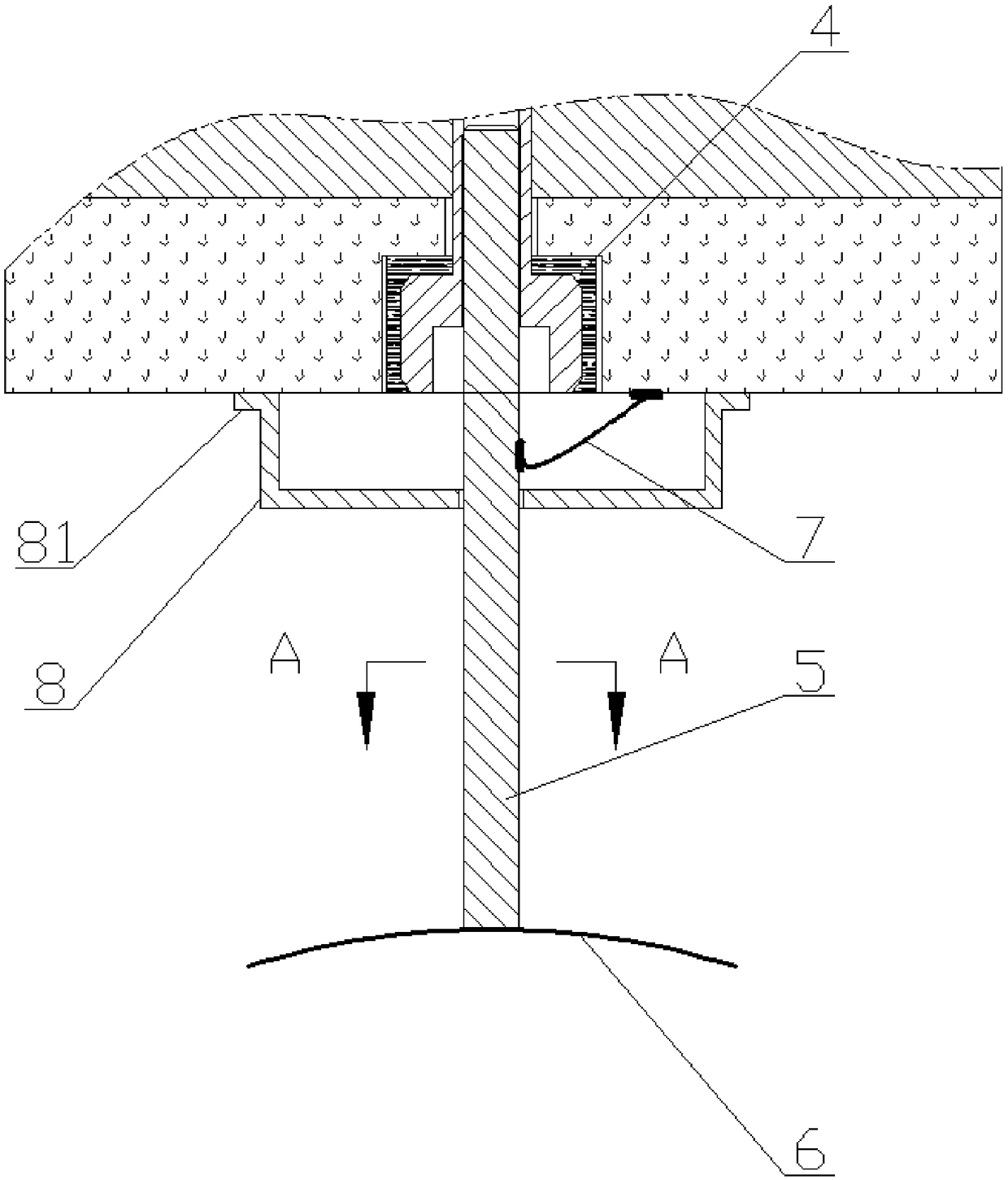

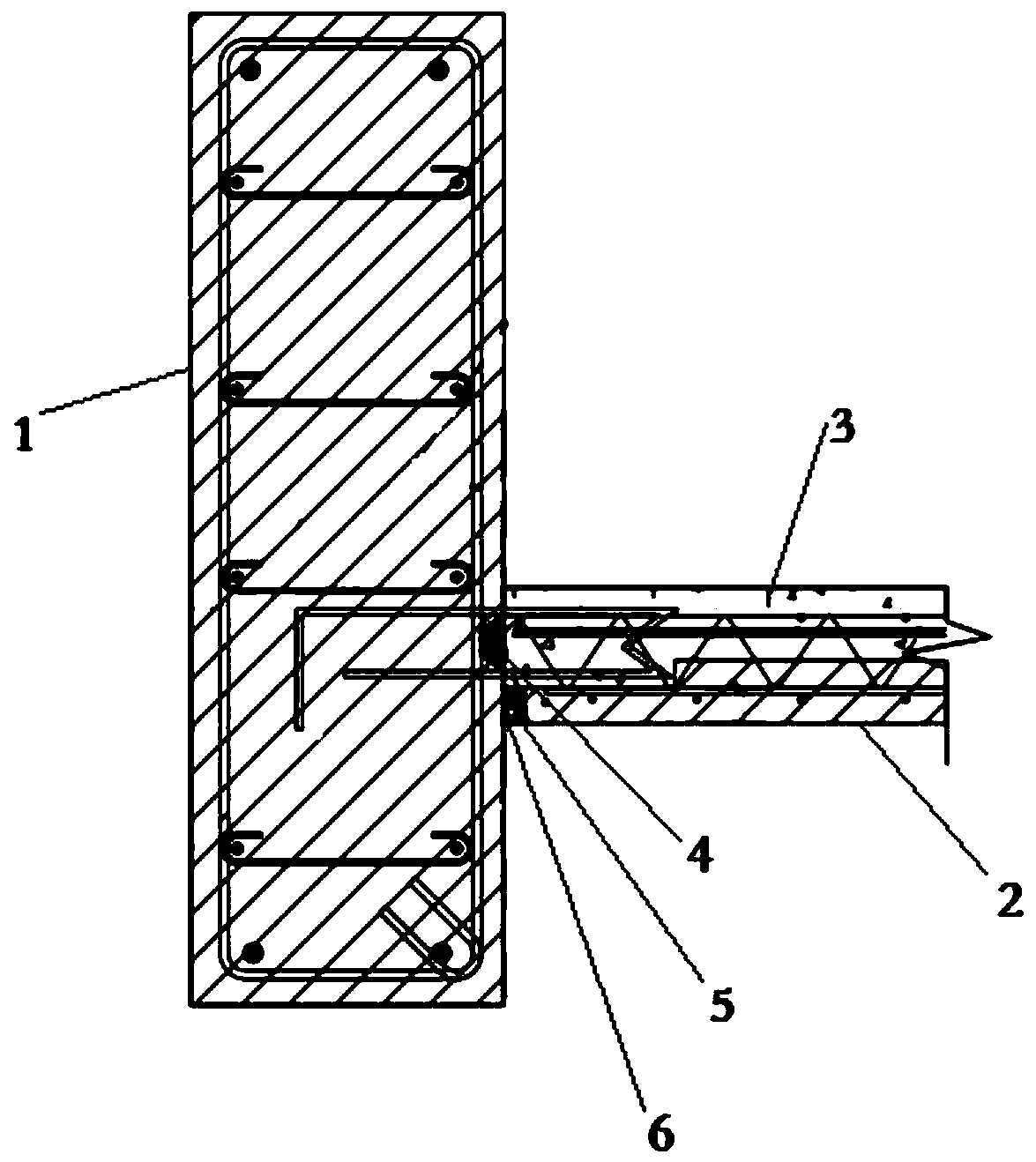

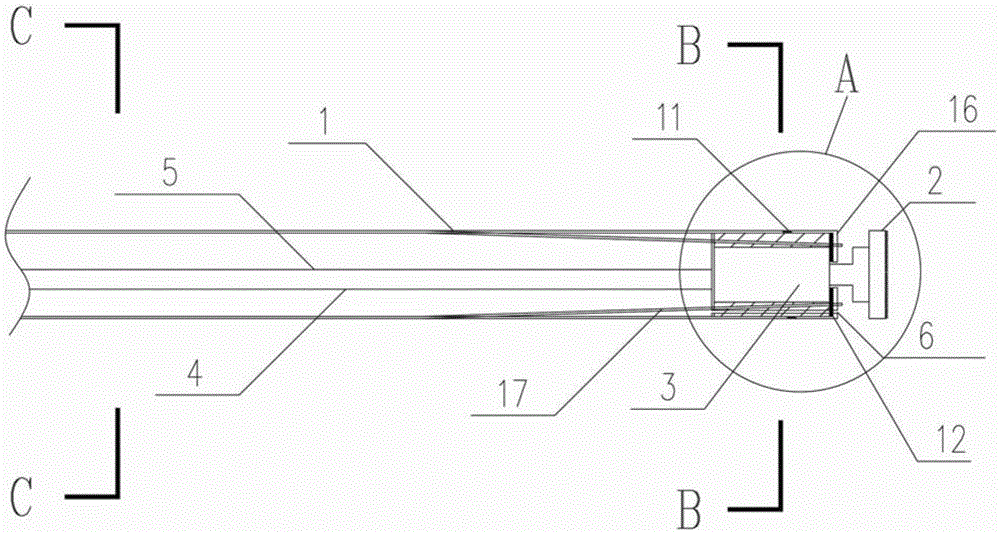

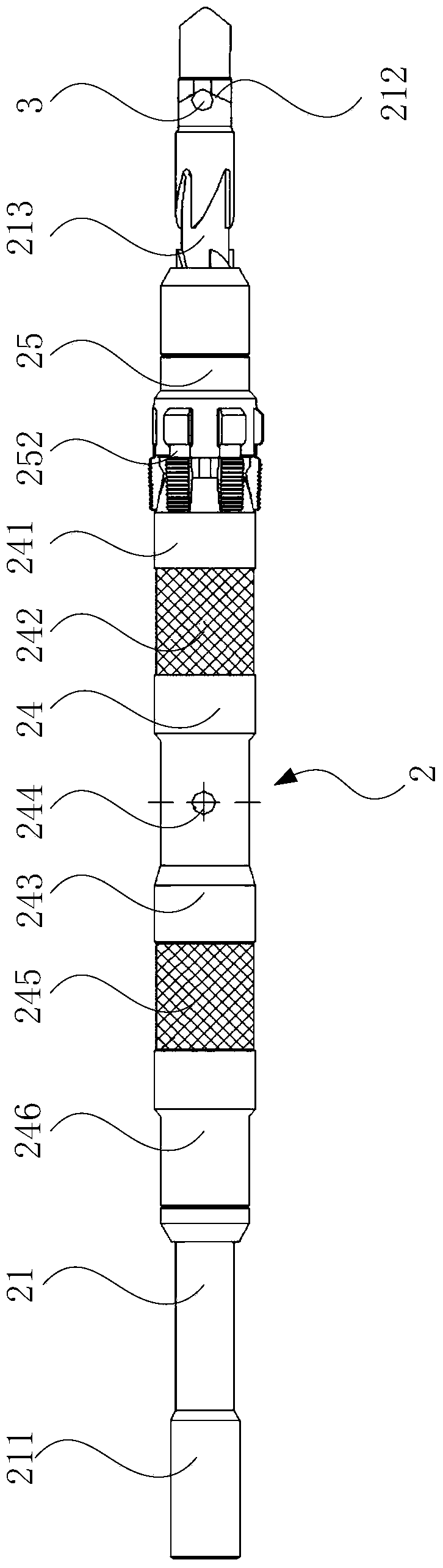

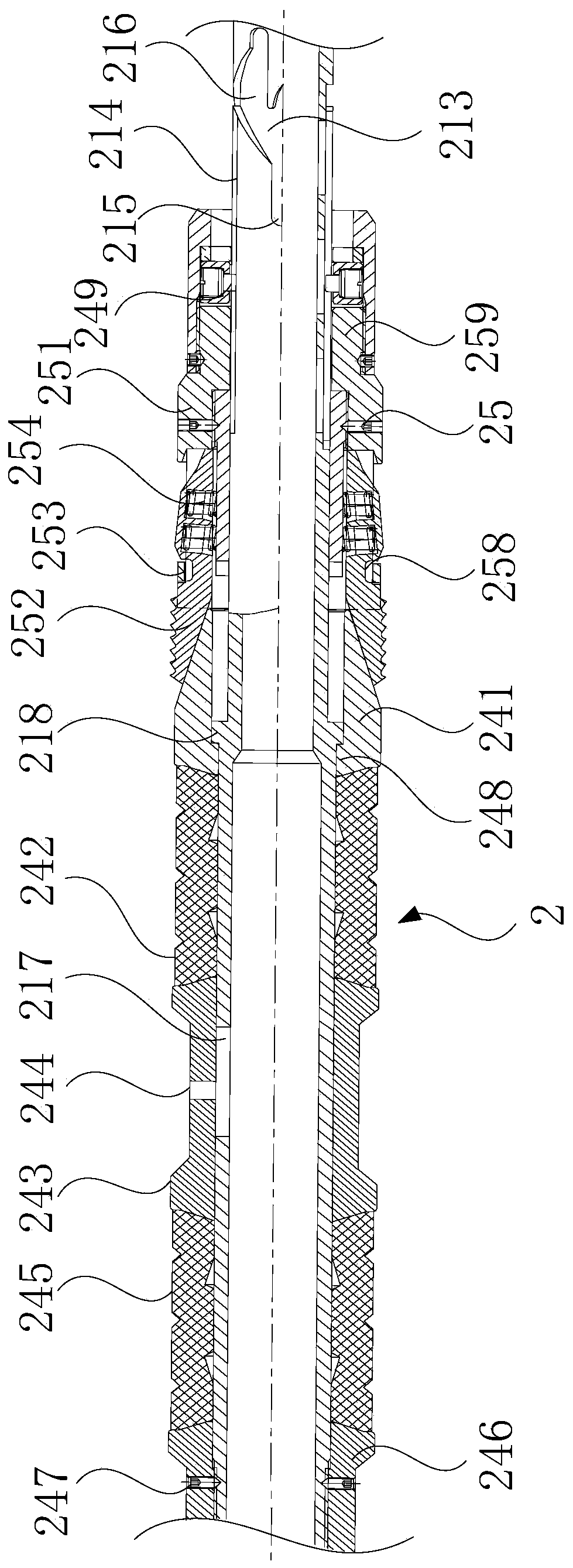

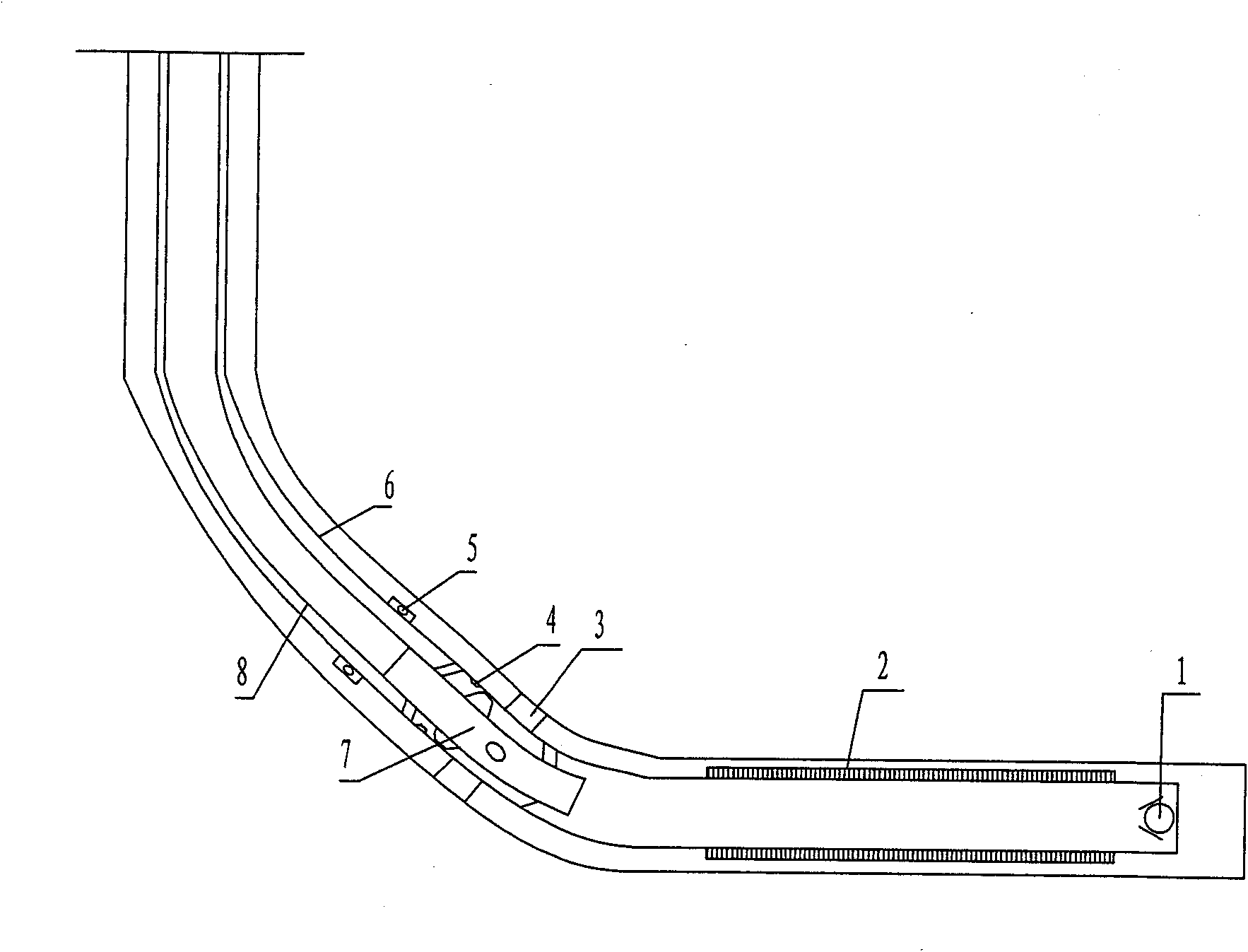

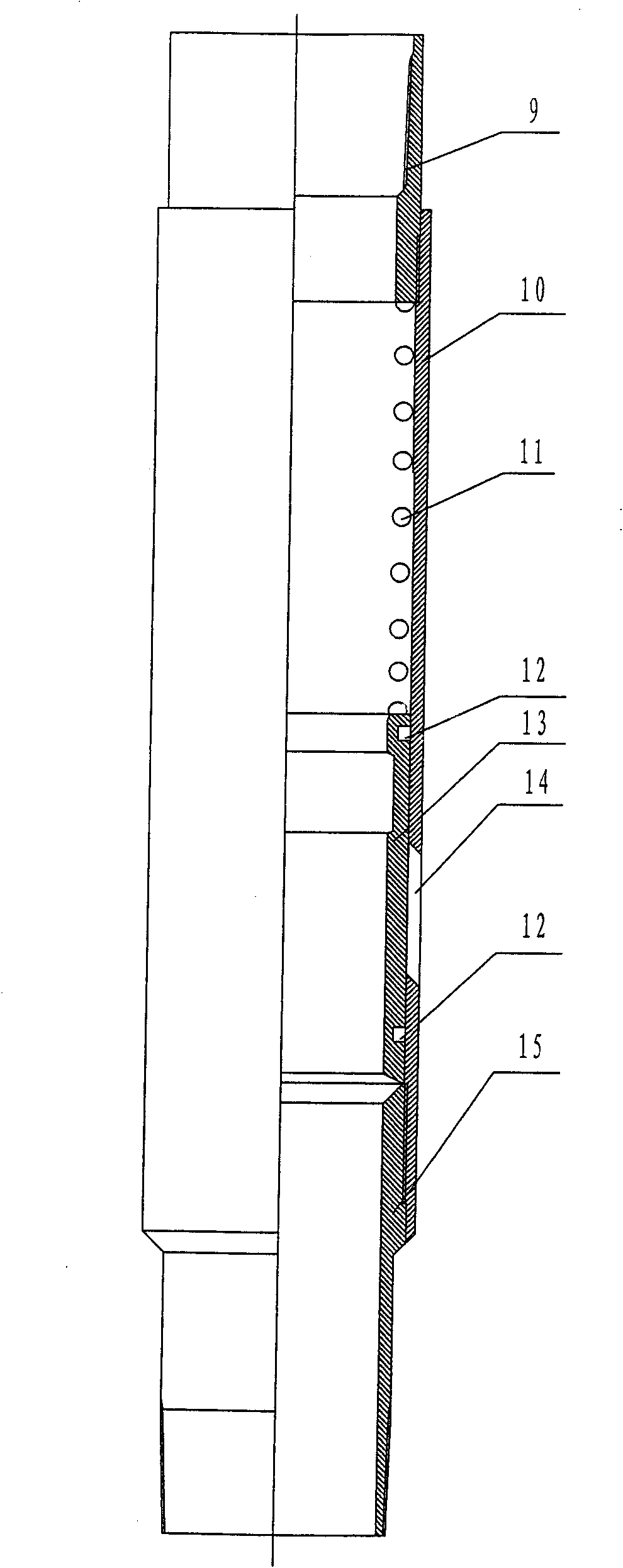

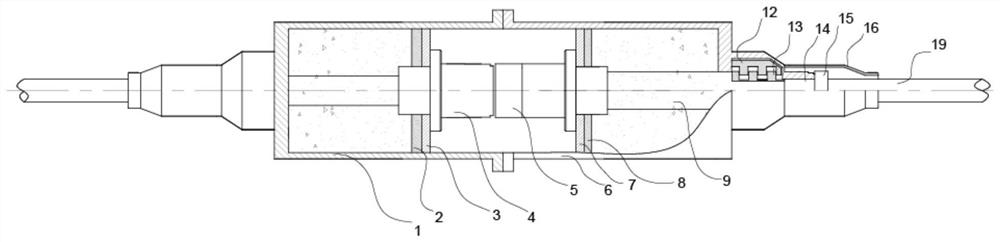

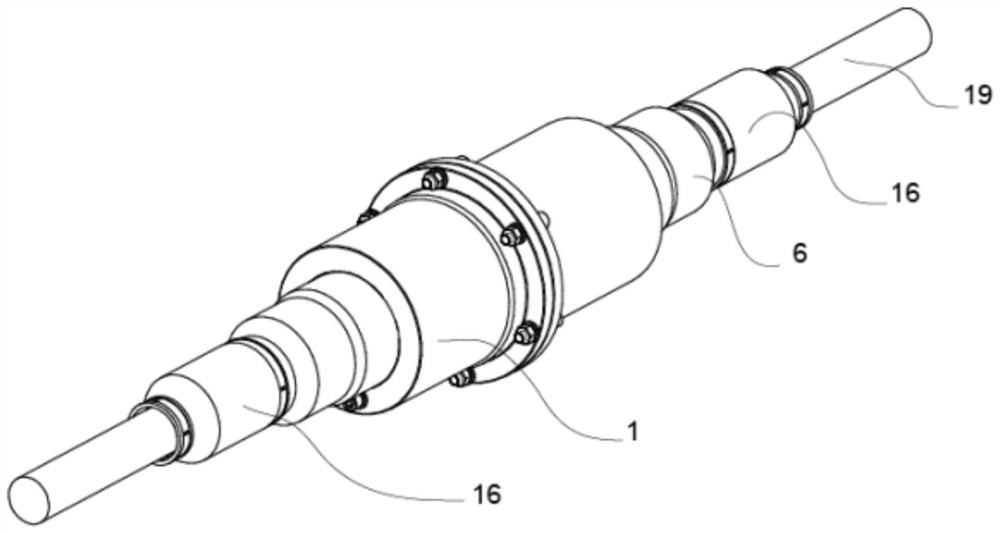

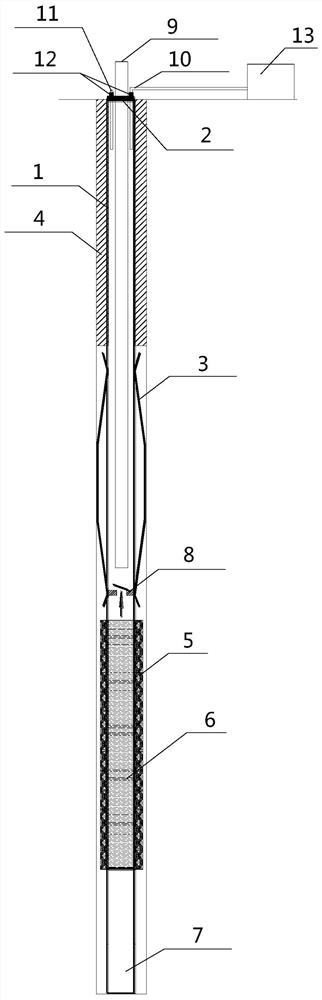

Drilling-plug free tubular column with sand control and well cementation for open-hole horizontal well

ActiveCN101701513ASimplify operating proceduresReduce operating costsFluid removalSealing/packingAcid washingUltimate tensile strength

The invention relates to a drilling-plug free tubular column with sand control and well cementation for an open-hole horizontal well, which comprises an external tubular column and an inner tubular column. The external tubular column comprises a sand control screen (2), an open-hole packer (3), an external positioning step (4), an external cementing machine (5) and a sleeve tube (6) are sequentially installed and connected on the an acid-washing filling valve (1). The inner tubular column comprises an oil tube (8) and an inner cementing machine (7) which is installed and connected on the oil tube (8). The inner tubular column is arranged in the external tubular column and the inner tubular column and the external tubular column are mutually fixed sealed. The invention can simplify operating procedures and reduce the frequency of running string, and does not need to perform drilling-plug operation free after cementing for well cementation, and also has the advantages of low operating cost, large drift diameter, regular inner wall, clean well-hole of sand control and well completion, high construction success ratio, large construction stability, low labor intensity, high oil well yield and the like, and can be widely applied to the process of sand control, well cementation and well completion of the open-hole horizontal well for oil exploration.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

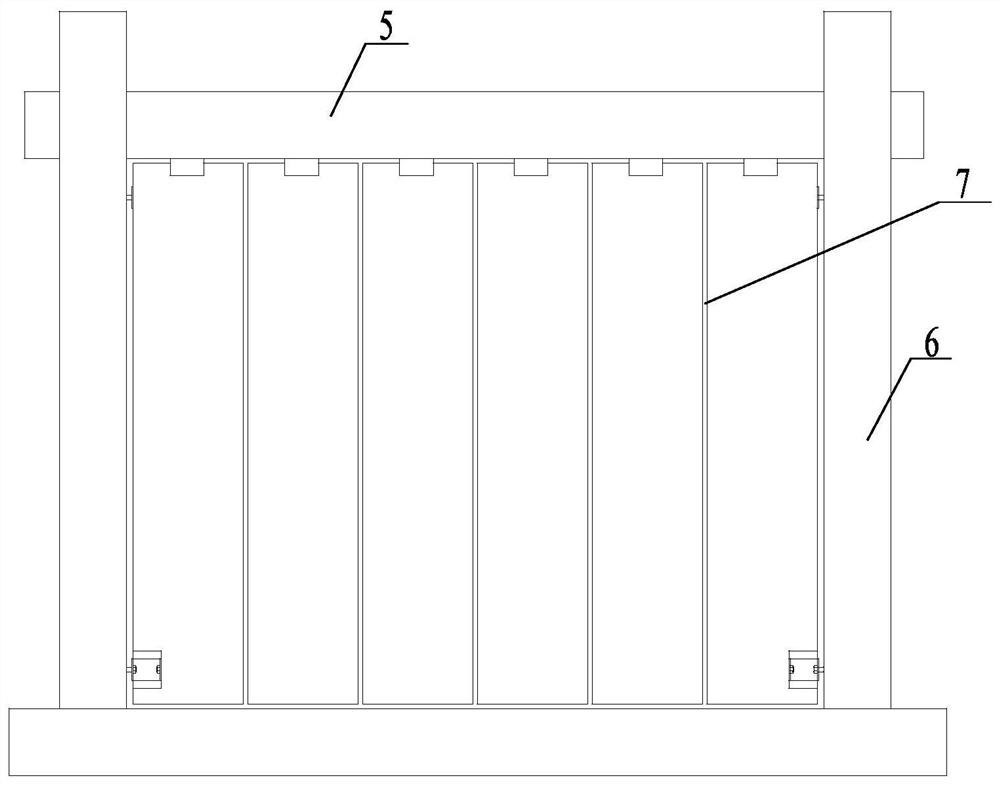

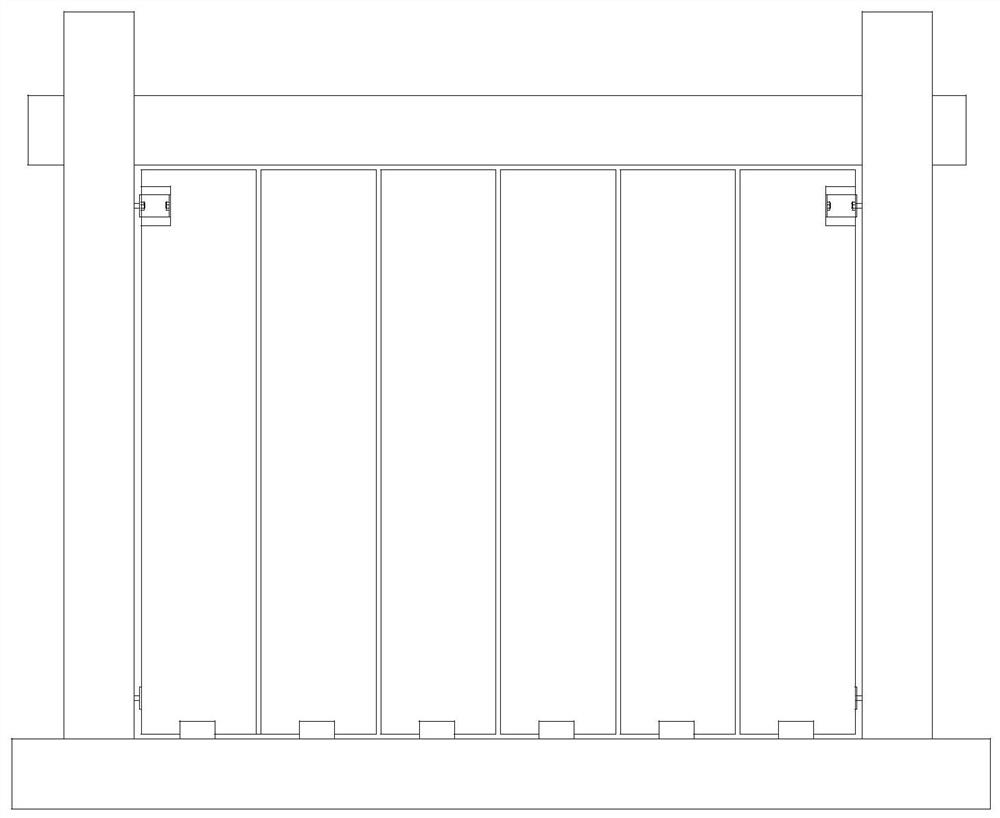

Outer shear wall suspension board stereotyping aluminum template supporting system and construction method

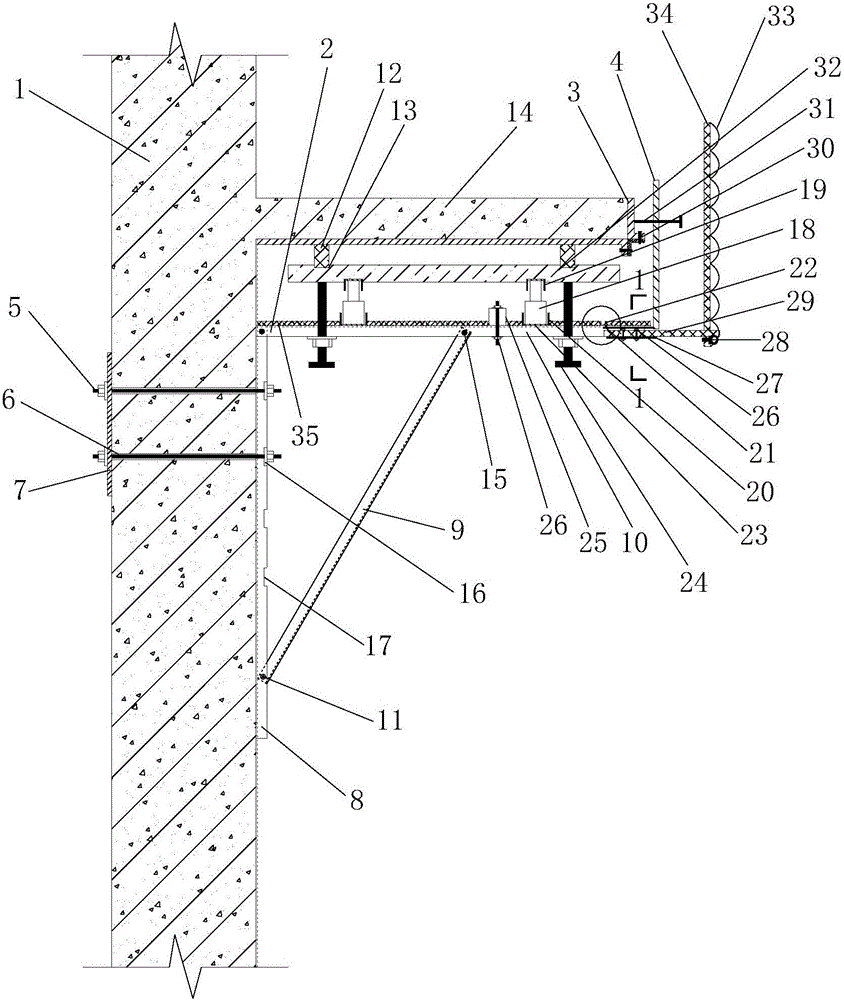

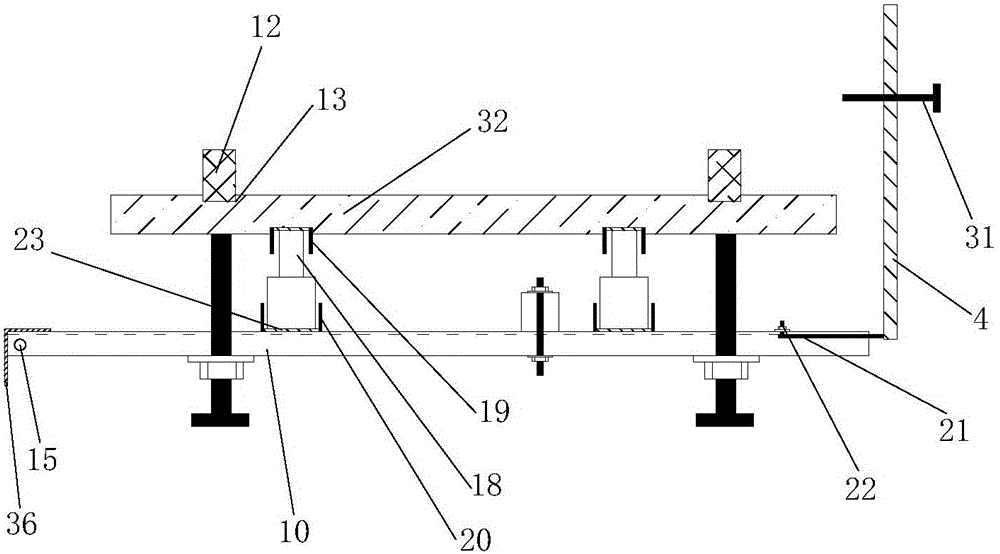

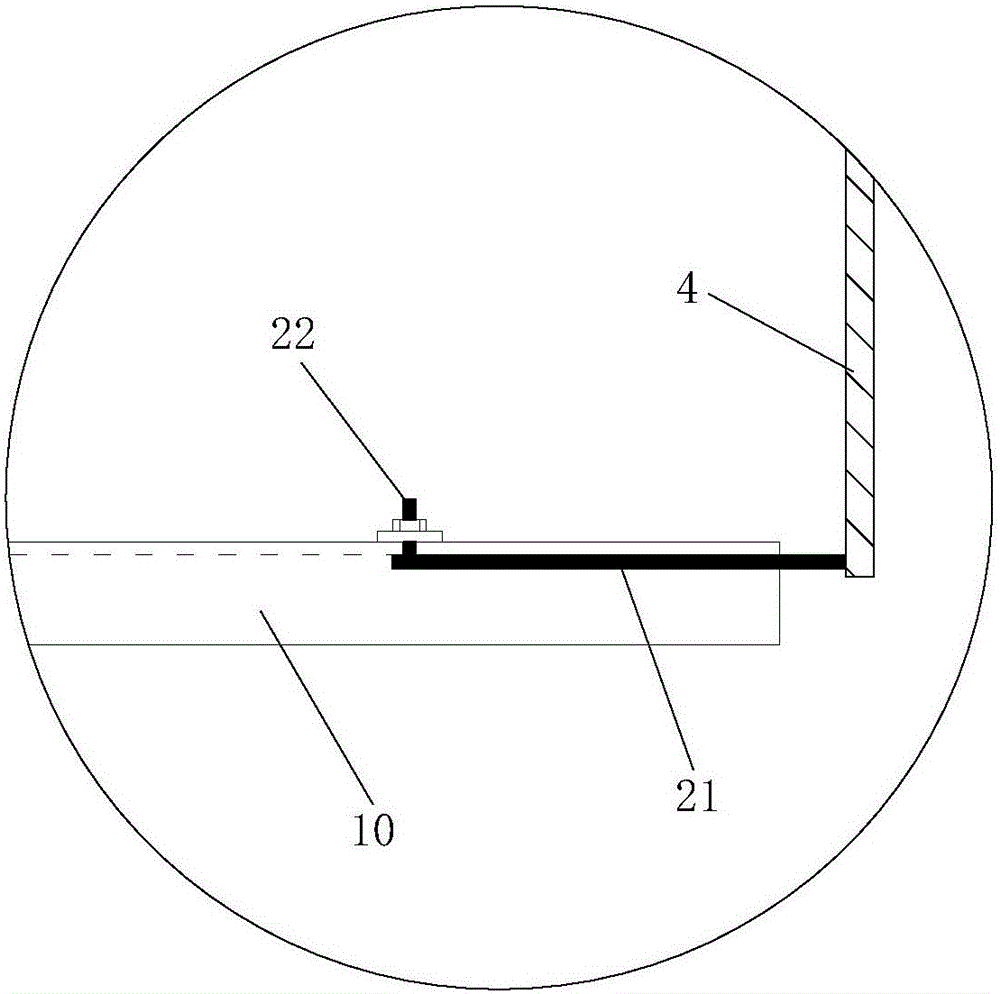

InactiveCN105952156AEasy to storeHigh strengthAuxillary members of forms/shuttering/falseworksBuilding material handlingSupporting systemEngineering

The invention relates to an outer shear wall suspension board stereotyping aluminum template supporting system. The lower part of the stereotyping aluminum template is provided with a supporting system, the supporting system is divided into a lower supporting frame and an upper adjusting structure, the lower supporting frame mainly comprises a cross rod, a vertical rod and an oblique rod, and the upper adjusting structure mainly comprises a small-sized jack, a slab and an end plate. The invention also provides a construction method of the supporting system. By adopting the structure and the construction method of the invention, an elevation can be precisely adjusted by utilizing the jack, the width is adjusted transversely by virtue of the end plate, the supporting system is suitable for constructing a suspension board in a given size range, and an antiskid design can be adopted at additional positions, so that slippage is prevented in the construction, the supporting system is convenient to machine and install and good in economic and technical benefit.

Owner:建伟新能源集团有限公司

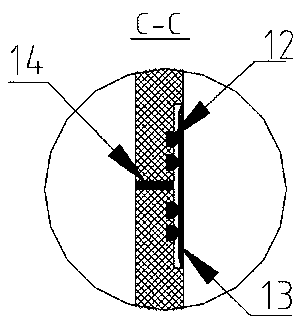

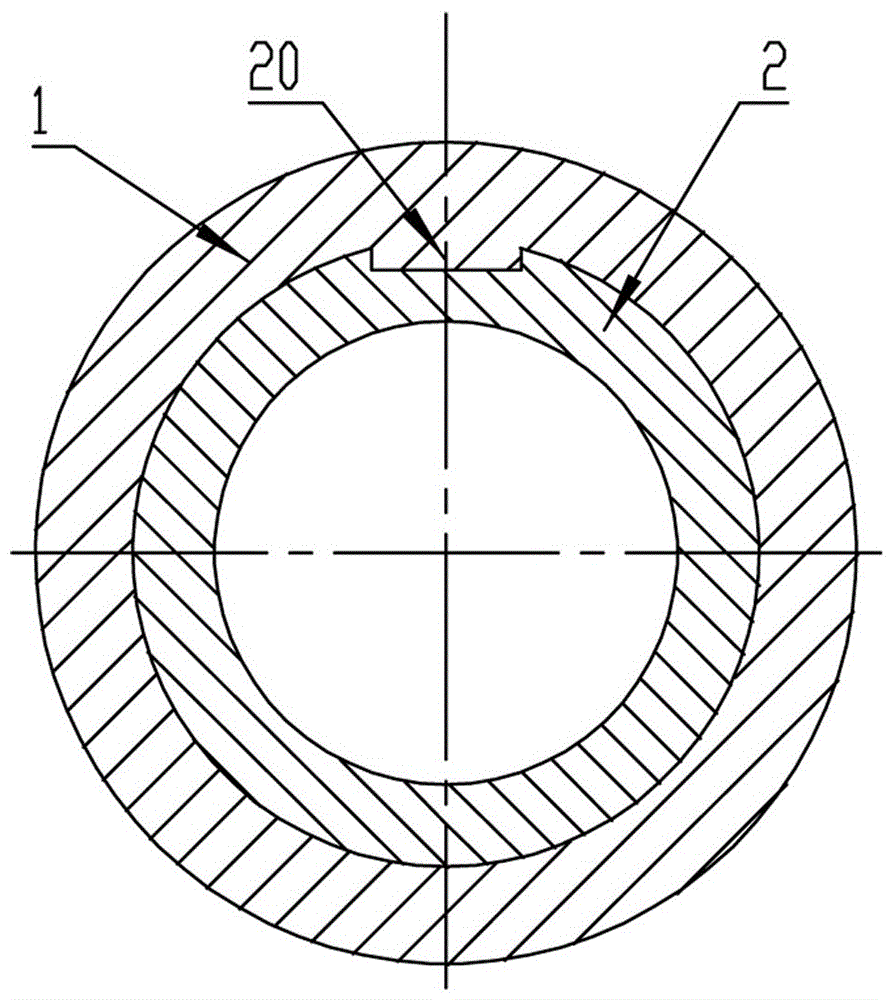

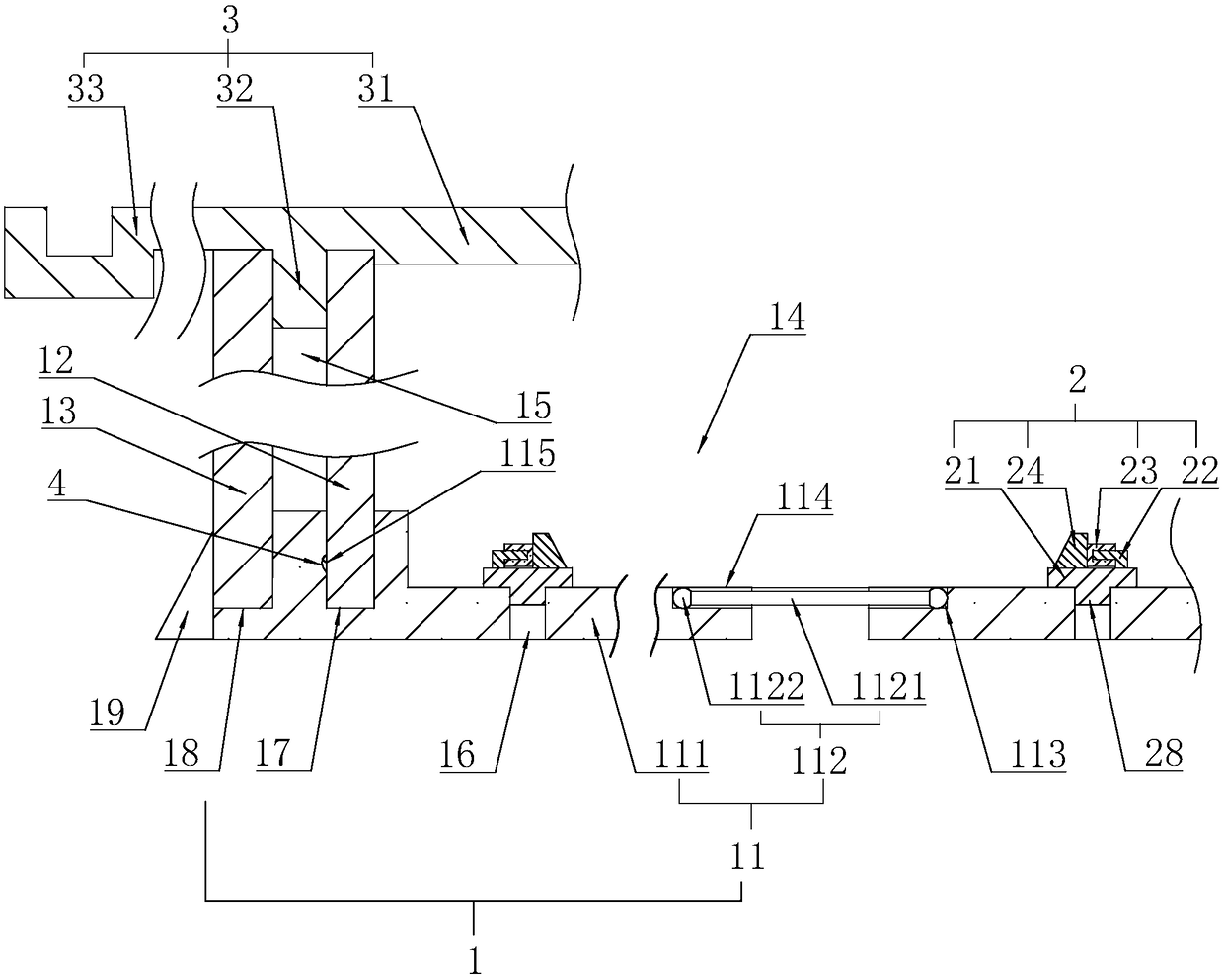

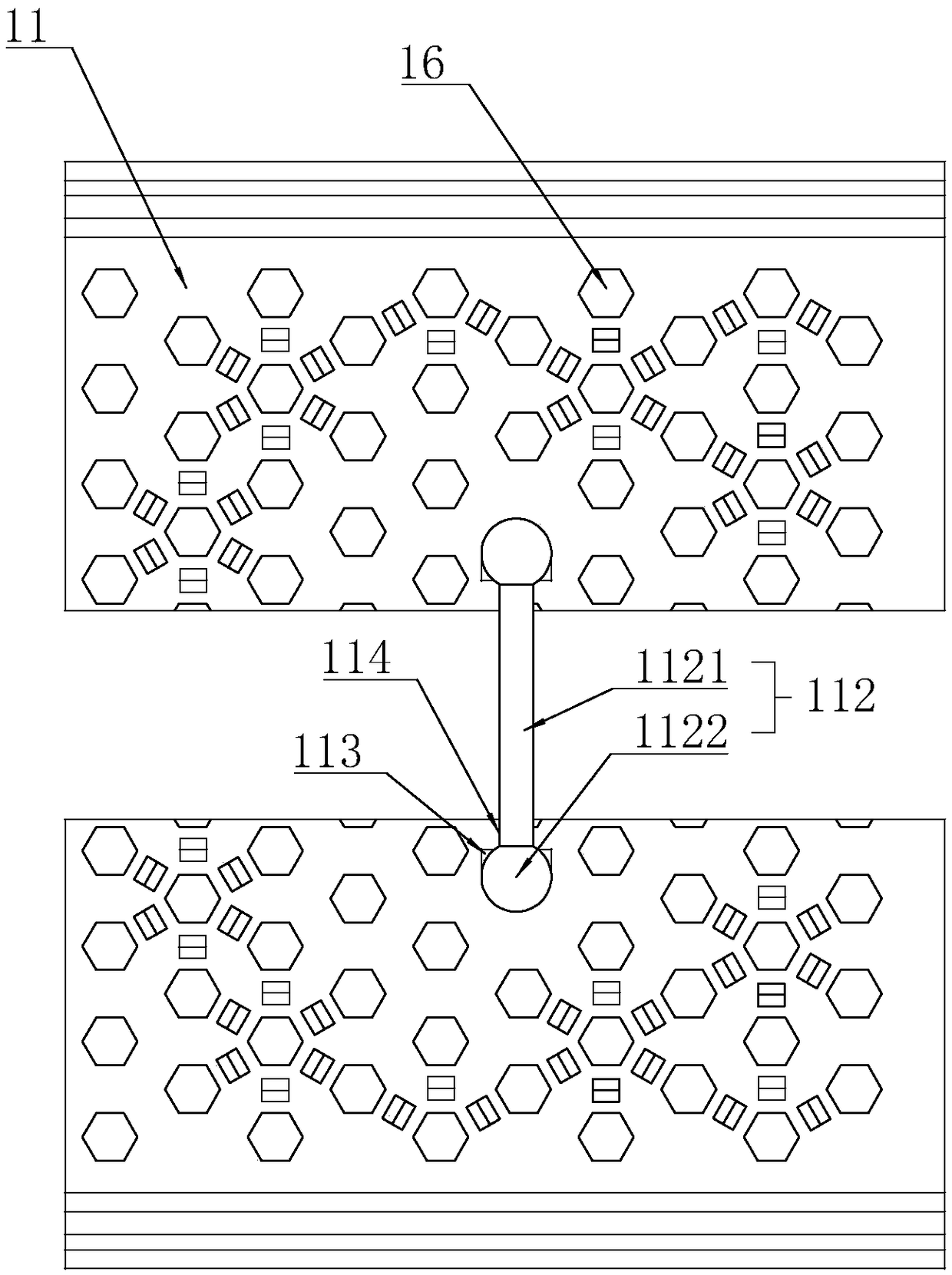

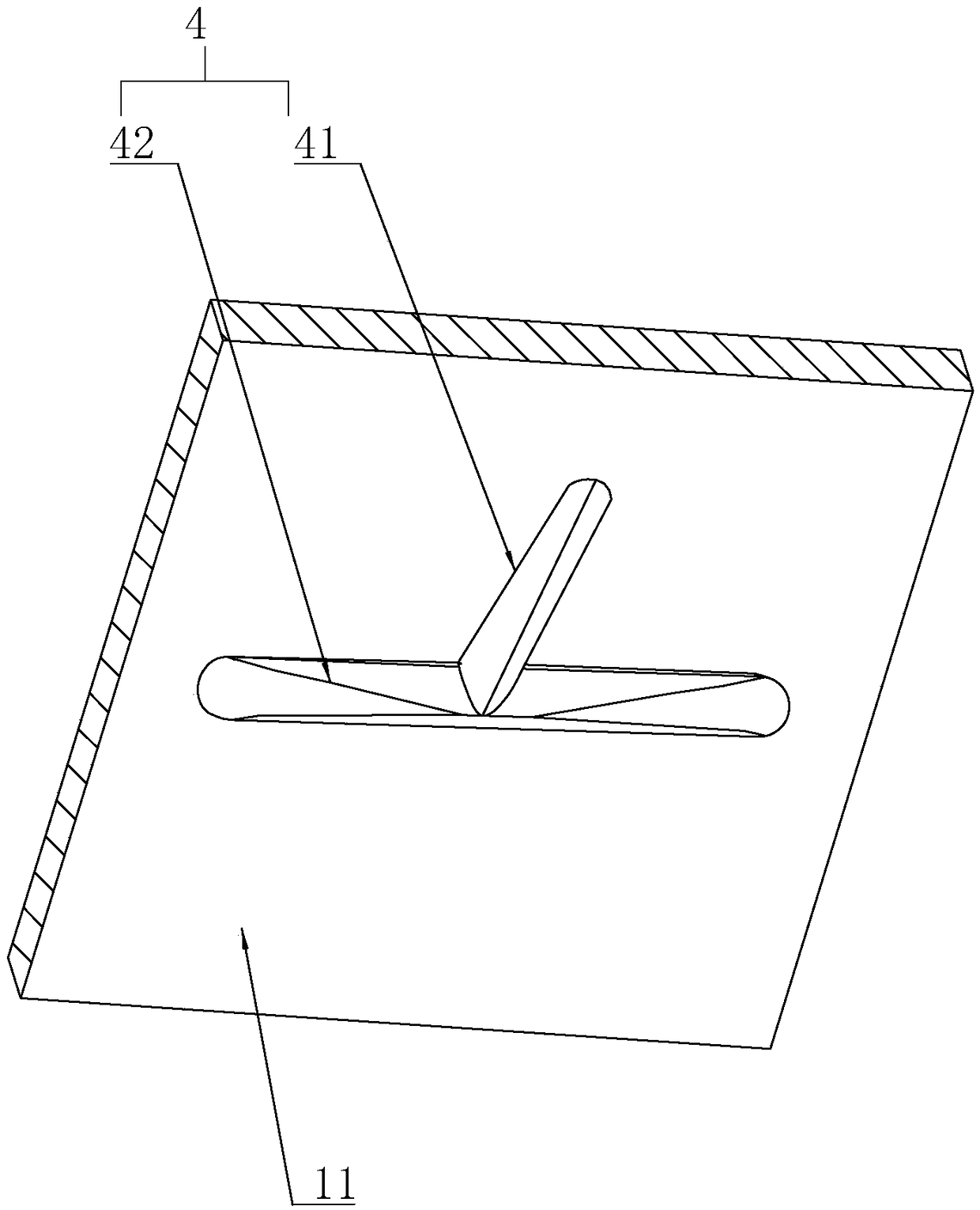

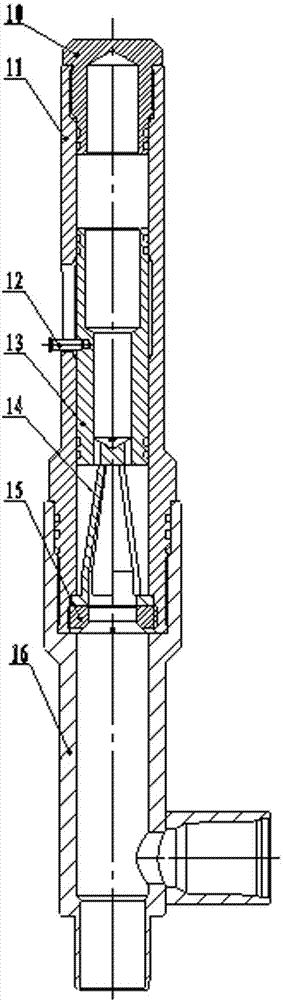

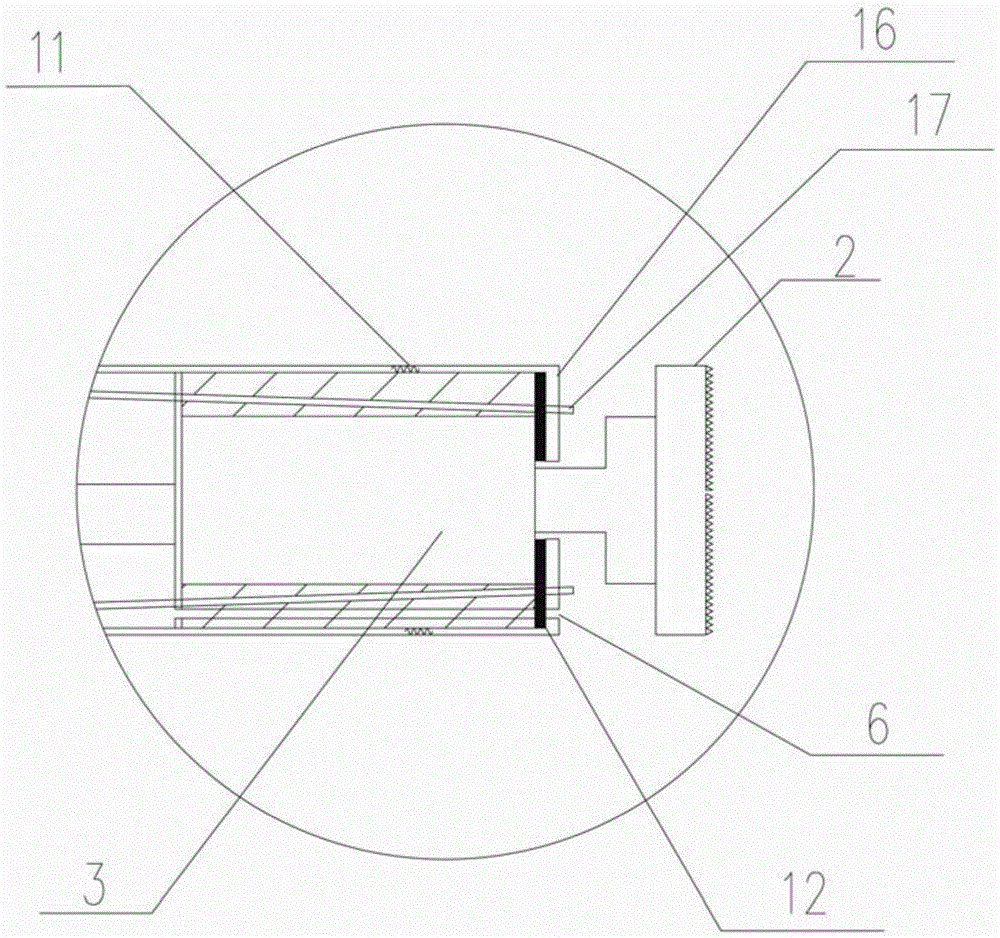

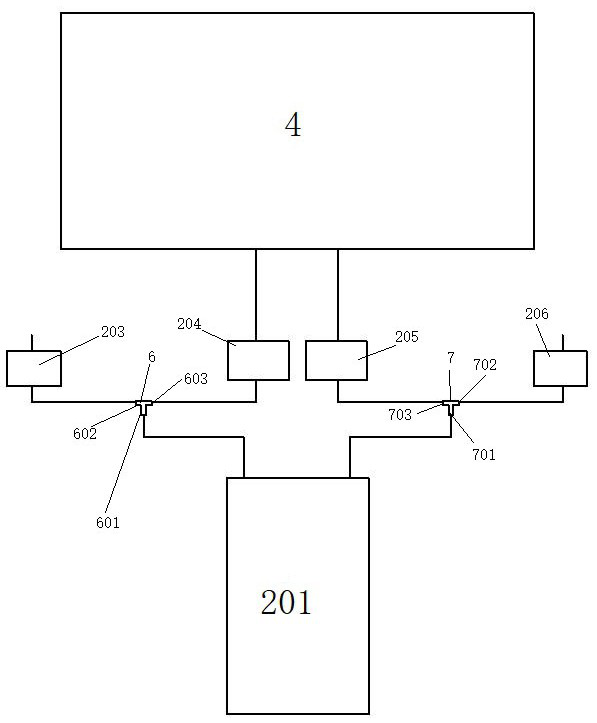

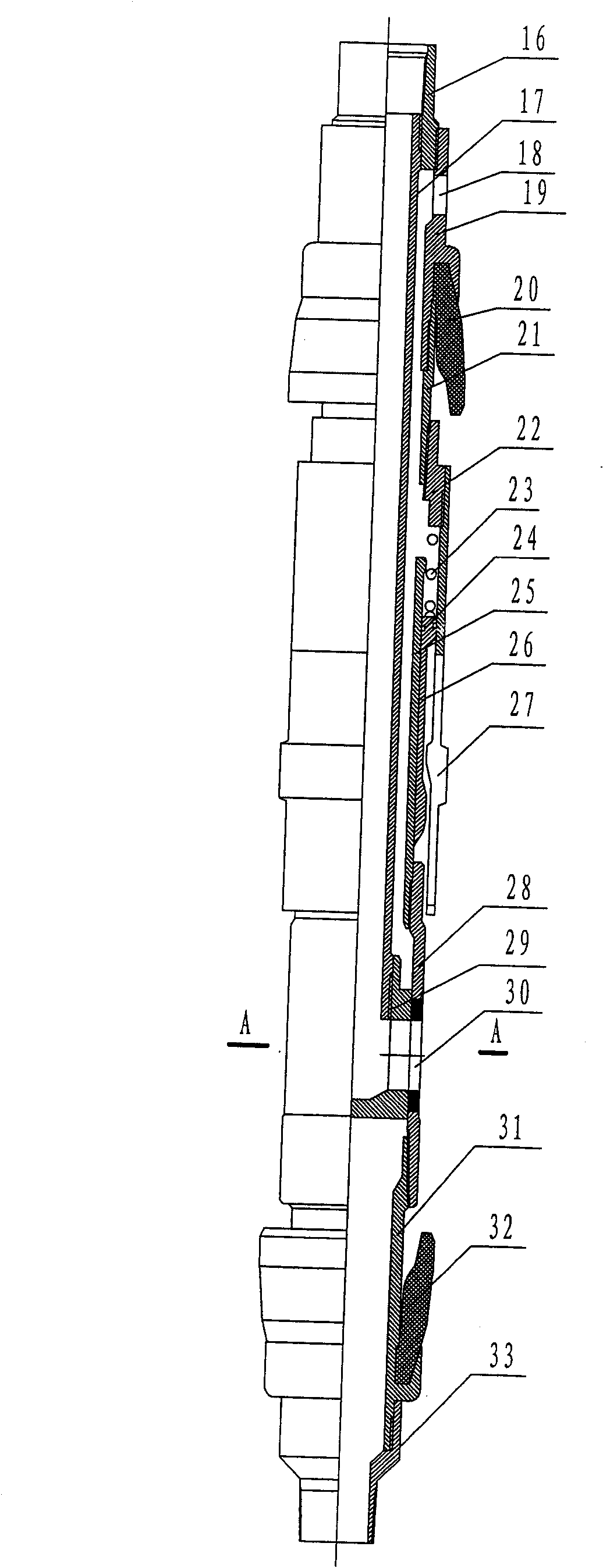

Fracturing hole opening and closing system

ActiveCN107313761ASimple structureGood for flowbackFluid removalWell/borehole valve arrangementsEngineeringHydraulic pressure

The invention relates to a fracturing hole opening and closing system which comprises a slide sleeve. The sleeve slide comprises an inner sleeve, an outer sleeve and an isolation sleeve; the inner sleeve is provided with an inner fracturing hole; the outer sleeve is arranged on the inner sleeve in a sleeving mode and is provided with an outer fracturing hole; an annular cavity which is used for accommodating the isolation sleeve and communicates with the inner fracturing hole and the outer fracturing hole is formed between the inner sleeve and the outer sleeve; and the isolation sleeve can be driven by hydraulic pressure to slide in the annular cavity so as to enable the outer fracture hole and the inner fracturing hole to communicate with each other or disconnect from each other. The slide sleeve has the advantages that the structure is simple; the goal of no fracturing stage limitation can be realized; the whole through diameter is realized in the slide sleeve; the later period operation liquid flow back and subsequent tool entering are facilitated; the construction reliability is high; and the drilling removal operation is not needed. Under the condition of difficult drilling pressure exertion in the horizontal section, the slide sleeve is opened or closed in a hydraulic pressure mode; operation is simple and convenient; and the fracturing hole opening and closing system is particularly suitable for slide sleeve opening and closing operation of a deep well, an ultra-deep well and a horizontal well.

Owner:CHINA PETROLEUM & CHEM CORP +1

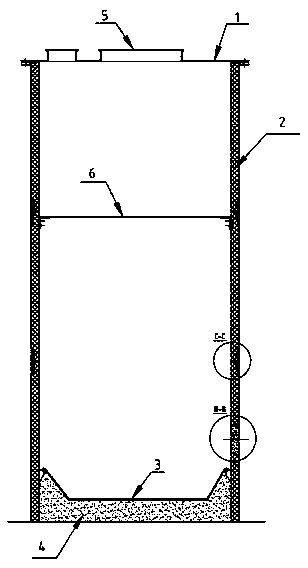

Integrated prefabricated pump station glass fiber reinforced resin concrete tube

The invention relates to a prefabricated pump station, in particular to an integrated prefabricated pump station glass fiber reinforced resin concrete tube. The prefabricated pump station is used for solving the technical problem that an integrated prefabricated pump station glass fiber reinforced plastic tube in the prior art is low in rigidity and easy to deform and break and can only be used for excavating construction. In order to solve the technical problem, the technical scheme includes that the integrated prefabricated pump station glass fiber reinforced resin concrete tube comprises a tube body, a top seal and a base seal, and is characterized in that a plurality of tube body units are in sleeve or socket connection to form the tube body, the tube body has a composite layer structure and is made of resin concrete, a glass fiber reinforced plastic impermeable layer and an internal structure layer are arranged on the inner wall of the tube body, an external structure layer and a wear-resistant layer are arranged on the outer wall of the tube body, and a resin mortar layer is arranged between the inner wall and the outer wall of the tube body. The prefabricated pump station is mainly used for pump station construction.

Owner:上海耀华玻璃钢有限公司

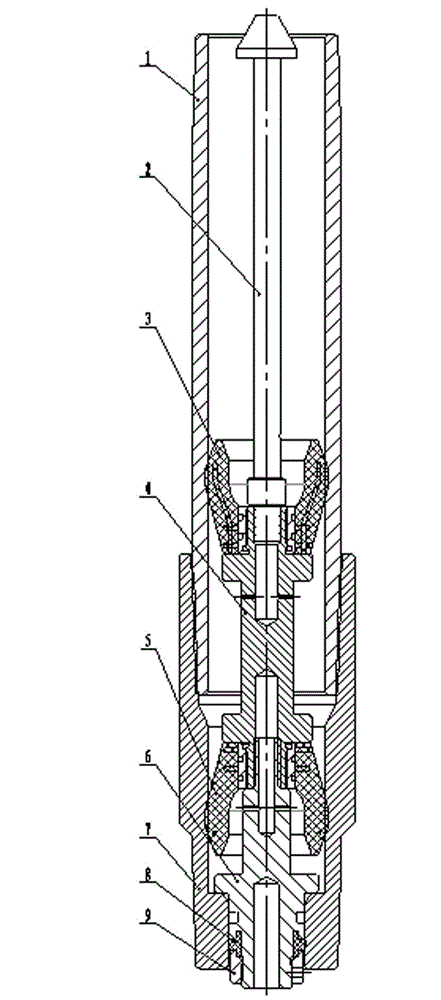

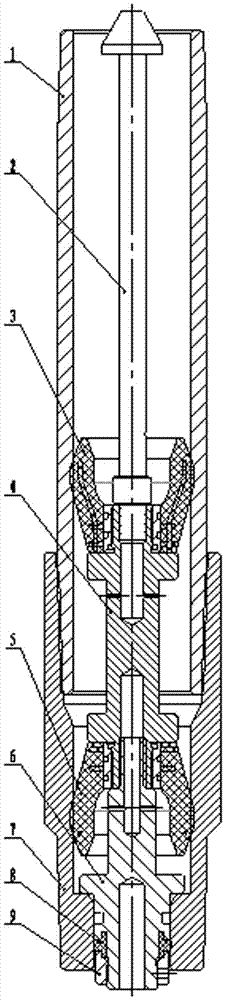

Throwing type washable downhole pressure-bearing plugging device and plugging method thereof

InactiveCN102913181AEasy to judgeReduce construction proceduresSealing/packingMarine engineeringWater well

The invention relates to a throwing type washable downhole pressure-bearing plugging device and a plugging method thereof. The throwing type washable downhole pressure-bearing plugging device and the plugging method thereof are applicable to constructions such as oil-water well tubular pile pressure testing, monolayer positioning and acidifying, layering acidifying, cementing and sand prevention. A downhole portion and a ground portion of the device are connected through an oil pipe, the downhole portion is provided with a cup assembly, the ground portion is provided with a fishing assembly, a fishing rod of the cup assembly is matched with a fishing cap of the fishing assembly so as to realize fishing the cup assembly. The cup assembly is manually placed into an oil pipe below a three-way barrel of the ground portion from the ground, is conveyed to a valve seat through an oil pipe pump, and can be fished by the fishing assembly of the ground portion when being washed. The throwing type washable downhole pressure-bearing plugging device can be used with a packer, a throttler and the like to realize acidifying, cementing and plugging construction of determining layers, and also can realize multilayer acidifying, plugging and sand prevention constructions through a tubular lifting pile. Whether the cup assembly is washed out or not is judged by observing moving positions of indicating screws, downhole working conditions can be conveniently judged, and construction is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

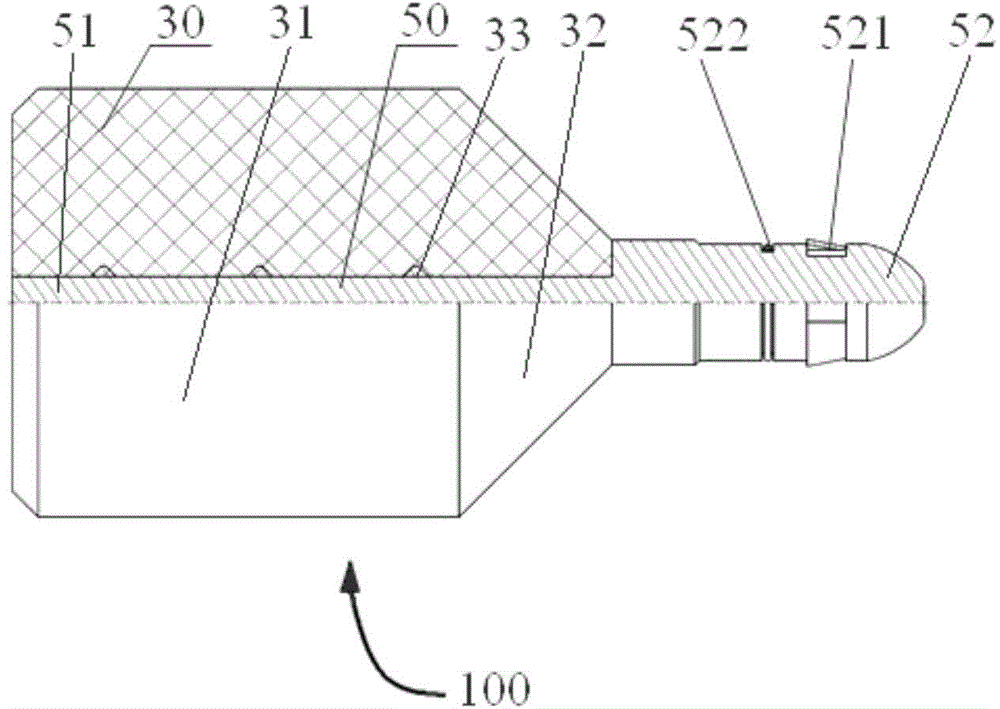

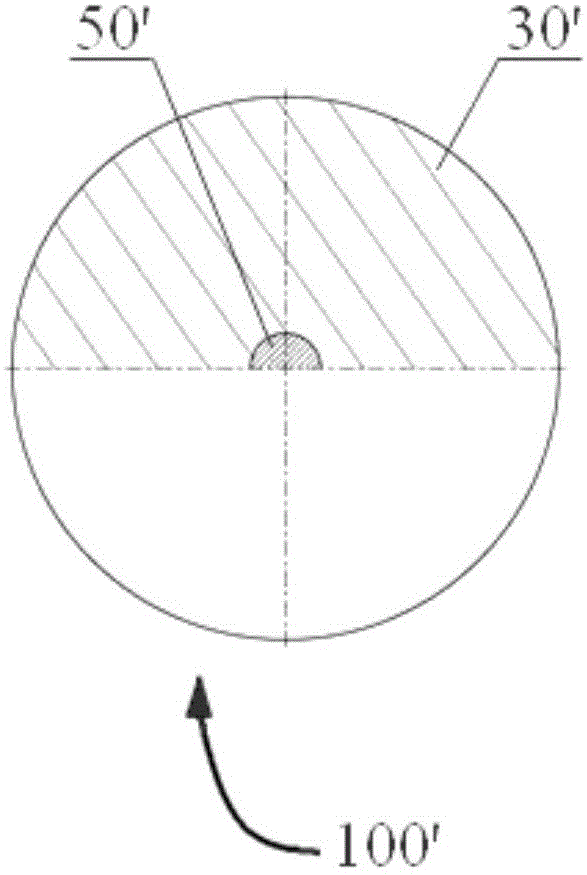

Rotary type fracture sand jet and multistage sand jetting and fracturing process

ActiveCN106121610AThe rotation angle is easy to controlGuaranteed hierarchical managementFluid removalType fractureAbrasive blasting

The invention relates to a rotary type fracture sand jet and a multistage sand jetting and fracturing process. The rotary type fracture sand jet is structurally characterized in that an upper connector and a lower connector are connected with the two ends of the fracture sand jet; a rotary type slide sleeve inner core is arranged on the inner circumference of the fracture sand jet; a plurality of shear pin grooves are formed in the middle of the surface of the outer circumference of the rotary type slide sleeve inner core; a plurality of spring type extensible shear pin assemblies are arranged on a fracture sand jet body, and one spring type extensible shear pin assembly falls into the corresponding shear pin groove; a rotary control mechanism is arranged at the end, close to the upper connector, of the rotary type slide sleeve inner core; rotary sand jetting holes distributed evenly and circumferentially are formed in the end, close to the lower connector, of the rotary type slide sleeve inner core; outer sand jetting holes distributed evenly and circumferentially are formed in the fracture sand jet body; and the outer sand jetting holes correspond to the rotary sand jetting holes in position. A rotary opening type is adopted for the fracture sand jet. In the construction process, the opening process is stable and reliable, and construction can be conducted independently for a layer section; and after construction, a slide sleeve of the constructed layer section can be closed, and layered sand jetting management can be effectively conducted for the stratum.

Owner:铁岭曲氏石油技术开发服务有限公司

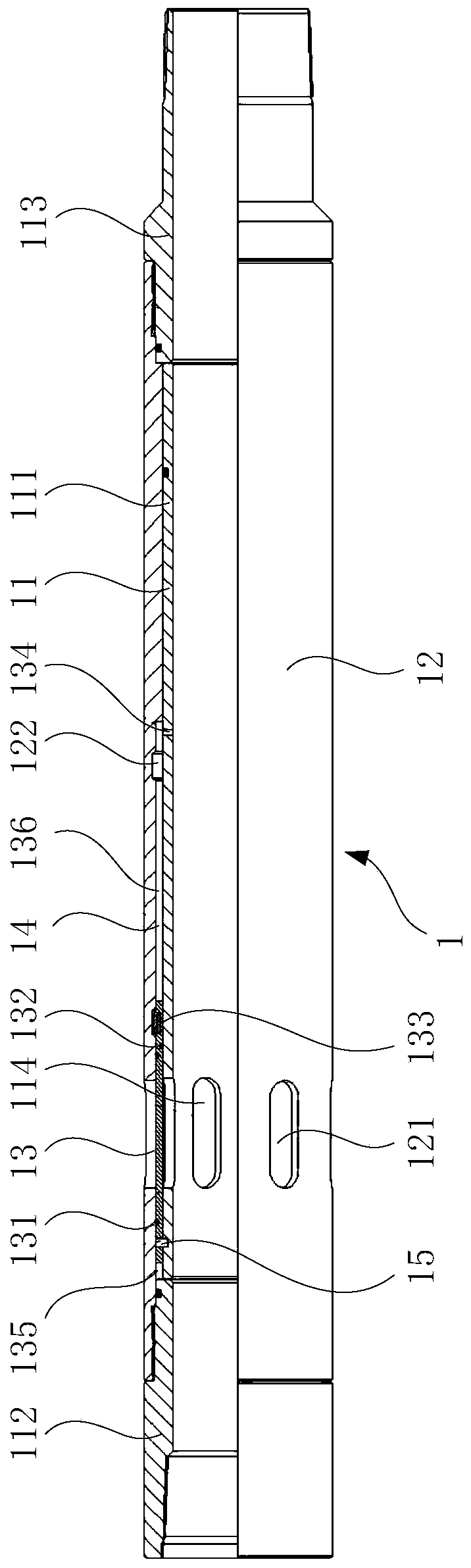

Irregular glass ceiling connection structure and ceiling lamp connection structure matched with irregular glass ceiling connection structure

The invention provides a glass ceiling connection structure. The glass ceiling connection structure comprises a keel, a fire retardant panel and art glass which are arranged from top to bottom in sequence, and a through hole is only formed in the art glass. A tapping screw passes through the through hole, so that it is achieved that the art glass, the fire retardant panel and the keel are fixed. The through hole is a counter bored hole. An elastic layer is arranged at the head of the tapping screw, so that the tapping screw is isolated from the bottom wall and the side wall of the counter bored hole. In this way, in the installation construction process of a single piece of art glass, the tapping screw makes elastic contact with the bottom wall of the counter bored hole, and in the compression process, the phenomenon that stress of joint parts is not uniform can be effectively avoided. Besides, even when the tapping screw is obliquely inserted, the tapping screw can be prevented from making rigid contact with the art glass, so that cracks are generated in the contact part of the art glass, and the construction reliability is improved. Besides, the invention further provides a ceiling lamp connection structure matched with the glass ceiling connection structure.

Owner:GOLD MANTIS CONSTR DECORATION

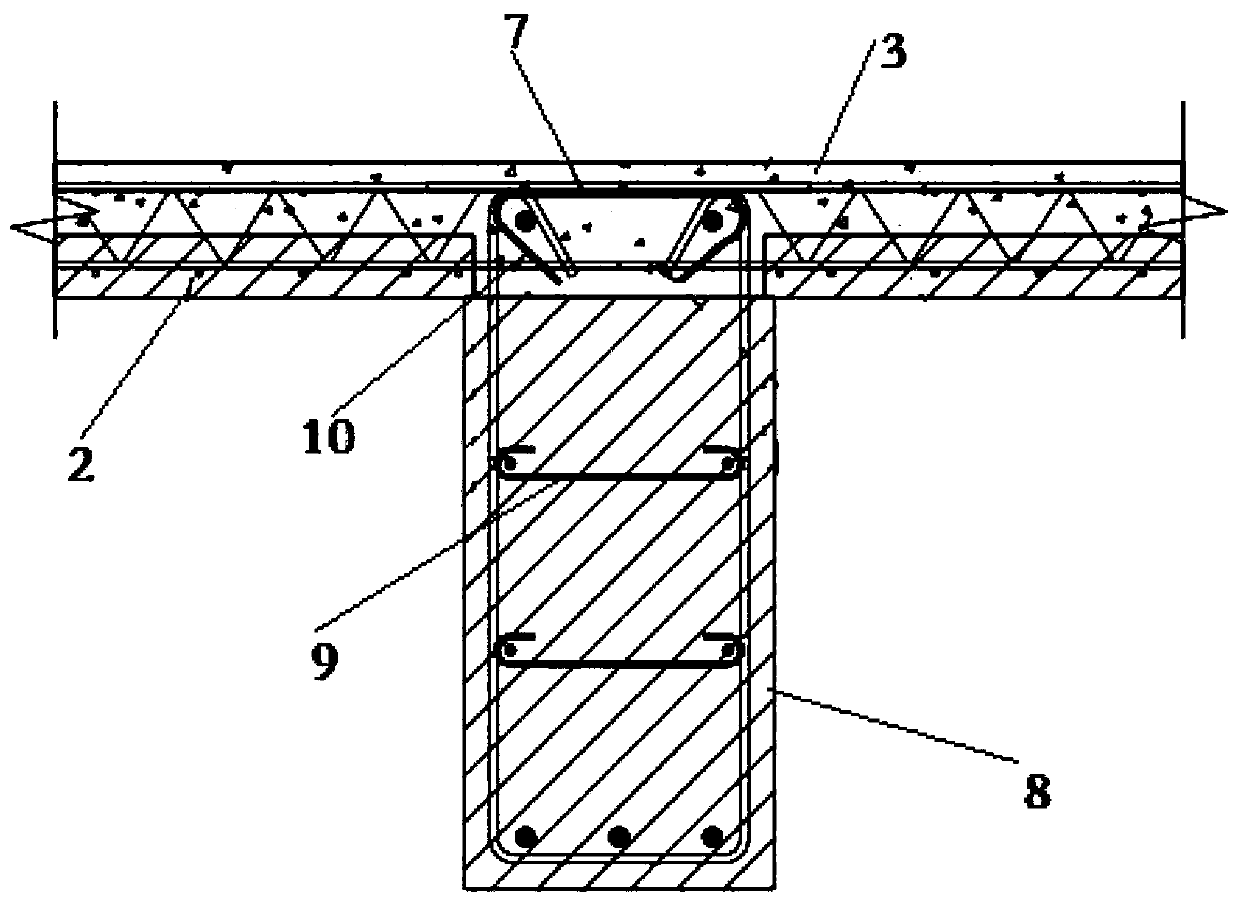

Building connecting node and construction method thereof

The invention provides a building connecting node. The building connecting node comprises prefabricated parts, cast-in-place parts, connecting parts, and sealing parts, the prefabricated parts are fixedly connected through the connecting parts and forms a whole structure with the cast-in-place parts, and then the whole structure is sealed through the sealing parts. Through sequential hoisting andaccurate detection, the smooth progress of construction and the feasibility of construction operation can be ensured, and the stress requirement of the whole building is met. According to the buildingconnecting node, a prefabricated beam, a prefabricated column and a prefabricated laminated plate are fixedly connected, the cast-in-place concrete is reduced, so that the construction is simpler andmore convenient, the construction efficiency and the construction reliability are improved, a shear groove arranged in a through manner is formed in the portion, between the two rows of steel bars, of a prefabricated turnover beam, connection with the laminated plate is facilitated, and linear cracks are avoided; and in addition, the step type design is adopted by the prefabricated laminated plate, stable lap joint with the floor rib of the floor slab can be ensured, so that the stress is reasonable, and the construction safety is improved.

Owner:佛山建装建筑科技有限公司

A method for conveying dregs and soil for excavation of subway station foundation pit

ActiveCN109533859BConducive to excavation construction organizationSolve the problem of construction slag transportationSupporting framesMechanical conveyorsArchitectural engineeringSubway station

The invention discloses a method for conveying slag and soil for excavating a foundation pit of a subway station. A set of corrugated sidewall belt conveyors is arranged. The corrugated sidewall belt conveyor includes a conveyor body and a belt storage mechanism; the conveyor body consists of a machine head. From the end to the end of the machine, there are the horizontal section of the nose, the inclined section of the body and the vertical section of the machine body; the horizontal section of the machine head is arranged on the ground foundation outside the foundation pit, and the vertical section of the machine body is arranged on the side wall of the continuous wall along the vertical direction. And its end is close to the bottom of the foundation pit; as the excavation depth of the foundation pit increases, the length of the corrugated sidewall conveyor belt of the belt storage mechanism section can be reduced; when it is necessary to continue to extend the length of the vertical section of the body, it can be shortened. The length of the horizontal section of the head, extending to the vertical section of the body. The construction method uses the corrugated sidewall conveyor to transport the muck, which can realize the continuous transportation of the muck, and can extend the length of the corrugated sidewall conveyor with the increase of the depth of the foundation pit. The degree of automation is high, the labor intensity of workers is low, and the muck High delivery efficiency.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

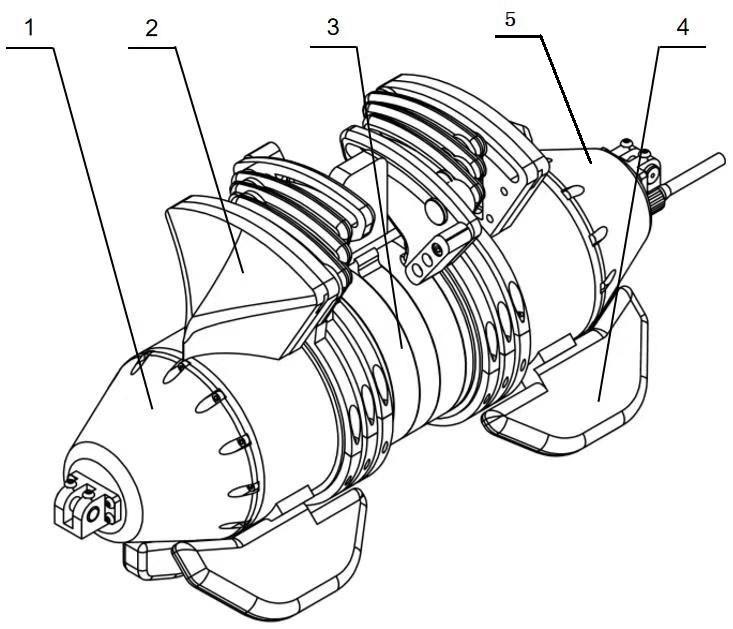

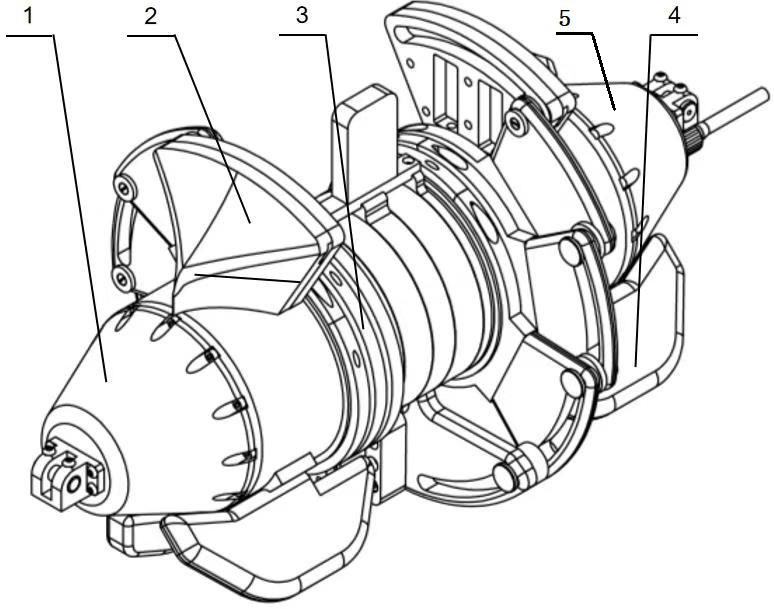

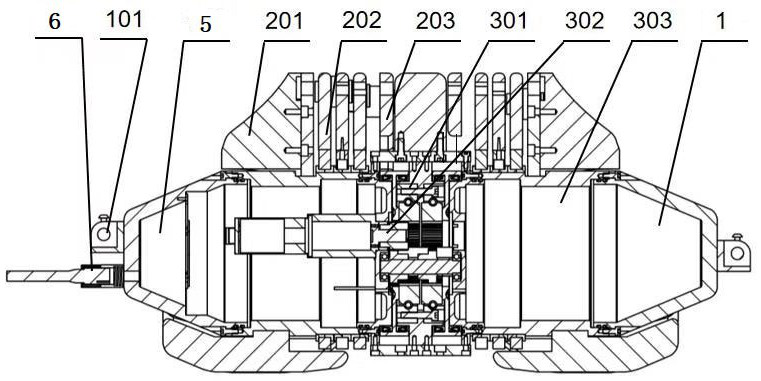

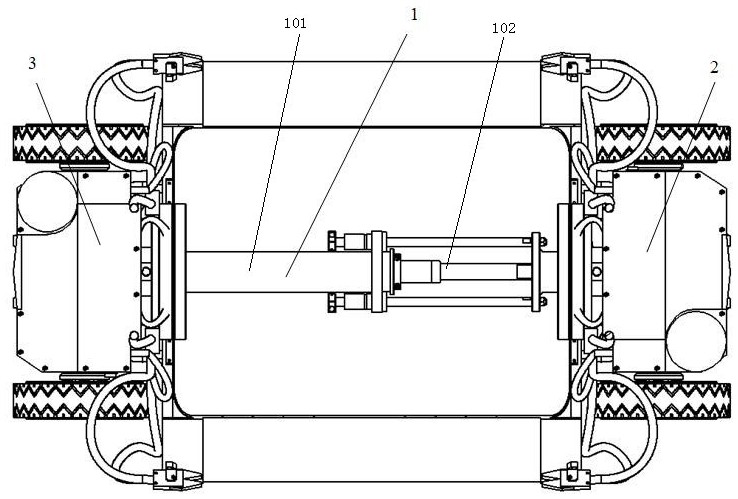

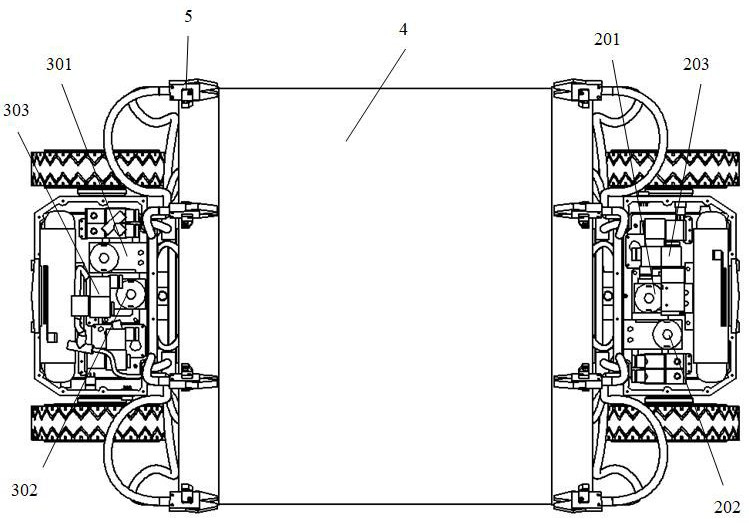

Pipeline dredging device

InactiveCN113026929AWide applicability to the environmentImprove construction reliabilitySewer cleaningMarine engineeringSludge

The invention discloses a pipeline dredging device, and belongs to the technical field of sludge cleaning equipment. The pipeline dredging device comprises a front end structure, a rear dredging scraper mechanism, a front dredging scraper mechanism, a machine body, a guide sliding shoe, a rear end structure and a cable system, wherein one end of the machine body is fixedly connected with the rear end structure, the cable system is arranged on the rear end structure, the other end of the machine body is fixedly connected with the front end structure, the rear dredging scraper mechanism and the front dredging scraper mechanism are symmetrically arranged on the machine body, and the guide sliding shoe is arranged below the machine body. The pipeline dredging device works in a pipeline, only one wire dragging auxiliary device is arranged on the road surface, potential safety hazards of personnel are avoided, construction operation is easy, the dredging speed is high, cost is low, and the influence on the road surface is small. The pipeline dredging device is wide in environmental applicability and high in construction reliability.

Owner:NANJING ANTOUKE INTELLIGENT SYST CO LTD

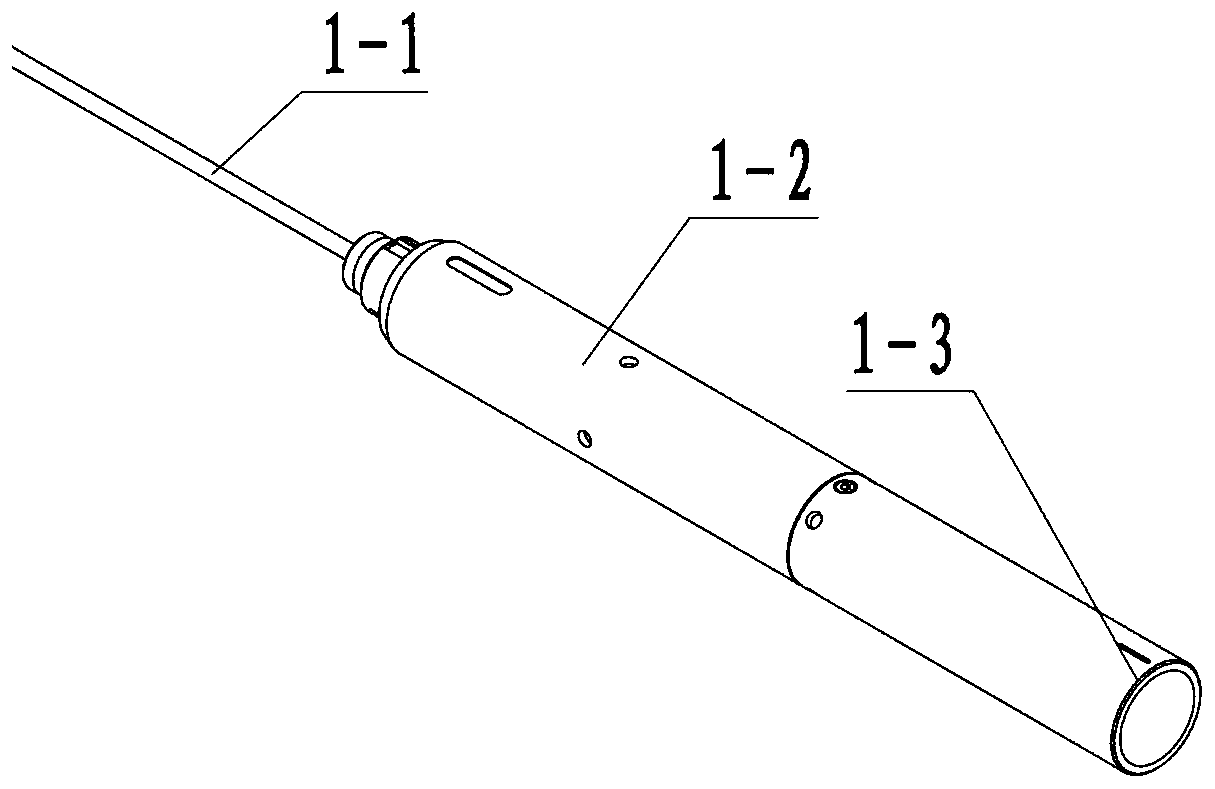

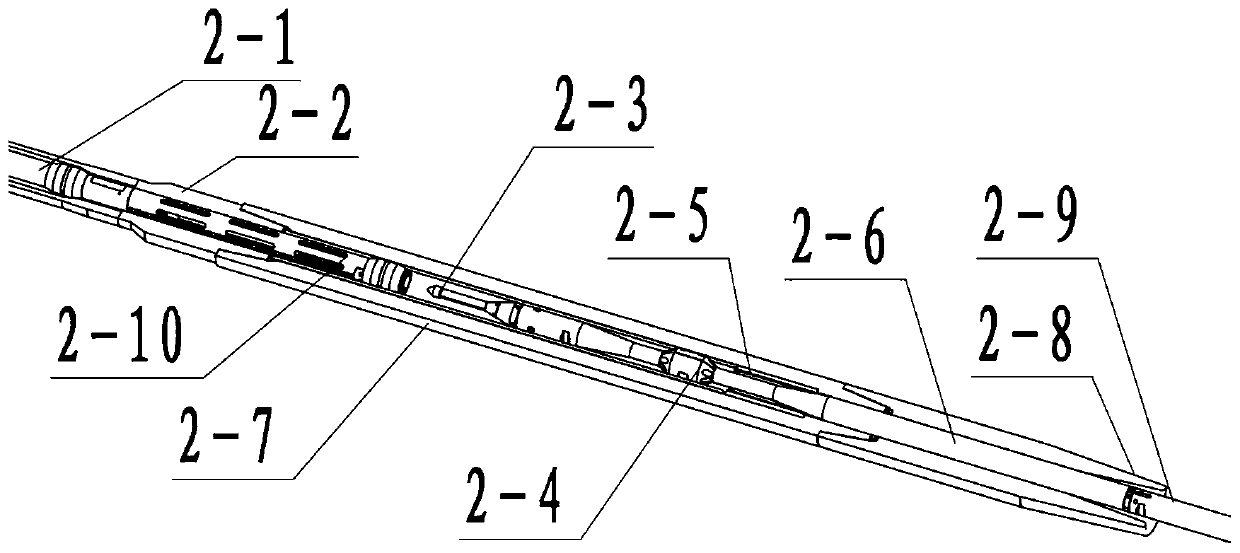

Cable throwing and withdrawing type drill pipe through logging process

ActiveCN110295883AAvoid shock damageImprove logging timeSurveyDrilling rodsWell loggingInstrumentation

The invention discloses a cable throwing and withdrawing type drill pipe through logging process and relates to the field of geophysical well logging. The process comprises the following steps: S1, running a drilling tool into a well; S2, connecting a logging instrument at a mouth of the well; S3, conveying a logging instrument string; S4, landing and releasing the logging instrument string; S5, withdrawing a cable; S6, pulling out the hole for logging; and S7, withdrawing the instrument. The process solves the problems of a large displacement horizontal well, a large displacement-perpendicularity ratio horizontal well, a highly-deviated well and complex well conditions.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drainage pipeline construction component and method

InactiveCN109440899AImprove construction reliabilityReduce construction damageSewer pipelinesArchitectural engineeringApplication site

The invention relates to a drainage pipeline construction component and method. The drainage pipeline construction component comprises an external frame, a cushion component and a covering component.The external frame encloses a mounting channel having an opening and at least two fixing channels distributed on two sides of the mounting channel in spaced manner; the bottom of the mounting channelis provided with a plurality of positioning channels; the cushion component is arranged in the mounting channel, and the bottom of the cushion component is provided with positioning protrusions matingwith the positioning grooves; the covering component includes a cover plate and a fixing connector fixed to the bottom of the cover plate and embedded in a fixing channel. The drainage pipeline construction component has the advantages that stable positioning supports are freely formed according to different application sites and structures, protection is provided around, construction reliabilityand early and late protective effects are effectively improved, construction damage is decreased, and the service life of a pipeline is extended.

Owner:温州金德市政建设有限公司

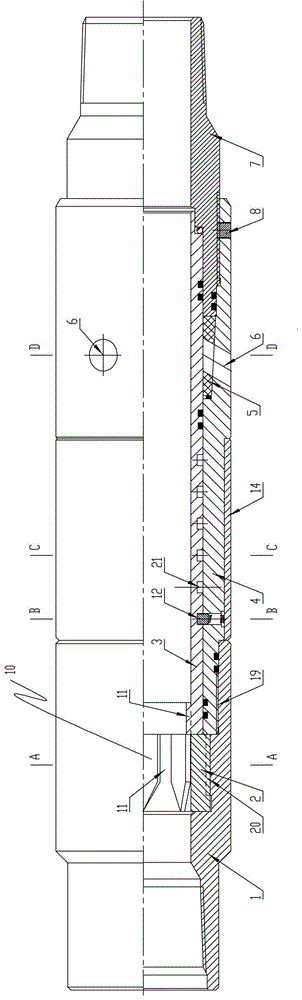

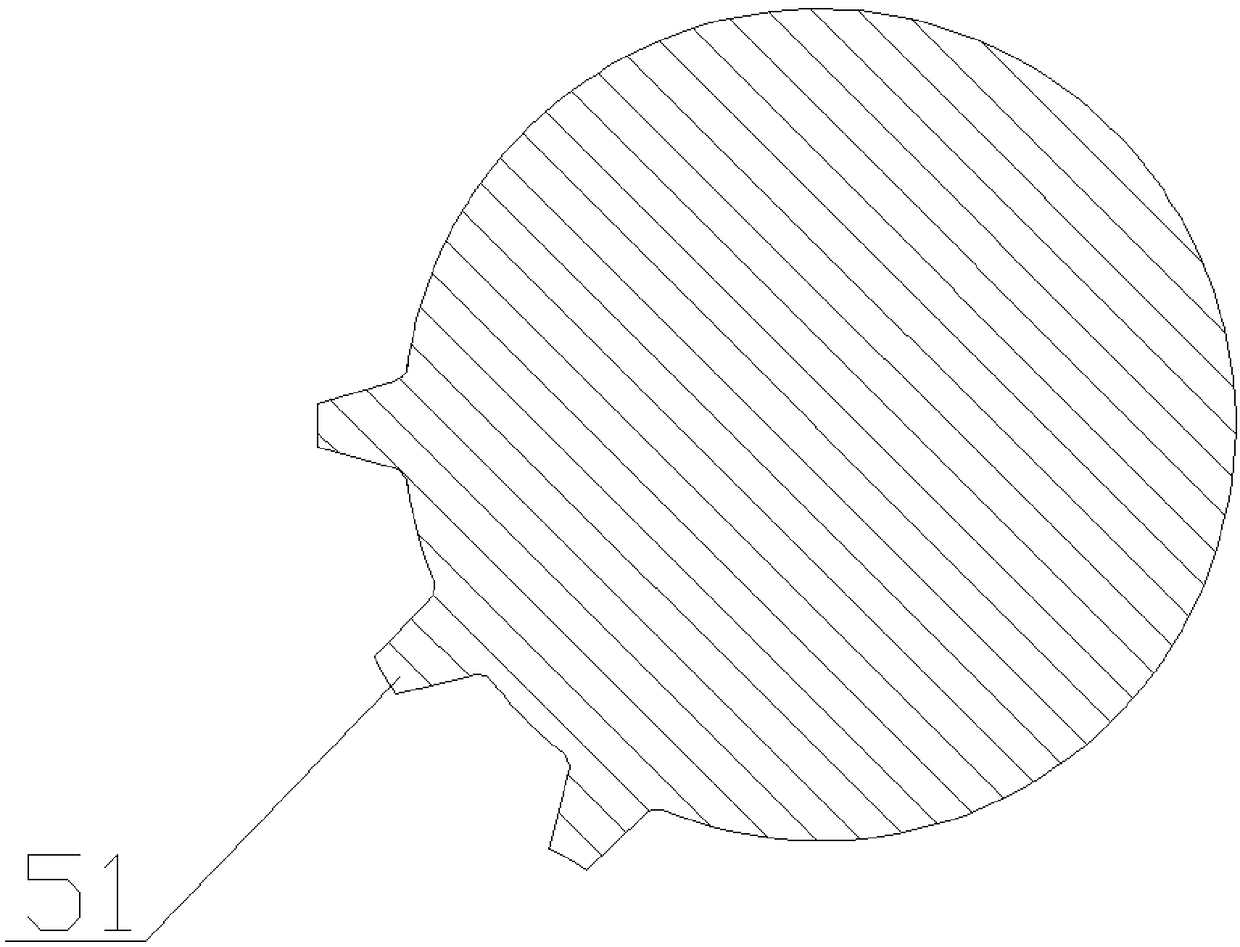

Well cementation rubber plug, well cementation method using same and staged fracturing device

InactiveCN106285556AImprove replacement efficiencyReduce construction riskSealing/packingElastomerWell cementing

The invention discloses a well cementation rubber plug which can pass through a tubular column with a variable inner diameter and finally achieve bumping with a bump-pressure seat. The well cementation rubber plug comprises a core body and an elastic body at least partially uniformly covering the outer surface of the core body, wherein the core body is used for supporting the elastic body or fixing the well cementation rubber plug to the bump-pressure seat, and the elastic body is used for making tight contact with the inner wall of the tubular column with the variable inner diameter and realizing relative sliding. According to the well cementation rubber plug, the outer surface of the core body is uniformly covered with the elastic body, and the outer surface of the elastic body makes complete contact with the inner wall of the tubular column, so that the well cementation rubber plug in the invention is different from a rubber bowl structure and the like of an elastic body of a well cementation rubber plug in the prior art. Elastic material of the elastic body has good elasticity so that the well cementation rubber plug can successfully pass through the tubular column with the different inner diameters and finally achieve bumping with the bump-pressure seat, and especially the well cementation rubber plug can successfully pass through a tubular column with a greatly variable inner diameter. The well cementation displacement efficiency is improved, and the well cementation construction risk is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Throwing type washable downhole pressure-bearing plugging device and plugging method thereof

InactiveCN102913181BEasy to judgeReduce construction proceduresSealing/packingMarine engineeringWater well

The invention relates to a throwing type washable downhole pressure-bearing plugging device and a plugging method thereof. The throwing type washable downhole pressure-bearing plugging device and the plugging method thereof are applicable to constructions such as oil-water well tubular pile pressure testing, monolayer positioning and acidifying, layering acidifying, cementing and sand prevention. A downhole portion and a ground portion of the device are connected through an oil pipe, the downhole portion is provided with a cup assembly, the ground portion is provided with a fishing assembly, a fishing rod of the cup assembly is matched with a fishing cap of the fishing assembly so as to realize fishing the cup assembly. The cup assembly is manually placed into an oil pipe below a three-way barrel of the ground portion from the ground, is conveyed to a valve seat through an oil pipe pump, and can be fished by the fishing assembly of the ground portion when being washed. The throwing type washable downhole pressure-bearing plugging device can be used with a packer, a throttler and the like to realize acidifying, cementing and plugging construction of determining layers, and also can realize multilayer acidifying, plugging and sand prevention constructions through a tubular lifting pile. Whether the cup assembly is washed out or not is judged by observing moving positions of indicating screws, downhole working conditions can be conveniently judged, and construction is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

A three-in-one anchor cable construction device for hole forming, installation and grouting

ActiveCN104532836BShorten the timeShorten construction timeDrilling rodsDrilling casingsPush pullOperability

The invention discloses an anchor cable construction device combining hole forming, mounting and grouting into one. The anchor cable construction device comprises a drill rod assembly and a push-pull power system, the drill rod assembly comprises a drill rod, a drill bit and a hydraulic power motor, the drill rod is hollow, the hydraulic power motor, a grouting pipe and an oil supply pipeline are arranged in the drill rod, the hydraulic power motor is fixed in the hole drilling end of the drill rod, a grouting hole is formed in the hole drilling end, and the drill bit is arranged on the hydraulic power motor. A plurality of grooves extending in the length direction of the drill rod are distributed in a rod body of the drill rod at intervals in the circumferential direction. A plurality of anchor cable penetrating holes are formed in the inner side wall of the hole drilling end of the drill rod at intervals in the circumferential direction, an inclined channel is communicated between each anchor cable penetrating hole and the corresponding groove, and the inclined channels extend from the anchor cable penetrating holes to the other end of the drill rod. The drill rod is provided with an anchor cable separator used for clamping an anchor cable placed in the grooves in the hole retreating and pulling out process. The anchor cable construction device is higher in operability and wider in application range, construction time can be greatly saved, and construction efficiency can be improved.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Pipeline repairing robot

The invention discloses a pipeline repairing robot, and relates to the technical field of pipeline repairing. The pipeline repairing robot comprises an electric push rod, a driving rear seat module, a driving front seat module, an air bag and an air clamp. The electric push rod is composed of a fixed rod and a telescopic rod, the telescopic rod is connected with the driving rear seat module, the fixed rod is connected with the driving front seat module, and the driving rear seat module and the driving front seat module are both connected with the air bag and the air clamp. The pipeline repairing robot avoids the problem of traffic jam caused by road closing during repairing, and has the characteristics of simplicity and convenience in construction, low construction cost, wide environmental applicability and high construction reliability.

Owner:NANJING ANTOUKE INTELLIGENT SYST CO LTD

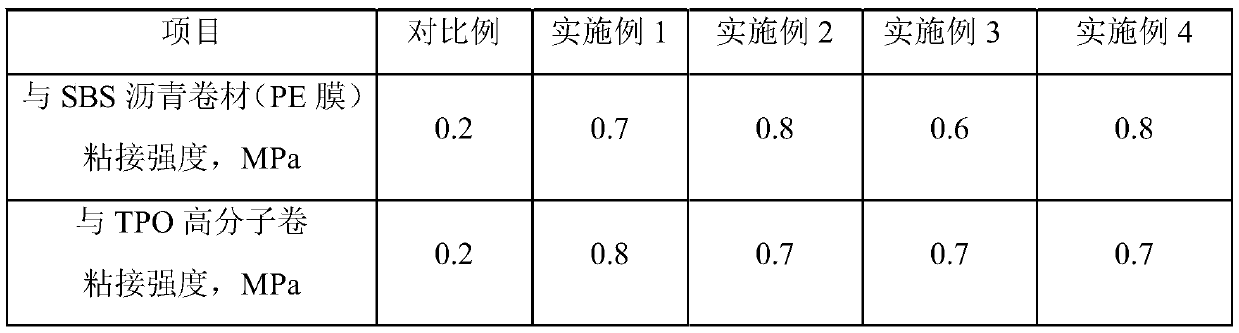

Two-component polyurethane waterproof coating containing non-polar polymer modified compound and preparation method thereof

ActiveCN107955516BImprove construction reliabilitySolve compound problemsPolyurea/polyurethane coatingsPolymer sciencePolymer modified

The invention discloses a two-component polyurethane waterproof coating containing a non-polar polymer modified compound and a preparation method of the two-component polyurethane waterproof coating.The two-component polyurethane waterproof coating is prepared from a component A and a component B, wherein the component A is a polyurethane prepolymer prepared from 3-15 parts by weight of isocyanate and 2-40 parts by weight of first polyol; the component B comprises 2-20 parts by weight of second polyol, 2-30 parts by weight of the compound subjected to epoxidation modification with a non-polarpolymer, 2-15 parts by weight of a chain extender and 0.1-2 parts by weight of a catalyst, and a main chain of the non-polar polymer contains multiple C=C double bonds. The polyurethane waterproof coating has good performance of adhesion with a bituminous waterproof coiled material and a polymer waterproof coiled material and is used for adhesion, composition or repair of the bituminous waterproof coiled material or the polymer waterproof coiled material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

A fracturing hole opening and closing system

ActiveCN107313761BSimple structureGood for flowbackFluid removalWell/borehole valve arrangementsEngineeringHydraulic pressure

The invention relates to a fracturing hole opening and closing system which comprises a slide sleeve. The sleeve slide comprises an inner sleeve, an outer sleeve and an isolation sleeve; the inner sleeve is provided with an inner fracturing hole; the outer sleeve is arranged on the inner sleeve in a sleeving mode and is provided with an outer fracturing hole; an annular cavity which is used for accommodating the isolation sleeve and communicates with the inner fracturing hole and the outer fracturing hole is formed between the inner sleeve and the outer sleeve; and the isolation sleeve can be driven by hydraulic pressure to slide in the annular cavity so as to enable the outer fracture hole and the inner fracturing hole to communicate with each other or disconnect from each other. The slide sleeve has the advantages that the structure is simple; the goal of no fracturing stage limitation can be realized; the whole through diameter is realized in the slide sleeve; the later period operation liquid flow back and subsequent tool entering are facilitated; the construction reliability is high; and the drilling removal operation is not needed. Under the condition of difficult drilling pressure exertion in the horizontal section, the slide sleeve is opened or closed in a hydraulic pressure mode; operation is simple and convenient; and the fracturing hole opening and closing system is particularly suitable for slide sleeve opening and closing operation of a deep well, an ultra-deep well and a horizontal well.

Owner:CHINA PETROLEUM & CHEM CORP +1

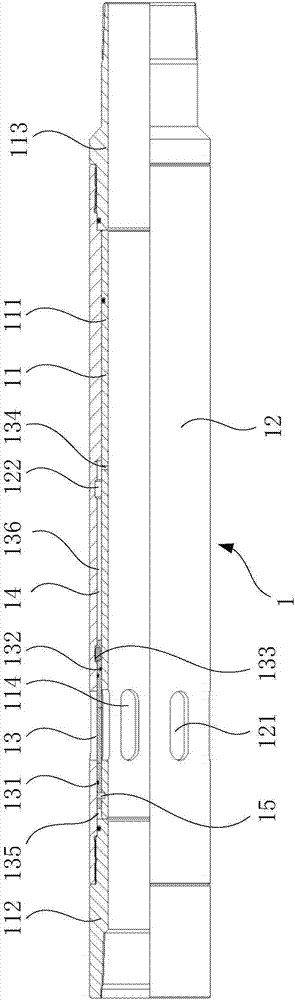

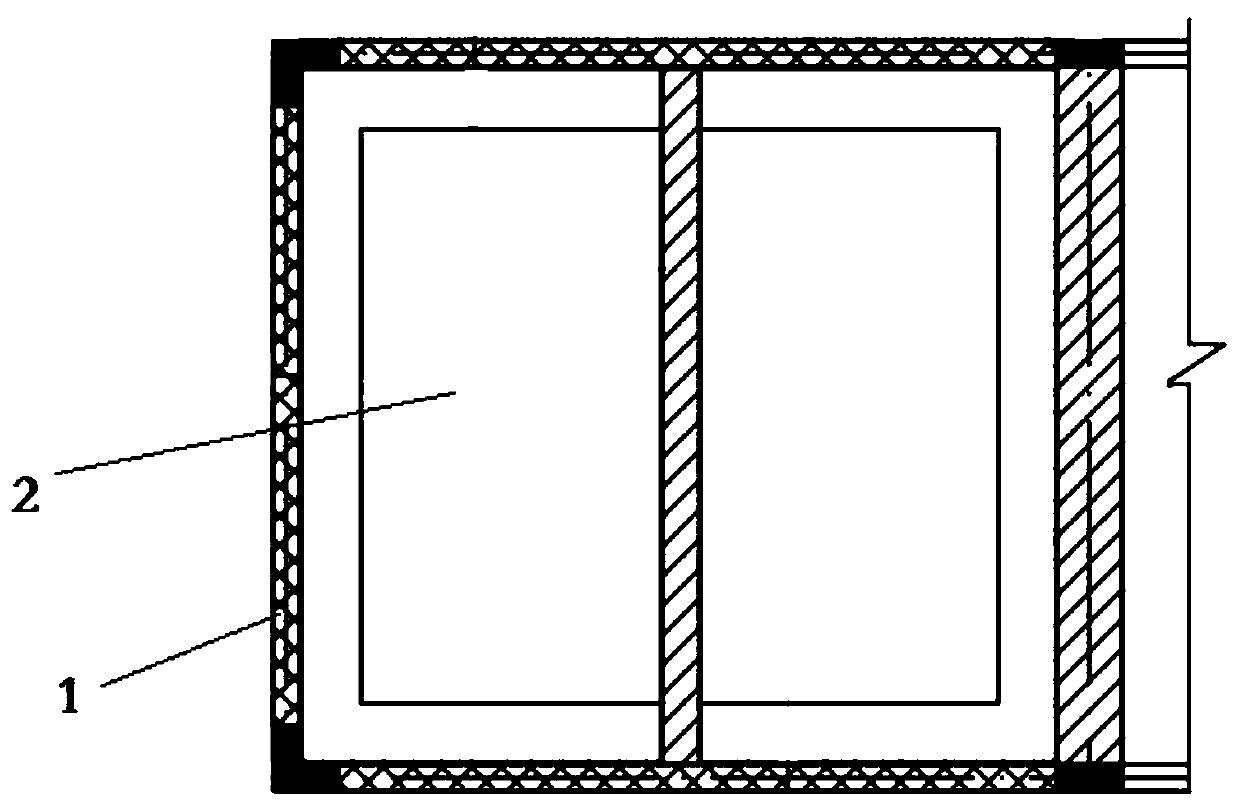

A fast-assembled energy-dissipative infill wall panel

ActiveCN109838031BLimit out-of-plane motionLittle impact on construction levelProtective buildings/sheltersShock proofingThermal insulationTongue and groove

The invention discloses a fast-assembled energy-consuming filling wallboard, which belongs to the technical field of building construction equipment. It includes the first wallboard group at the end and the second wallboard group at the middle, the first wallboard group and the second wallboard group and the second wallboard group are connected together by tenon and tenon ; and the length of the mortise is greater than the depth of the mortise, so that the filled wall after splicing has vertical energy-dissipating joints of 15 mm to 25 mm, which can dissipate seismic energy. The thickness direction of the first wall panel group and the second wall panel group are respectively spliced by two first wall panels and two second wall panels. When installing, rotate one wall panel vertically by 180 degrees to splice with the other. The cavity formed in the middle of the spliced filling wall can be filled with thermal insulation material. The energy-consuming filling wallboard of the invention is easy to install, can greatly improve construction efficiency, can reduce environmental pollution and noise pollution in the construction process, and improve construction reliability.

Owner:QINGDAO HUANGHAI UNIV

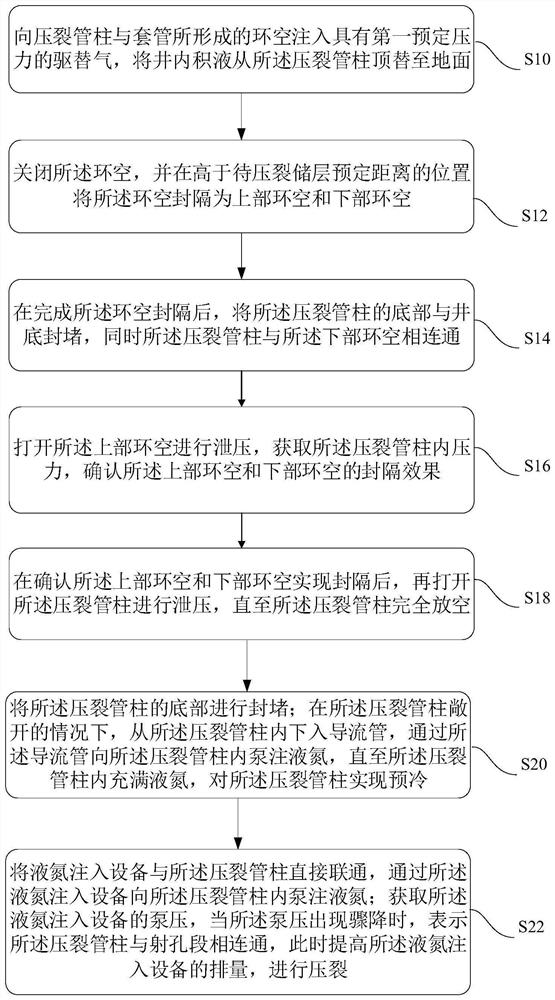

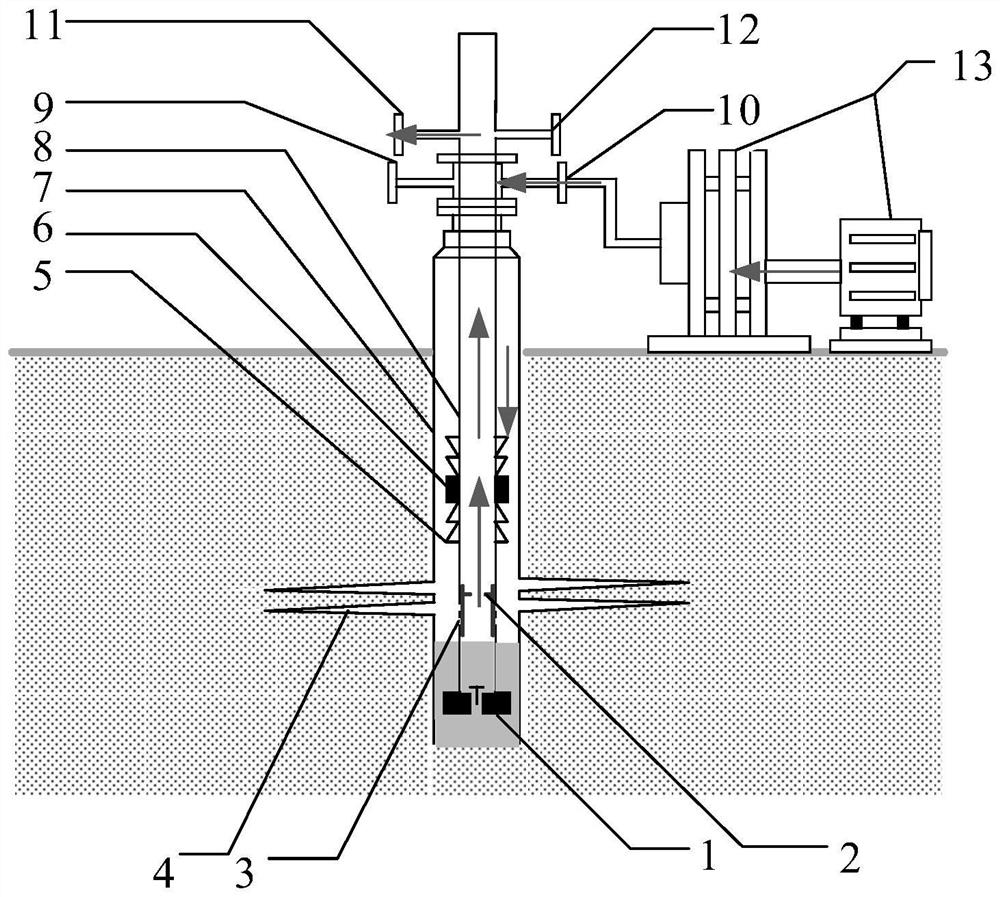

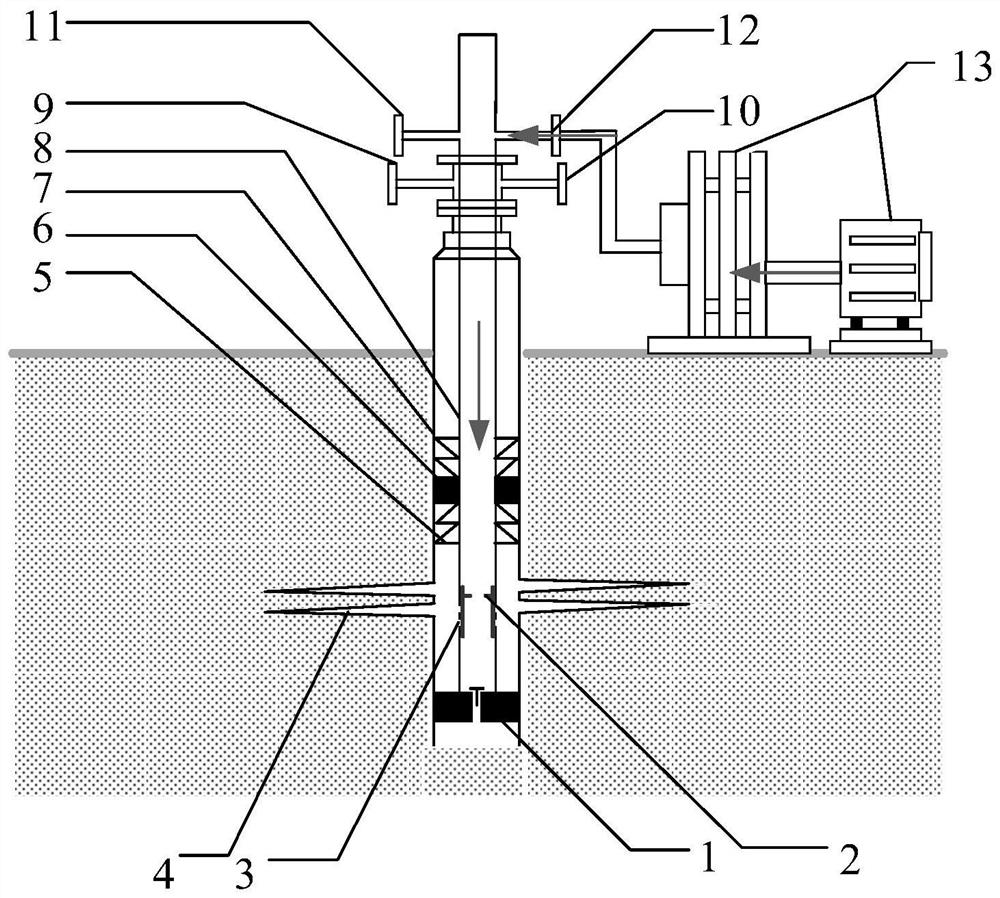

Liquid nitrogen fracturing process

InactiveCN111271036BReduce delivery efficiencyImprove pre-cooling efficiencyFluid removalMechanicsPetroleum engineering

The invention discloses a liquid nitrogen fracturing process method. The method comprises the steps that replacing accumulated fluid in a well to the ground from a fracturing pipe column; at the position higher than a reservoir to be fractured by the reserved distance, packing an annulus into an upper annulus and a lower annulus; blocking the bottom of the fracturing pipe column and the well bottom, and meanwhile enabling the fracturing pipe column to communicate with the lower annulus; opening the upper annulus for pressure relief, obtaining pressure in the fracturing pipe column, and after confirming that the upper annulus and the lower annulus are packed, opening the fracturing pipe column for pressure relief; blocking the bottom of the fracturing pipe column; under the condition of opening the pressuring pipe column, lowering a flow guide pipe from the fracturing pipe column, and pumping and injecting liquid nitrogen into the fracturing pipe column through the flow guide pipe untilthe interior of the fracturing pipe column is full of the liquid nitrogen, and achieving precooling of the fracturing pipe column; communicating a liquid nitrogen injection device with the fracturingpipe column, and pumping and injecting the liquid nitrogen; and when the fracturing pipe column communicates with a perforation segment, increasing the displacement to carry out fracturing. It can beensured that the low-temperature liquid nitrogen has the higher conveying efficiency and better heat preservation effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Drilling-plug free tubular column with sand control and well cementation for open-hole horizontal well

ActiveCN101701513BSimplify operating proceduresReduce operating costsFluid removalSealing/packingAcid washingUltimate tensile strength

The invention relates to a drilling-plug free tubular column with sand control and well cementation for an open-hole horizontal well, which comprises an external tubular column and an inner tubular column. The external tubular column comprises a sand control screen (2), an open-hole packer (3), an external positioning step (4), an external cementing machine (5) and a sleeve tube (6) are sequentially installed and connected on the an acid-washing filling valve (1). The inner tubular column comprises an oil tube (8) and an inner cementing machine (7) which is installed and connected on the oil tube (8). The inner tubular column is arranged in the external tubular column and the inner tubular column and the external tubular column are mutually fixed sealed. The invention can simplify operating procedures and reduce the frequency of running string, and does not need to perform drilling-plug operation free after cementing for well cementation, and also has the advantages of low operating cost, large drift diameter, regular inner wall, clean well-hole of sand control and well completion, high construction success ratio, large construction stability, low labor intensity, high oil well yield and the like, and can be widely applied to the process of sand control, well cementation and well completion of the open-hole horizontal well for oil exploration.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

Cable lap joint device

PendingCN111786181AGuaranteed tightnessNovel structural designEngagement/disengagement of coupling partsCouplings bases/casesLap jointEngineering

The invention relates to a cable lap joint device. The device belongs to the field of cable connection. The device comprises a first lap joint shell and a second lap joint shell. A first inserting piece and a second inserting piece are connected into the first lap joint shell and the second lap joint shell. The first inserting piece is connected with the second inserting piece; the first insertingpiece is connected and fixed through a mounting flange and the first adjusting flange; the second inserting piece is connected and fixed through a second adjusting flange and a mounting base; the tail parts of the first inserting piece and the second inserting piece are connected with a tail fiber; the first inserting piece, the connecting piece connected to the first inserting piece, the secondinserting piece and the connecting piece connected to the second inserting piece are all arranged in a cavity formed by connecting the first lap joint shell and the second lap joint shell. The tail parts of the first lap joint shell and the second lap joint shell are connected with a locking mechanism, so that the problem that underwater cables are difficult to connect is solved, and the beneficial effects are as follows: the application in a complex water environment is met; the internal structure of the cable lap joint device is novel in design, multi-watertight protection and redundant safety design can be achieved, the construction reliability is improved, and the locking mechanism ensures the sealing performance of the underwater environment.

Owner:CCCC FIRST HARBOR ENG +1

A high-performance sand mist-containing sealing layer material and its preparation method

ActiveCN111777945BImprove compatibilityImprove stabilityAntifouling/underwater paintsPaints with biocidesRoad engineeringSuspending Agents

A high-performance sand mist-containing sealing layer material and its preparation method belong to the road engineering technical field, and the material composition includes zwitterionic emulsified asphalt, suspension thickener, viscosity-increasing and toughening agent, film-forming agent, suspending agent, and preservative and anti-skid fine sand; the preparation method includes preparing a base material, preparing a concentrated solution of a sand-mist seal layer, preparing a high-performance sand-mist seal layer material and construction. The finger-drying time of the sand mist-containing sealing layer material obtained in the present invention is 10-30 minutes, the drawing strength at 60°C is 0.35-1.1 MPa, and the wet wheel abrasion value is 22.8-56 g / m 2 , Corundum 7 days of uniform suspension, service life of more than 3 years. The high-temperature drawing strength of the present invention is at least 20% higher than the existing traditional sand mist-containing sealing layer materials, which can solve the problems of poor high-temperature adhesion and poor wear resistance of existing materials, and has the advantages of short drying time, good maintenance effect, and easy to use. Long life and other advantages.

Owner:辽宁省交通科学研究院有限责任公司

Prefabricated underground silo compound shaft construction method and silo structure

ActiveCN106088154BReduce the internal force of the rectangular sectionReduce settlementArtificial islandsUnderwater structuresArchitectural engineeringHalothermal circulation

Owner:黄竟强

A rapid precipitation structure and precipitation method for confined water

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

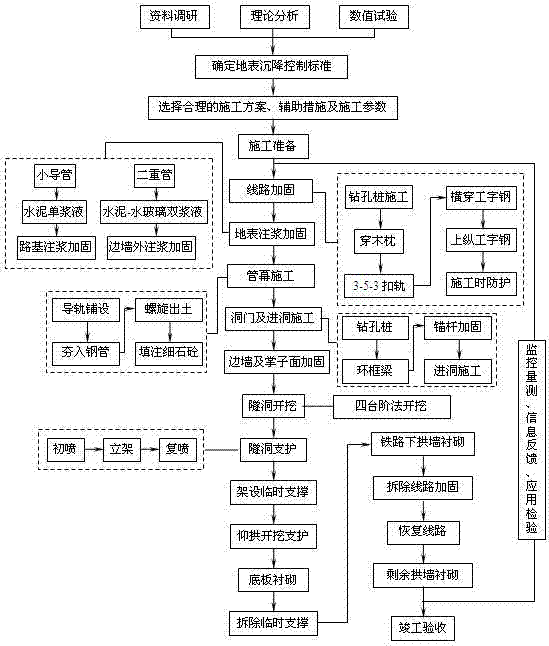

Underground excavation construction deformation control method for three-hole small clear distance tunnel underpass trunk railway

ActiveCN103375170BGuaranteed operational safetyReduce pollutionTunnelsTrackwayArchitectural engineering

The invention discloses an underground excavation construction deformation control method for a three-hole small clear distance tunnel underpass trunk railway, and belongs to the technical field of tunnel (hole) shallow buried soil stratum construction. Firstly, construction surface subsidence control standards are determined according to the requirement of an existing trunk railway for track smoothness; secondly, construction schemes and construction parameters of the three-hole tunnel are tested and determined by the aid of three-dimensional finite element static and dynamic numerical values. Construction includes the steps: reinforcing lines; grouting and reinforcing the earth surface; constructing an advanced tube screen; constructing a tunnel portal; constructing a tunnel crevasse; grouting and reinforcing side walls and tunnel faces; excavating the tunnel; supporting the tunnel; forming a secondary liner of the tunnel; recovering the lines, and monitoring measurement is performed in the whole construction process. Construction quality is strictly controlled according to a predetermined scheme and process in the construction process, the construction parameters are timely fed back and adjusted by the aid of an information construction technology, and operation safety of existing lines and structural stability of the tunnel are guaranteed.

Owner:中铁六局集团石家庄铁路建设有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com