Shale gas horizontal well bridge plug separation and ball throwing segmented fracturing process

A technology for staged fracturing and horizontal wells, applied in the directions of sealing/isolation, wellbore/well components, production fluid, etc., which can solve problems such as difficult to achieve high production, difficult to ensure pressure-opening, falling into the wellbore, etc., to achieve construction The effect of high reliability, high economic return and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

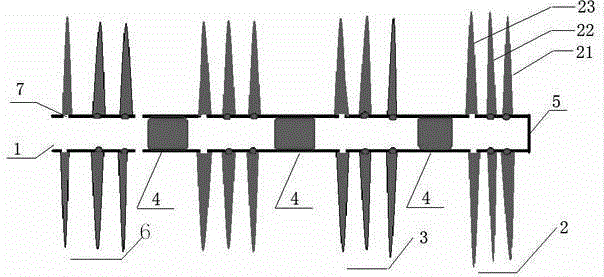

[0031] The present invention as figure 1 As shown, a shale gas horizontal well bridge plug separation and pitching staged fracturing process method specifically includes the following steps:

[0032] 1) First pass, explore and wash the wellbore, and clean the wellbore;

[0033] 11) Use the well gauge and tubing thread to connect to the bottom of the artificial well,

[0034] 12) Adopt the method of positive well washing, and use the fracturing truck to wash the wellbore with large displacement of clean water.

[0035] 13) Use TCD-15 anti-swelling fluid with a concentration of 0.05% instead of clear water for washing wells;

[0036] 2) Carry out cluster perforation for the first section, and lower the perforating gun connected in series with the lower crawler to the designated position of the wellbore. The specific perforating parameters are: the pressure resistance of the gun body is 120MPa, the gun type is 89, and the perforating bullet type is BH42RDX28-2, phase angle 60°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com