Patents

Literature

38results about How to "Rupture will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon dioxide gel micro-encapsulated phase change energy storage material and preparation thereof

InactiveCN101503618AImprove liquidityImprove toughnessHeat-exchange elementsMicroballoon preparationTemperature controlSilicon oxide

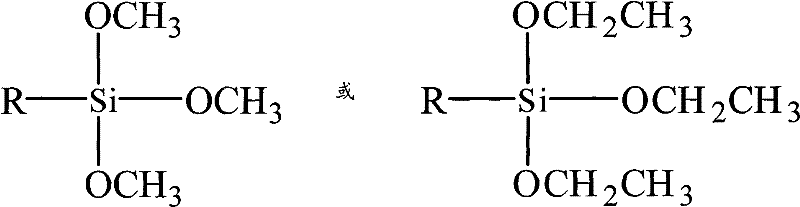

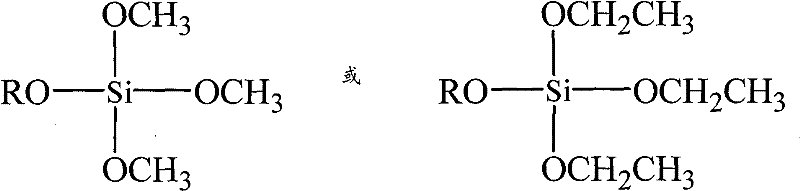

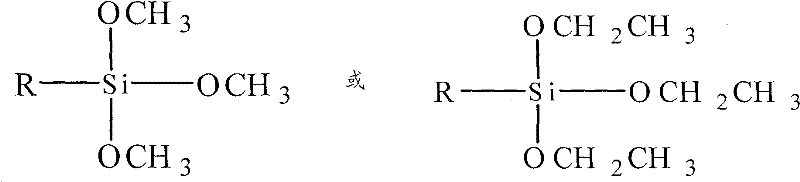

The invention discloses a silicon dioxide gel microencapsulated phase change energy storage material and a preparation method thereof. The preparation method is characterized by comprising the following steps: melting a phase change energy storage material in ethanol water solution at a temperature of between 30 and 90 DEG C, emulsifying under high-speed stirring, adding alkaline solution to ensure that the pH value of a reaction system is between 8 and 12, dropwise adding organic silicon oxide which accounts for 5 to 30 percent of the weight of the phase change energy storage material at a speed of between 1.5 and 8ml / m, reacting for 2 to 4 hours, and cooling, filtering and drying to obtain a micro-capsule which takes silicon dioxide gel produced by the organic silicon oxide under alkaline condition as a capsule wall and the emulsified phase change energy storage material as a capsule core, wherein the weight ratio of the phase change energy storage material to the organic silicon oxide is 2.3-19: 1. The obtained product has the average particle size not obviously increased, good free mobility of particles and compact and even capsule wall, and can be applied in the fields of energy utilization, heat exchange and temperature control.

Owner:UNIV OF SCI & TECH OF CHINA

Aqueous polyurethane micro-encapsulated phase change energy storage material and preparation thereof

ActiveCN101503617AImprove liquidityImprove brittlenessHeat-exchange elementsMicroballoon preparationSaline waterPhase change

The invention discloses a metal ion crosslinked aqueous polyurethane microencapsulated phase change energy storage material and a preparation method thereof. The preparation method is characterized by comprising the following steps: melting a phase change energy storage material in deionized water at a temperature of between 30 and 90 DEG C, adding a nonionic surfactant which accounts for 0.5 to 10 percent of the weight of the phase change energy storage material, emulsifying under high-speed stirring, then adding aqueous polyurethane with the polyurethane content which accounts for 0.5 to 20 percent of the phase change energy storage material and metal salt water solution with the metal ion weight which accounts for 0.1 to 10 percent of the polyurethane in the aqueous polyurethane, reacting for 0.5 to 4 hours, and cooling, filtering and drying to obtain a phase change energy storage material micro-capsule which takes the phase change energy storage material as a capsule core and metal ion crosslinked aqueous polyurethane as a capsule wall, wherein the weight ratio of the phase change energy storage material to the aqueous polyurethane is 0.5-20: 1. The product has the average particle size not obviously increased, good free mobility of particles and compact and even capsule wall.

Owner:UNIV OF SCI & TECH OF CHINA

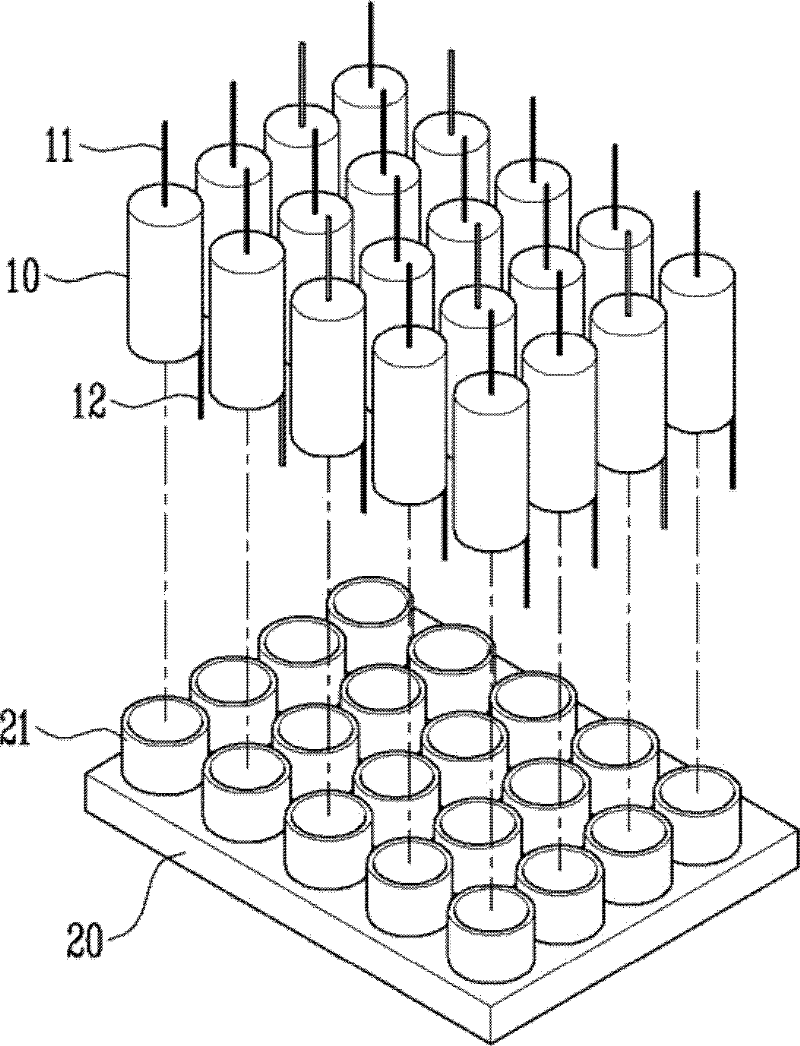

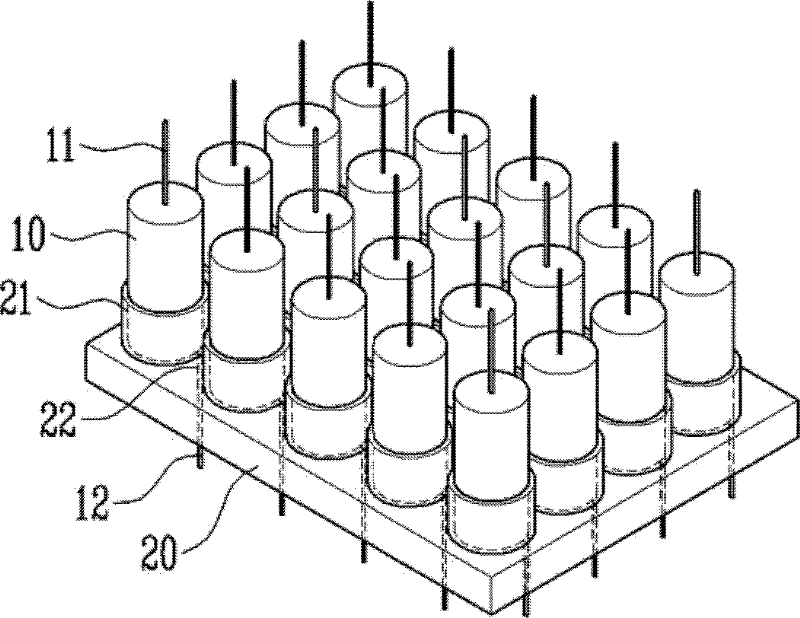

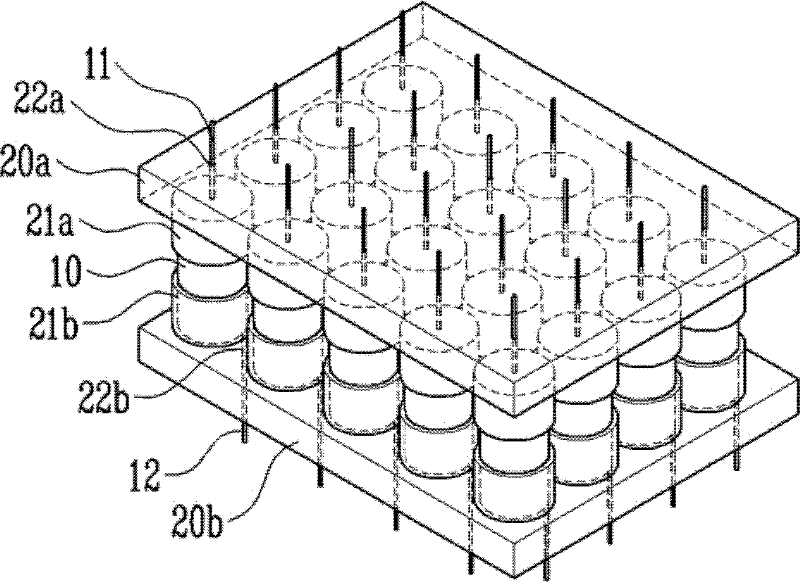

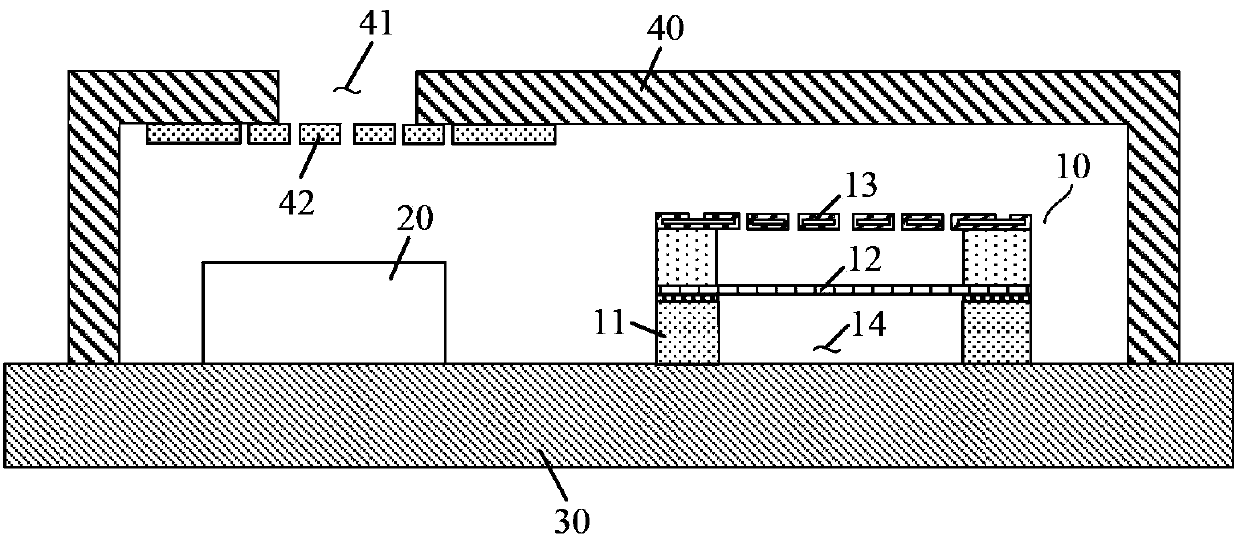

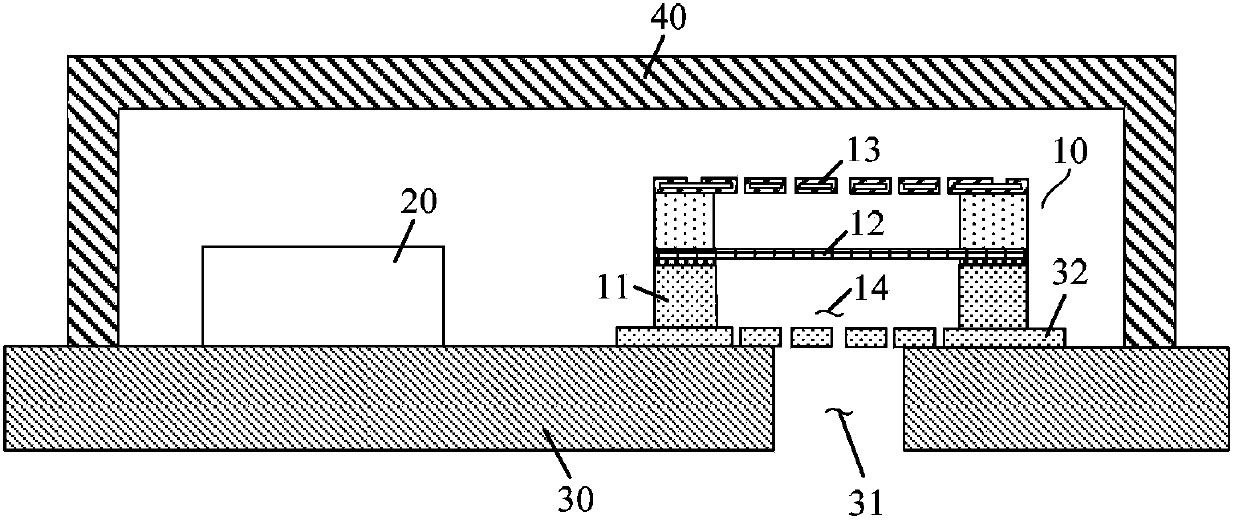

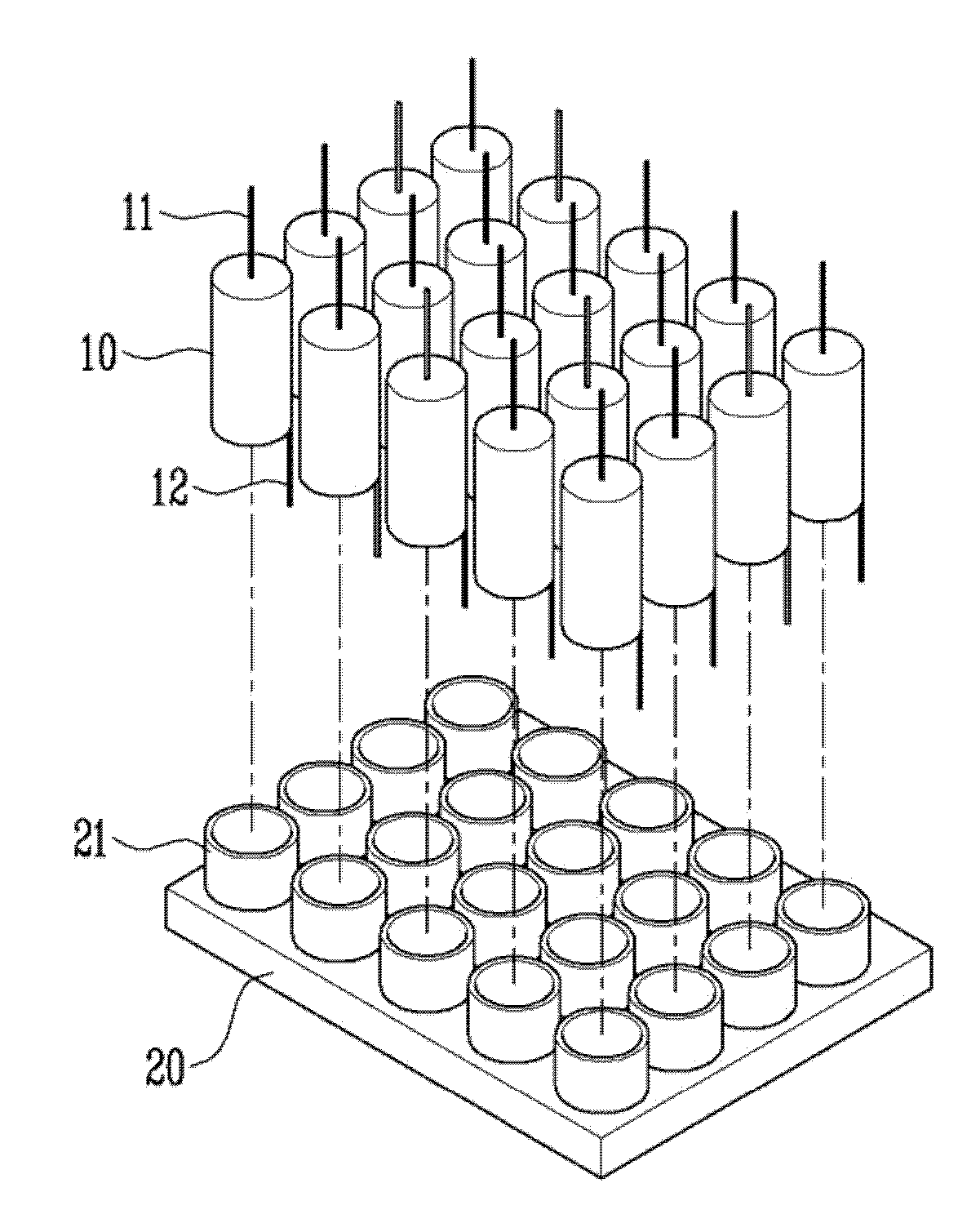

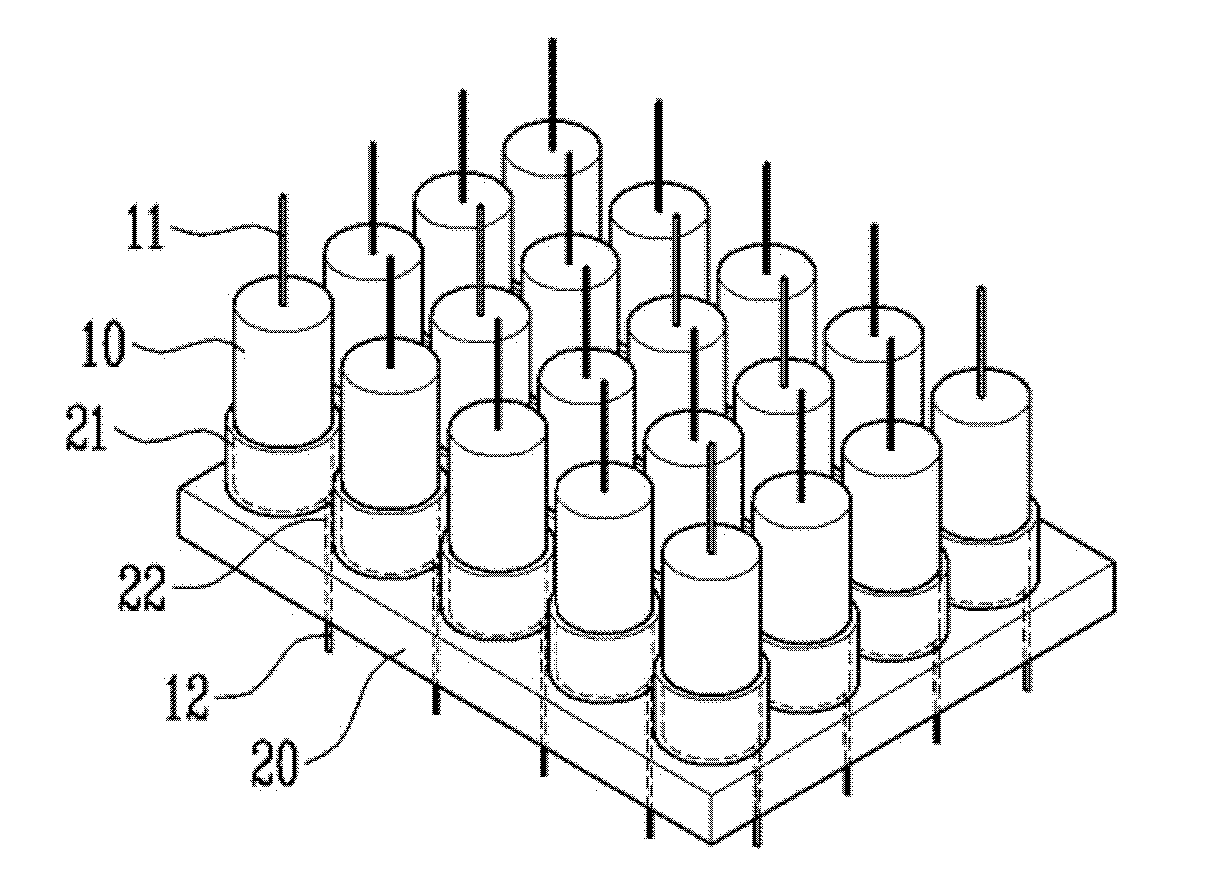

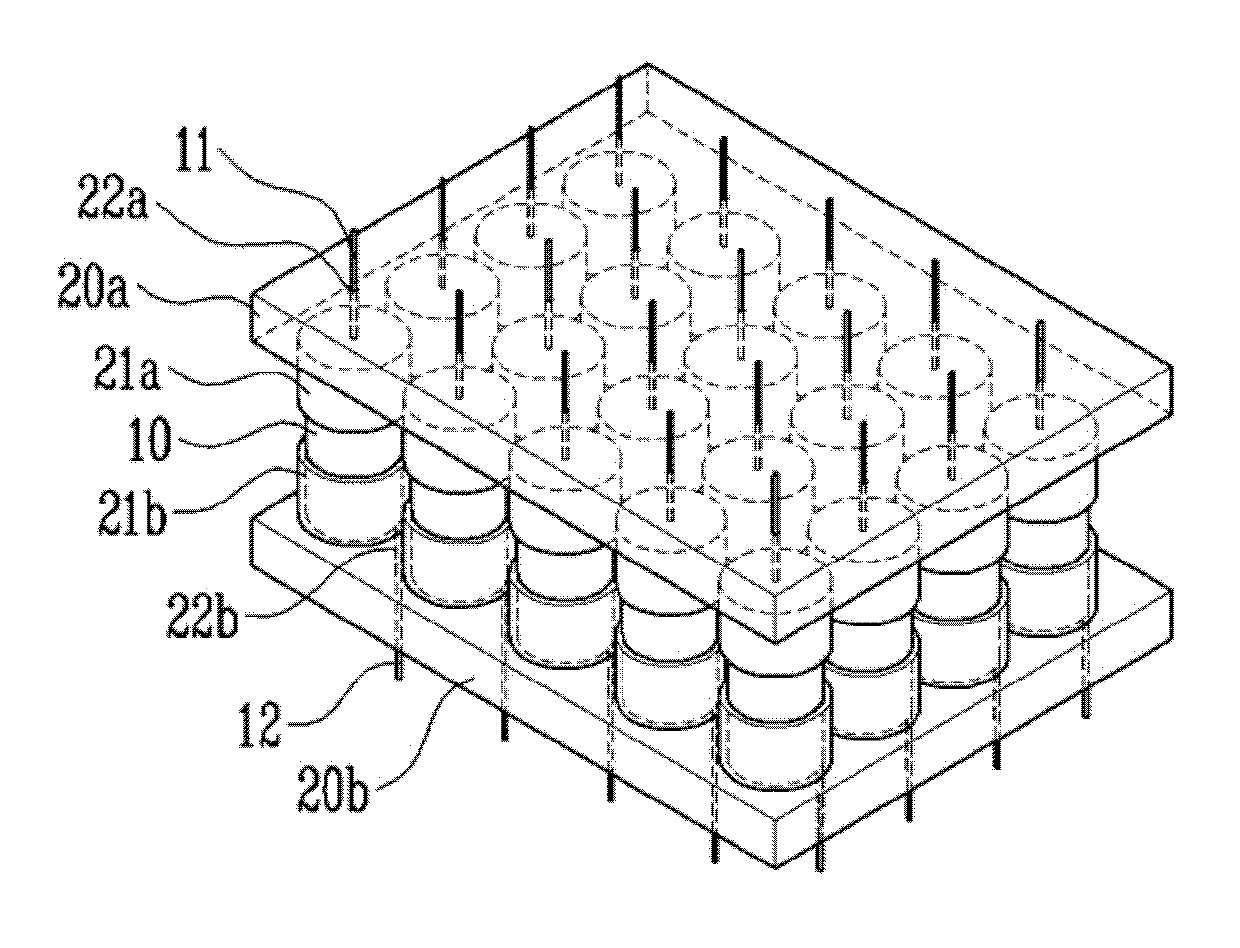

Battery module

InactiveCN102214806AAvoid deformationEasy to manufactureCell component detailsEngineeringElectrical and Electronics engineering

Battery modules have a plurality of electrode assemblies in which the electrode tabs of electrode assemblies are easily attached to the battery cases by a common insulator including receptacles for receiving the electrode assemblies. These configurations enable easy manufacture of medium- and large-sized battery modules with a plurality of electrode assemblies. In some embodiments, a battery module includes an insulator capable of mounting a plurality of electrode assemblies and receptacles in the insulator for receiving a portion of each electrode assembly.

Owner:SAMSUNG SDI CO LTD

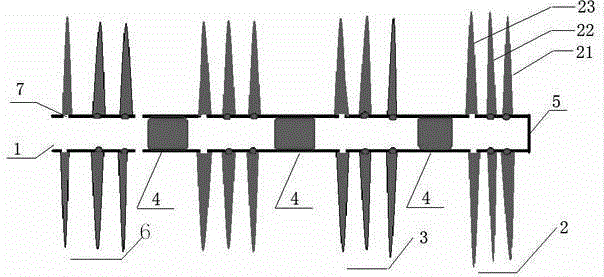

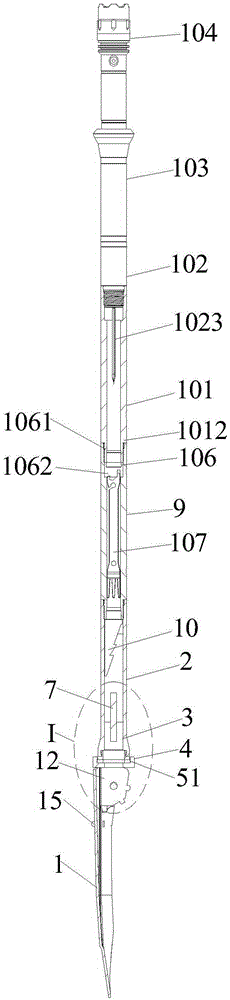

Shale gas horizontal well bridge plug separation and ball throwing segmented fracturing process

InactiveCN104989358AGood flow channelReasonable designFluid removalSealing/packingShale gasMaterial Perforation

The invention discloses a shale gas horizontal well bridge plug separation and ball throwing segmented fracturing process, which concretely comprises the following steps of: 1, draining, exploring and washing a well tube; 2, performing clustering perforation on a first segment; 3, performing fracturing construction on a first cluster; 4, throwing balls for sealing the first cluster; 5, repeatedly performing the fracturing construction, ball throwing and sealing steps in the third step and the fourth step on a second cluster, a third cluster to an N-th cluster; 6, sealing the first segment by a lower bridge plug, and performing clustering perforation on a second segment; 7, sequentially and repeatedly performing fracturing construction, ball throwing, sealing and lower bridge plug sealing steps in the third, fourth, fifth and sixth steps on the second segment to the N-th segment; and 8, performing sweeping grinding. The process method has the advantages that the design is reasonable; the construction cost is low; the optimum flowing passage of shale gas can be realized by adopting the process method; high economic return is obtained at high speed and high yield; and the fractures can be limited to the most economic positions.

Owner:中国石油化工股份有限公司华东分公司采油厂

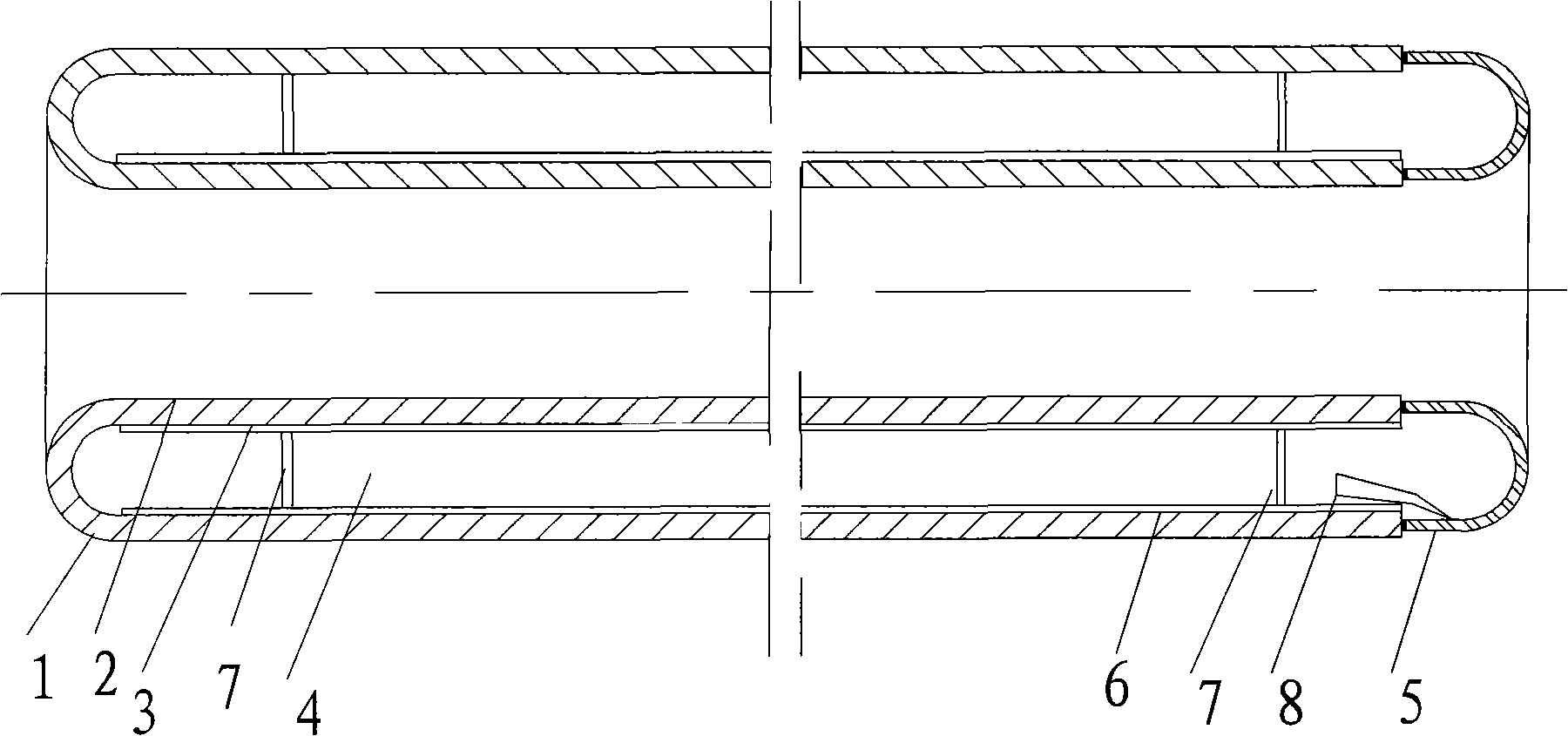

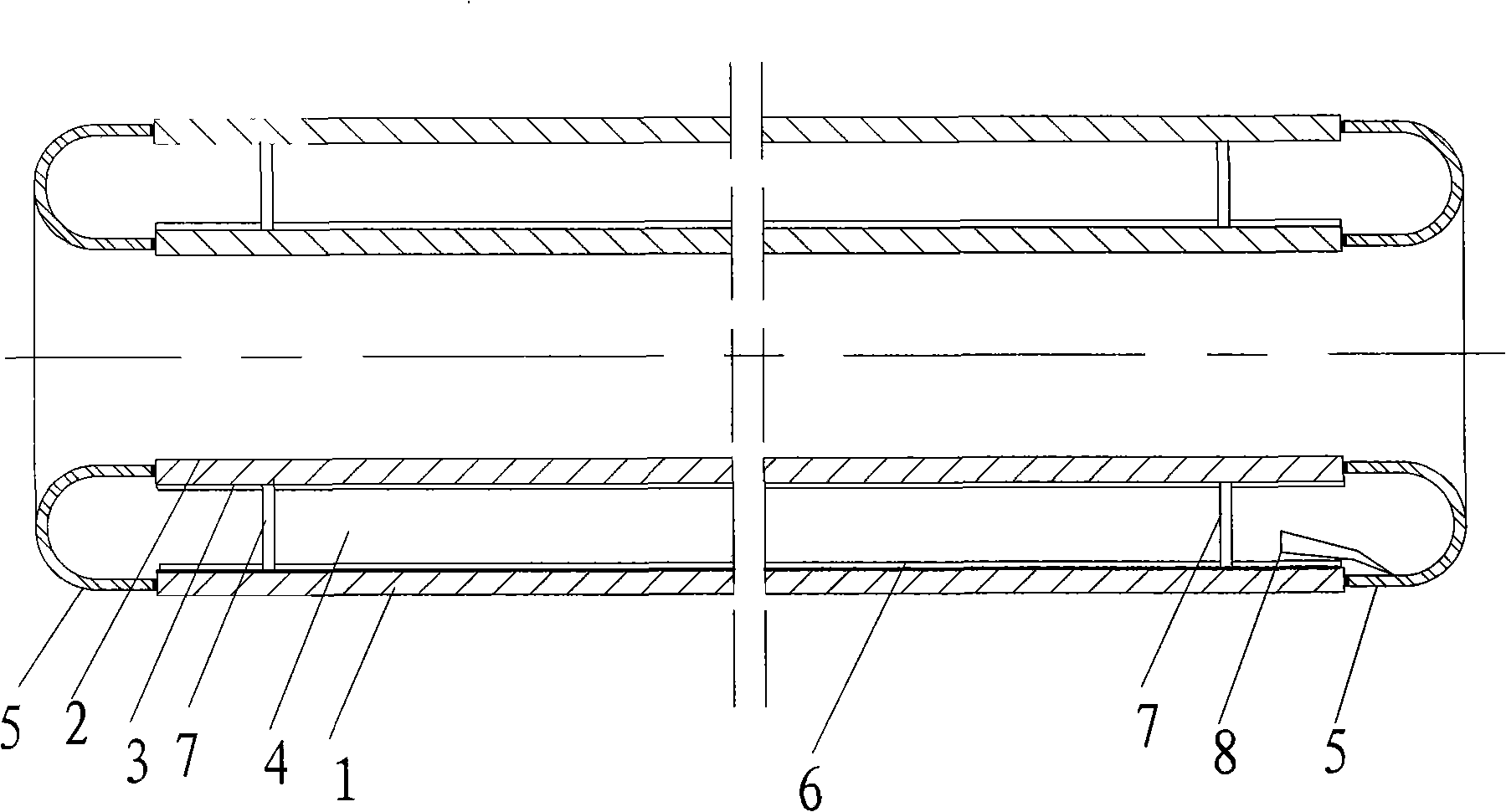

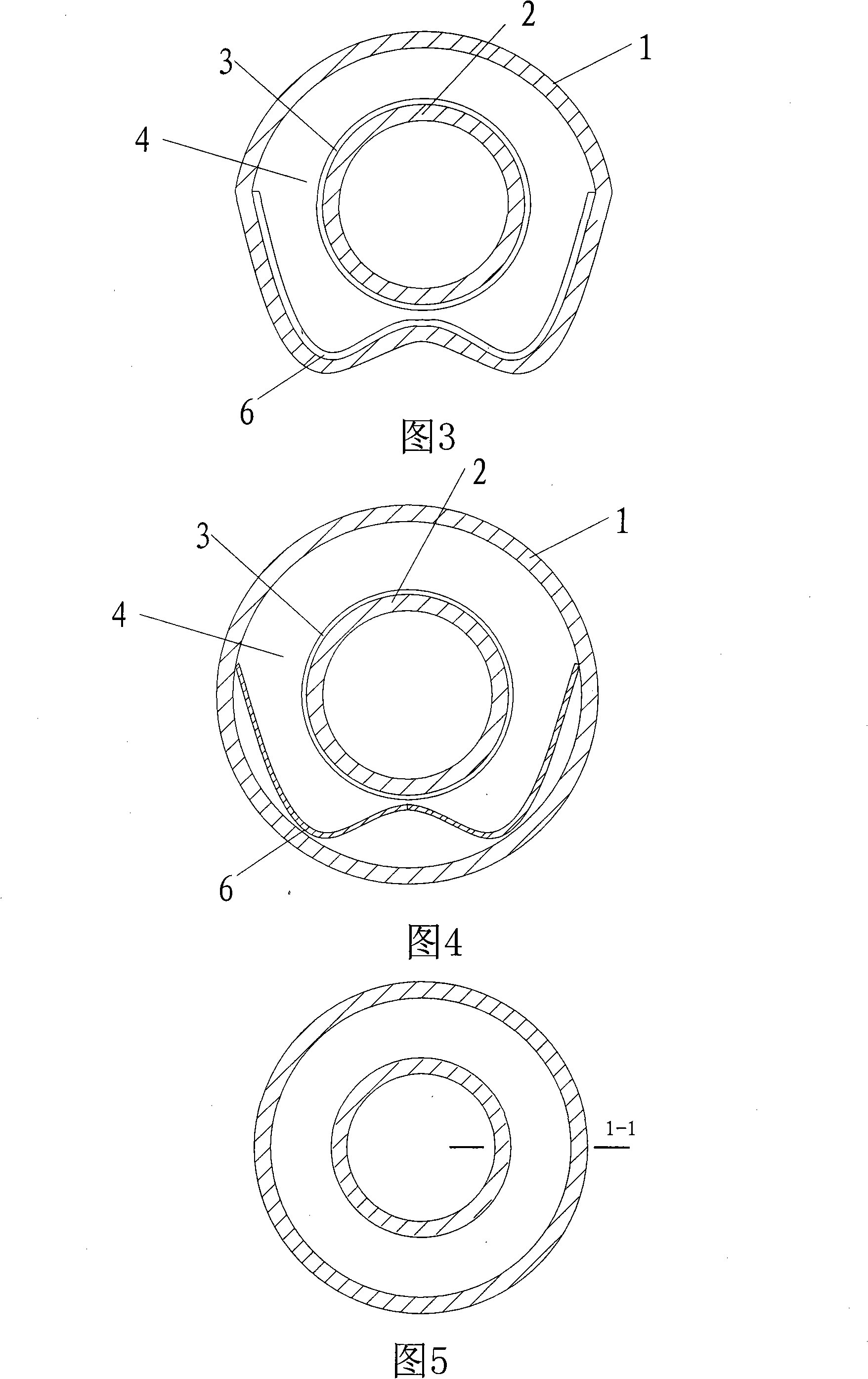

Straightthrough type double glazing vacuum solar heat collection tube

InactiveCN101256033AAvoid pipe burstGood effectSolar heating energySolar heat devicesGetterEngineering

Owner:SOUTHEAST UNIV

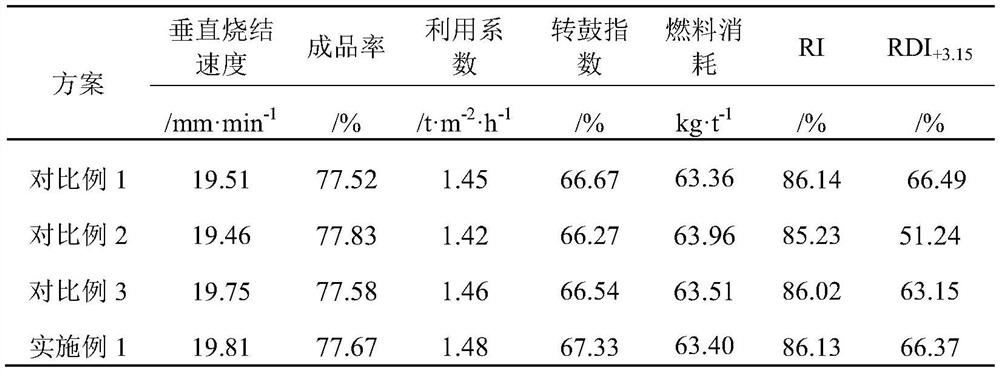

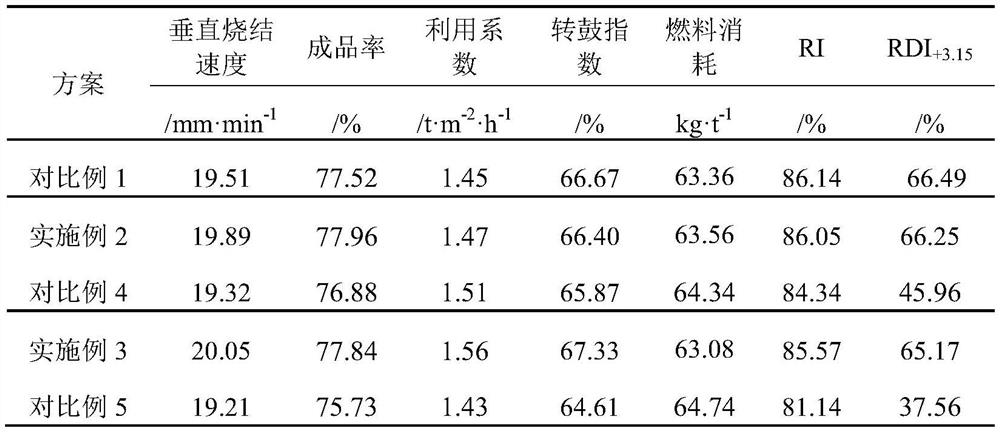

Method for treating spent catalyst by utilizing magnetite in sintering process

ActiveCN111763825AAffect productionRupture will notProcess efficiency improvementPtru catalystMetallurgy

The invention discloses a method for treating a spent catalyst by utilizing magnetite in a sintering process, and belongs to the technical field of catalyst recovery. The method comprises the following steps that pre-granulation on a spent catalyst containing TiO2 and magnetite is conducted, and adding is conducted to other sintering raw materials for sintering after pre-granulation. According tothe method, the TiO2 in the spent catalyst reacts with the magnetite to form a phase product which does not affect sintering quality, the sintering quality is guaranteed, and effective processing on the spent catalyst is further conducted.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Resin composition and optical element

There are provided a resin composition, which has optical properties such as a high refractive index, has excellent restorability and scratch resistance, and has good adhesion to a substrate, and, when utilized as an optical member (lens) used, for example, in screens for projection televisions or the like, can satisfy various property requirements, and a cured product of the resin composition. The resin composition comprises: an oligomer component comprising urethane (meth)acrylate, produced by reacting a bisphenol A polyalkoxydiol, an organic diisocyanate and a hydroxyl-containing mono(meth)acrylate, and a bisphenol A epoxy (meth) acrylate; a monomer component comprising a phenoxy polyethylene glycol (meth)acrylate and a bisphenol A polyethoxydiol di(meth)acrylate; and a photopolymerization initiator. The resin composition has a refractive index of not less than 1.55 after resin curing.

Owner:DAI NIPPON PRINTING CO LTD +1

Ceramic product and production method thereof

The invention belongs to the field of ceramic, and more specifically relates to a ceramic product and a production method thereof. The ceramic product comprises the following raw materials in parts by weight: 20-25 parts of bentonite, 5-8 parts of nano calcium carbonate, 10-15 parts of red feldspar, 15-18 parts of kaolin, 15-18 parts of potash feldspar, 10-15 parts of pyrophillite, 10-13 parts of wollastonite, 8-12 parts of blue feldspar, 6-10 parts of quartz, 10-13 parts of spodumene, 1-2 parts of chrome oxide, 3-5 parts of silicon carbide powder, and 2-4 parts of jade powder. The production method comprises the steps of weighing, grinding, filtering, drying, cleaning, glazing and sintering. The ceramic product has the advantages of small expansion coefficient, good toughness, wear resistance, and high intensity..

Owner:崔松伟

Low-shrinkage-expansion-rate ceramic product and preparing method thereof

InactiveCN106518036ASmall thermal shock resistanceImprove thermal shock resistancePyrophyllitePotassium

The invention particularly relates to a low-shrinkage-expansion-rate ceramic product and a preparing method thereof. The low-shrinkage-expansion-rate ceramic product is prepared from raw materials of, by weight, 5-8 parts of nanometer calcium carbonate, 10-15 parts of red feldspar, 15-18 parts of kaoline, 15-18 parts of potassium feldspar, 10-15 parts of pyrophyllite, 10-13 parts of wollastonite, 8-12 parts of blue feldspar, 6-10 parts of quartz, 10-13 parts of spodumene, 0.08-0.12 part of nanometer cerium oxide and 3-5 parts of silicon carbide. The preparing method comprises the steps of weighing, grinding, filtering, blank drying, washing, glazing and firing and the like. According to the method, the special optimal raw material formula is adopted, the thermal expansion coefficient of the low-shrinkage-expansion-rate ceramic product is low, the shrinkage rate is low in the ceramic forming process, thermal impact resistance is high, and cracking does not occur easily in the heat exchange process.

Owner:崔松伟

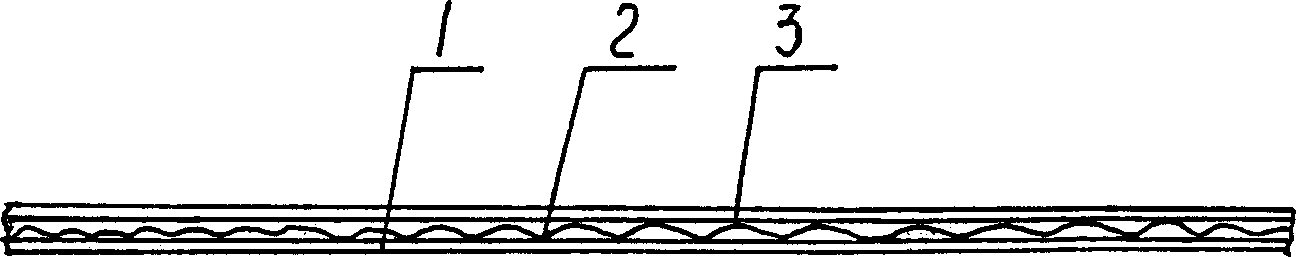

Canvas with steel screen

InactiveCN1903591AStrong crack resistanceStrong coloring powerOther artistic work equipmentsMetal layered productsAdhesiveHost material

Owner:张蓬勃

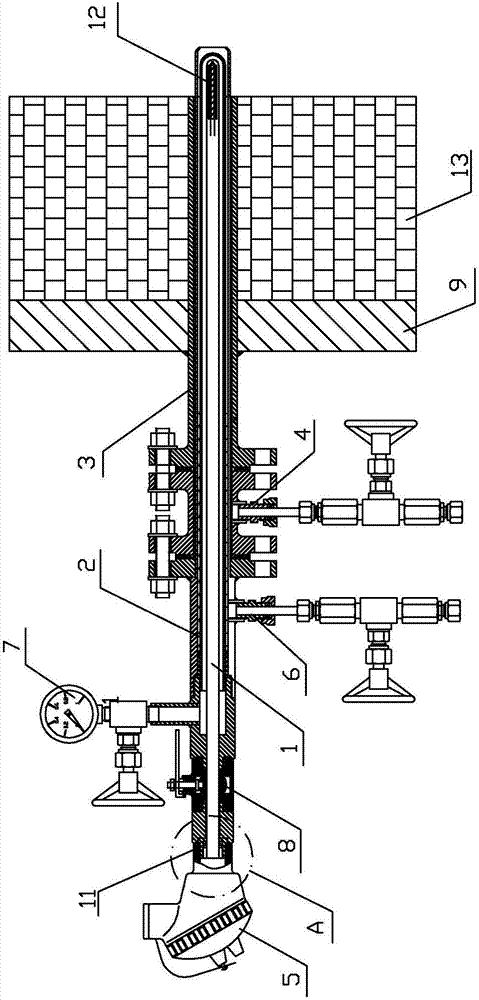

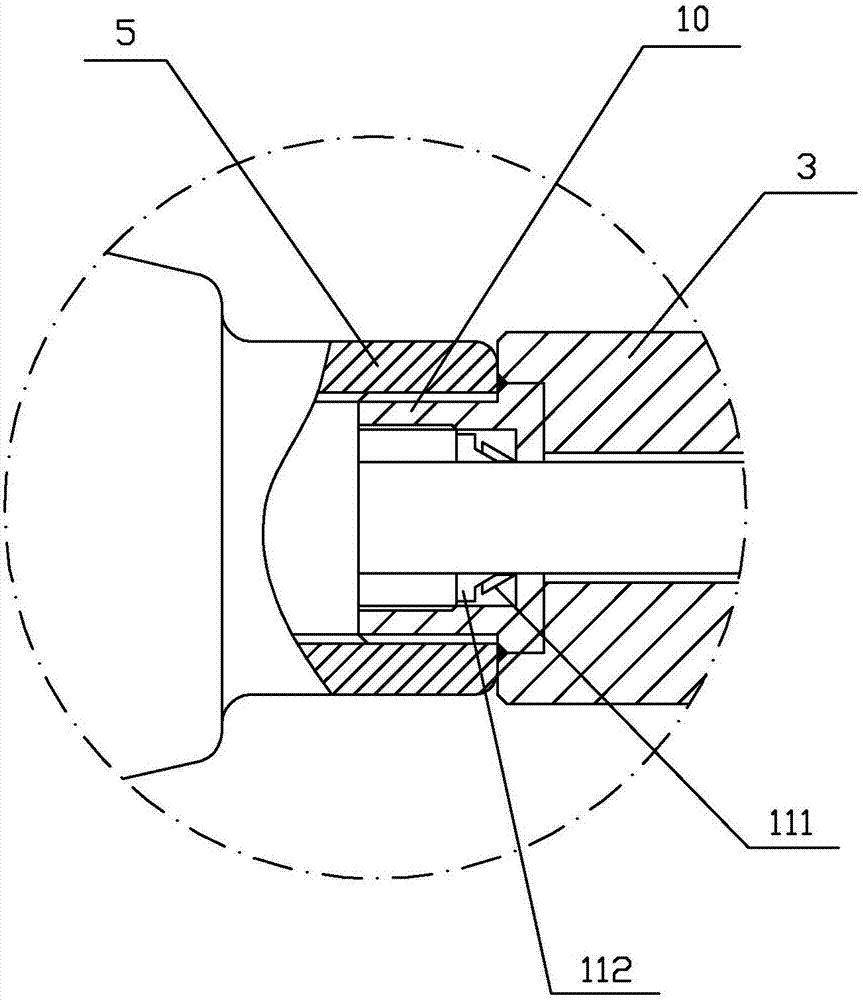

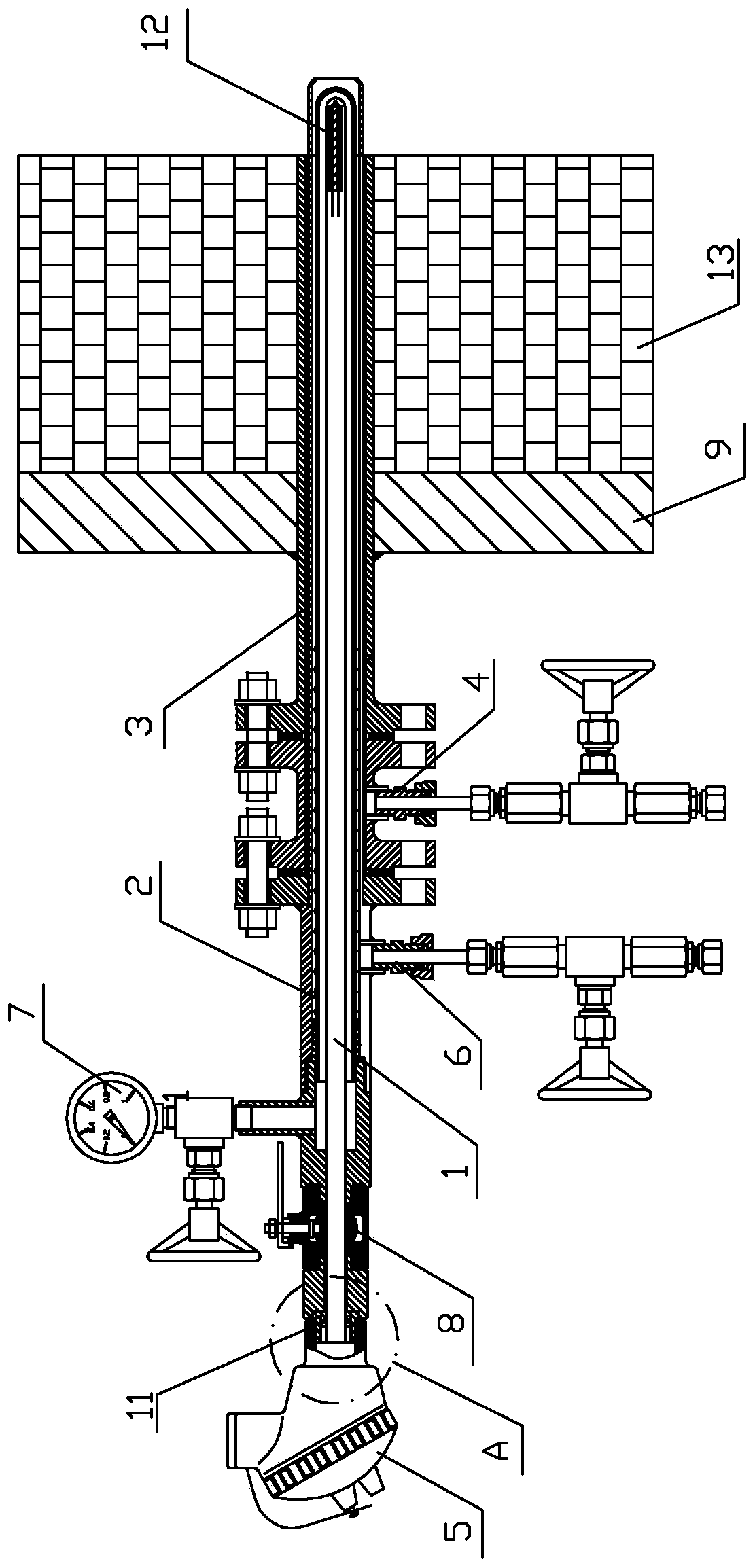

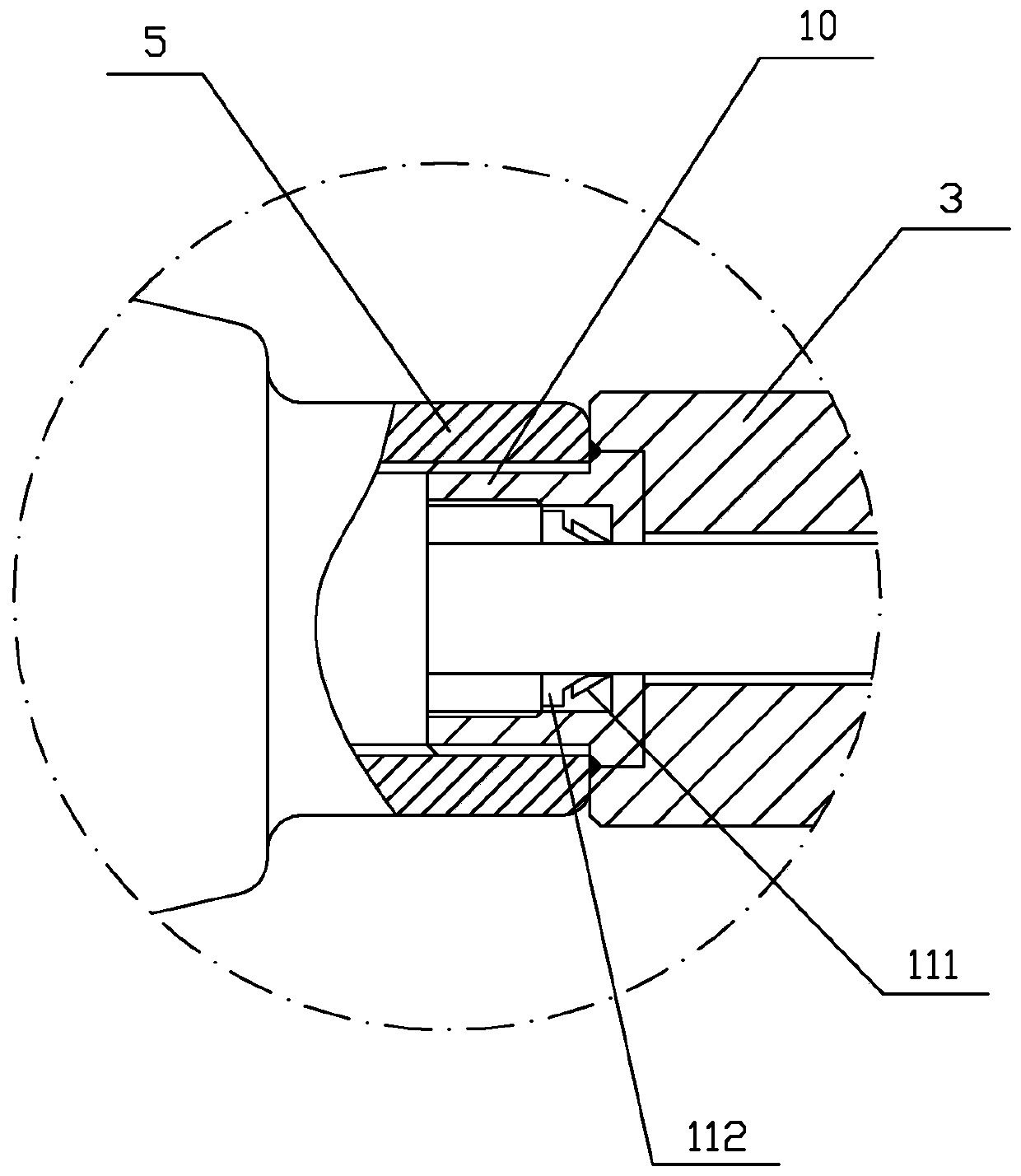

Online operation exchangeable thermocouple for testing temperature of sulphur furnace

ActiveCN107543628APrevent leakageExtended service lifeThermometer detailsThermometers using electric/magnetic elementsHydrogenCoupling

The invention relates to an online operation exchangeable thermocouple for testing the temperature of a sulphur furnace. The thermocouple includes a thermocouple and a protection bushing which sleevesthe thermocouple. The thermocouple which has the protection bushing extends into a sulphur furnace through a temperature testing support pipe which is installed in the sulphur furnace. The side surface of the temperature testing support pipe is provided with a first blowing interface and a second blowing interface which are disposed at intervals in front-rear direction. One ends of the first blowing interface and the second blowing interface are in communication with the temperature testing support pipe, and the other ends are connected a protection gas source. The rear end of the thermocouple is connected to a junction box which is in tight coupling with the temperature testing support pipe. The temperature testing support pipe between the protection bushing and the junction box is provided with a micropressure pressure gage thereon. The rear end of the temperature testing support pipe is provided with a rotary valve which can block the temperature testing support pipe. According tothe invention, the thermocouple can effectively prevent permeation and leakage of sulfuretted hydrogen, prolongs service life of thermocouple, increases accuracy in testing temperature, and since thethermocouple obviates the need for suspending the work of the furnace for exchanging the thermocouple, the operation period is prolonged and the production efficiency is greatly increased.

Owner:杭州亿泰自控设备有限公司

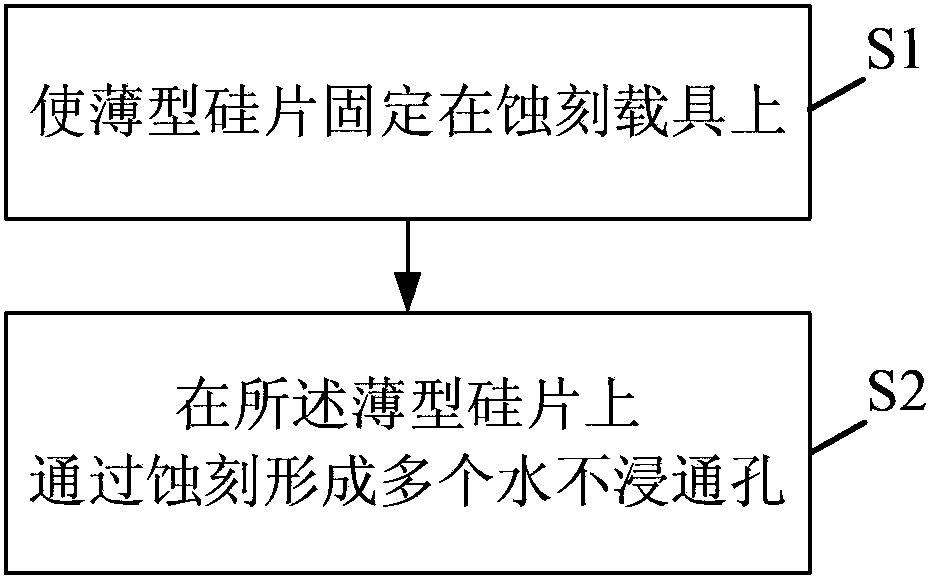

Method for manufacturing waterproof sheets of microphones

The invention provides a method for manufacturing waterproof sheets of microphones. The method comprises the steps of a) fixing thin silicon wafers on etching carriers; b) forming a plurality of water-impermeable through holes on the thin silicon wafers through etching. The waterproof sheets of the microphones, which are manufactured according to the method, are good in structural integrity, good in waterproof performance, good in sound effect, thin and accurate in thickness, resistant to high-temperature backflows and good in batch productivity.

Owner:GOERTEK INC

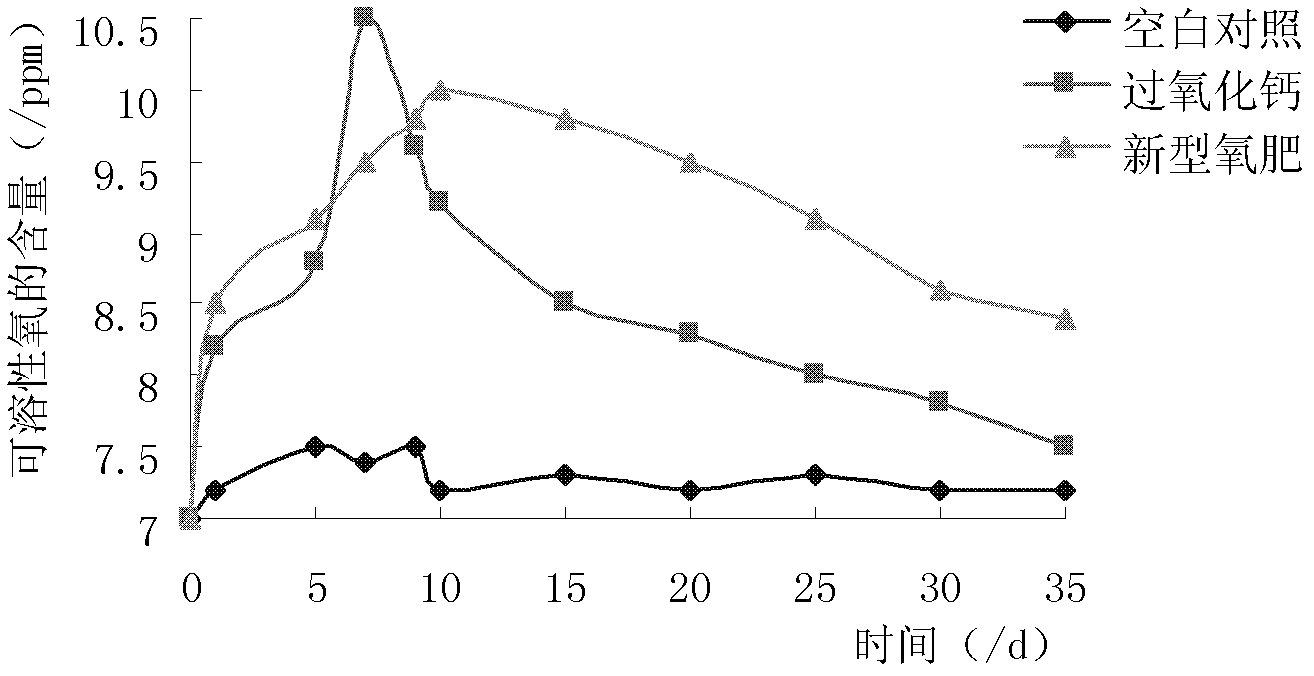

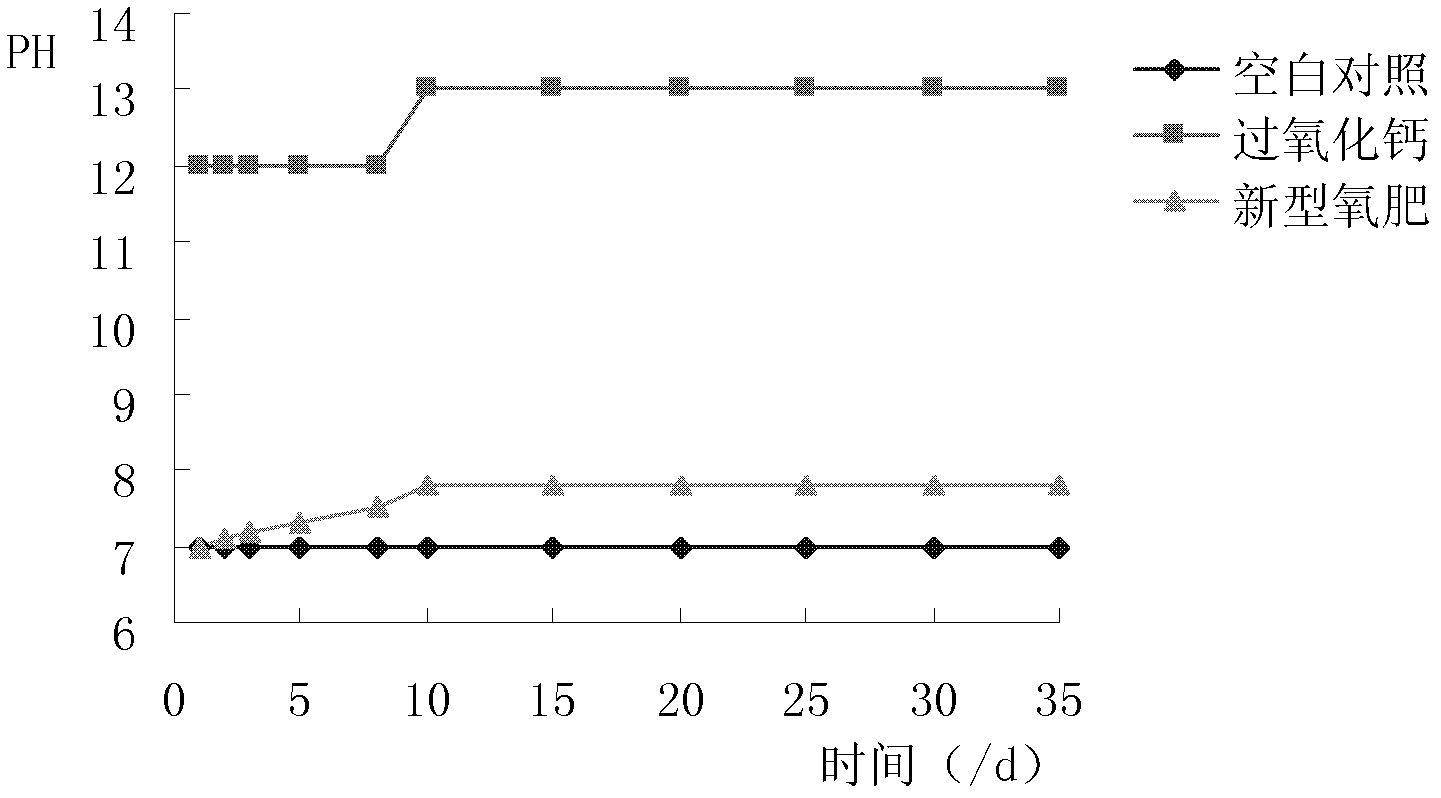

Oxygen fertilizer and preparation and application methods thereof

InactiveCN102584466BLift deathReduce economic costsFertilizer mixturesOxygen preparationParaffin oilsSodium oxide

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

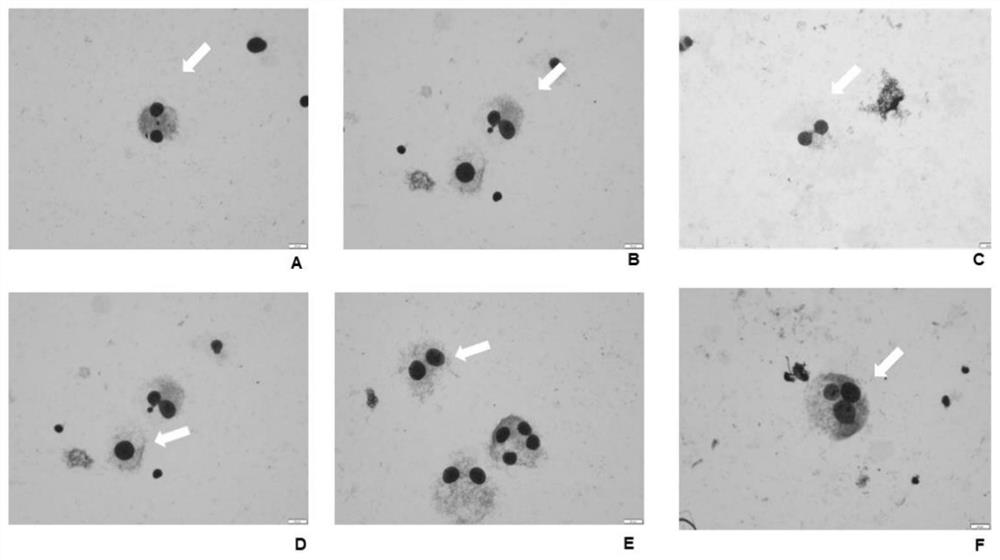

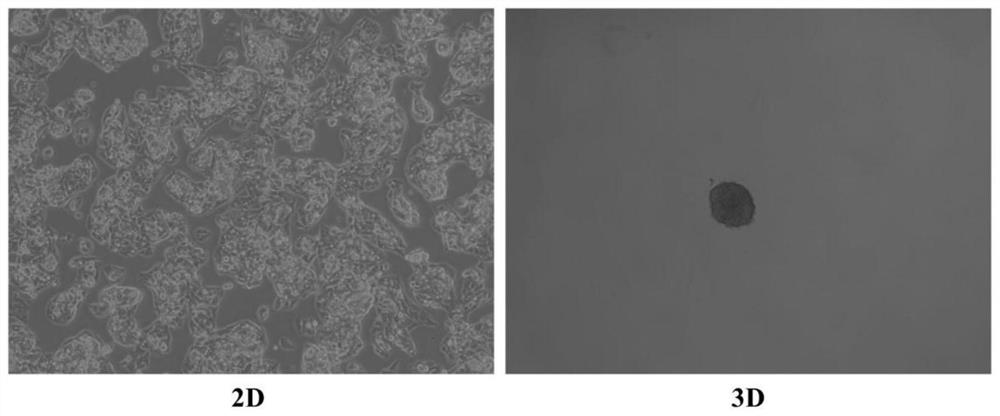

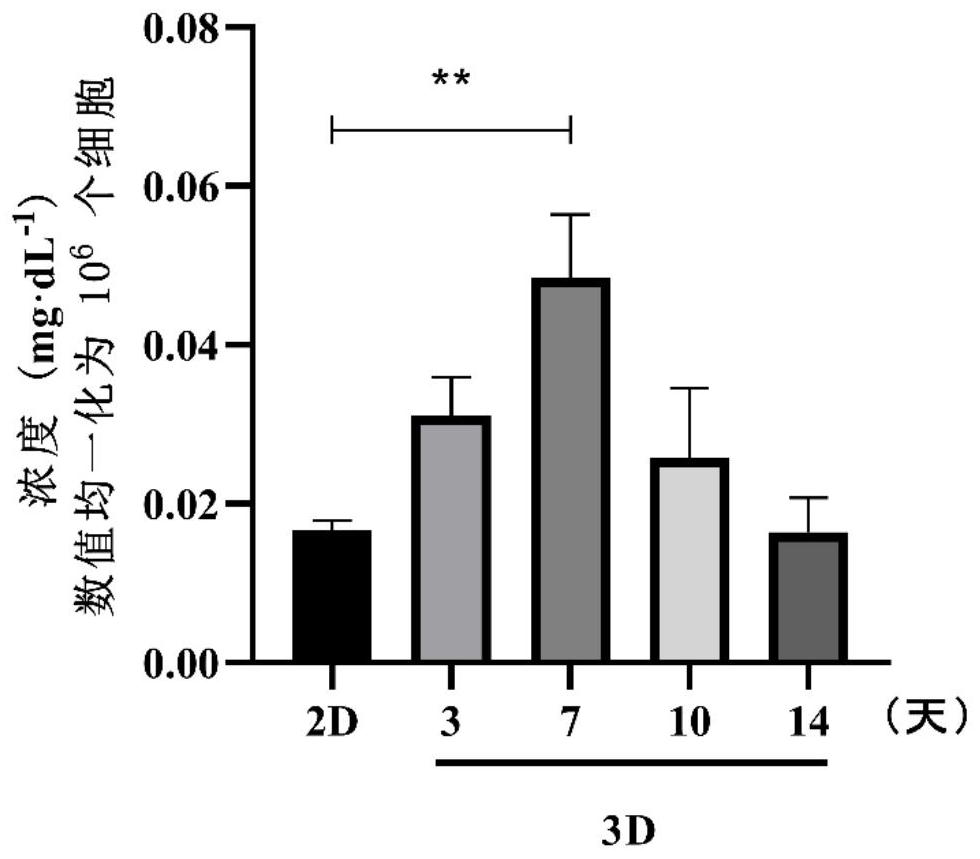

Method for detecting genetic toxicity by using 3D hepatocyte in-vitro micronucleus cells

ActiveCN113774106AFully digestedGuaranteed accuracyCell dissociation methodsMicrobiological testing/measurementChemical compoundPharmaceutical drug

The invention discloses a method for detecting genetic toxicity by using 3D hepatocyte in-vitro micronucleus cells. The method comprises the following steps of (1) constructing a 3D hepatocyte model in vitro by using common humanized hepatocytes HepG2 as a cell material by adopting a scaffold-free culture method combining hanging drops and ultra-low adsorption culture; and (2) carrying out micronucleus cell detection on a compound by using the 3D hepatocyte model, and analyzing the genetic toxicity mechanism of the compound. The in-vitro detection method can be used for analyzing various genetic toxicity mechanisms of the compound, improving the capability of predicting the genetic toxicity of drugs by an in-vitro cell model and providing information related to human body tests.

Owner:SHANGHAI INNOSTAR BIO TECH

Heat-resisting high-strength ceramic product and preparation method thereof

The invention belongs to the ceramic field, and particularly relates to a heat-resisting high-strength ceramic product and a preparation method thereof. The heat-resisting high-strength ceramic product is made from the following raw materials by weight: 20-30 parts of aluminum oxide, 10-15 parts of nano calcium carbonate, 5-10 parts of red feldspar, 5-10 parts of kaolin, 20-25 parts of potash feldspar, 5-8 parts of wollastonite, 10-15 parts of blue feldspar, 10-15 parts of quartz, 5-8 parts of chromium hemitrioxide, 15-20 parts of spodumene, and 1-1.5 parts of nano cerium oxide. The preparation method comprises the steps of weighing, grinding, filtering, drying a blank, washing, glazing, firing and so on. The ceramic product has the characteristics of low coefficient of thermal expansion, and strong thermal shock resistance, is not easily broken in the heat exchange process, and can be used under the harsh environment.

Owner:崔松伟

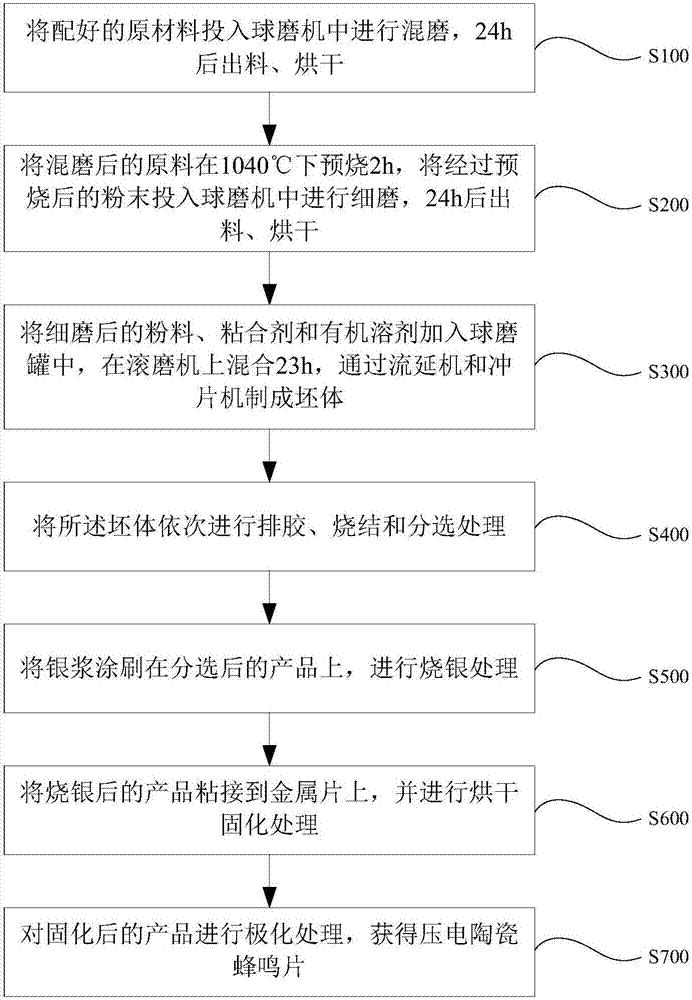

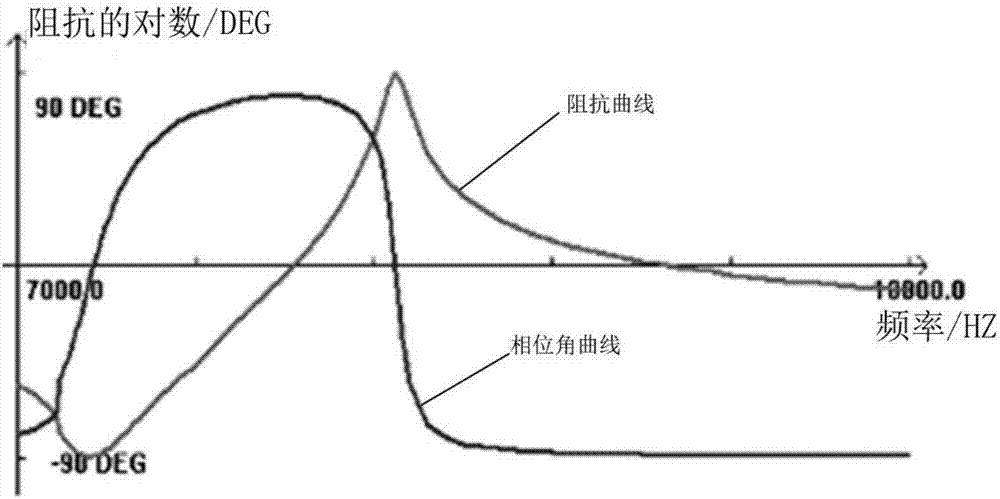

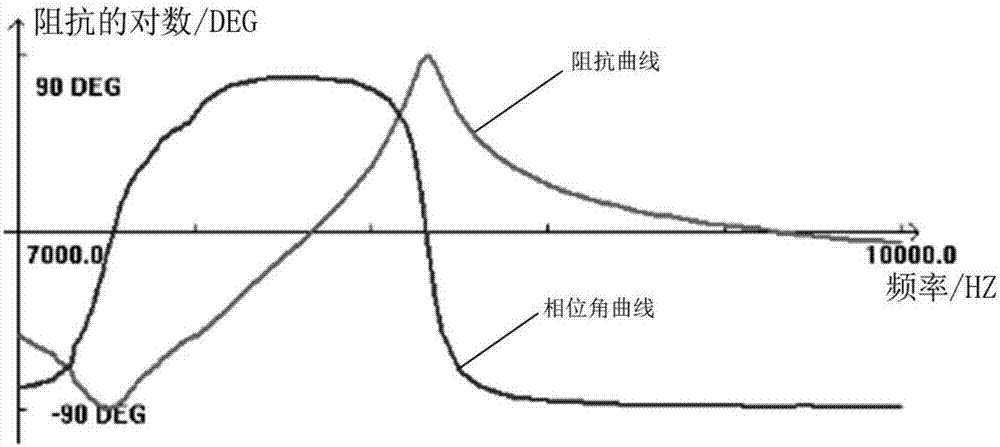

Manufacturing process of small-sized thin buzzer piece

ActiveCN107473773AReduce processing difficultyImprove pass ratePiezoelectric/electrostrictive device manufacture/assemblySilver pasteSilver ink

The application discloses a manufacturing process of a small-sized thin buzzer piece. The manufacturing process comprises the following steps: throwing raw materials for manufacturing the buzzer piece into a ball mill to be mixed and milled, and performing discharging and drying after 24 h; pre-burning the mixed and milled raw materials at 1,040 DEG C for 2 h, and finely grinding pre-burned powder; performing mixed barreling on the finely ground powder, a binder and an organic solvent, and making the obtained slurry into a green body through a casting machine and a sheet-punching machine; sequentially performing rubber discharging, sintering and fragmenting treatment on the green body; brushing segmented products with a silver paste, and performing silver ink firing treatment; adhering the products subjected to silver ink firing to a metal sheet, and performing drying and curing; and polarizing the cured product to obtain a piezoelectric ceramics buzzer piece. According to the manufacturing process provided by the application, the technological order of polarization and adhesion in a conventional process are reversed, the manufactured piezoelectric ceramics buzzer piece is thicker than a buzzer piece manufactured by the conventional process, the product reliability is not influenced, the technological difficulty in producing the small-sized thin buzzer piece is reduced, the qualification rate is greatly improved, and waste is avoided.

Owner:HUNAN JIAYEDA ELECTRONICS

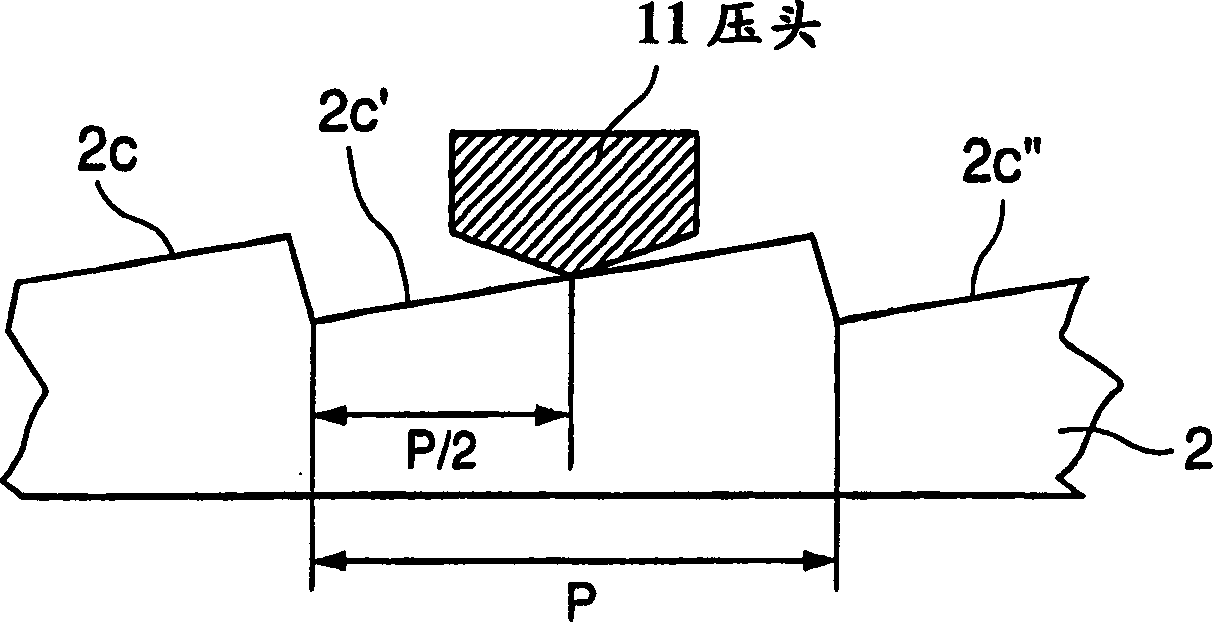

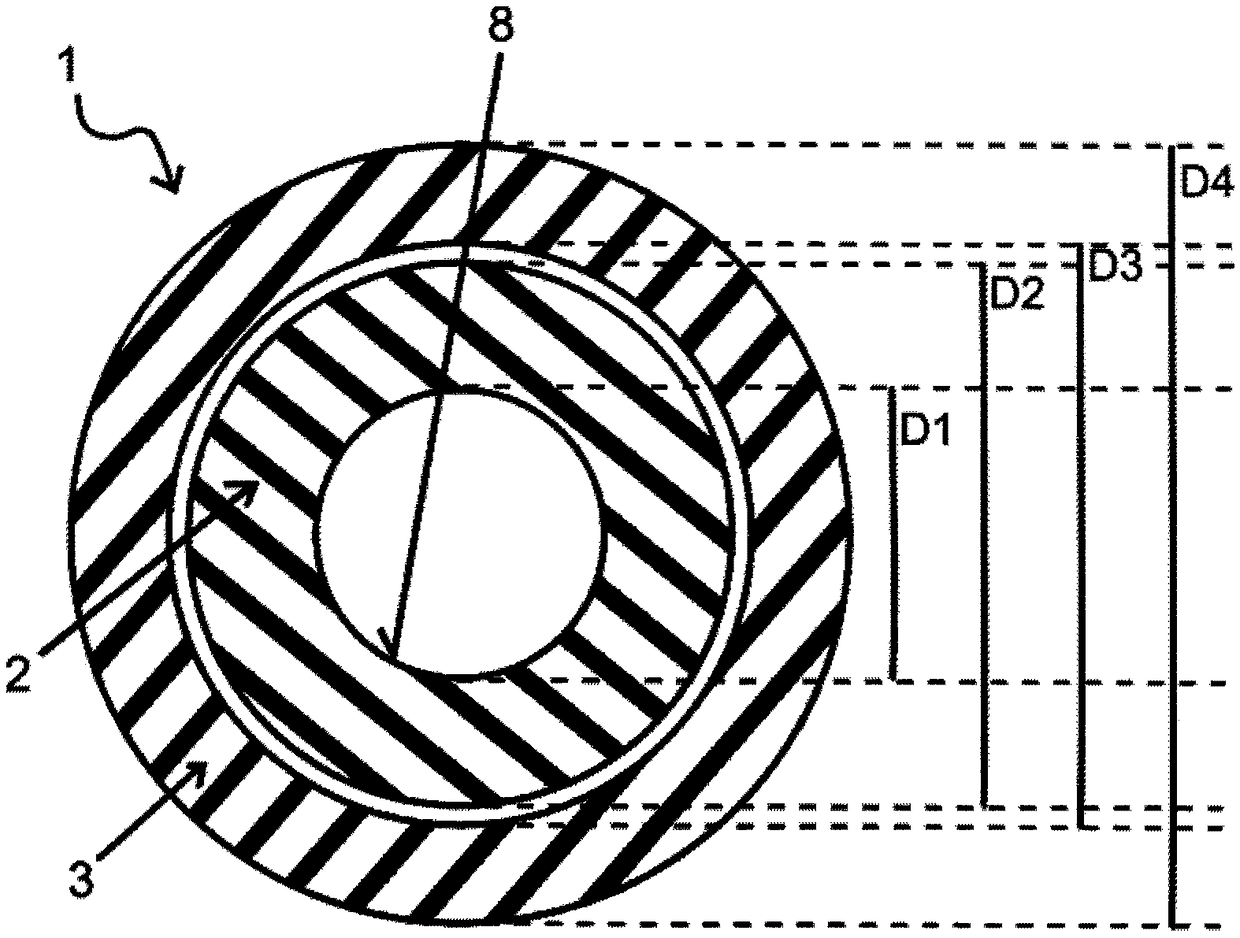

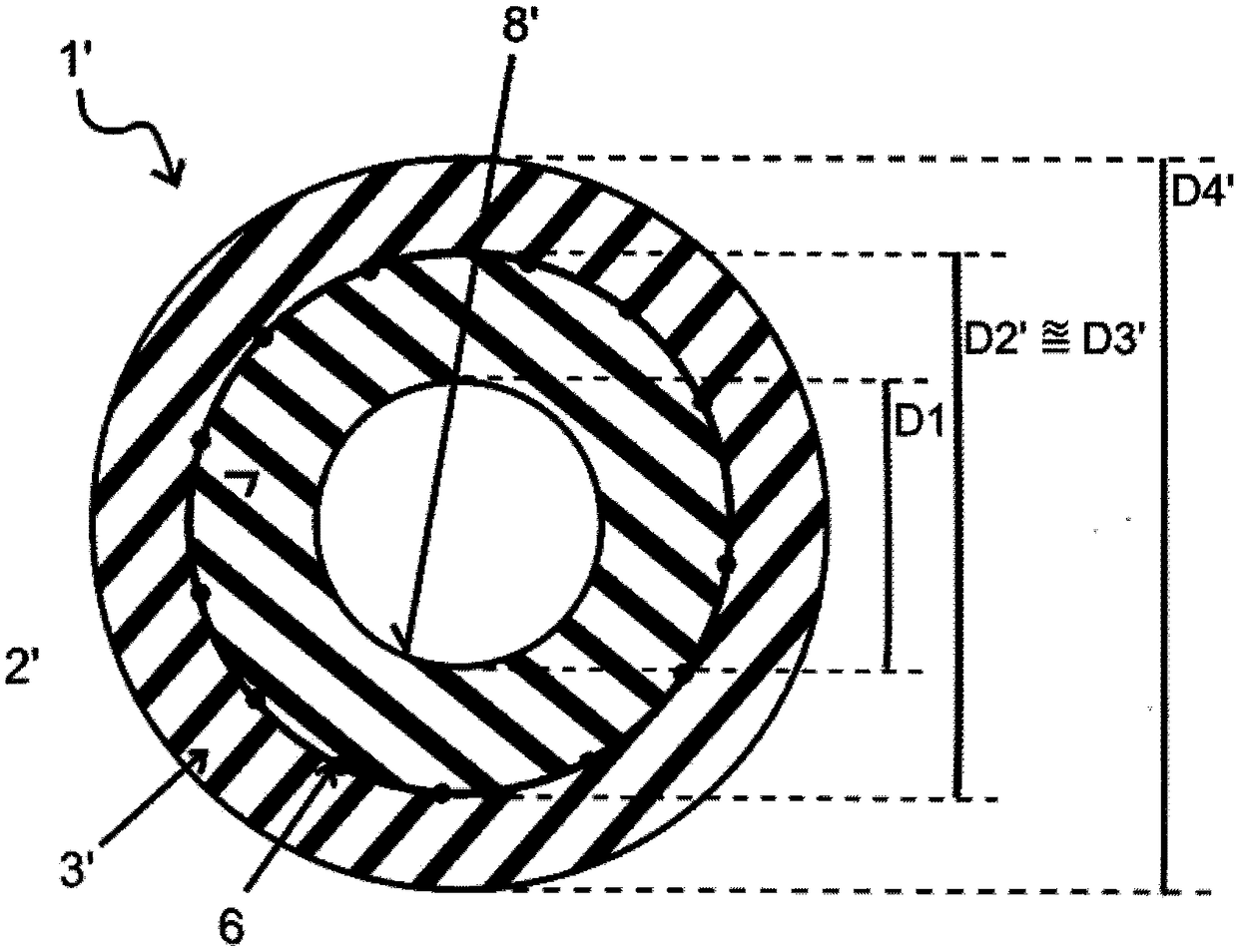

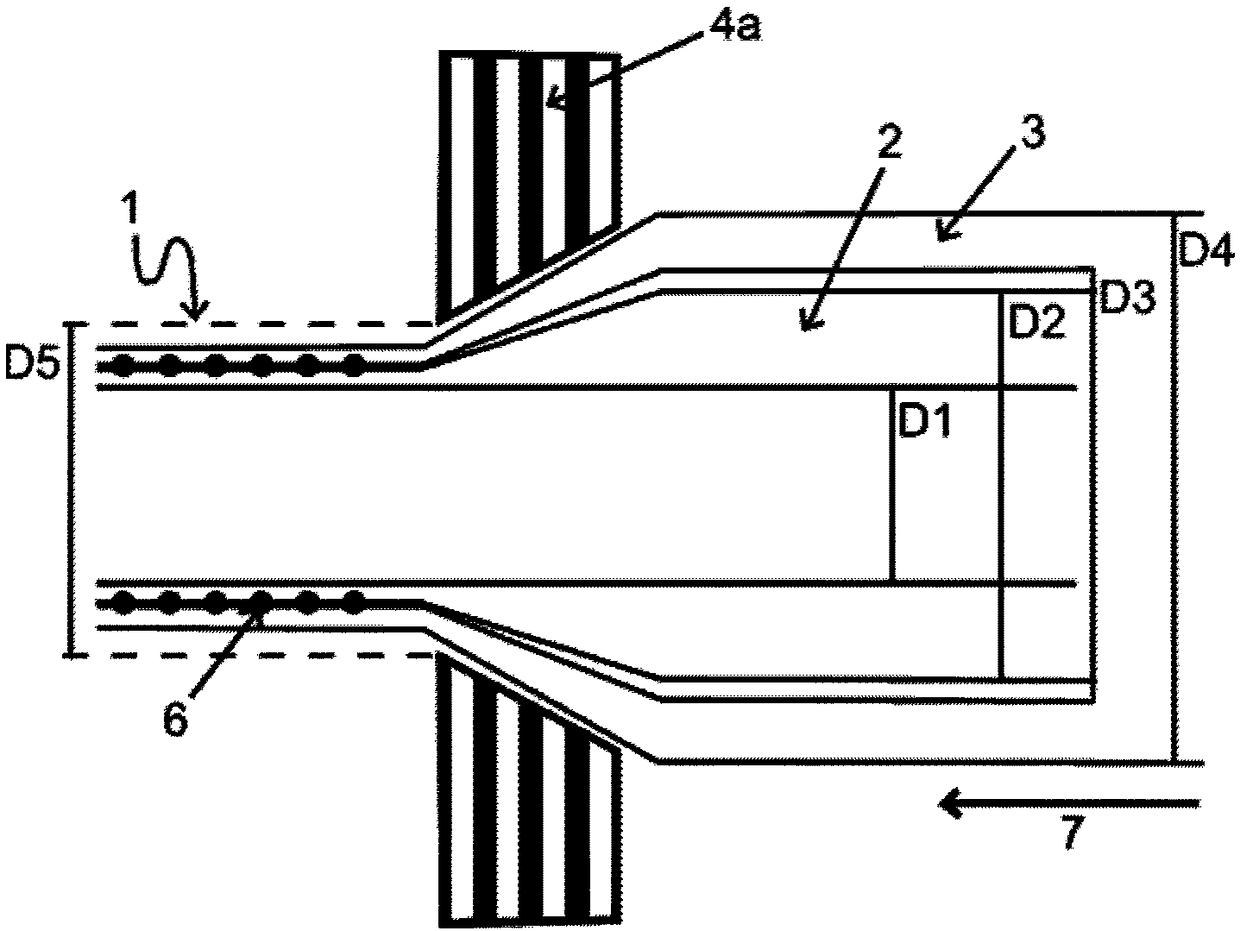

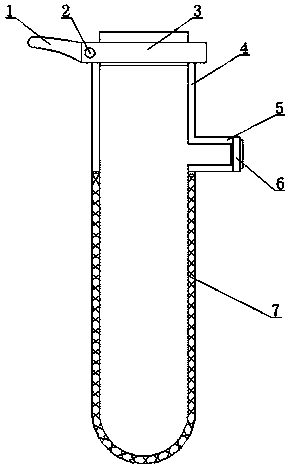

Method for producing high-pressure pipe

PendingCN108463295AImprove protectionImprove stress resistanceCorrosion preventionPipe protection against corrosion/incrustationEngineeringHigh pressure

The invention relates to a method for producing a high-pressure pipe (1). An inner pipe (2) made of metal and an outer pipe (3) made of metal are drawn together through a first drawing die (4a). The outer diameter (D2) of the inner pipe is smaller than the inner diameter (D3) of the outer pipe. By drawing the outer pipe and the inner pipe, which extends in the outer pipe, together through the first drawing die, a very stable force-fitting connection is produced between the inner pipe and the outer pipe. As a result, a pipe is produced with a large wall thickness, by means of which the producedpipe is very robust and pressure-resistant while having a very high quality outer lateral surface and in particular a very high quality inner lateral surface by virtue of the cold forming process. These two properties allow a sufficiently high protection of the pipe to be produced against bursting when pressures in excess of 12,000 bar are applied to the pipe. Accordingly, the method according tothe invention is particularly suitable for producing a pipe with clearly improved dynamic pressure resistance against high pressures by combining a large wall thickness of the pipe to be produced with a high quality inner lateral surface of the pipe to be produced.

Owner:SANDVIK MATERIALS TECH DEUTLAND

Bamboo joint earthen pot production process

PendingCN113493307ASolution to short lifePrecise content of ingredientsClaywaresMining engineeringTitanium

The invention provides a bamboo joint earthen pot production process. The product comprises the following components in percentage by weight: 68.8%-75.52% of silicon, 19.59%-26.38% of aluminum, 0.66%-1.5% of iron, 0.09%-1% of titanium, 0.04%-0.5% of calcium, 0.08%-0.5% of magnesium, 0.34%-1% of potassium, 0.01%-0.1% of sodium and 1.39%-2.5% of lithium. The process comprises the steps of grinding, high-pressure forming, turning table forming, glazing, firing and the like. The components of the earthen pot are limited in a more accurate percentage mode, the earthen pot is integrally fired and formed through combination and arrangement of the production process, different colors are presented in cooperation with glaze, the service life of the earthen pot is longer, the earthen pot is more attractive, and especially the earthen pot cannot be broken when fired on fire at 400 DEG C.

Owner:台宜陶瓷(宜兴)有限公司

A core-shell type silicon-containing synergistic flame retardant and preparation method thereof

Owner:UNIV OF SCI & TECH OF CHINA

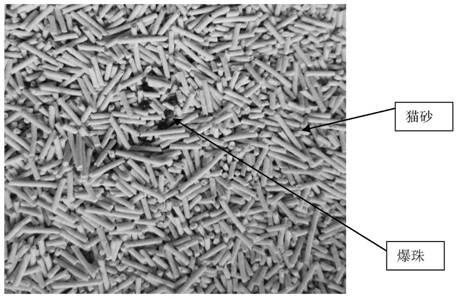

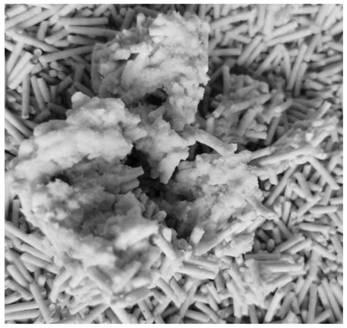

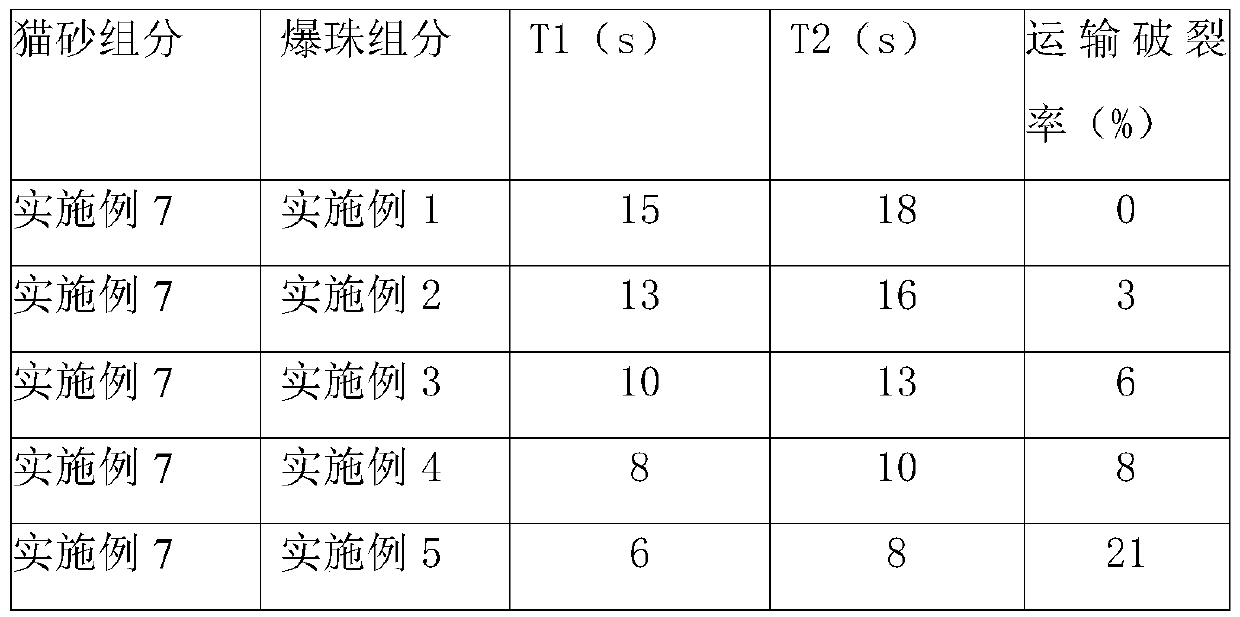

Deodorization blast bead, deodorization animal sand and manufacturing method thereof

ActiveCN111498920AQuality is not affectedAchieve deodorizing effectSpecific water treatment objectivesAnimal housingCarrageenanMedicine

The invention relates to a deodorization blasting bead, a deodorization cat litter and a manufacturing method thereof; the deodorization blasting bead comprises a rubber skin and a wrapping liquid, and the compressive strength of the deodorization blasting bead is 0.4-1 Pa; the rubber skin comprises konjac glucomannan or guar gum or agar or carrageenan or xanthan gum or the like, and the deodorizing blast bead is applied to deodorizing animal sand. After encountering urine, the blasting bead is broken, the liquid in the bag is released for deodorization, and the effect is good. By controllingthe pressure resistance of the blasting bead, the blasting bead is broken when encountering urine, the urine is dissolved and absorbed within 15-20 s, then the deodorization effect is achieved, and meanwhile breakage cannot be caused in the transportation process, so that the product quality is not affected.

Owner:宜昌市宠冠宠物用品有限公司

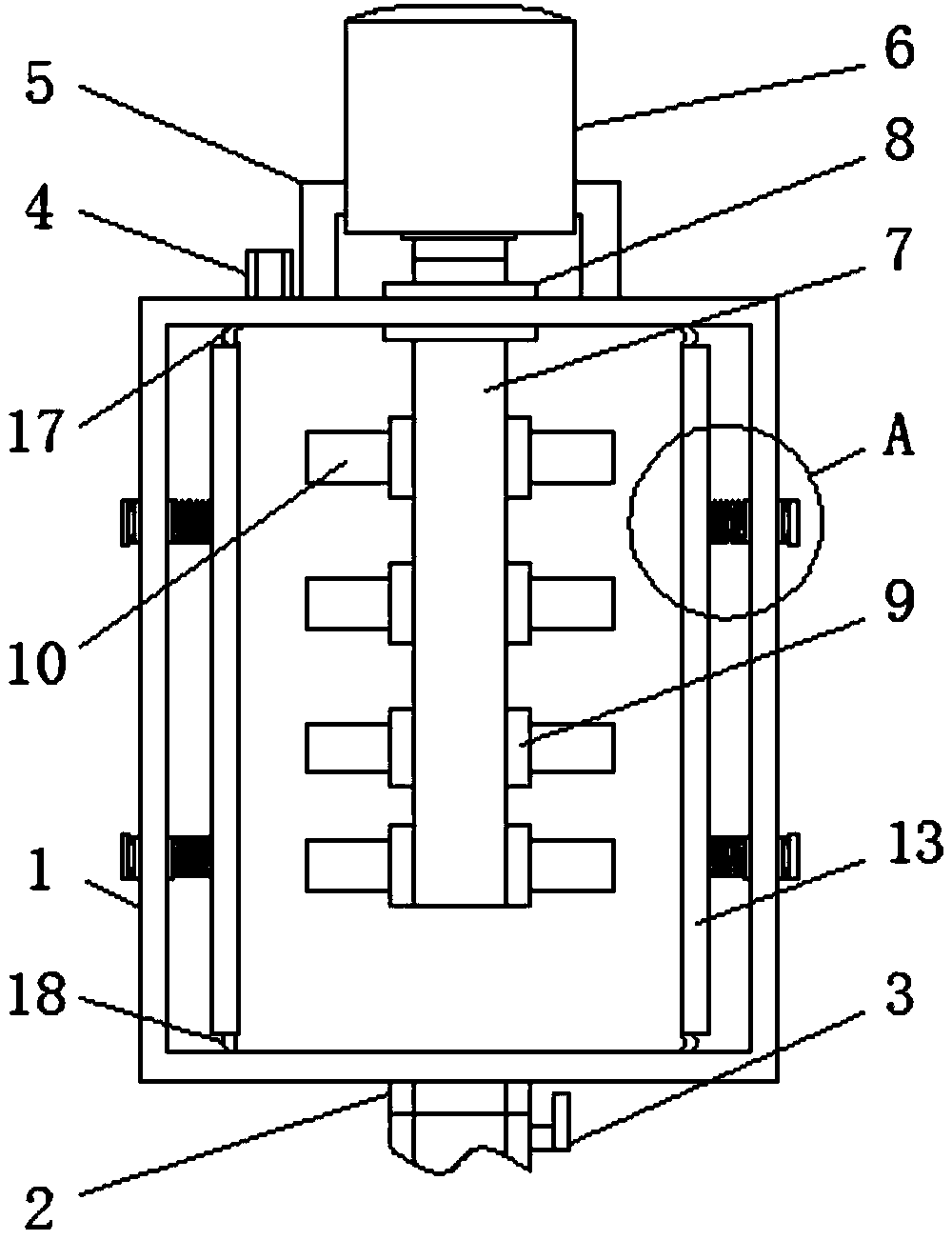

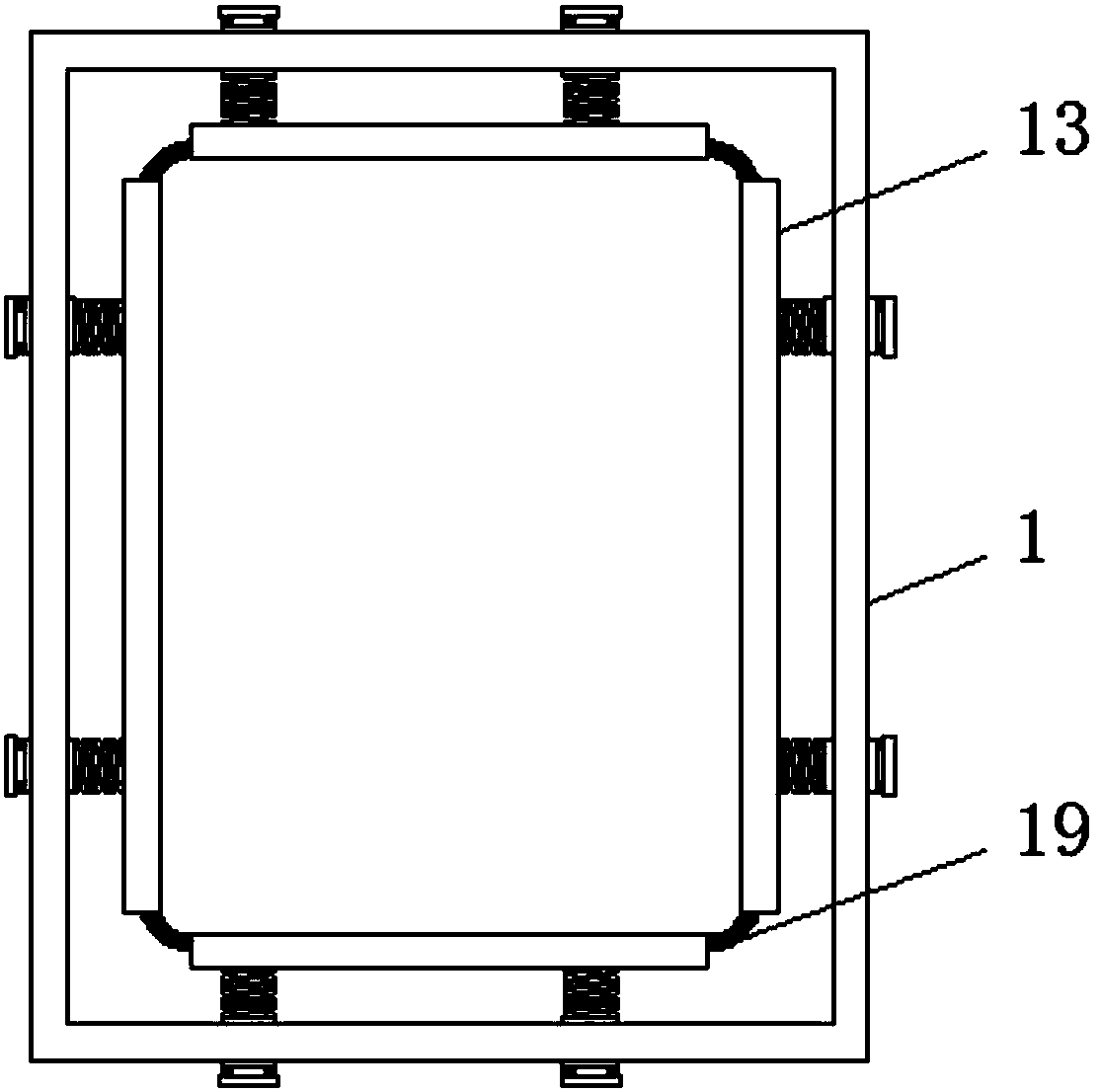

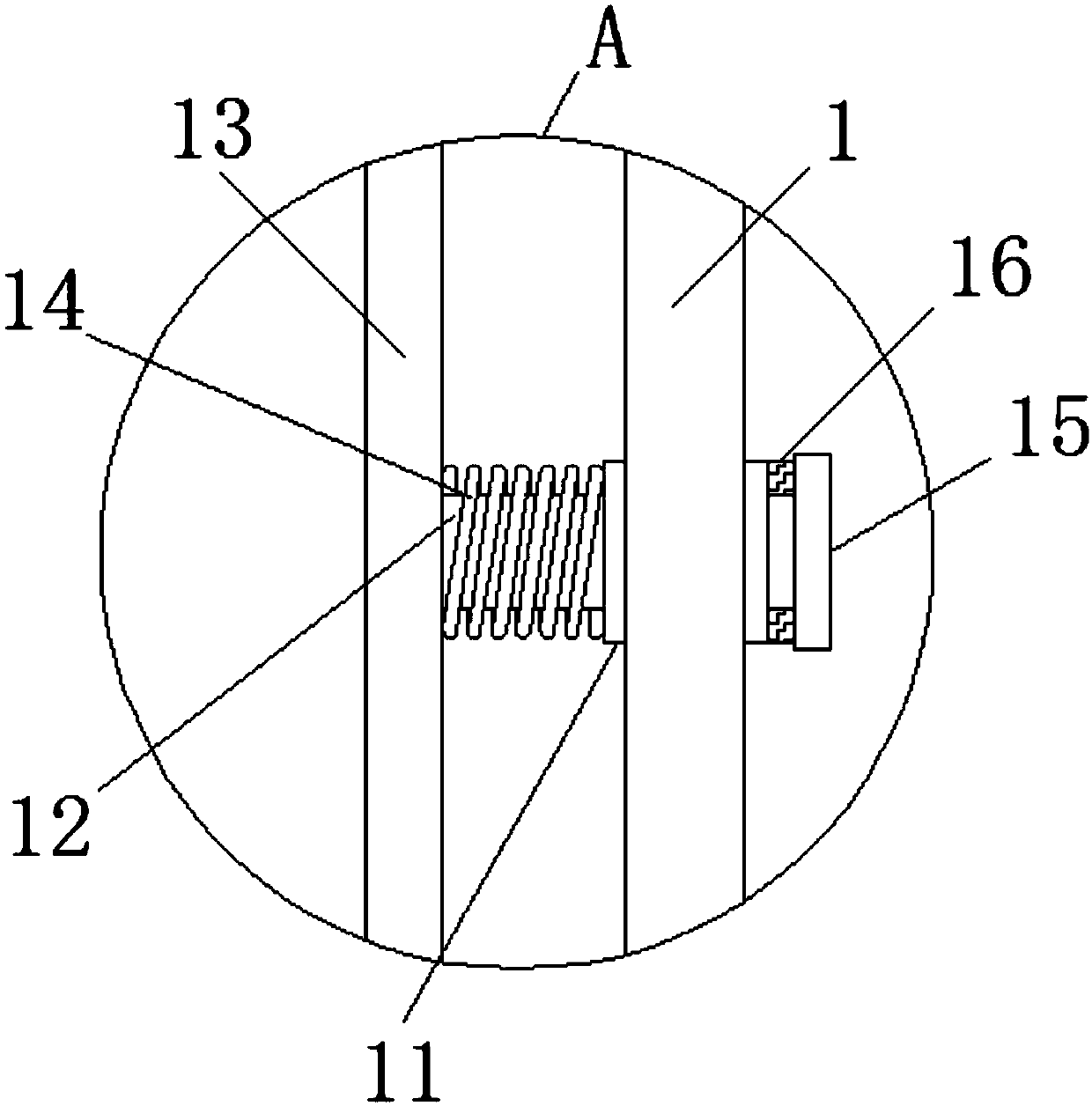

Sewage treatment apparatus capable of preventing box breakage

InactiveCN107583558AAvoid breakingRupture will notRotary stirring mixersMixer accessoriesSewageEngineering

The invention relates to the technical field of sewage treatment equipment, and discloses a sewage treatment apparatus capable of preventing box breakage. The sewage treatment apparatus comprises a box. The movable openings in the outer wall of the box are fixedly connected to a circular column. A support column is arranged in the circular column movably. One end of the support column is fixedly connected to a buffer block. The buffer block is arranged in the box. The external side of the support column is movably connected to a spring. One end of the spring is fixedly connected to one side ofthe internal wall of the box. The end, which is far from the internal wall of the box, of the spring is fixedly connected to the external side of the buffer block. Through the cooperation among the box, the circular column, the support column, the buffer block, and the spring, the buffer block can move the spring horizontally so as to minimize the impact force of sewage on the buffer block, the impact force on the buffer block is minimized, the buffer block and the box will not be broken, the service life of the box and the buffer block is prolonged, and the sewage in the box will not flow out and pollute the environment.

Owner:JIANGSU AEROSPACE HEWLETT ENVIRONMENTAL PROTECTION TECH

On-line replaceable thermocouples for sulfur furnace temperature measurement

ActiveCN107543628BImprove reliabilityPrevent leakageThermometer detailsThermometers using electric/magnetic elementsFurnace temperatureShielding gas

The invention relates to an on-line replaceable thermocouple used for measuring the temperature of a sulfur furnace, including a thermocouple and a protective sleeve outside the thermocouple, and the thermocouple with the protective sleeve measures temperature through the thermocouple installed on the sulfur furnace. The support pipe extends into the sulfur furnace, and the side of the temperature-measuring support pipe is provided with a first blowing interface and a second blowing interface which are spaced apart from each other. One end of the first and second blowing interfaces communicates with the temperature-measuring support pipe. The other end of the first and second blowing ports is connected to the protective gas source, the rear end of the thermocouple is connected to the junction box, the junction box is sealed with the temperature measurement support tube, and the temperature measurement support tube between the protective sleeve and the junction box A micro-pressure pressure gauge is installed on the top, and the rear end of the temperature-measuring support tube is provided with a rotary valve capable of closing the temperature-measuring support tube. The invention can effectively avoid the leakage and leakage of hydrogen sulfide gas, prolong the service life of thermocouples, improve the accuracy of temperature measurement, and replace the thermocouples without shutting down the furnace, thereby prolonging the operating period of the device and greatly improving the production efficiency.

Owner:杭州亿泰自控设备有限公司

Processing technology for enhancing nail-holding power of biomass fiberboard

PendingCN113910404AImprove densification performanceImprove nail holding powerPolyureas/polyurethane adhesivesDomestic articlesFiberImide

The invention discloses a processing technology for enhancing the nail-holding power of a biomass fiberboard, and relates to the technical field of fiberboard processing. The processing technology comprises the following steps: firstly preparing a polymeric monomer, then carrying out addition polymerization reaction on the polymeric monomer, polyhydric alcohol and diisocyanate, reacting the obtained mixture with a bismaleimide monomer to obtain a polymer powder material, then uniformly mixing the polymer powder material with biomass fiber for hot press molding, and conducting cooling treatment to obtain the fiberboard with excellent nail-holding power. Interpenetrating continuous phase polymer layers which penetrate through one another are formed in the biomass fiberboard, the friction force between steel nails and the fiberboard is increased while the compactness of the fiberboard is increased, and therefore the resistance generated when the steel nails are pulled out of the fiberboard is increased, and the nail-holding power of the fiberboard is remarkably improved.

Owner:阜阳大可新材料股份有限公司

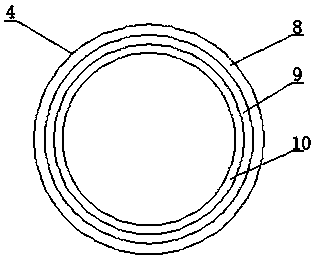

Test tube for medical detection

The invention discloses a test tube for medical detection. The test tube for medical detection includes a test tube, wherein tube cap is arranged at one end of the test tube; an openable central coveris arranged in the tube cap; a rotating shaft is arranged at one end of the tube cap; a spring is arranged on the surface of the rotating shaft; a tube cap opening handle is arranged on one side of the rotating shaft, a branch tube is arranged on one side of the test tube, a branch tube plug is arranged at one end of the branch tube, a uniform heat conduction mesh is arranged on the surface of the test tube, an explosion-proof layer is arranged in the test tube, a damping layer is arranged in the explosion-proof layer, and an experiment layer is arranged in the damping layer. By designing theexplosion-proof layer and the vibration reduction layer on the test tube, a problem that the test tube topples or falls off due to negligence of people in an experiment is avoided, wherein the explosion-proof layer and the vibration reduction layer can effectively reduce breakage of the test tube, protect an internal experiment layer from breakage and prevent reagents from running off, so that the problem that the test tube topples and is easy to break when the test tube is used for the experiment in the past is solved.

Owner:汪淑荣

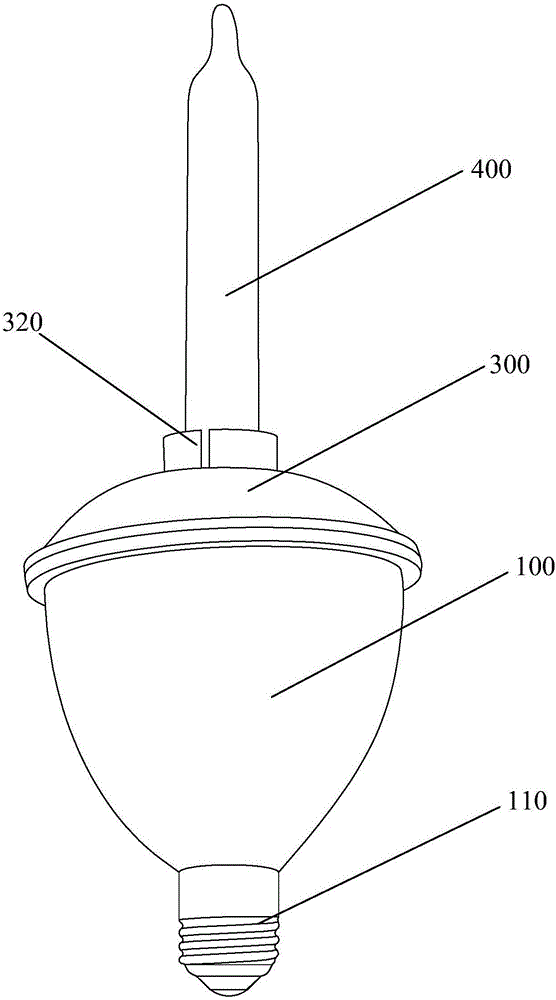

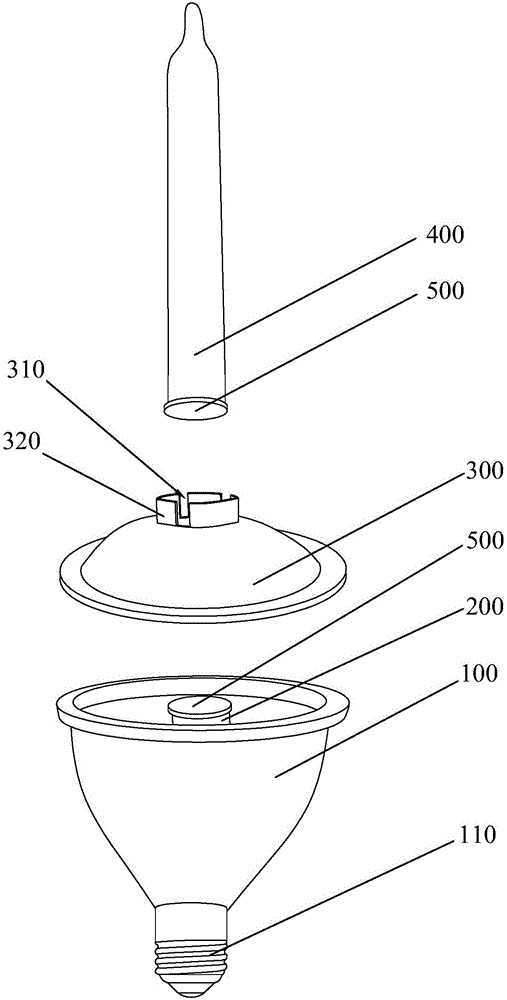

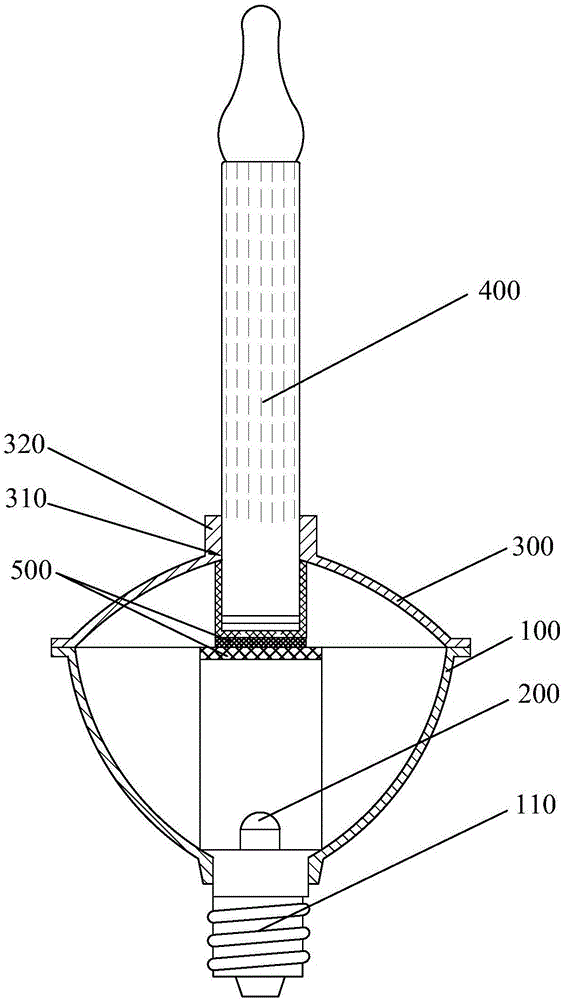

Rupture prevention bubble lamp

InactiveCN106051627AEasy to breakSimple processProtective devices for lightingLight effect designsLight sourceEngineering

The invention discloses a rupture prevention bubble lamp. The bubble lamp comprises a base, a light source arranged on the base, an upper cover connected to the base and a sealing decoration pipe. An insertion-connecting hole is formed in the upper cover in the direction facing the light source. The sealing decoration pipe is inserted into the insertion-connecting hole. A buffer part used for isolating the light source from the sealing decoration pipe is arranged between the light source and the sealing decoration pipe. According to the rupture prevention bubble lamp, the buffer part used for isolating the light source from the sealing decoration pipe is additionally arranged, so that the problem that light sources and sealing decoration pipes are prone to rupture due to heating expansion is effectively solved, and the structure is simple and easy to implement.

Owner:林金山

Aqueous polyurethane micro-encapsulated phase change energy storage material and preparation thereof

ActiveCN101503617BImprove liquidityImprove brittlenessHeat-exchange elementsMicroballoon preparationSaline waterPhase change

The invention discloses a metal ion crosslinked aqueous polyurethane microencapsulated phase change energy storage material and a preparation method thereof. The preparation method is characterized by comprising the following steps: melting a phase change energy storage material in deionized water at a temperature of between 30 and 90 DEG C, adding a nonionic surfactant which accounts for 0.5 to 10 percent of the weight of the phase change energy storage material, emulsifying under high-speed stirring, then adding aqueous polyurethane with the polyurethane content which accounts for 0.5 to 20percent of the phase change energy storage material and metal salt water solution with the metal ion weight which accounts for 0.1 to 10 percent of the polyurethane in the aqueous polyurethane, reacting for 0.5 to 4 hours, and cooling, filtering and drying to obtain a phase change energy storage material micro-capsule which takes the phase change energy storage material as a capsule core and metal ion crosslinked aqueous polyurethane as a capsule wall, wherein the weight ratio of the phase change energy storage material to the aqueous polyurethane is 0.5-20: 1. The product has the average particle size not obviously increased, good free mobility of particles and compact and even capsule wall.

Owner:UNIV OF SCI & TECH OF CHINA

Battery module

InactiveCN102214806BAvoid deformationEasy to manufactureCell component detailsElectrical batteryElectrical and Electronics engineering

Owner:SAMSUNG SDI CO LTD

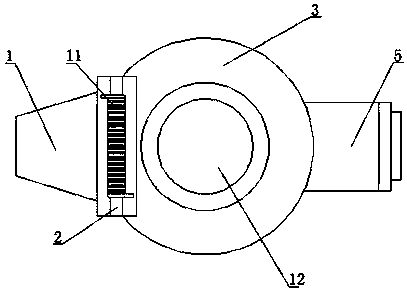

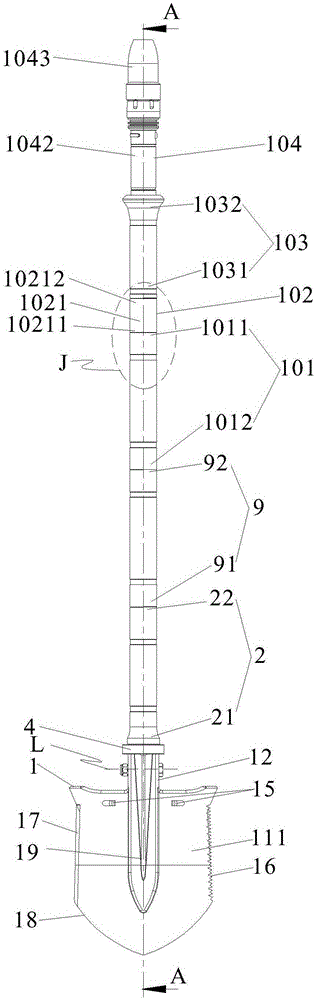

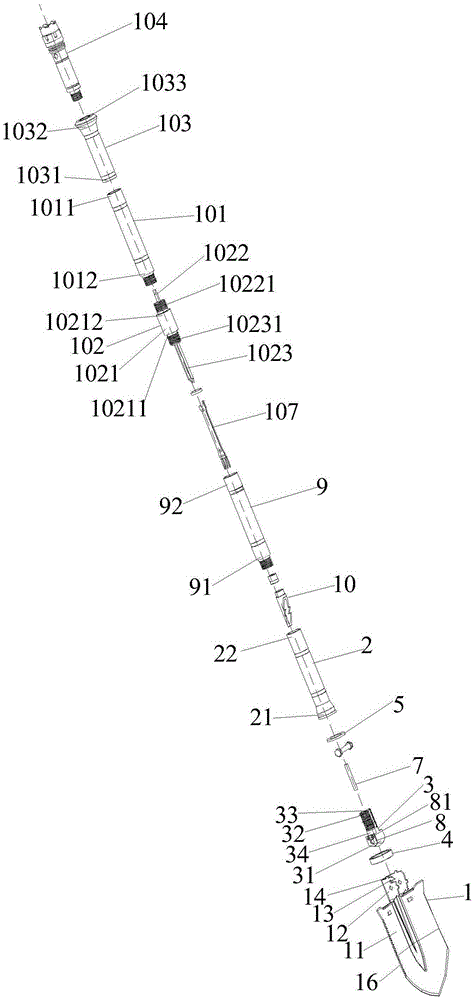

multifunctional shovel

The invention provides a multifunctional shovel comprising a hand shovel and a handle unit. The handle unit comprises a first handle and a square handle. The square handle is disposed in the hand shovel and the first handle. The front end of the first handle is connected with the hand shovel through the square handle. The part, fitting the front end of the first handle, of the hand shovel is provided with a steel ring; a first high-resilience ring is nested in the steel ring; a second high-resilience ring is nested in the front end of the first handle; the steel ring, the first high-resilience ring and the second high-resilience ring sleeve the square handle. The first and second high-resilience rings are made of spring plastic which is ductile, the second high-resilience ring is squeezed into the steel ring by the first handle, the inner wall of the steel ring is in the inverted taper structure, the second high-resilience ring is also in the inverted taper structure, and the steel ring and the first handle can be connected accordingly. Friction exists between plastics, and the handle rarely loosens or drops during use.

Owner:彭辉

Method for preparing rehabilitation die for oral cavity

InactiveCN100443069CImprove suitabilityRupture will notImpression capsDentistry preparationsOral ProsthesisMouth repair

A process for preparing the oral-cavity repairing model of oral reparing body includes proportionally mixing semi-hydrated gypsum, coagulation-expansion regulator and water, stirring for 2-3 min, and casting. Its advantages are high adaptability and strength and good memory characteristic.

Owner:SHANGHAI MEDICAL INSTR

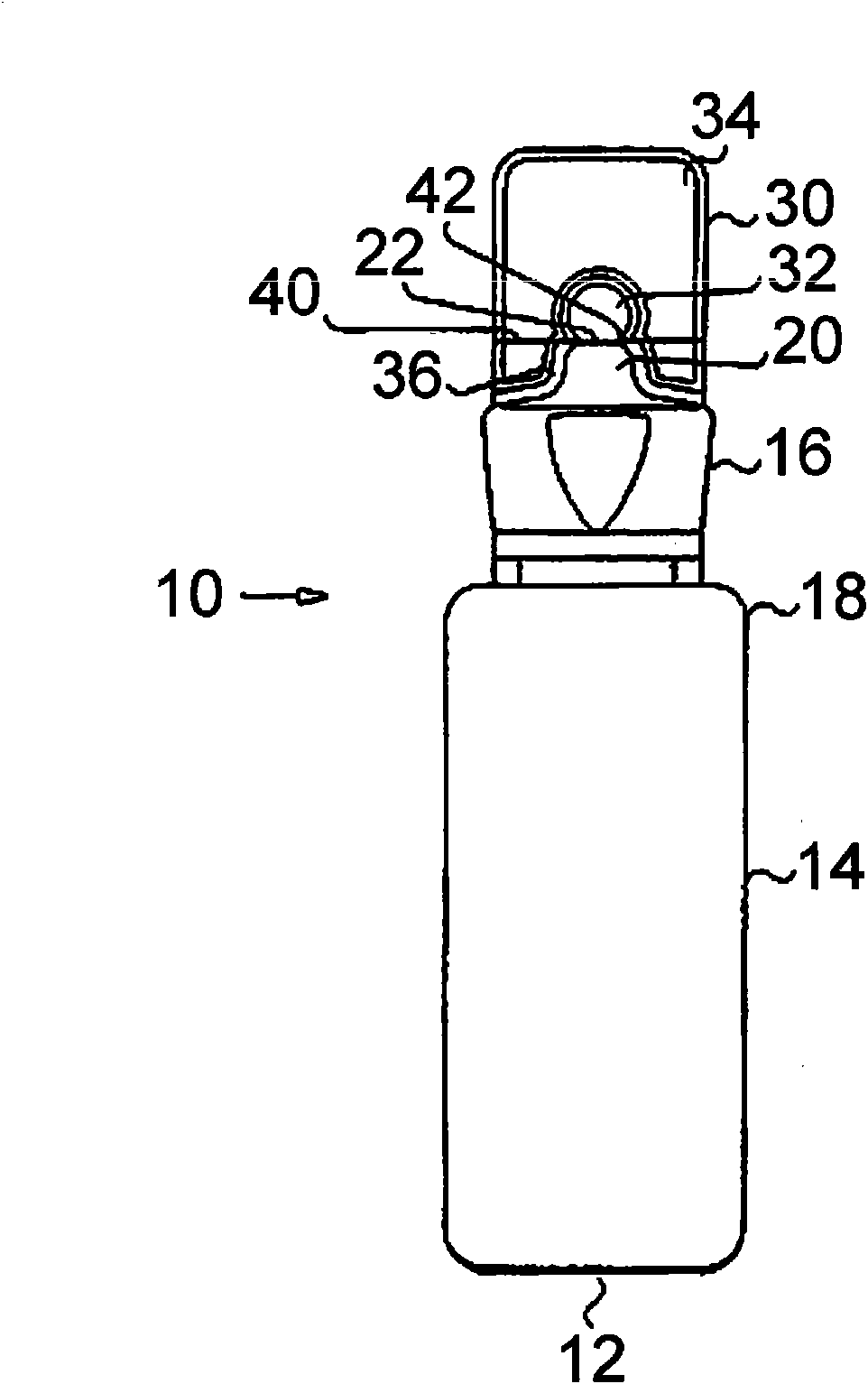

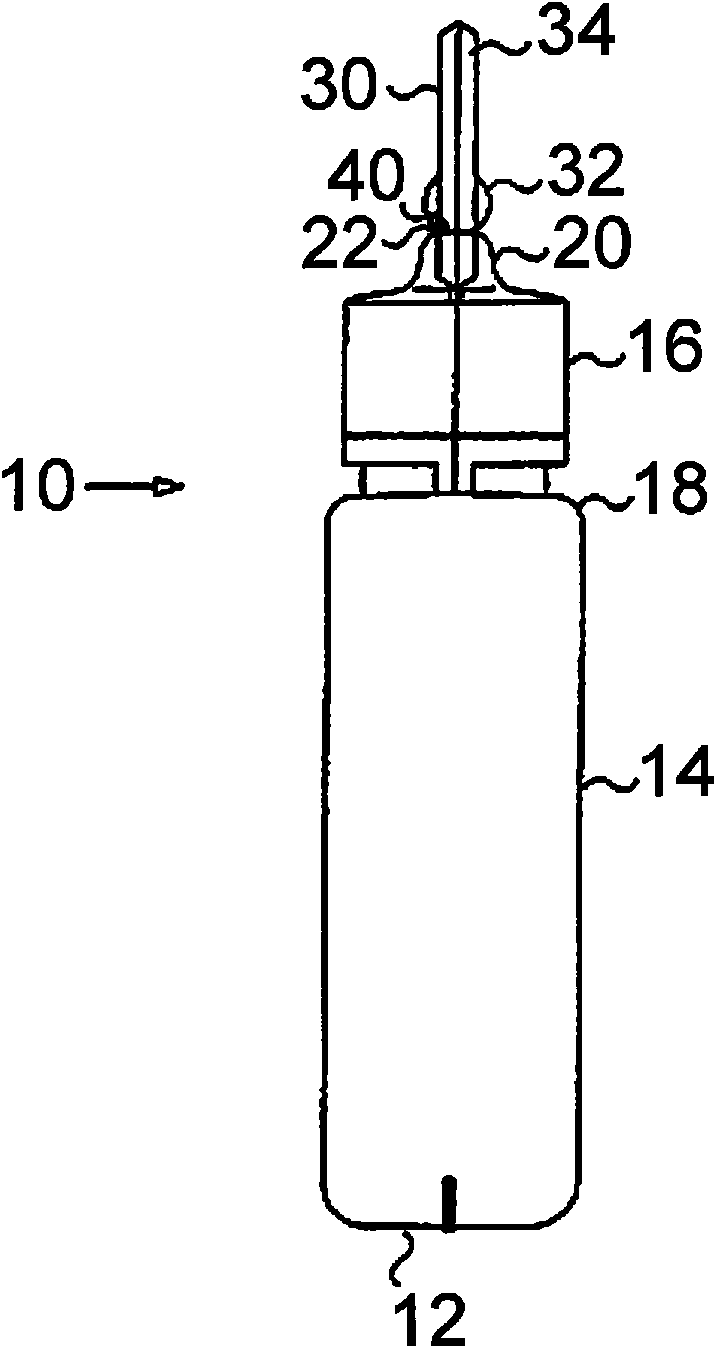

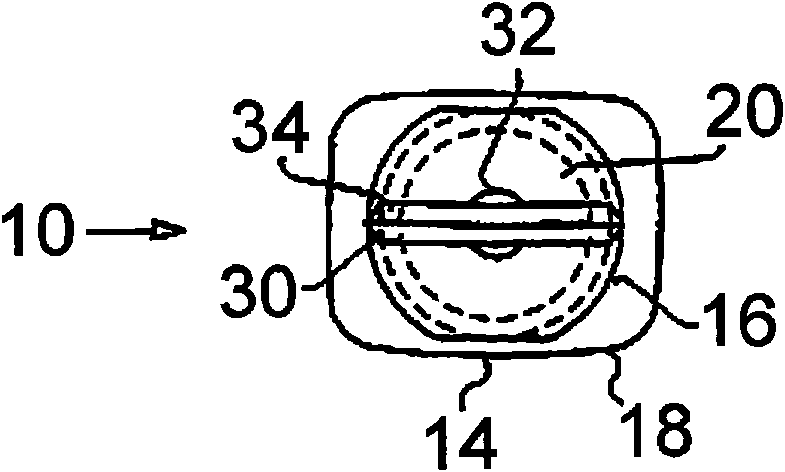

Polyester resin container with break part and process for producing the same

A polyester resin container with break part that is improved in opening easiness; and a process for producing the same. There is provided a container with break structure of polyester resin as constituent material, comprising mouth part (20) being continuous from the main body of container and break part (30) integrally disposed superior to the mouth part (20) so that a border portion between opening end (22) of the mouth part (20) and the break part (30) is broken to thereby attain opening, wherein groove (40) is formed in the direction approximately perpendicular to the external surface of the border portion between opening end (22) of themouth part (20) and the break part (30), and wherein the intrinsic viscosity of the polyester resin at the periphery of the groove (40) is set lower than the intrinsic viscosity of the polyester resin at the regions other than the periphery of the groove (40).

Owner:DAIWA CAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com