Method for manufacturing waterproof sheets of microphones

A manufacturing method and microphone technology, which is applied in the field of microphones, can solve the problems of insufficient mass production of thin slices, high-temperature reflow resistance of thin slices, and insufficient small mesh of thin slices, etc., and achieve good structural integrity, which is conducive to mass production and packaging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

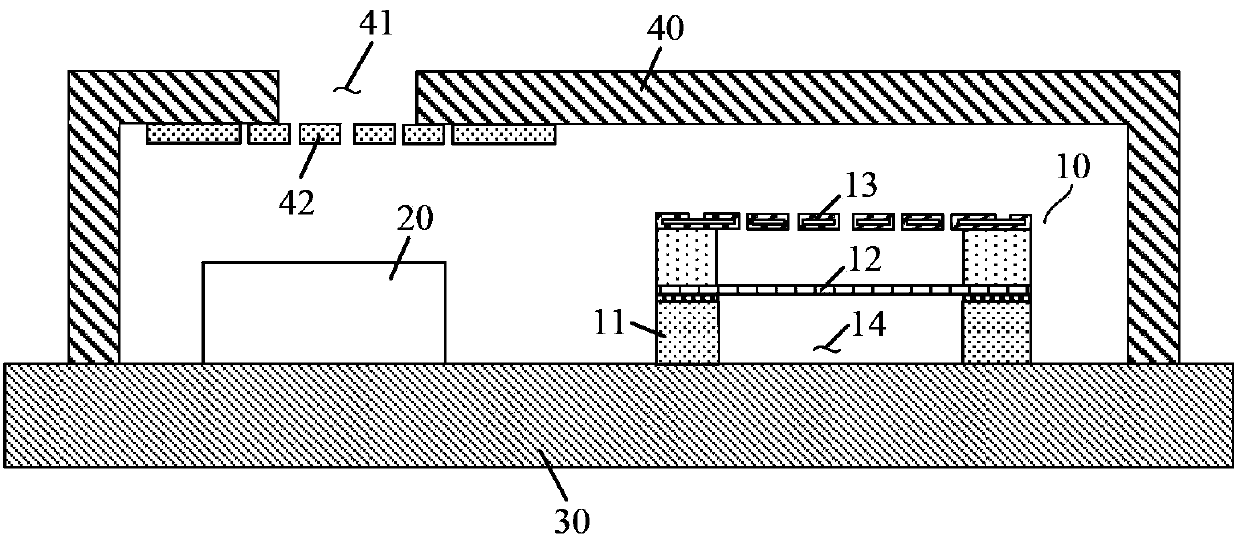

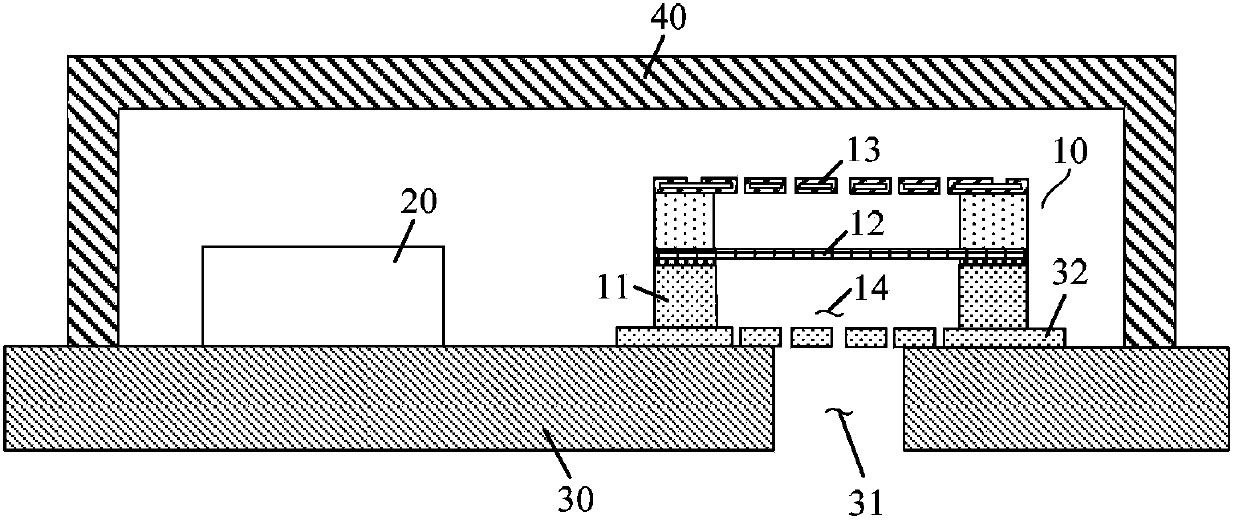

[0027] Figures 4a-4e is a sectional view showing a method of manufacturing the microphone waterproof sheet according to the first embodiment of the present invention. First, if Figure 4a As shown, a thin silicon wafer 100 is prepared. The thickness of the thin silicon wafer 100 can be in the range of about 50 μm to about 150 μm, so that the thin silicon wafer 100 has sufficient mechanical strength, and through holes can also be directly formed by etching, as described later. The thin silicon wafer 100 can be obtained from a silicon wafer supplier, or can be obtained by thinning an ordinary thick silicon wafer (with a thickness ranging from about 400 μm to about 1200 μm).

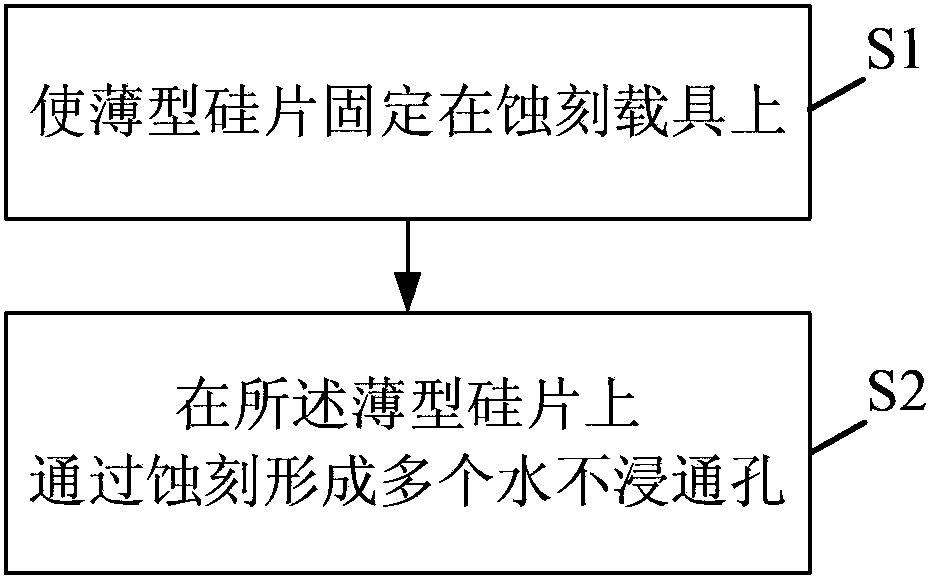

[0028] Next, if Figure 4b As shown, the thin silicon wafer 100 is fixed on the etching carrier 300 by the double-sided adhesive tape 200 . The etching carrier 300 can be a thick silicon wafer, a ceramic substrate, a glass substrate or a metal substrate. Since the thin silicon wafer 100 is too thin, i...

no. 2 example

[0034]In the manufacturing method of the microphone waterproof sheet according to the second embodiment of the present invention, except for the step of fixing the thin silicon wafer on the etching carrier, other steps are the same as those described in the first embodiment. Figure 6 is a cross-sectional view showing the method for fixing a thin silicon wafer on an etching carrier according to the second embodiment of the present invention. Such as Figure 6 As shown, after the thin silicon wafer 100 is prepared, the thin silicon wafer 100 is fixed on the etching carrier 300 by a clamp 200 or a single-sided adhesive tape.

no. 3 example

[0036] In the manufacturing method of the microphone waterproof sheet according to the third embodiment of the present invention, except for the step of fixing the thin silicon wafer on the etching carrier, other steps are the same as those described in the first embodiment. Figure 7 is a cross-sectional view showing the method for fixing a thin silicon wafer on an etching carrier according to the third embodiment of the present invention. Such as Figure 7 As shown, after the thin silicon wafer 100 is prepared, the thin silicon wafer 100 is fixed on the etching carrier 300 by bonding.

[0037] Specifically, a bonding layer 202 that can be bonded to the silicon wafer is formed on the etching carrier 300, and then the thin silicon wafer 100 is bonded to the bonding layer 202 through a hydrophilic bonding or a hydrophobic bonding mechanism. , so that the thin silicon wafer 100 is fixed on the etching carrier 300 . After forming a plurality of water non-immersion through holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com