Polyester resin container with break part and process for producing the same

A technology of polyester resin and manufacturing method, applied in the direction of soft tubular containers, containers, household containers, etc., can solve the problems of poor heat sealing performance of polyester resin, improve the ease of unsealing, suppress the increase of density, and improve unsealing The effect of ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

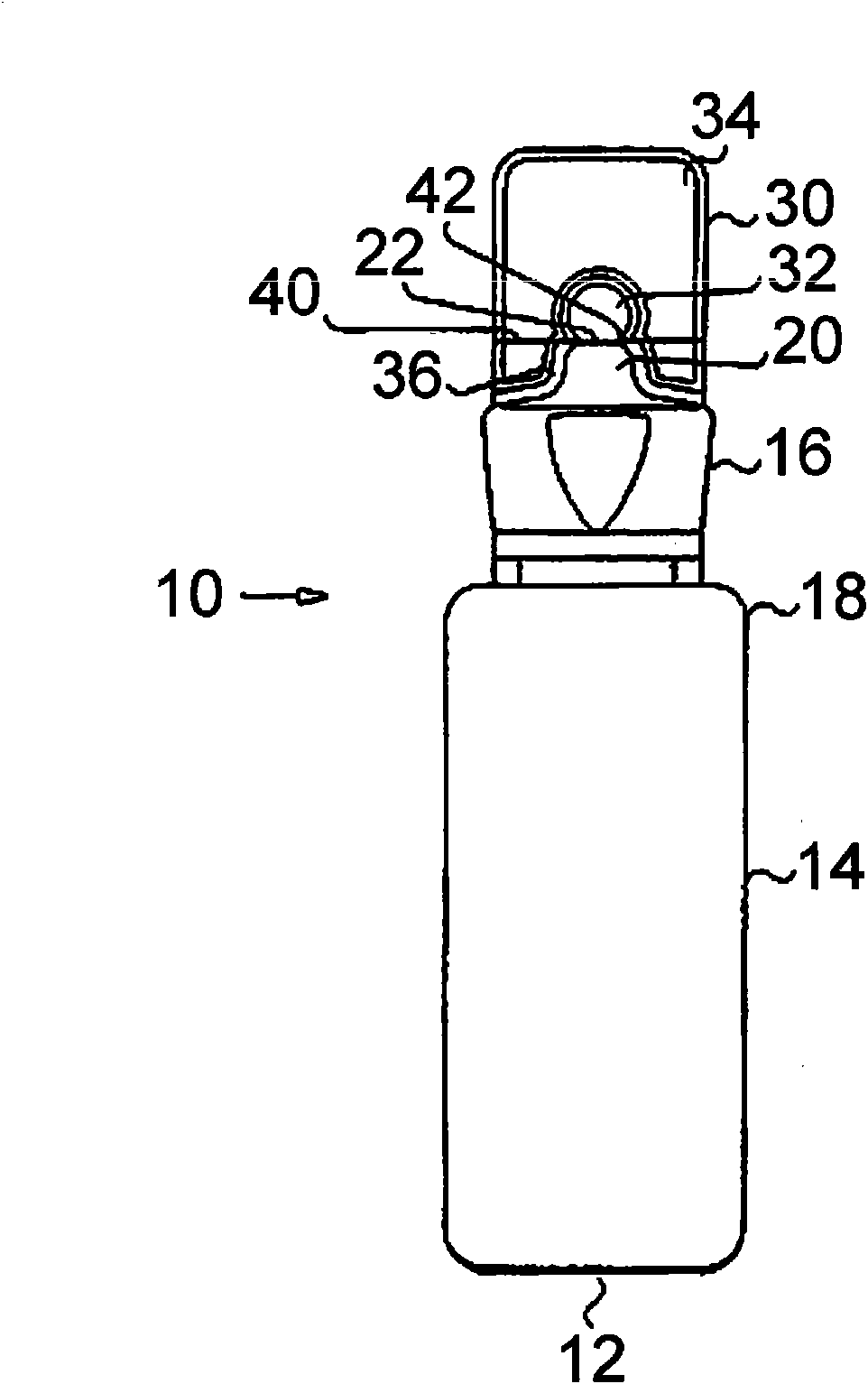

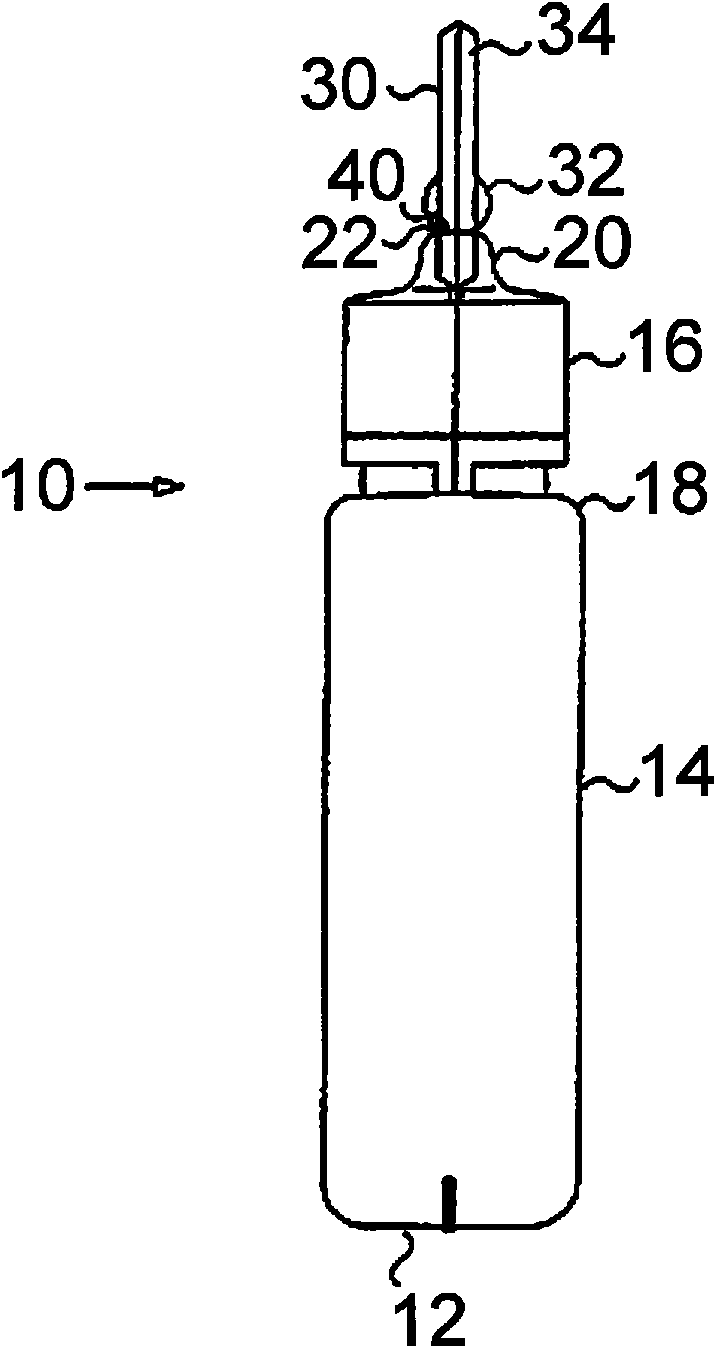

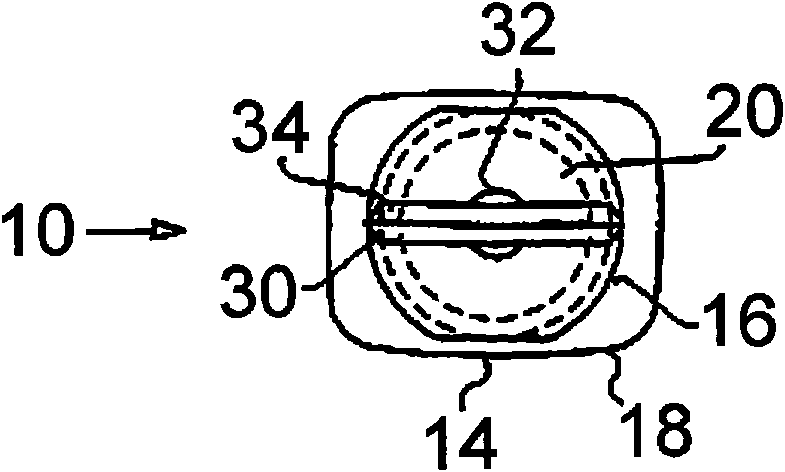

[0025] For the polyester resin container with the portion to be ruptured according to one embodiment of the present invention, figure 1 Indicates its main view; figure 2 represents its side view; image 3 shows its top view.

[0026]A container 10 made of polyester resin with a portion to be ruptured according to an embodiment of the present invention includes: a substantially rectangular flat plate-shaped bottom 12, a substantially square cylindrical cuboid portion 14 continuous with the bottom 12, and a substantially cylindrical mouth. The trunk portion 18 constituted by the neck portion 16 and the mouth portion 20 continuous above the bore portion 16 . Also, a portion to be broken 30 composed of a hollow spherical portion 32 , a plate-shaped grip portion 34 and a thin-walled portion 36 is integrally provided above the mouth portion 20 . The opening end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com