On-line replaceable thermocouples for sulfur furnace temperature measurement

A thermocouple and sulfur technology, applied in the direction of measuring heat, using electrical devices, using electromagnetic means, etc., can solve the problem of damage in a few hours, and the use time is only half a year at most, affecting the operation cycle and production efficiency of the device. Thermocouple Short service life and other problems, to achieve the effect of good resistance to hydrogen sulfide corrosion, improve temperature measurement accuracy, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

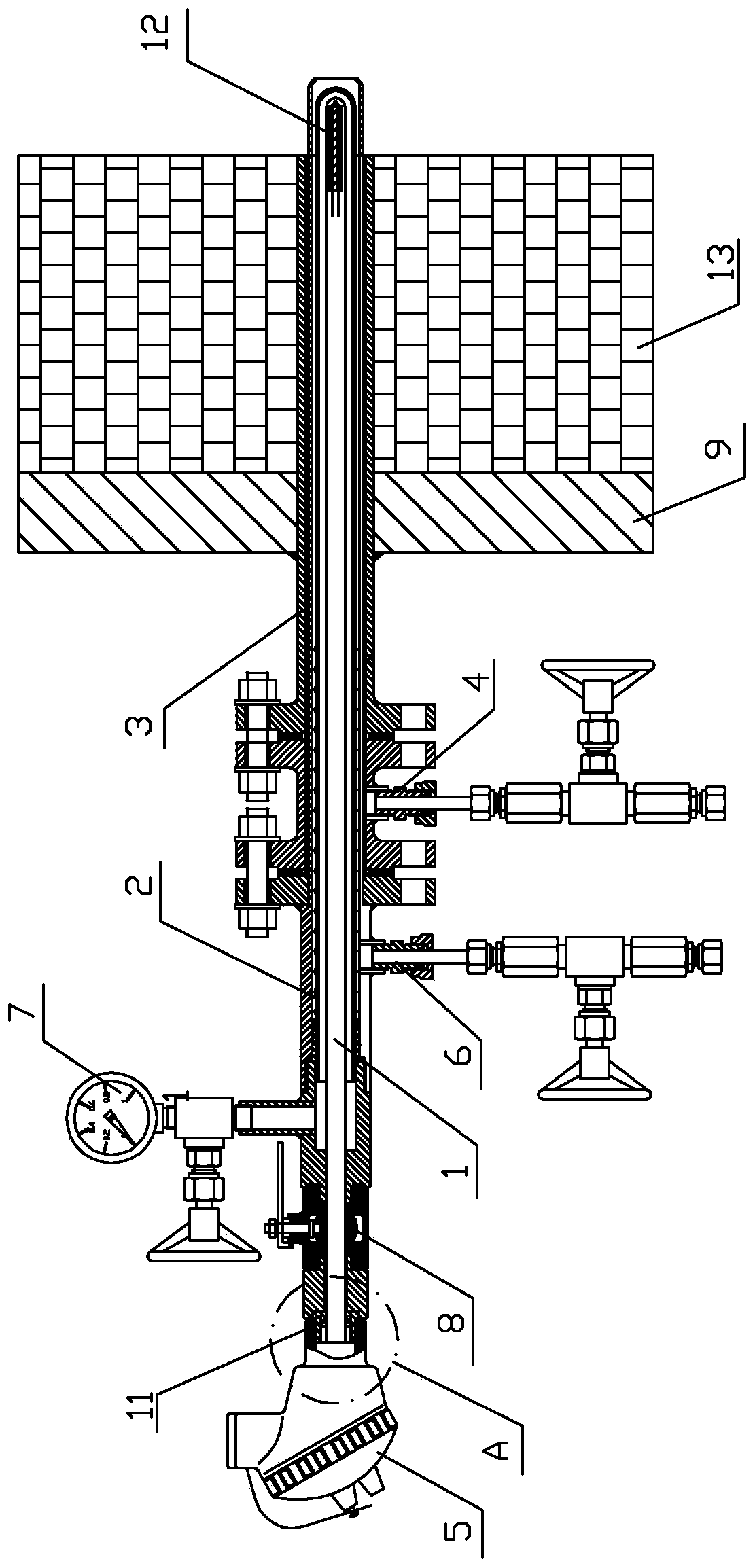

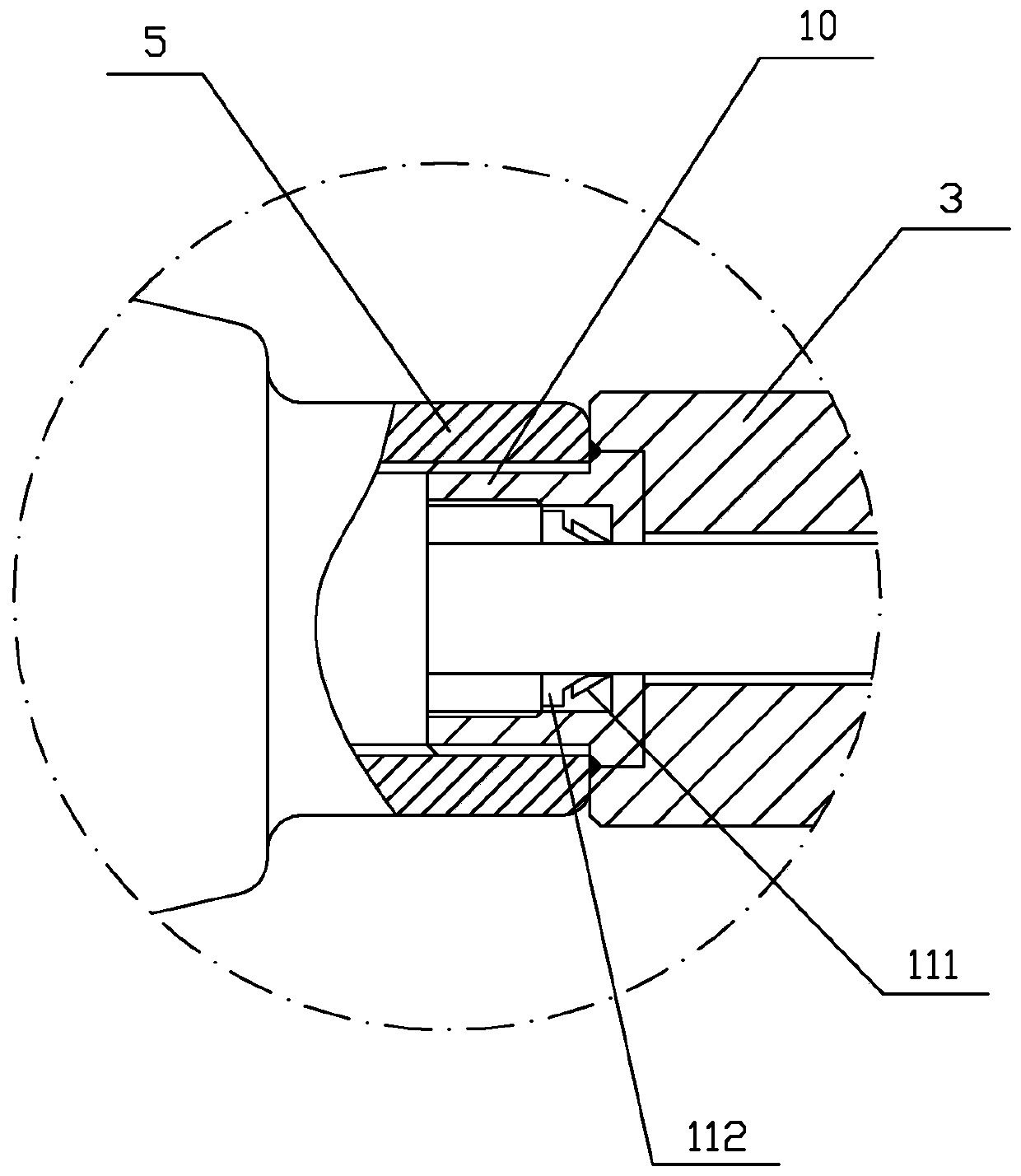

[0026] Embodiment: the on-line operation that is used for sulfur furnace temperature measurement of the present embodiment can replace the thermocouple, as figure 1 As shown, it includes a thermocouple 1 and a protective sleeve 2 set outside the thermocouple 1. The thermocouple 1 adopts a B-type double platinum-rhodium armored thermocouple, and the thermocouple and the protective sleeve are filled with a high-temperature 99.95% pure Magnesium oxide is used as an insulator, and the positive and negative electrodes of the thermocouple 1 are passed through the double-hole tube 12 made of 99.99% high-purity aluminum oxide to isolate the positive and negative electrodes. The protective sleeve 2 includes a non-metallic protective tube with a closed front end and a metal outer protective tube bonded to surround the outer surface of the non-metallic protective tube. The non-metallic protection tube is a silicon carbide tube made of submicron silicon carbide powder pressureless sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com