Deodorization blast bead, deodorization animal sand and manufacturing method thereof

A technology for deodorizing blasting beads and animal sand, which is applied in animal houses, chemical instruments and methods, special treatment targets, etc. The effect of rupture speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

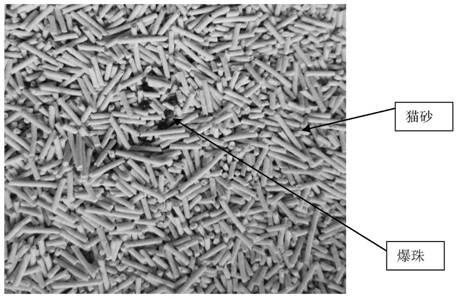

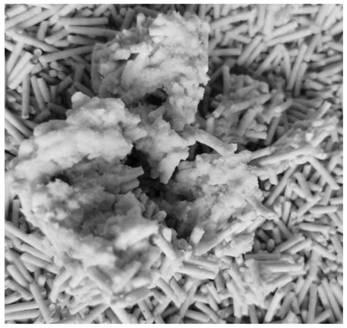

Image

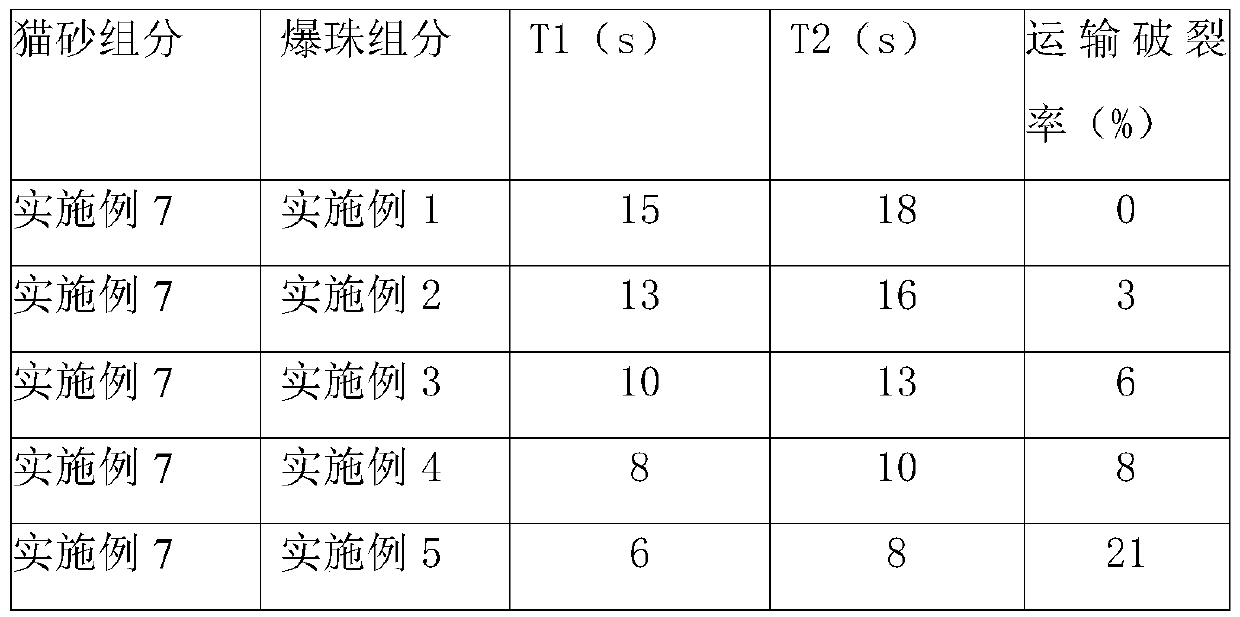

Examples

Embodiment 1

[0035] Disclosed is a deodorizing quick-fried bead, which includes a rubber skin and an encapsulation liquid, and the compressive strength of the deodorizing quick-fried bead is 1Pa.

[0036] Preferably, the rubber raw material includes the following components in parts by weight:

[0037] 40 parts of carrageenan, 25 parts of gelatin, 25 parts of hydroxypropyl cellulose, 20 parts of sodium alginate, 25 parts of calcium chloride, 5 parts of konjac gum, 6 parts of guar gum, 3 parts of xanthan gum, and 15 parts of glycerin.

[0038] Preferably, the liquid-encapsulated comprises the following components in parts by weight:

[0039] 32 parts of phytondine, 65 parts of essence, and 4 parts of negative ion solution.

Embodiment 2

[0041] Disclosed is a deodorant quick-fried bead, the deodorized quick-fried bead includes rubber and a liquid coating, and the compressive strength of the deodorized quick-fried bead is 0.9Pa.

[0042] Preferably, the gum includes konjac gum or guar gum or agar or carrageenan or xanthan gum or others.

[0043] Preferably, the rubber raw material includes the following components in parts by weight:

[0044] 45 parts of carrageenan, 30 parts of gelatin, 30 parts of hydroxypropyl cellulose, 30 parts of sodium alginate, 15 parts of calcium chloride, 2 parts of konjac gum, 6 parts of guar gum, 5 parts of xanthan gum, and 15 parts of glycerin.

[0045] Preferably, the liquid-encapsulated comprises the following components in parts by weight:

[0046] 29 parts of phytondine, 68 parts of essence, and 5 parts of negative ion solution.

Embodiment 3

[0048] Disclosed is a deodorizing quick-fried bead, which includes a rubber skin and an encapsulation liquid, and the compressive strength of the deodorizing quick-fried bead is 0.85Pa.

[0049] Preferably, the rubber raw material includes the following components in parts by weight:

[0050] 75 parts of carrageenan, 35 parts of gelatin, 35 parts of hydroxypropyl cellulose, 20 parts of sodium alginate, 15 parts of calcium chloride, 6 parts of konjac gum, 8 parts of guar gum, 6 parts of xanthan gum, and 25 parts of glycerin.

[0051] Further preferably, the rubber skin also includes the following components in parts by weight:

[0052] 13 parts of pectin, 13 parts of maltodextrin, 5 parts of chitosan.

[0053] Preferably, the liquid-encapsulated comprises the following components in parts by weight:

[0054] 25 parts of phytondine, 62 parts of essence, and 5 parts of negative ion solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com