Patents

Literature

85results about How to "Shorten break time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble self-emulsifying coupled modified silicone oil composite and application in pickling, tanning and dyeing of leather making

InactiveCN101629218AEasy to controlFooling the processTanning treatmentPre-tanning chemical treatmentAfter treatmentPollutant emissions

The invention is water-soluble self-emulsifying coupled modified silicone oil composite and an application in pickling, tanning and dyeing of leather, which is characterized in that the water-soluble self-emulsifying coupled silicone oil composite after modification is adopted to carry out oil pretanning, tanning, softening, dyeing and setting treatment on pickled skins of animals in a revolving drum. The crust leather to be coated has the advantages of plumpness, softness, no loose grain, good elasticity, good foaming sense and velvet silicon sense after treatment. By adopting the composite and the application method thereof to carry out oil pretanning, tanning, softening, dyeing and setting treatment, the quality of finished leather can be improved and stabilized, the production cost isreduced, the workshop sections such as wet blue pickling and degreasing, chrome retanning, alkali extraction overnight, neutralization and the like in the traditional leather making technique can be completely canceled, and the usage amounts of dye, fatliquor, stuffing and the like can be reduced, water washing is avoided by twice, thus saving more than 40% of water, shortening more than one third of the production period, reducing more than half of subsequent milling time, greatly stabilizing and simplifying the technique procedures, being easy to control the leather quality, and obviously reducing pollutant discharge in the traditional leather-making workshop sections of tanning, pretanning and dyeing water yard and lowering energy consumption such as water, electricity, manpower and the like.

Owner:CHENGDU KAITE ORGANOSILICON NEW MATERIALS TECH

Silane tanning dyeing retanning silica gel tabby filling tanning method

ActiveCN106191339ASolve the long-standing problem of loose noodlesEmbryo out time is shortTanning treatmentDyeing processChromium freeSilanes

The invention discloses a silane tanning dyeing retanning silica gel tabby filling tanning method. The method comprises the steps of silane softening chromium-free retanning filling fatliquoring deep dyeing, silane chromium retanning filling fatliquoring, high-temperature surface dyeing and fixed mold prevention. According to the method, water is not drained midway, and the big difficult problem of the loose grain of leather can be solved effectively. Traditionally tanned wet blue leather and scytoblastema which is subjected to loose grain can also be plumped back and fully filled and leveled up, prepared to-be-coated scytoblastema is flat and fine in grain surface, resistant to folding and compression and good in resilience, and the leather quality is upgraded and changed from ungraded to excellent. Meanwhile, the method is simple and stable to operate, the scytoblastema out time is short, the production cycle can be shortened greatly, subsequent leather milling time is reduced, and the time of the whole process is greatly shortened to 30-50% compared with the traditional process. According to the method, water and energy can further be saved, emission reduction is achieved, washing and water drainage are not conducted midway, and water usage and sewage discharge are reduced by 80% or above.

Owner:CHENGDU KAITE ORGANOSILICON NEW MATERIALS TECH

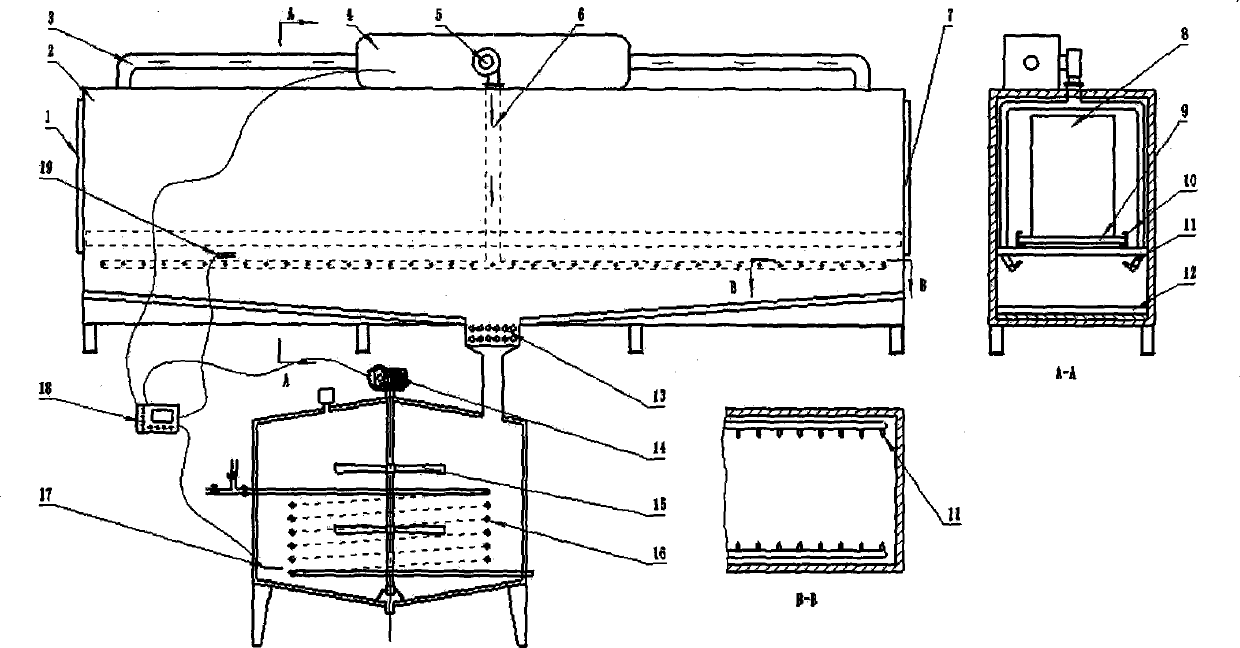

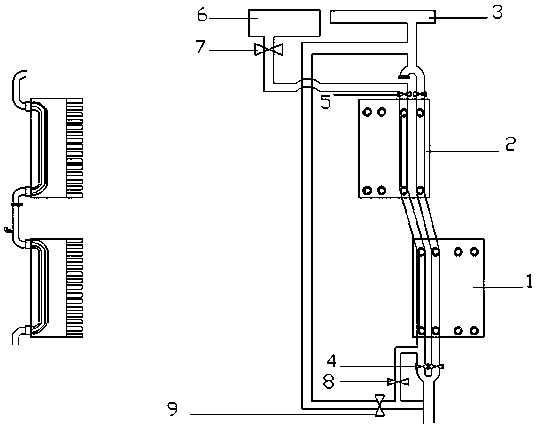

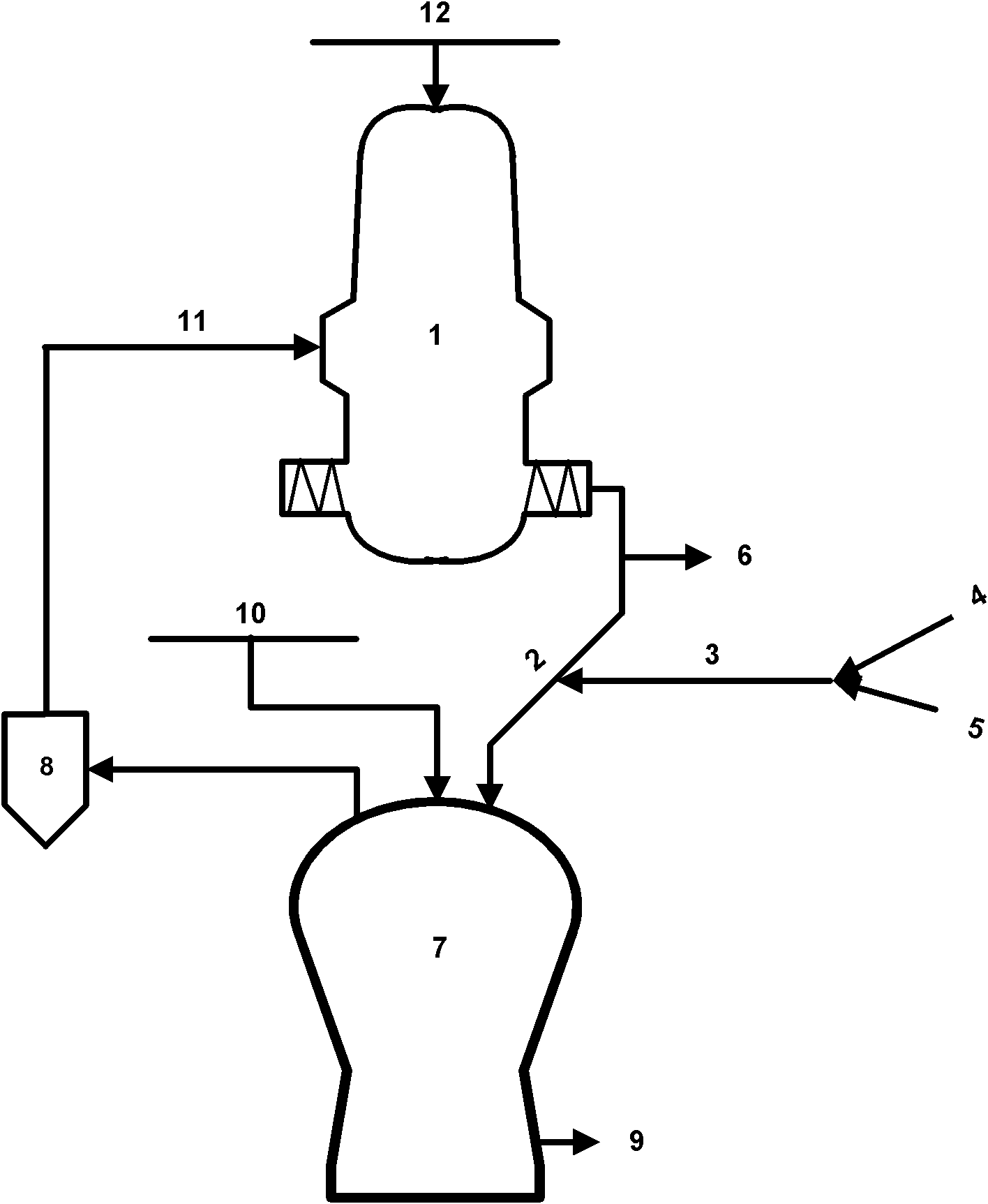

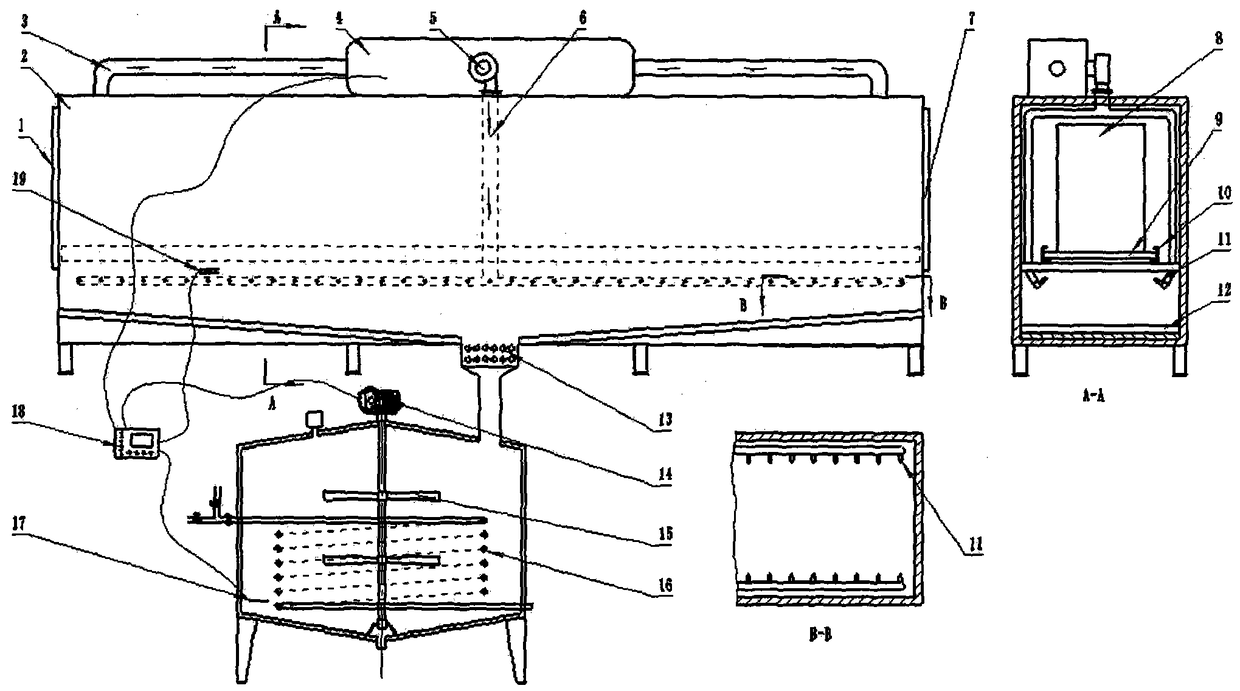

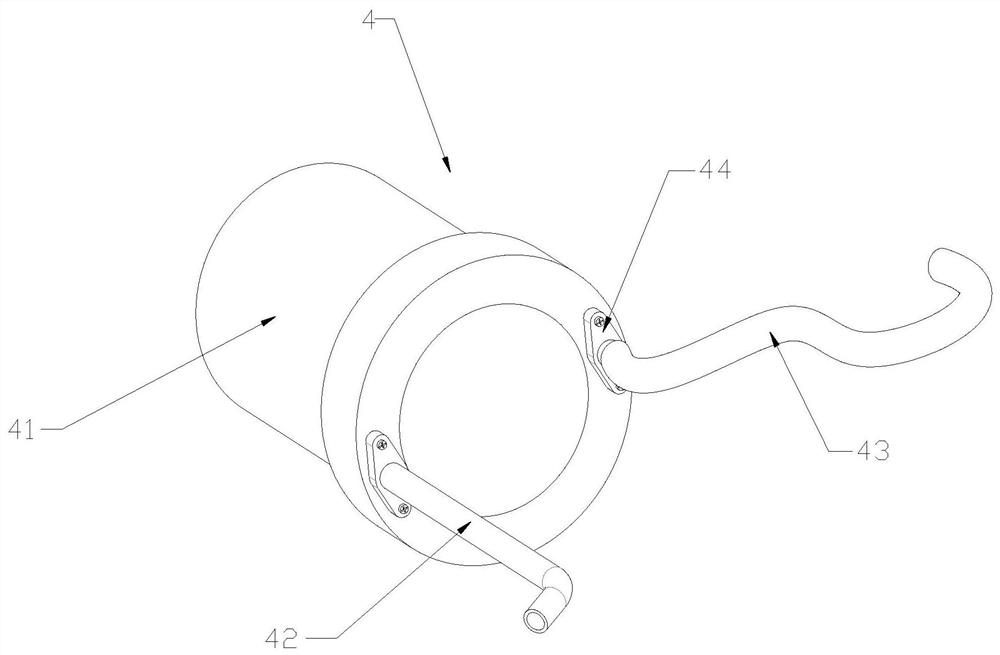

Honey decrystallization method and device

ActiveCN105495071AImprove heat transfer efficiencyIncrease the breaking speedFood preparationBee productsWater baths

The present invention discloses a honey decrystallization method and device and belongs to the technical field of bee product processing. The method includes the following steps: honey package barrel is washed clean and barrel lid is opened, the barrel is placed upside down in a crystal breaking chamber, and the air jet flow temperature is adjusted to 50-70 DEG C and the air flow speed is at 5-20 m / s to conduct air jet flow impact to break the crystal for 0.5-1.5 hours. After breaking the crystals, the honey flows into a honey melting chamber and the honey temperature is adjusted to a temperature of 40-60 DEG C to conduct crystal melting for 1-2 hours. The device includes: an air circulation channel (3), a heater (4), a fan (5), an air distribution pipe (6), a trailer (9), two sliding rails (10), two nozzles (11), a water bath heater (12), a steam heat exchanger (13), a stirring device (15), a heat exchange coil (16), a temperature sensor (17), and a temperature and air velocity sensor (19). The device is used to process the honey, which can effectively protect the biological activity of the honey, and the the device can save water and energy, is environmentally protective, and can achieve automatic control.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI +1

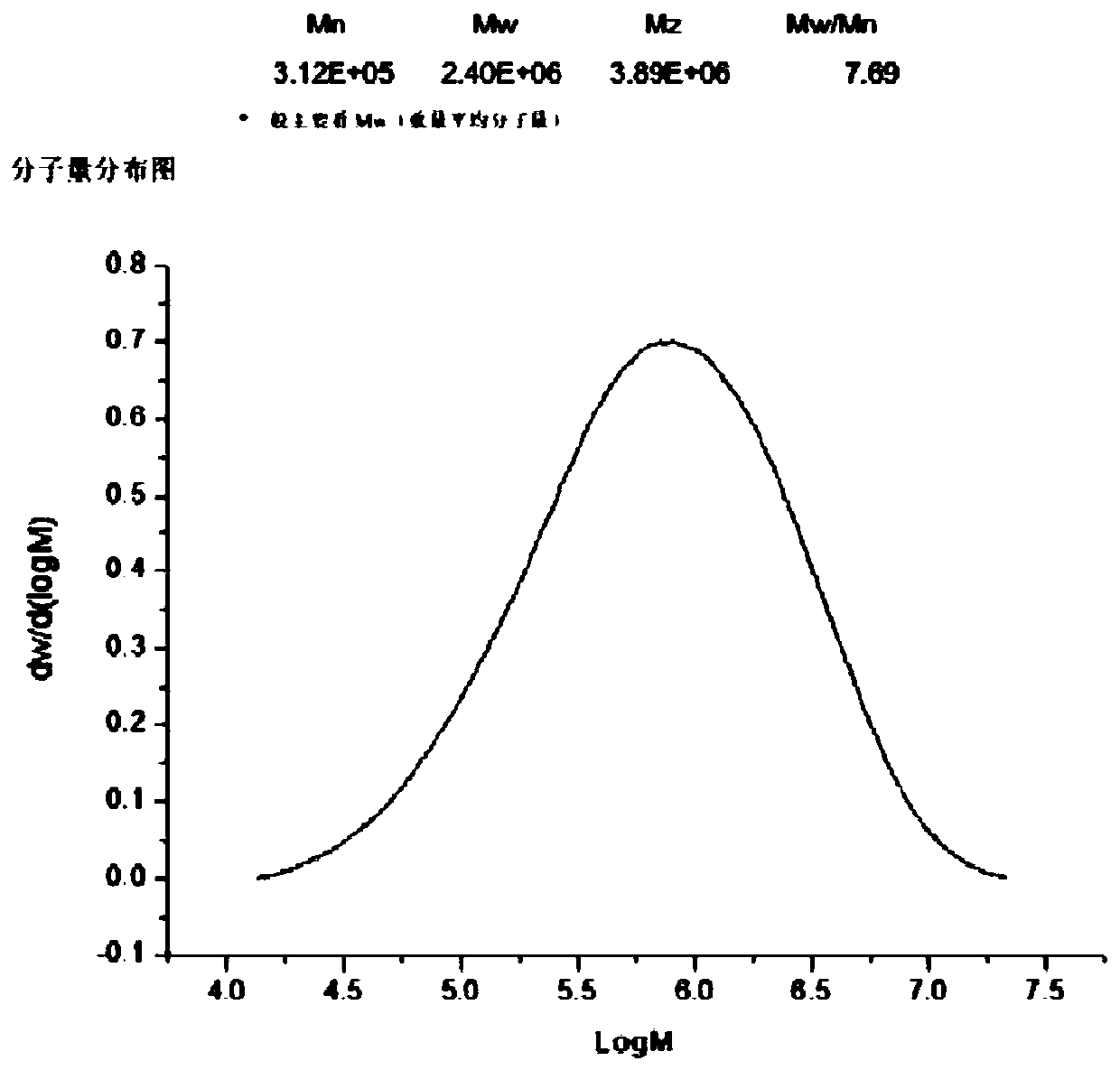

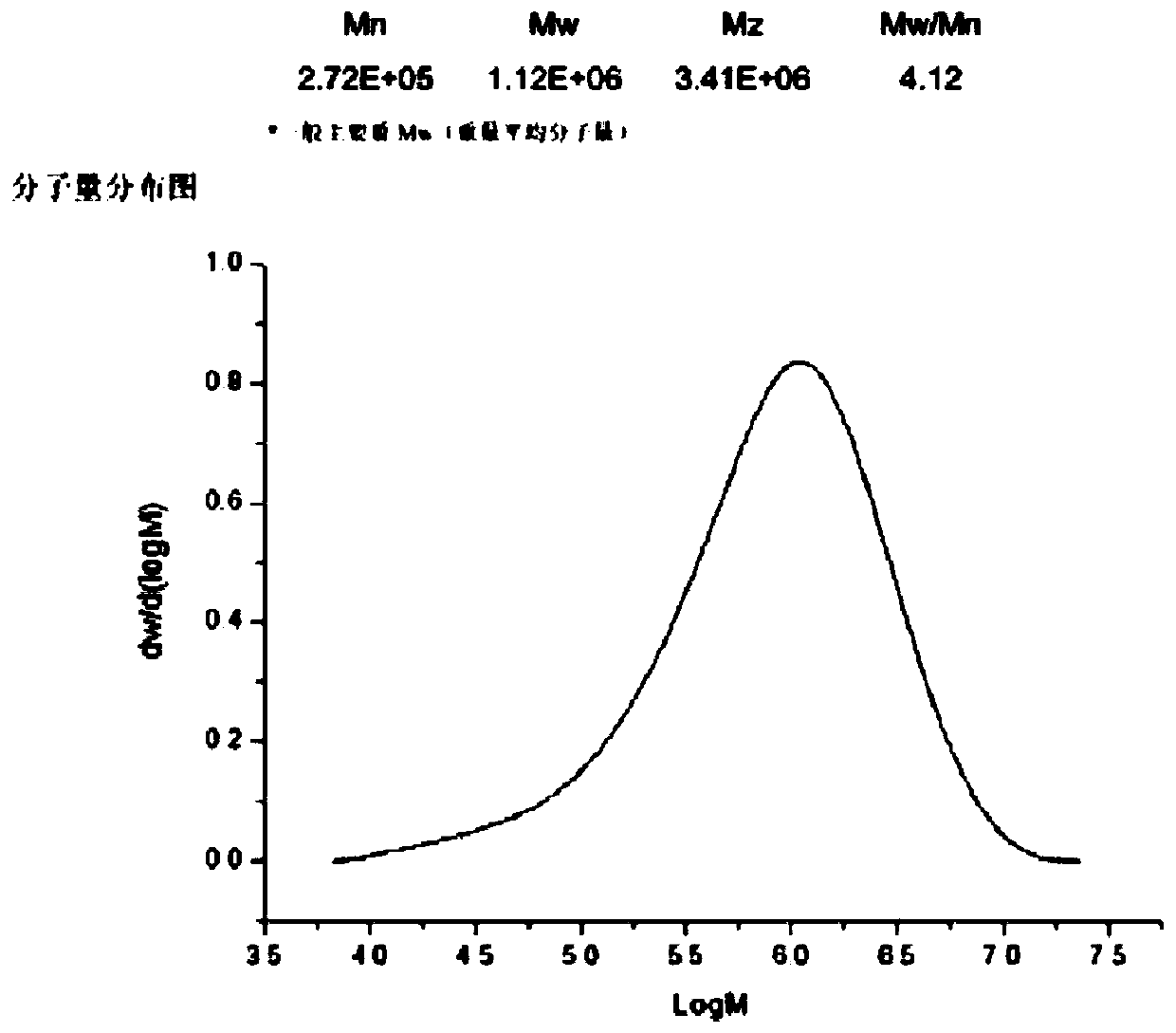

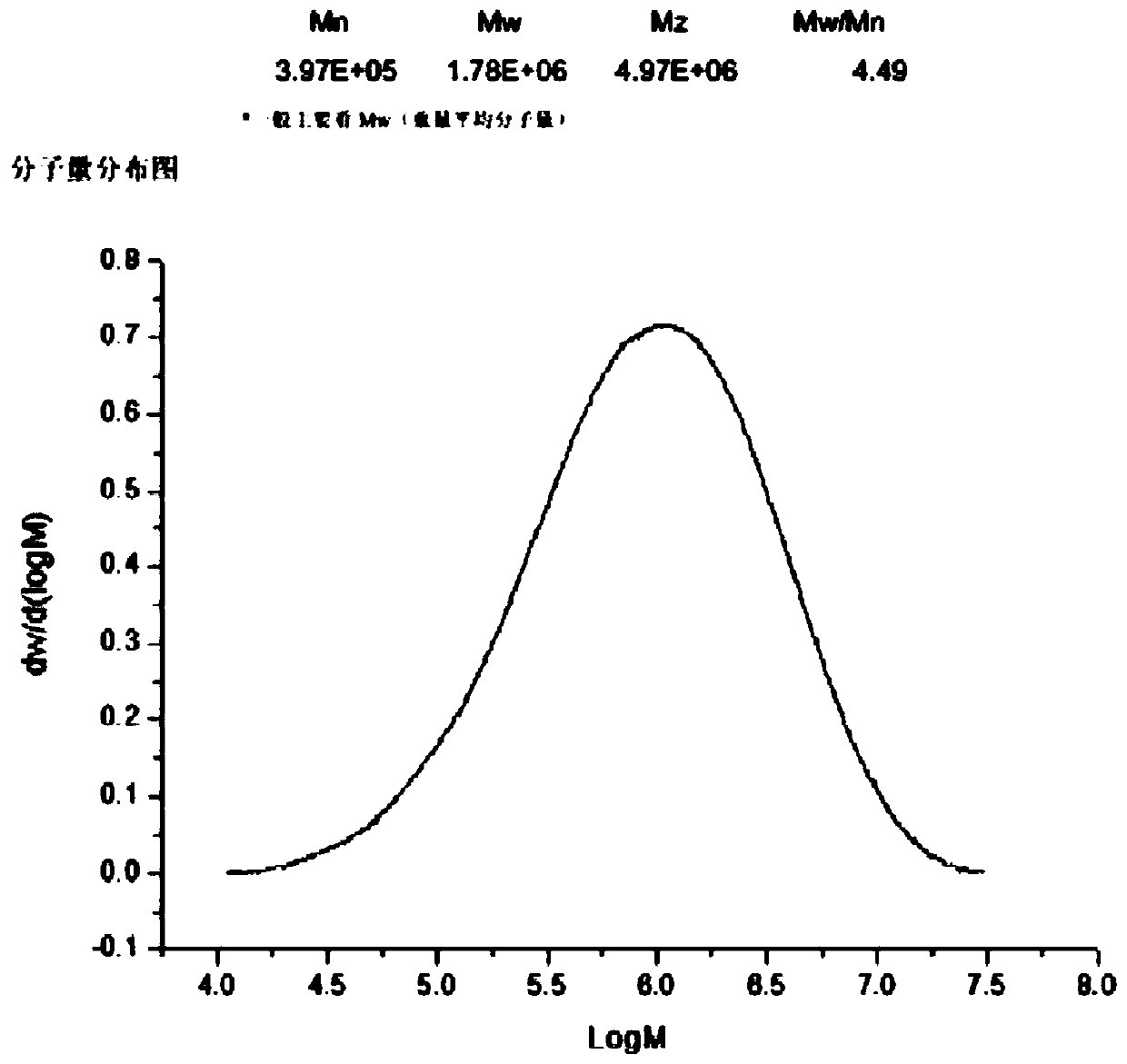

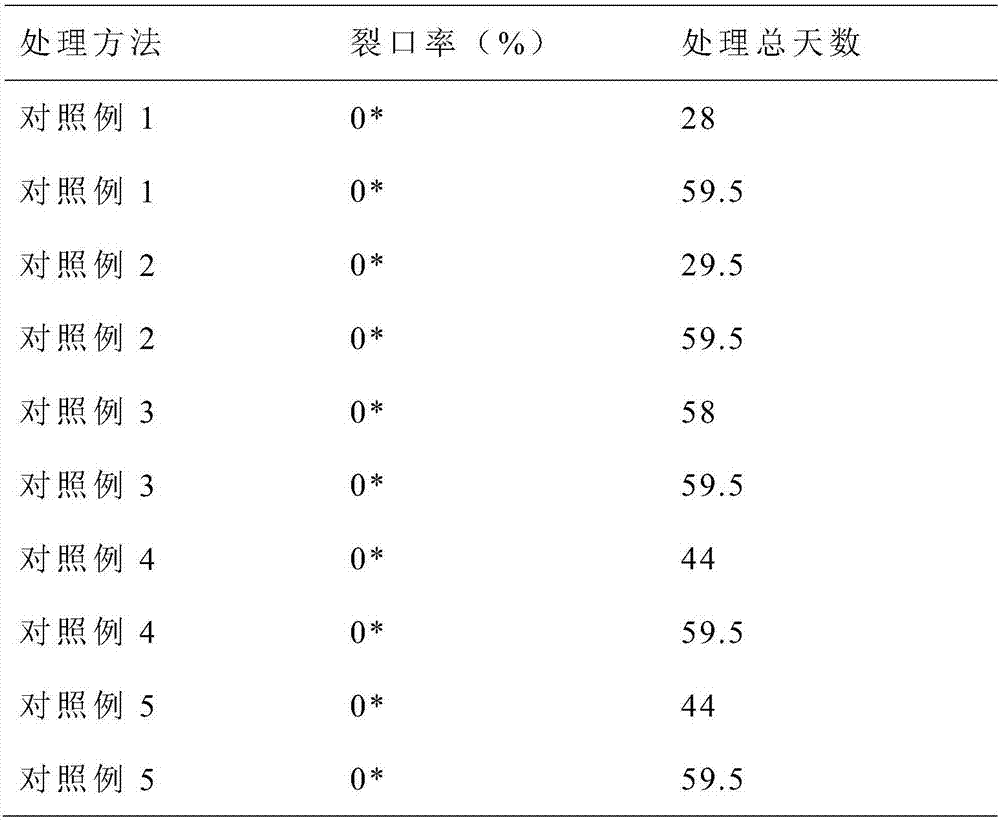

Plant soft capsule and preparation method and application thereof

PendingCN110075081ASimple ingredientsReduce manufacturing costTeaPharmaceutical non-active ingredientsCarrageenanActive component

The invention belongs to the technical field of soft capsules, and particularly relates to a plant soft capsule and a preparation method and application thereof. By controlling weight-average molecular weight of carrageenan to be 1.2*10<6>-2.0*10<6>, the plant soft capsule with excellent performance is prepared with starch, a plasticizer and water; compared with a plant soft capsule in the prior art, the plant soft capsule provided by the invention is lower in production cost, and the product quality reaches the requirements of a gelatin soft capsule; under the premise of high production efficiency, low oil leaking rate is realized and fracture time reaches the standard of United States Pharmacopeia (USP). The plant soft capsule prepared by the preparation method provided by the inventioncan be filled with active components as contents, and is used for preparing multiple drugs, functional foods or dietary nutrition supplements.

Owner:JIANGSU ALAND NOURISHMENT

Extraction method of microalgae grease

The invention discloses an extraction method of microalga grease. The method comprises the following steps of: (1) stirring and mixing collected microalgae with a C1-C6 short-chain alcohol solvent and an extractant; (2) adding the mixed liquid into a supergravity crushing device to perform microalgae cell crushing and grease extraction; and (3) after the microalgae cell crushing and the grease extraction are finished, cooling the discharge liquid of the supergravity crushing device to room temperature, permitting the liquid to stand, respectively extracting an organic solvent layer (an oil phase) and a water layer (a water phase), and recovering the organic solvent in the oil phase by a distillation way, and meanwhile, obtaining the microalga grease. The method has the advantages of simple operation processes, short extraction time, the high microalga grease yield, suitability for directly extracting grease from alga ooze, and the like over the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-performance foam light soil foaming agent

The invention discloses a high-performance foam light soil foaming agent and a preparation method thereof.The high-performance foam light soil foaming agent is prepared from, by mass, 20%-50% of a surfactant, 5%-15% of a foam stabilizer, 15%-30% of a water reducing agent, 5%-10% of a coagulant, 1%-3% of a nano oxide and 10%-50% of water. The prepared foaming agent has good foaming capacity and foaming stability, and foam holes formed in the foamed light soil are uniform in size and uniform in distribution. And the influence of moisture on the foamed light soil can be reduced, and the service life of the foamed light soil in a rainy humid and hot environment is prolonged.

Owner:GUANGDONG SHENGRUI TECH CO LTD

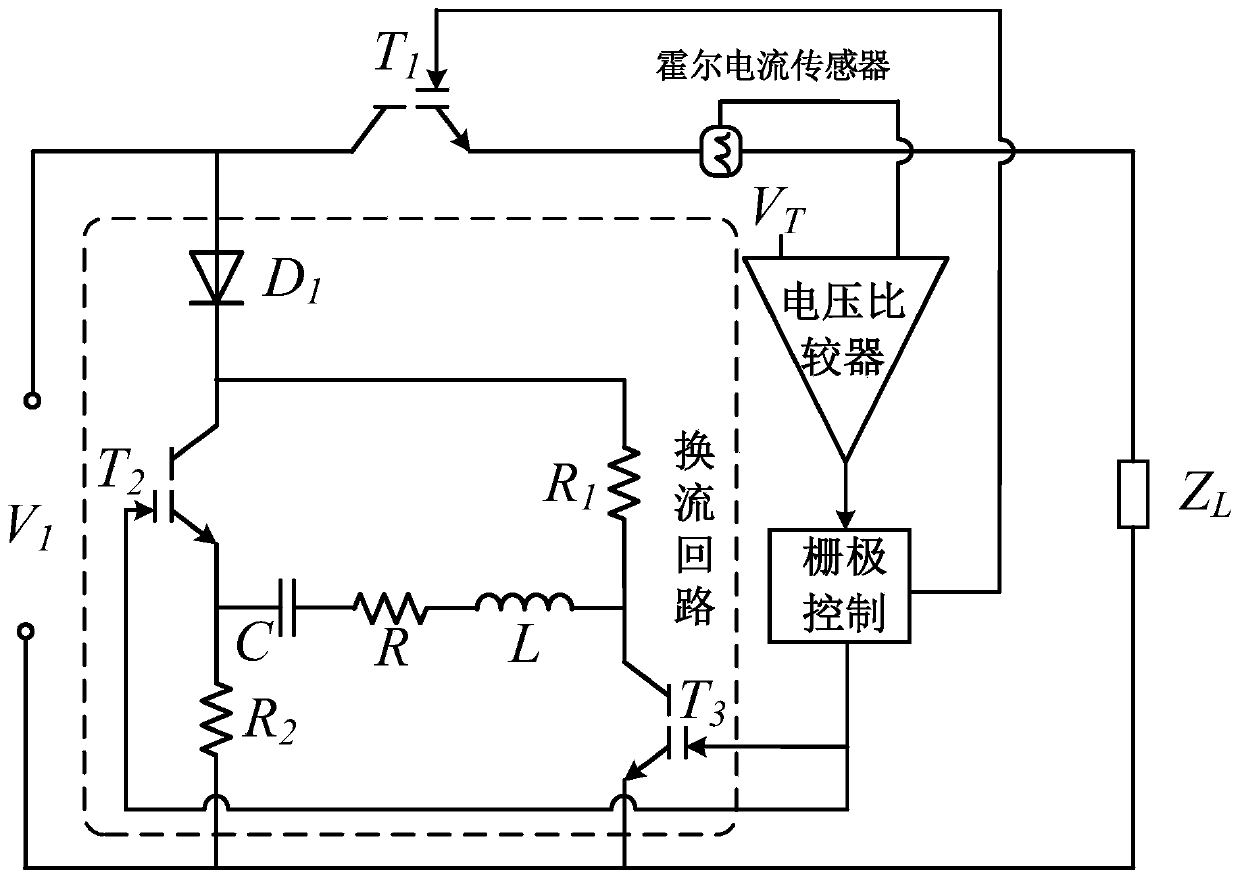

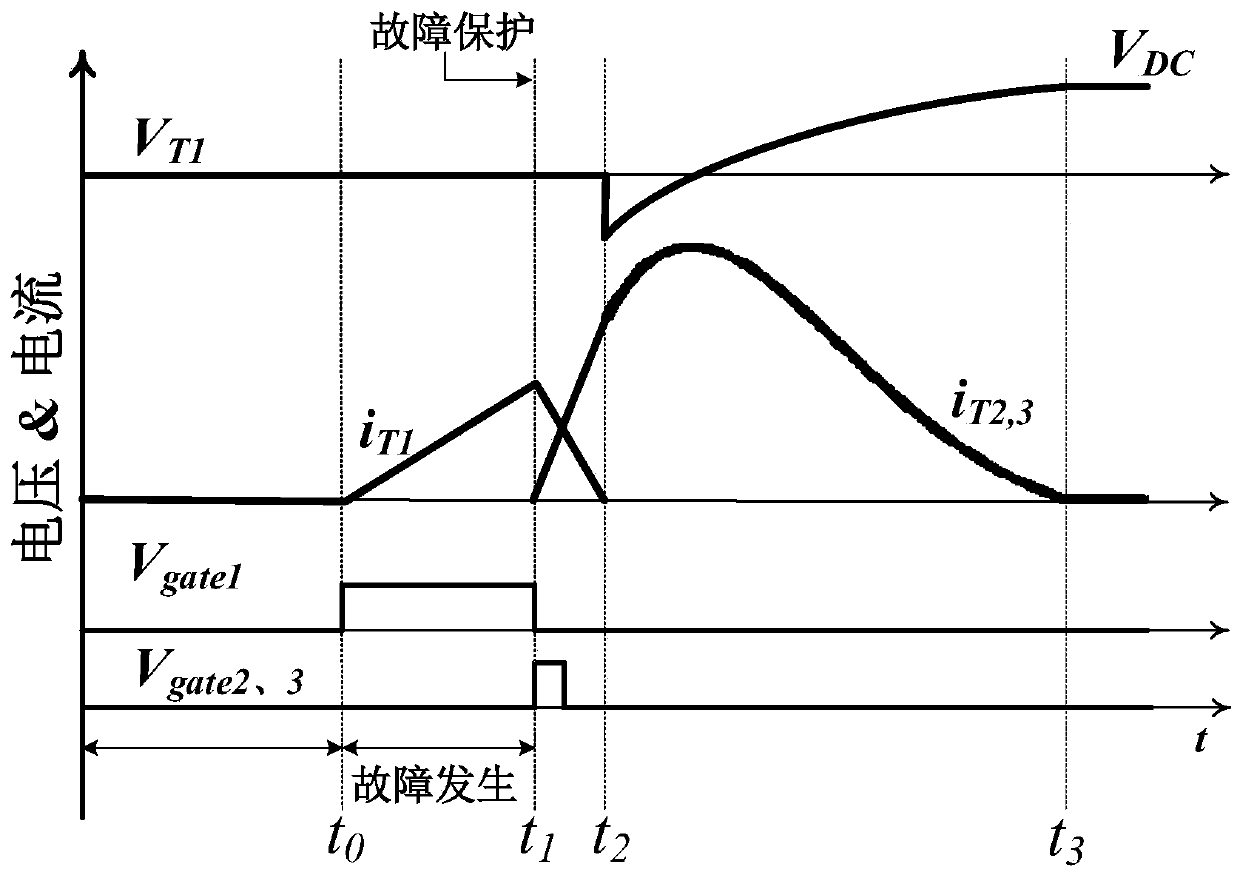

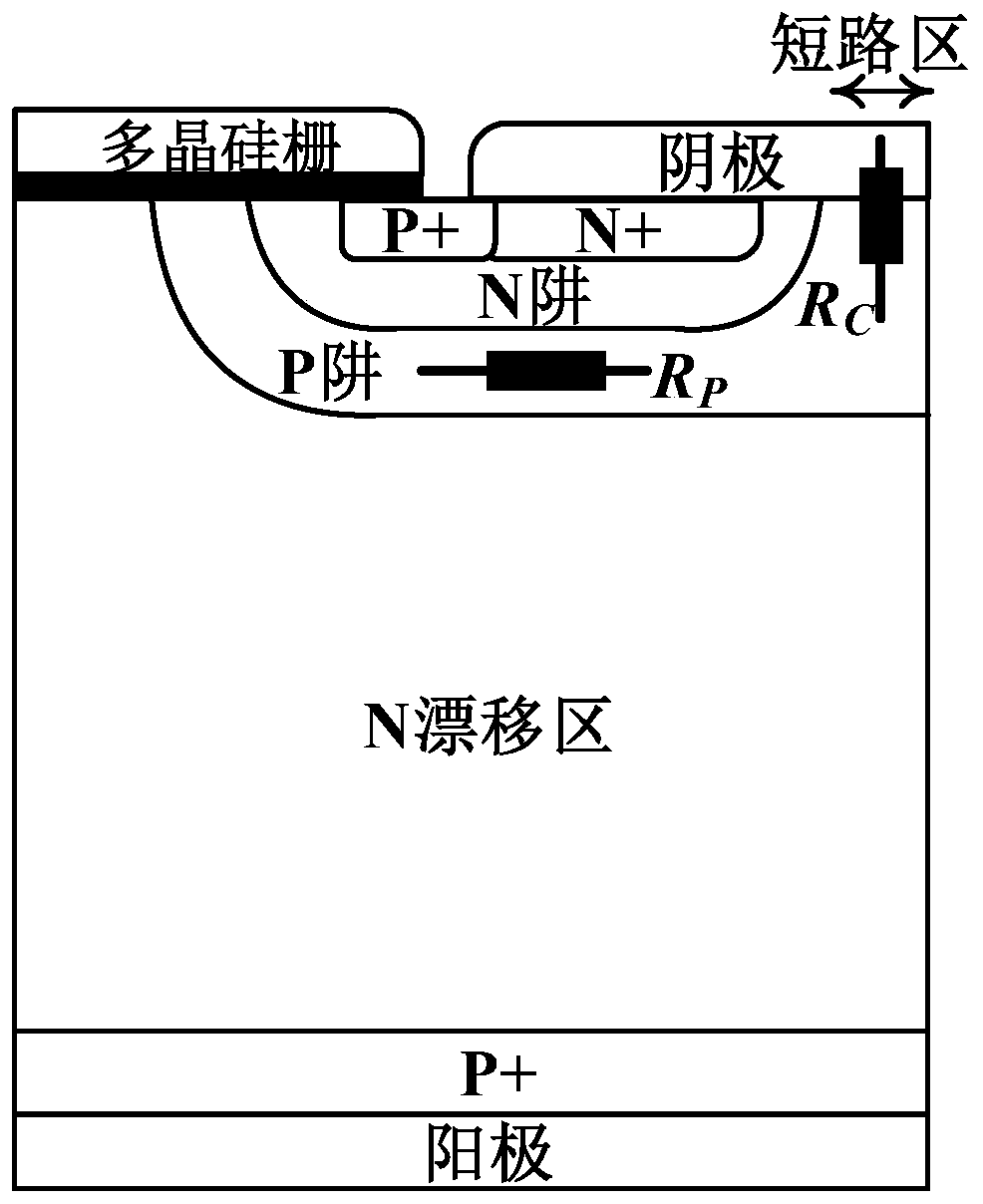

Direct-current solid-state circuit breaker based on cathode short-circuit grid-control thyristor

The invention belongs to the technical field of electronics, and particularly relates to a direct-current solid-state circuit breaker based on a cathode short-circuit grid-control thyristor. The circuit mainly comprises a main loop composed of a first direct-current power supply (V1), a load (ZL) and a first CS-MCT (T1), a first diode (D1), a second CS-MCT (T2) and a third CS-MCT (T3), wherein thecurrent conversion loop is composed of a first resistor (R1), a second resistor (R2), a current conversion capacitor (C), an inductor (L) and a third resistor (R), and the monitoring unit is composedof a Hall current sensor and a voltage comparator. The method is characterized in that CS-MCT with low on-resistance and high di / dt capability is used as a semiconductor switch, and rapid interruption of fault current can be realized by combining a monitoring unit and a gate control unit. Compared with a traditional solid-state circuit breaker, the CS-MCT-based solid-state circuit breaker has theadvantages of low power consumption and high response speed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Blast furnace cooling wall water pipe repairing method

ActiveCN111041142ASmall resistanceGuaranteed cooling strengthCooling devicesSoftened waterWater flow

The invention relates to a blast furnace cooling wall water pipe repairing method, and belongs to the technical field of cooling wall repairing. The method comprises the following steps that a, pipe penetrating water returning bags are additionally arranged; b, a damaged water pipe is confirmed; c, a hard pipe is arranged; d, the damaged water pipe is subjected to pipe penetrating; e, a miniaturecooler is arranged; f, a softened water pump is arranged; and g, step-by-step water transferring is carried out. According to the method, the resistance loss of softened water flowing in the water pipe is reduced, the necessary water flow is ensured, and the cooling strength of pipe penetrating is improved; the blast furnace blowing-down time is shortened; the damaged cooling water pipe can be quickly confirmed, and the accuracy is 100%; the resistance loss of a hose is favorably reduced, and the subsequent trepanning operation of the hard pipe is facilitated; by arranging the miniature cooler, the cooling function of the damaged water pipe which cannot be subjected to pipe penetrating is repaired; and after blast furnace reblowing, the softened water pump is additionally started, and a step-by-step water quantity adjusting scheme is adopted, so that the cooling strength of the cooling water pipe is ensured.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

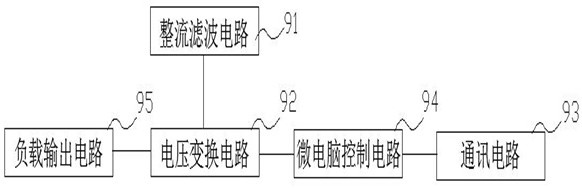

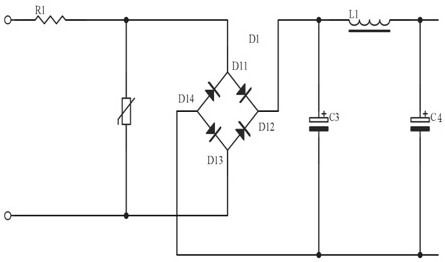

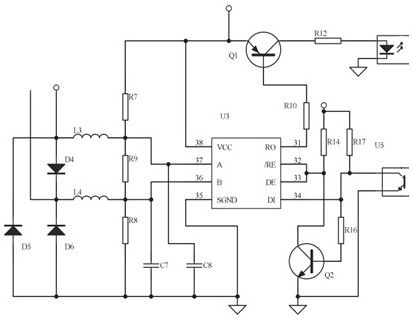

Energy-saving intelligent relay based on Internet of Things

ActiveCN112992607ASimple structureEasy to useCircuit arrangementsElectric switchesTelecommunicationsInternet of Things

The invention discloses an energy-saving intelligent relay based on Internet of Things. The intelligent relay comprises a relay and a control system electrically connected with the relay, wherein the control system comprises a rectification filter circuit, a voltage conversion circuit connected with the rectification filter circuit, a microcomputer control circuit connected with the voltage conversion circuit, a communication circuit connected with the microcomputer control circuit, and a load output circuit connected with the microcomputer control circuit, the load output circuit is electrically connected with the relay, a communication module is arranged in the communication circuit; the relay comprises a contact bridge assembly, a linkage rod connected to the contact bridge assembly, a movable iron core fixed at one end of the linkage rod and a static iron core enabling the movable iron core to move, the static iron core is arranged in a coil framework, a magnetizer is arranged on the periphery of the coil framework, a coil is wound on the coil framework, and two electrodes of the coil are connected with a load output circuit. The intelligent relay is advantaged in that intelligent relay energy conservation and emission reduction are realized, the breaking time is shortened, and flexibility of the relay is improved.

Owner:NANJING QUANNING ELECTRIC

Method for controlling gas backflow in melting reduction smelting

InactiveCN103184301AEvenly distributedReduce the chance of enrichmentShaft furnaceDifferential pressureNitrogen

The invention relates to a method for controlling gas backflow in melting reduction smelting. Each DRI downcomer connected with a shaft furnace is mounted with a cold gas and nitrogen adding pipe which is provided with a control valve. The DRI downcomer is mounted with a temperature detection galvanic couple to detect gas temperature in the downcomer. Through inputting cold gas or nitrogen to the DRI downcomer, the temperature of the backflow gas in the DRI downcomer is controlled at 650-750 DEG C. The high temperature backflow gas which does harm to shaft furnace running is transformed into normally used reduction gas, which participates in reduction inside the shaft furnace to achieve control of the gas backflow. Conventional practice of suppressing backflow gas is changed by the present invention, adding powder to shaft furnace center is cancelled, and the backflow gas is dredged and used. Cold gas / nitrogen is fed into the DRI downcomer to reduce the temperature of backflow gas, improve dust distribution and enrichment condition in the shaft furnace, reduce shaft furnace differential pressure, improve gas utilization, prolong shaft furnace emptying cycle, reduce downcomer blockage frequency and damping down time, and improve operation rate and yield.

Owner:CHINA BAOWU STEEL GRP CORP LTD

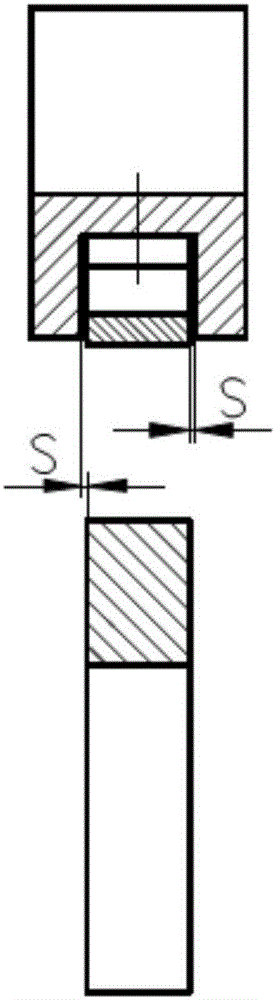

Grouting pile head breaking and removing method

The invention relates to grouting piles, in particular to pile heads of the grouting piles. A grouting pile head breaking and removing method includes the steps that when a grouting pile steel reinforcement cage is machined, each steel reinforcement of the top of the cage is sleeved with a plastic pipe, the length of each plastic pipe is designed from the designed pile top position to the top of the steel reinforcement cage, and the diameter of each plastic pipe is larger than that of the corresponding steel reinforcement; the pipe bottoms of the plastic pipes are tightened with adhesive tapeand iron wires, isolation powder fills in the plastic pipes, after the plastic pipes are full of the isolation powder, the pipe tops of the plastic pipes are sealed, and sealed pipe openings of the plastic pipes are tightened with iron wires; after construction of the grouting piles is finished, during breaking and removing of the pile heads of the concrete grouting piles, four separation holes are drilled at equal intervals around the piles at the designed pile top elevation, and the diameters of the holes are slightly smaller than the diameter of an air pick drill bit; symmetrical impact isperformed in the four separation holes through an air pick, and the concrete pile heads are directly cut off in the positions; and holes are symmetrically drilled in the positions one third away fromthe upper ends of the pile heads, two steel reinforcement hanging rings are mounted, the cut-off pile heads are hung away with machinery, and breaking and removing work of the pile heads is finished.By means of the grouting pile head breaking and removing method, the difficulty and intensity of the pile head breaking and removing are reduced.

Owner:CHINA MCC20 GRP CORP

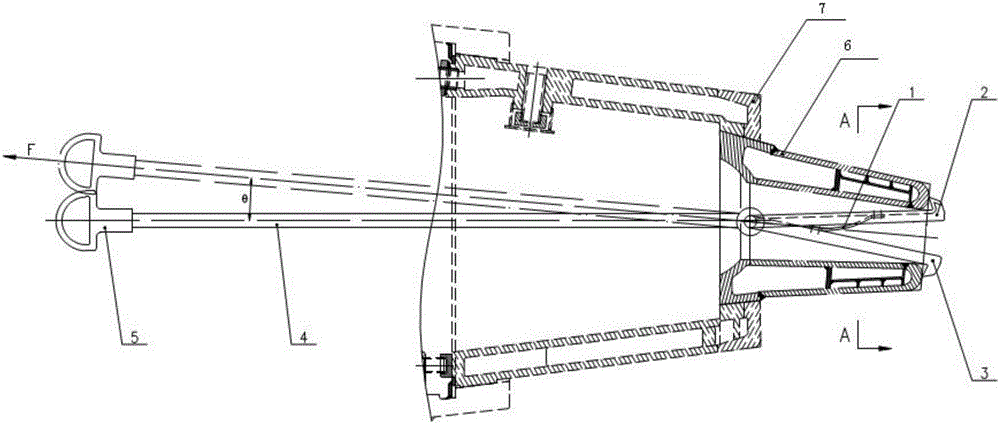

Drop-out fuse for power construction

PendingCN112420465AGuaranteed initial state of unityShorten break timeEmergency protective devicesEngineeringStructural engineering

The invention belongs to the field of fuses, and particularly relates to a drop-out fuse for power construction. The drop-out fuse comprises an insulator, a hook-type socket, a pin shaft A, an incomplete gear, a pin shaft B, a fuse tube, a memory alloy spring and the like, wherein the insulator is mounted on an electric pole through a mounting bracket, the hook-type socket is mounted at a wire outlet end at the lower end of the insulator, and the hook type socket is matched with a mounting plate. According to the invention, the range of fusing current can be judged according to the number of teeth, crossed by a sharp corner of the tail end of an inner rod of a telescopic rod, of the incomplete gear, so maintenance personnel can better take corresponding measures to maintain a circuit, andhigh safety is achieved.

Owner:荆门麦隆珂机器人科技有限公司

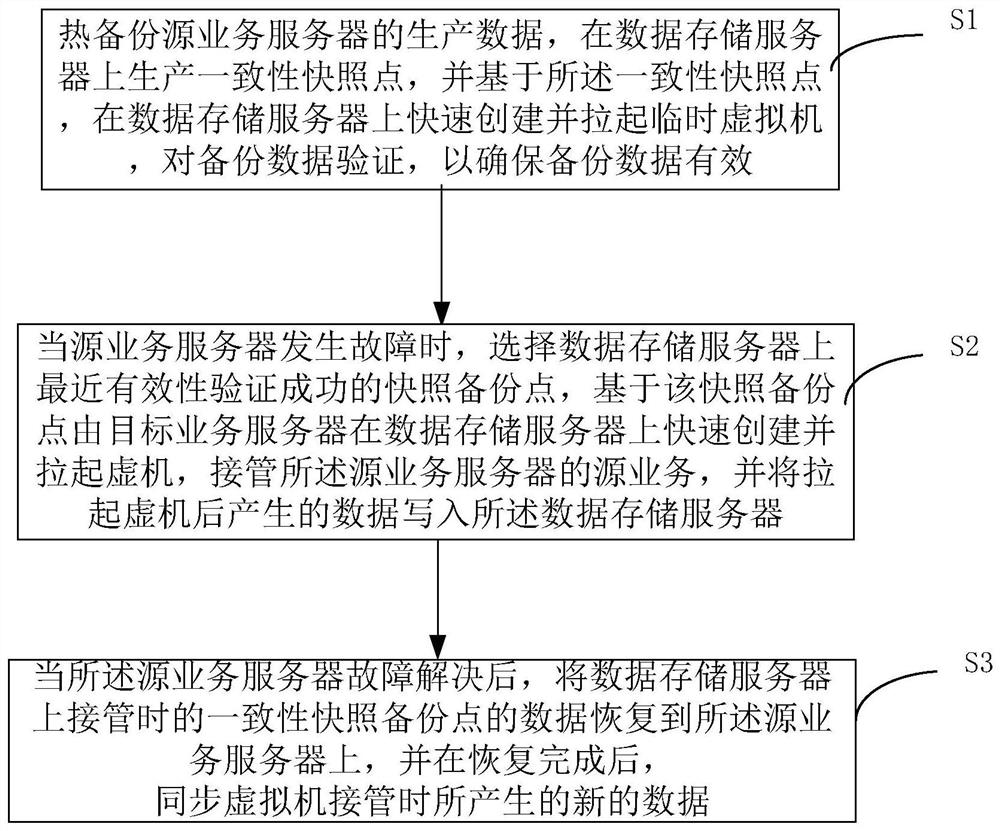

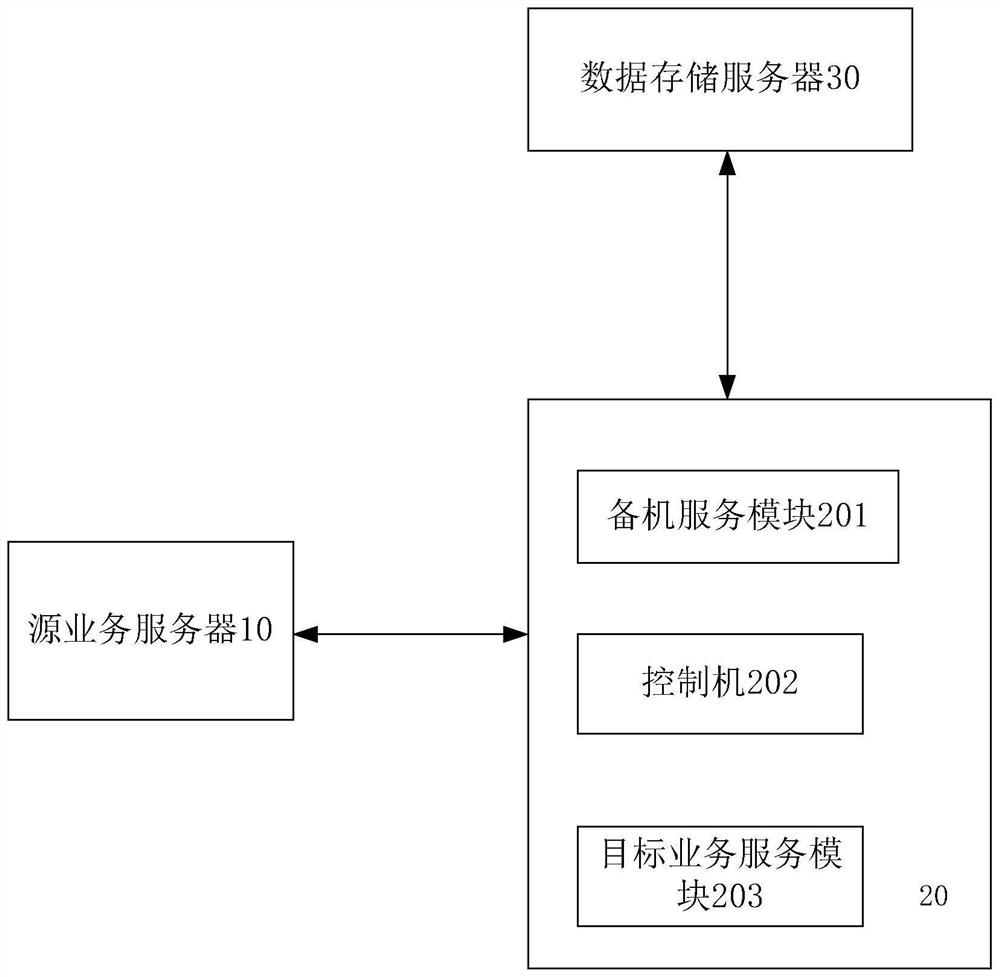

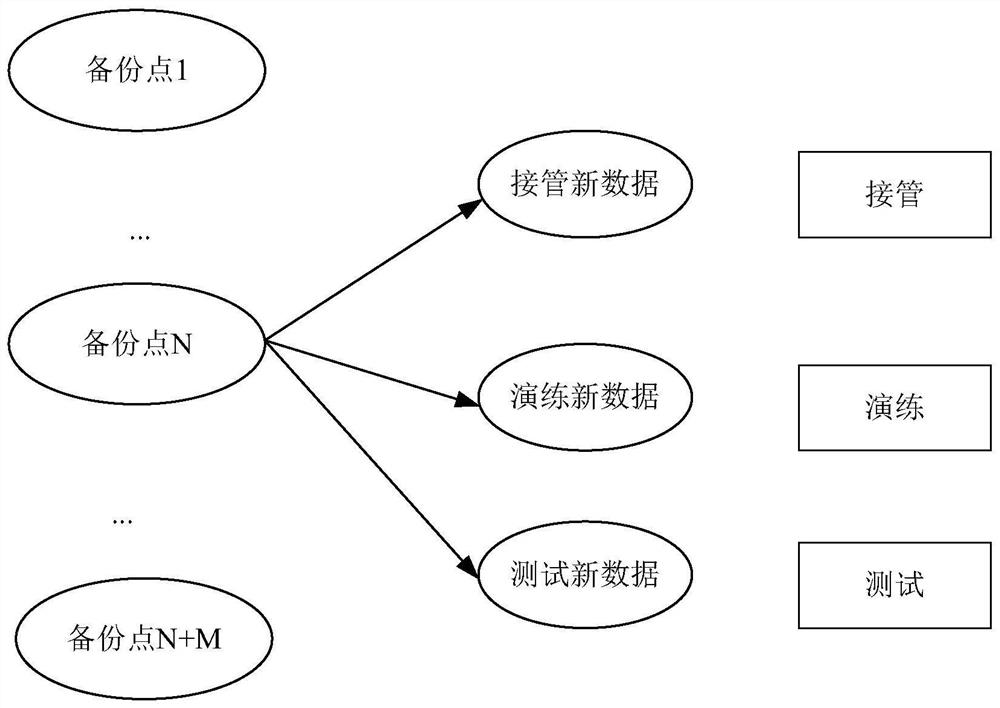

Method and system for repeatedly and quickly recovering system based on system backup points

InactiveCN112380062APromote recoveryShorten break timeSoftware simulation/interpretation/emulationRedundant operation error correctionService systemVirtual machine

The invention discloses a method and system for quickly recovering a service system for multiple times based on a system backup point, and the method comprises the following steps: S1, carrying out hot backup of the production data of a source service server, generating a consistent snapshot point on a data storage server, and quickly building and pulling a temporary virtual machine based on the consistent snapshot point, to verify the backup data; S2, when the source service server fails, selecting a snapshot backup point with successful recent validity verification on the data storage server, quickly creating and pulling up a virtual machine on the data storage server based on the snapshot point, taking over the source service of the source service server, and writing data generated after pulling up the virtual machine into the data storage server; and S3, after the fault of the source service server is solved, recovering the data of the consistent snapshot backup point when the datastorage server takes over to the source service server, and synchronizing new data generated when the virtual machine takes over after the recovery is finished.

Owner:INFORMATION2 SOFTWARE SHANGHAI

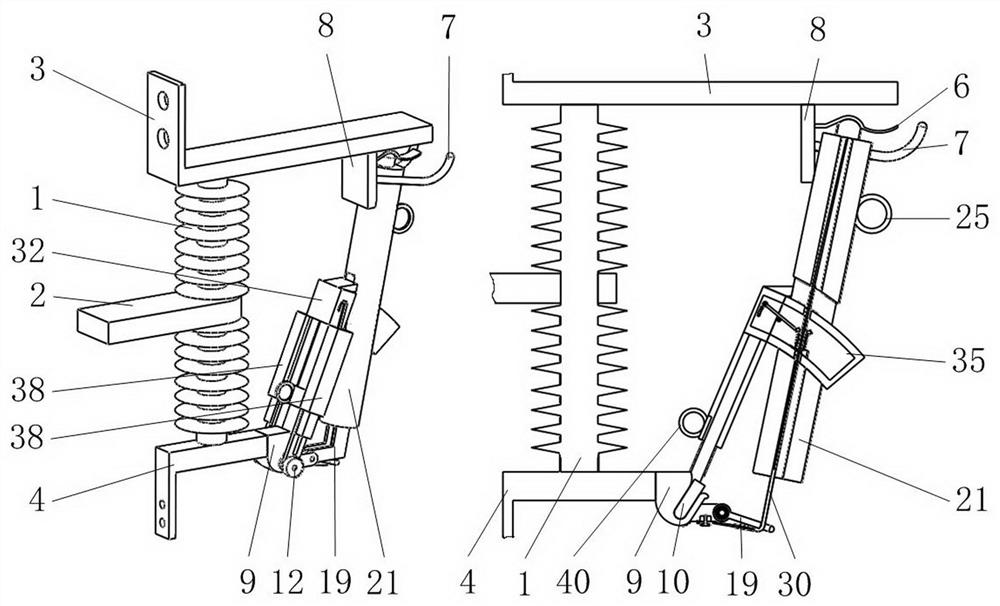

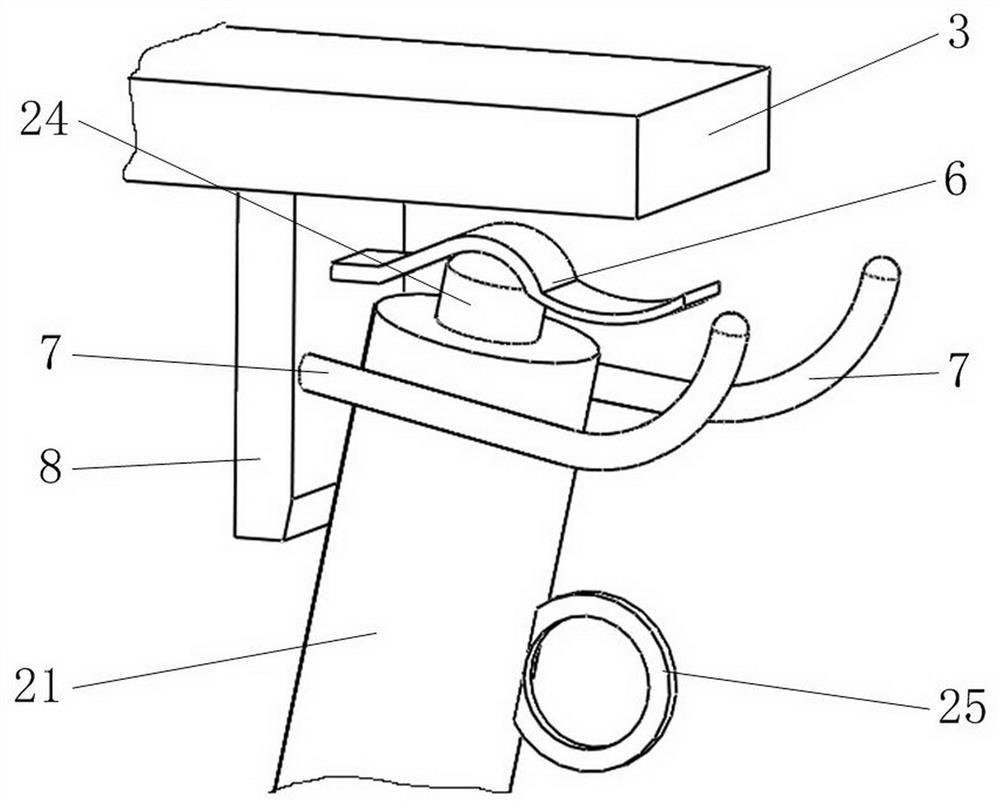

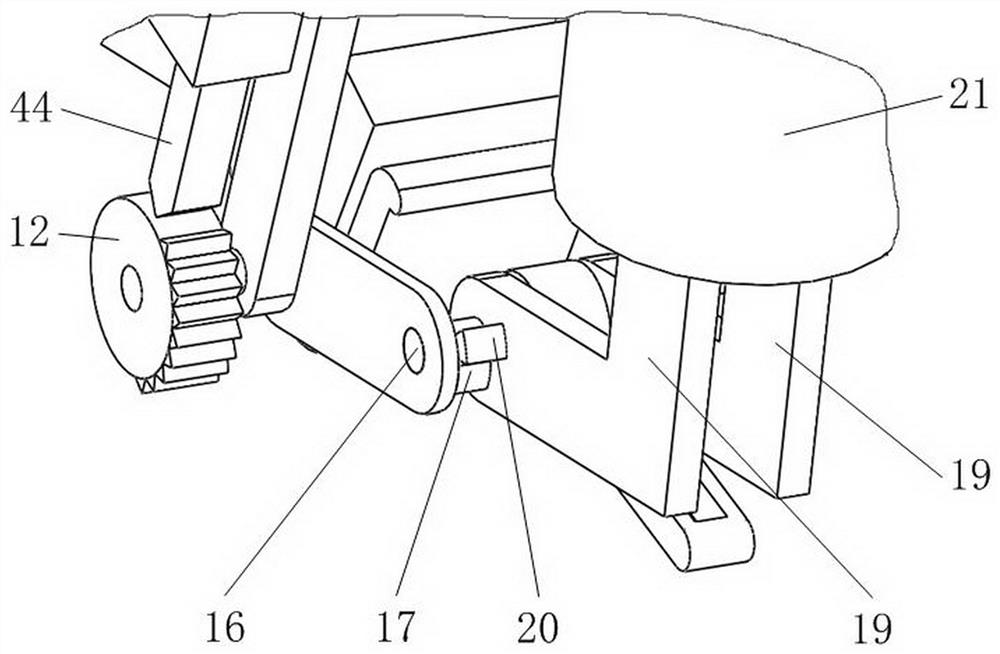

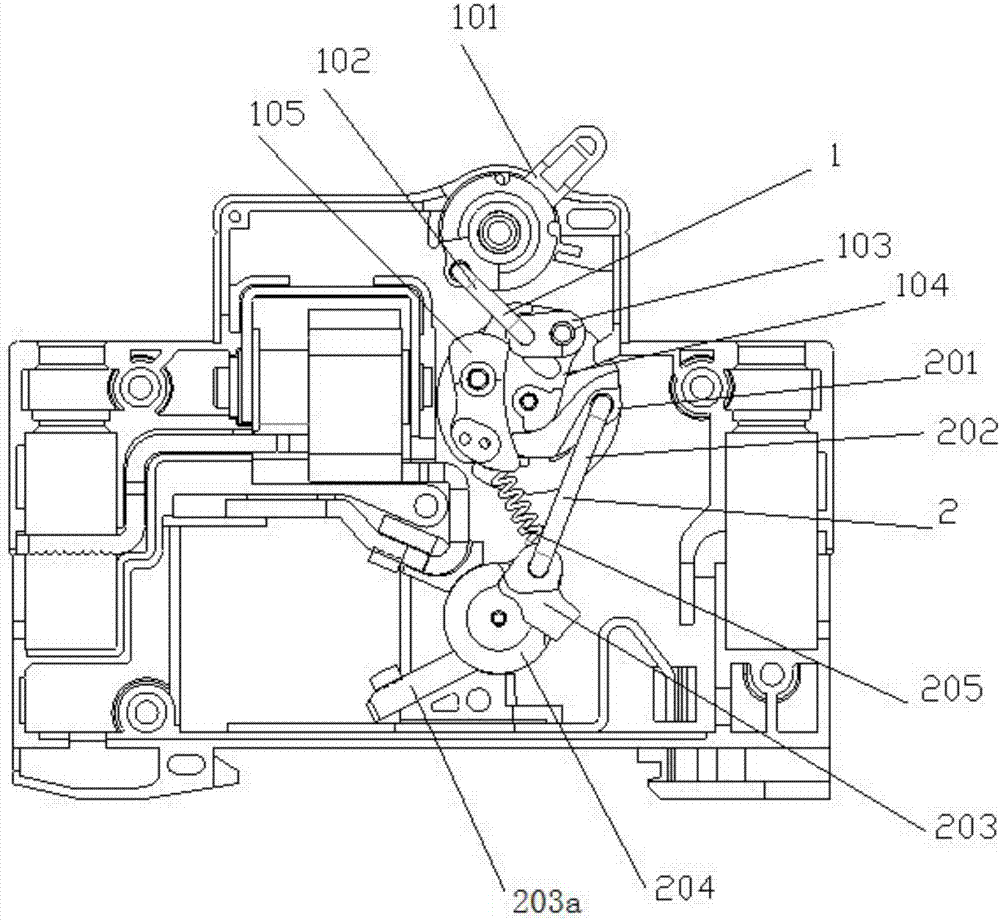

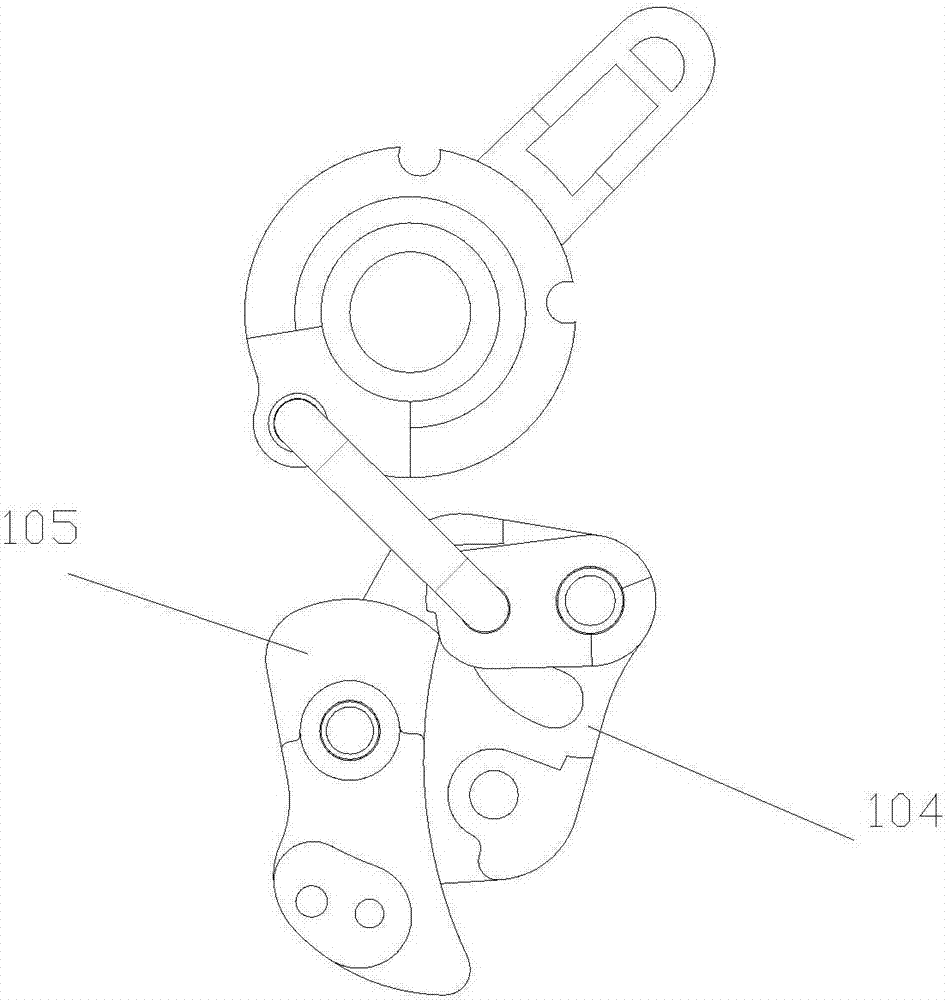

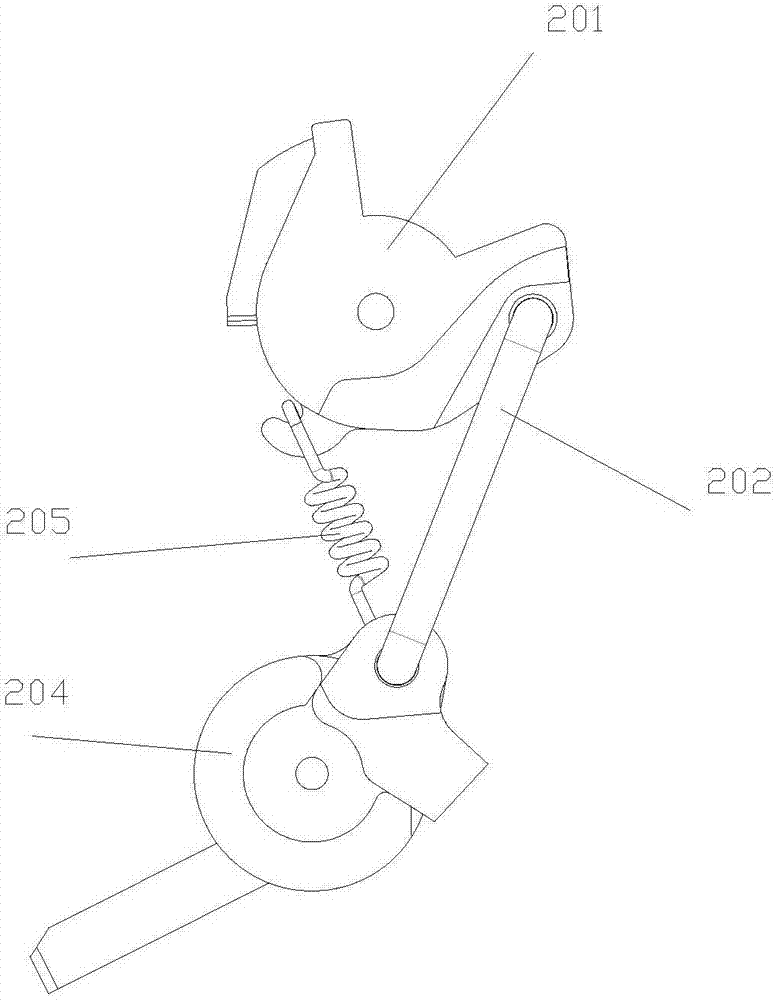

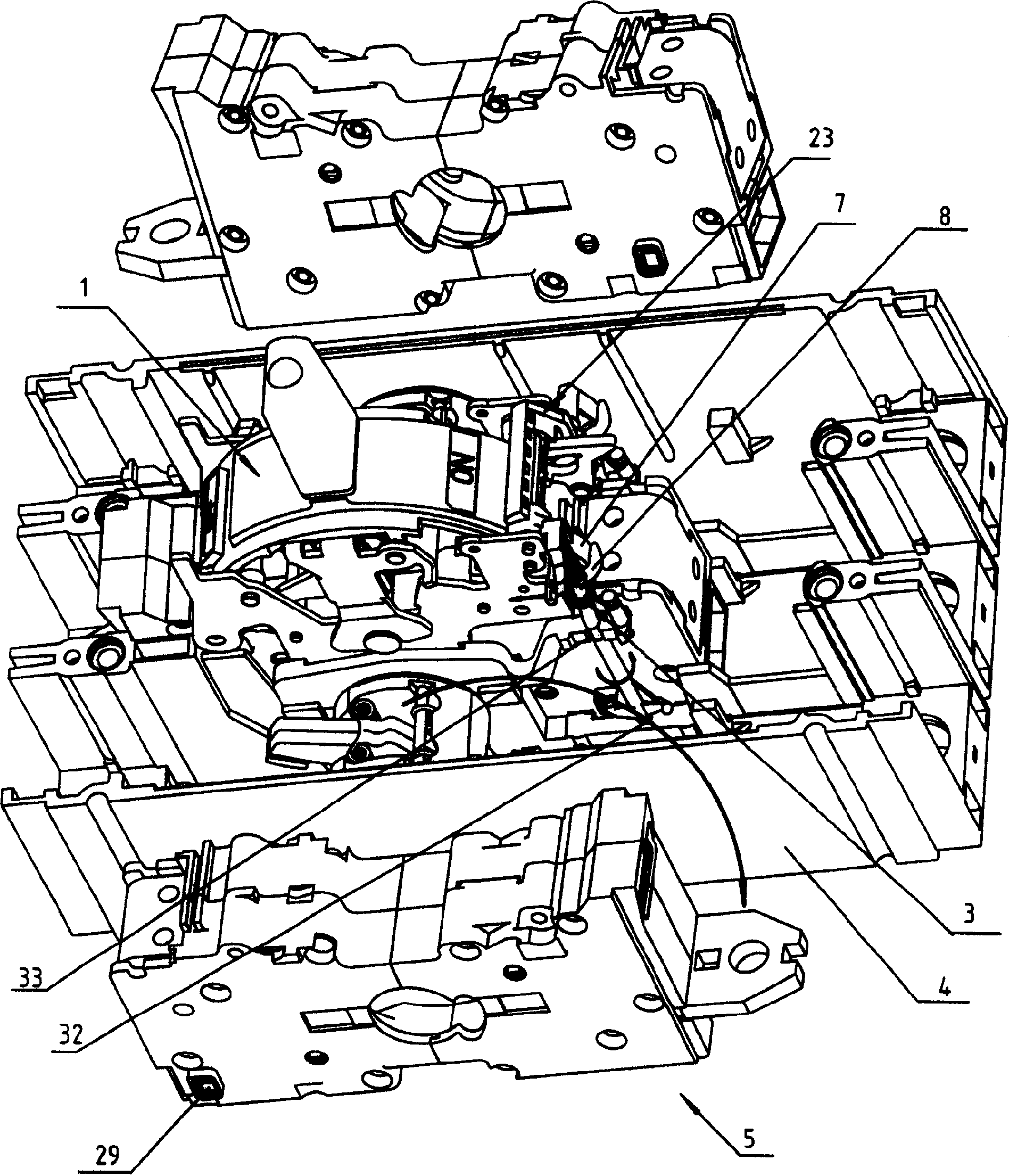

Improved structure of miniature circuit breaker operating mechanism

ActiveCN107546073ASimple structureImprove breaking capacityProtective switch operating/release mechanismsEngineeringBreaking capacity

The invention relates to an improved structure of a miniature circuit breaker operating mechanism. The characteristics lie in that the improved structure comprises an upper four-bar linkage (1) and alower four-bar linkage (2), wherein the upper four-bar linkage (1) and the lower four-bar linkage (2) are connected in series. The improved structure shortens the unlocking time of the mechanism whena circuit breaker breaks high current. Meanwhile, the improved structure eliminates drop of a moving contact reliably and effectively, is increased in spacing, shortened in arc striking path, enhancedin arc extinguishing capacity, accelerated in tripping speed and shortened in breaking time, and improves the breaking capacity of the circuit breaker.

Owner:SHANGHAI LIANGXIN ELECTRICAL

Method for blocking gas spurt leakage of gas enclosing cover on furnace foundation of large-sized blast furnace

ActiveCN106702047APrevent seal leakageShorten break timeBlast furnace detailsEngineeringBlast furnace

The invention discloses a method for blocking gas spurt leakage of a gas enclosing cover on a furnace foundation of a large-sized blast furnace. The method is characterized by including a blocking treatment step of the gas enclosing cover and a grouting treatment step of the gas enclosing cover to a wind gap section, namely (1) the gas enclosing cover is subjected to blocking treatment and (2) a grouting mode is adopted for treatment from the gas enclosing cover to the wind gap section. The method for blocking gas spurt leakage of the gas enclosing cover on the furnace foundation of the large-sized blast furnace has the advantages that a plastic sealing material is pressed into the gap between a furnace shell and a refractory material through a grouting hole formed in a furnace body by the adoption of a blast furnace body grouting blocking technology, the gap between the furnace shell and a ramming material inside the furnace can be filled completely, and the purpose of stopping gas from inter-leaking into the gas enclosing cover is achieved; and one part is constructed in blast furnace production, and then the other part is constructed after the blast furnace is subjected to blowing out and damping down, so that damping-down time is shortened, the sealing effect on the blast furnace body is obvious, blowing-out and damping-down time of the blast furnace is short, and the overhauling engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Disassembling mechanism for tuyere small sleeve and disassembling method of tuyere small sleeve

The invention discloses a disassembling mechanism for a tuyere small sleeve. The disassembling mechanism comprises a push rod device, a first hook claw and a second hook claw which are installed at the head part of the push rod device, and an elastic part for connecting the first hook claw and the second hook claw, wherein the two ends of the elastic part are respectively fixed with the first hook claw and the second hook claw; the first hook claw and the second hook claw are respectively hinged with the push rod device by a hinge; two sharp-angled reverse hooks used for hooking the tuyere small sleeve are respectively arranged at the ends, far away from the push rod device, of the first hook claw and the second hook claw. The disassembling mechanism for the tuyere small sleeve is simple and reliable in structure and convenient to use.

Owner:WISDRI ENG & RES INC LTD

Preparation method of foam stabilizer for concrete foaming agent

The invention discloses a preparation method of a foam stabilizer for a concrete foaming agent and belongs to the field of chemical building materials. The preparation method utilizes potato starch and guar gum to prepare the foam stabilizer. In the starch gelatinization process, the starch granules expand to the limit, the interaction between the starch chain and the moisture is promoted at a high temperature, and through use of guar gum, the starch granule expansion is inhibited, the dissolved starch chains are reduced so that the water motility is further improved and the floc formation isreduced. The potato starch and the guar gum have strong viscosity, through use of the potato starch and the guar gum, the foam liquid film viscosity is improved, the liquid on two surfaces of the liquid film are not easily discharged, and a liquid film thinning rate is reduced so that the time of foam rupture is prolonged and the foam stability is improved. The existing foaming agent in the marketutilizes cellulose and starch and easily forms floc in mixing with the solution so that the foam stability is reduced.

Owner:周荣

Safe and durable towing hook for blast furnace

The invention provides a safe and durable towing hook for a blast furnace. The safe and durable towing hook comprises a main body, two hook heads, a front baffle plate, a sliding weight and a handle, wherein the main body is rod-shaped; the hook heads are arranged on one side of the back end of the main body; the front baffle plate is arranged on the main body and is close to the front end of the main body; the sliding weight comprises a sliding weight body and an operating handle which is arranged on the sliding weight body, and the sliding weight main body can be sleeved on the main body in a sliding mode and is positioned between the front baffle plate and the hook heads; the handle is arranged at the front end of the main body; and the two hook heads are respectively arranged on two opposite sides of the back end of the main body. The safe and durable towing hook has a long service life, the hook heads are bilateral hook heads, and during operations of replacing medium-size and small-size sleeves, particularly during the operations of replacing the medium-size sleeves, the hook heads are uniformly heated and stressed, so that the service life of the towing hook is long.

Owner:DAYE SPECIAL STEEL CO LTD

Method for rapidly processing bend loss tuyere small sleeve of blast furnace

The invention discloses a method for rapidly processing a bend loss tuyere small sleeve of a blast furnace and belongs to the field of blast furnace iron making, wherein the bend loss tuyere small sleeve is processed by water closing and melting loss during the damping down process under a hot air pressure of 80-100 KPa. The method for rapidly processing bend loss tuyere small sleeve of a blast furnace can achieve the aims of immediately processing the bend loss tuyere small sleeve, reducing the time of changing tuyere small sleeve and relieving the difficulty of replacing the tuyere small sleeve, thereby shortening the damping down time, weakening the labor strength of the manual operation and reducing the yield loss.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

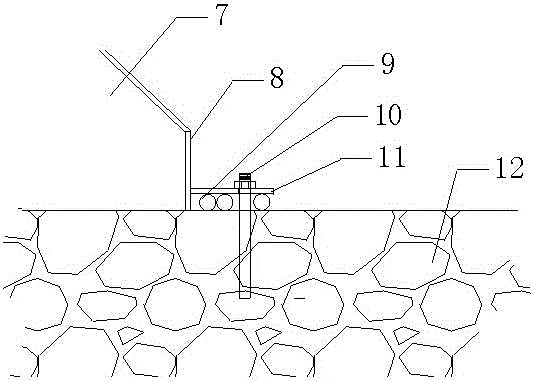

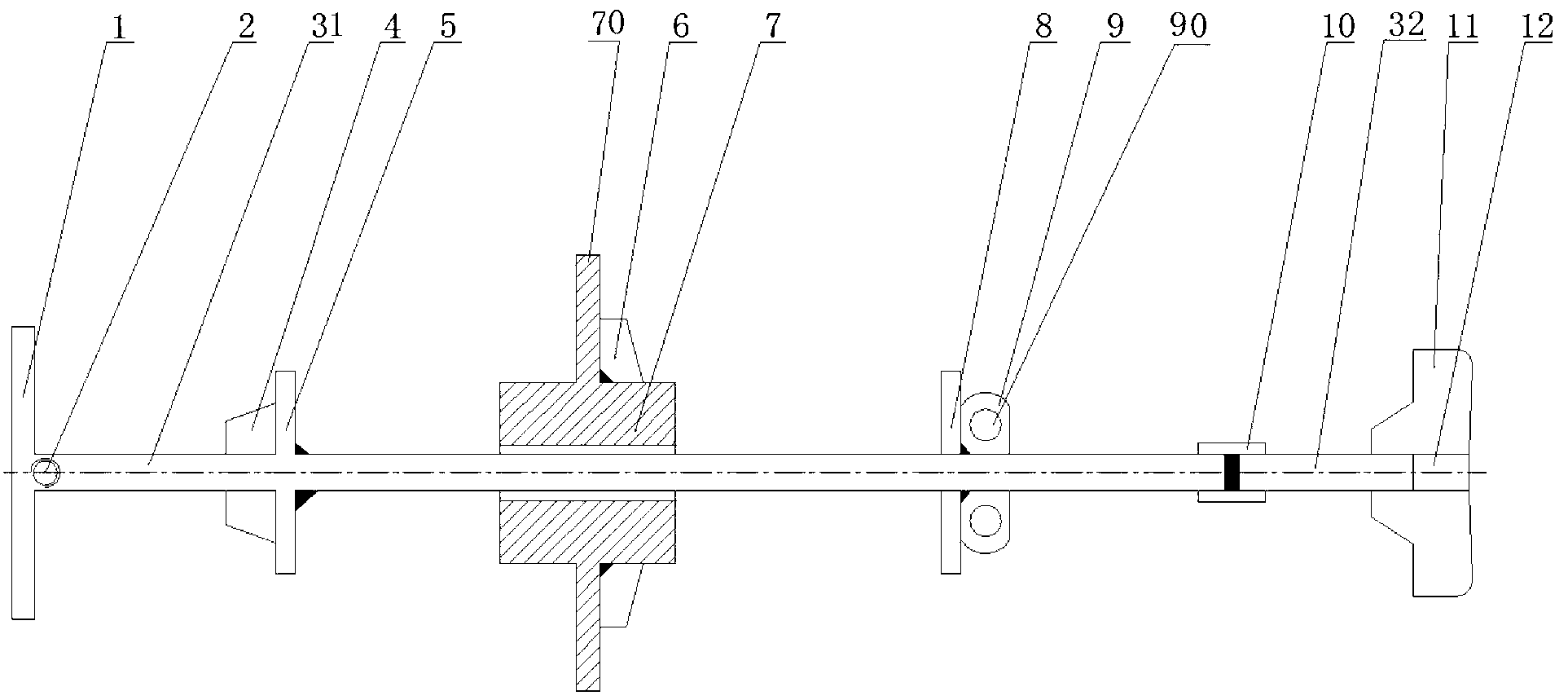

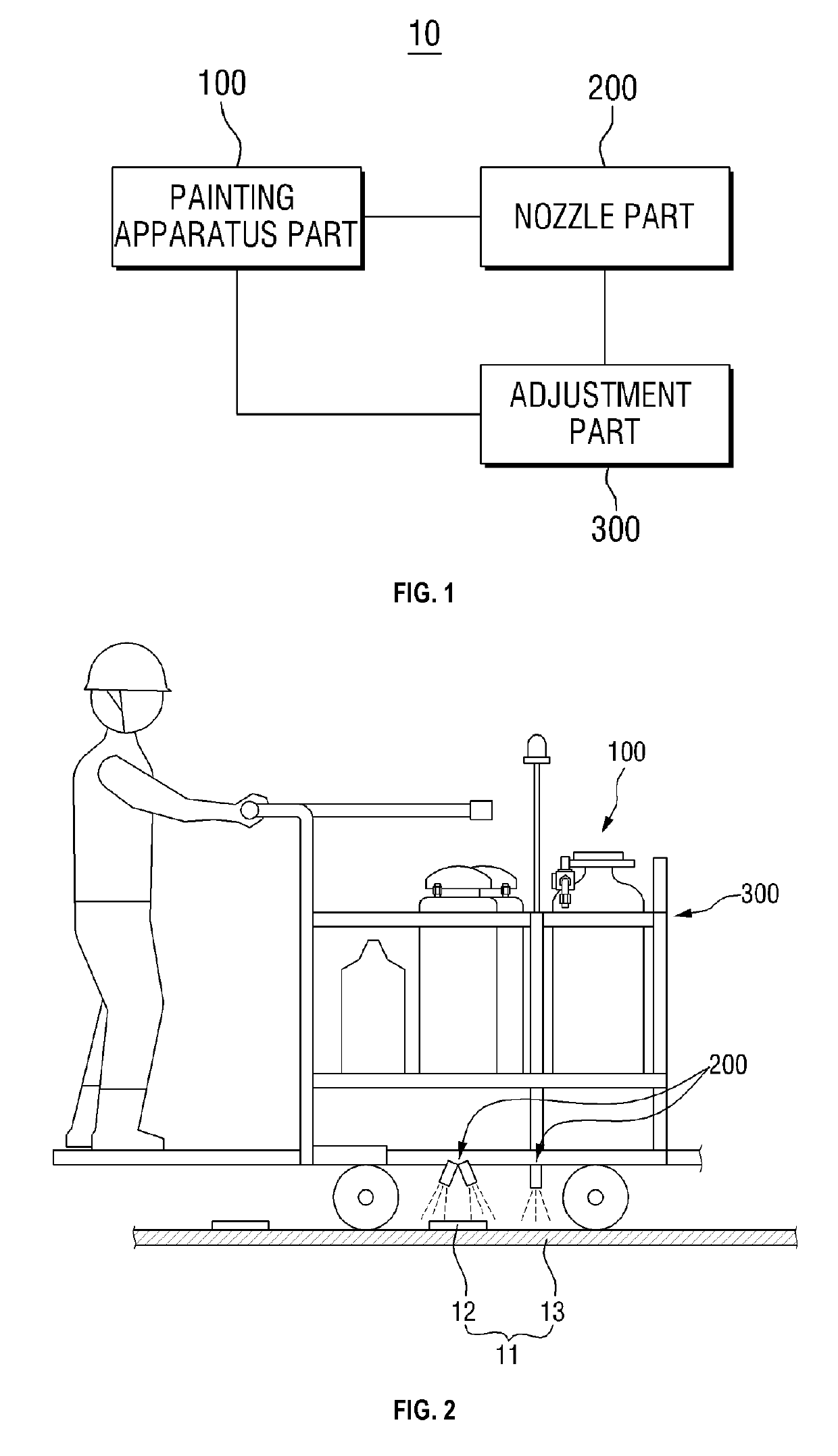

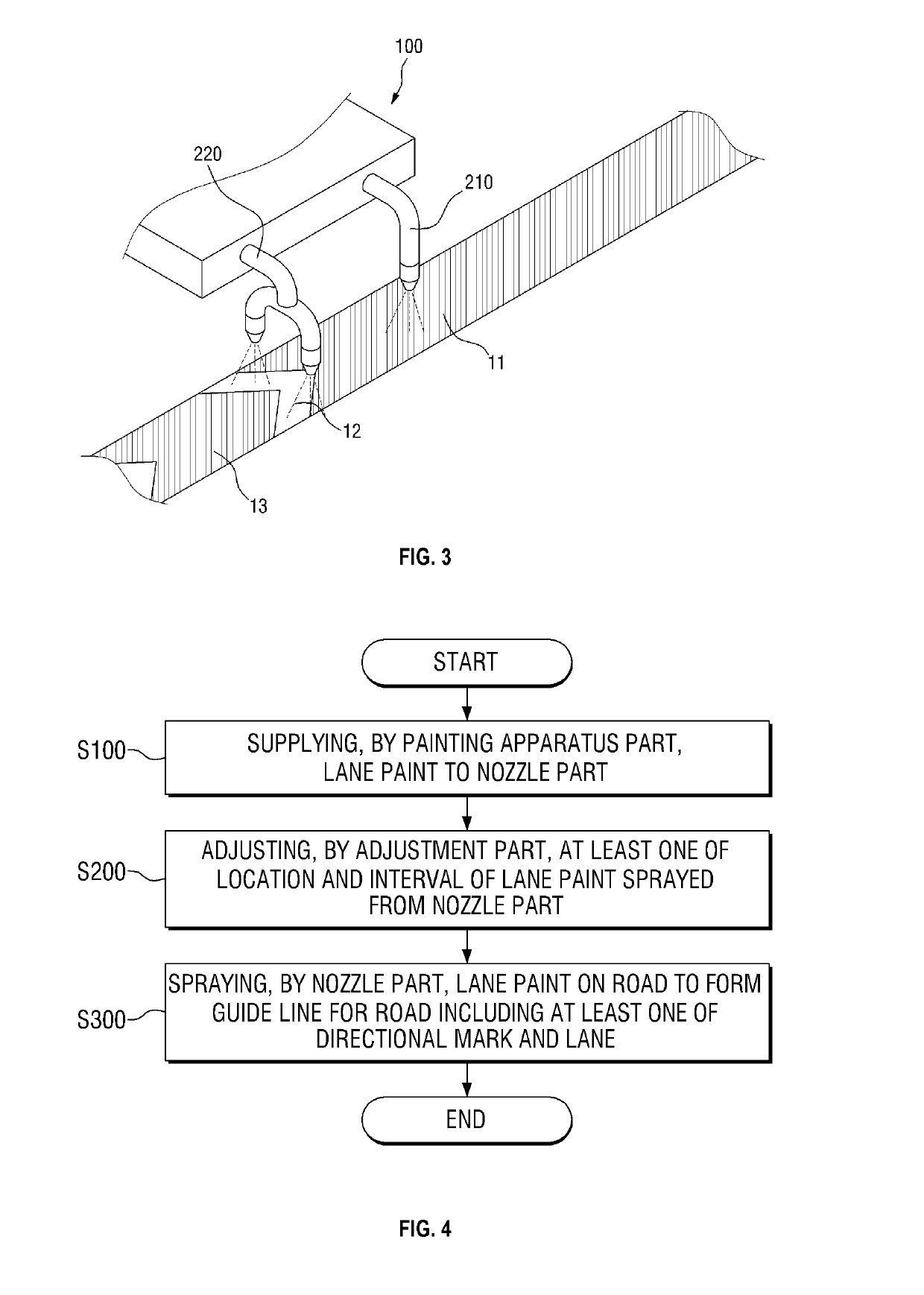

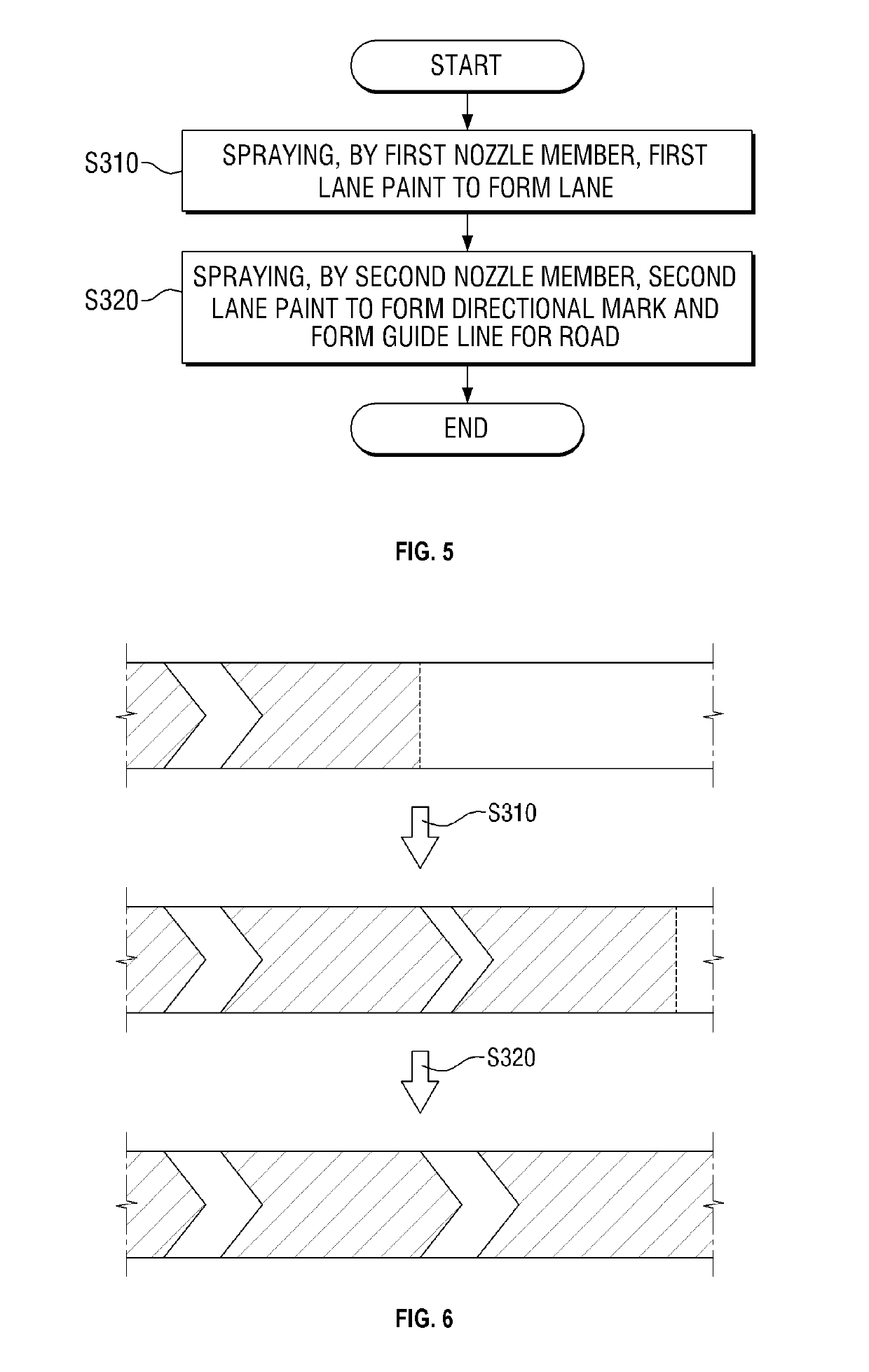

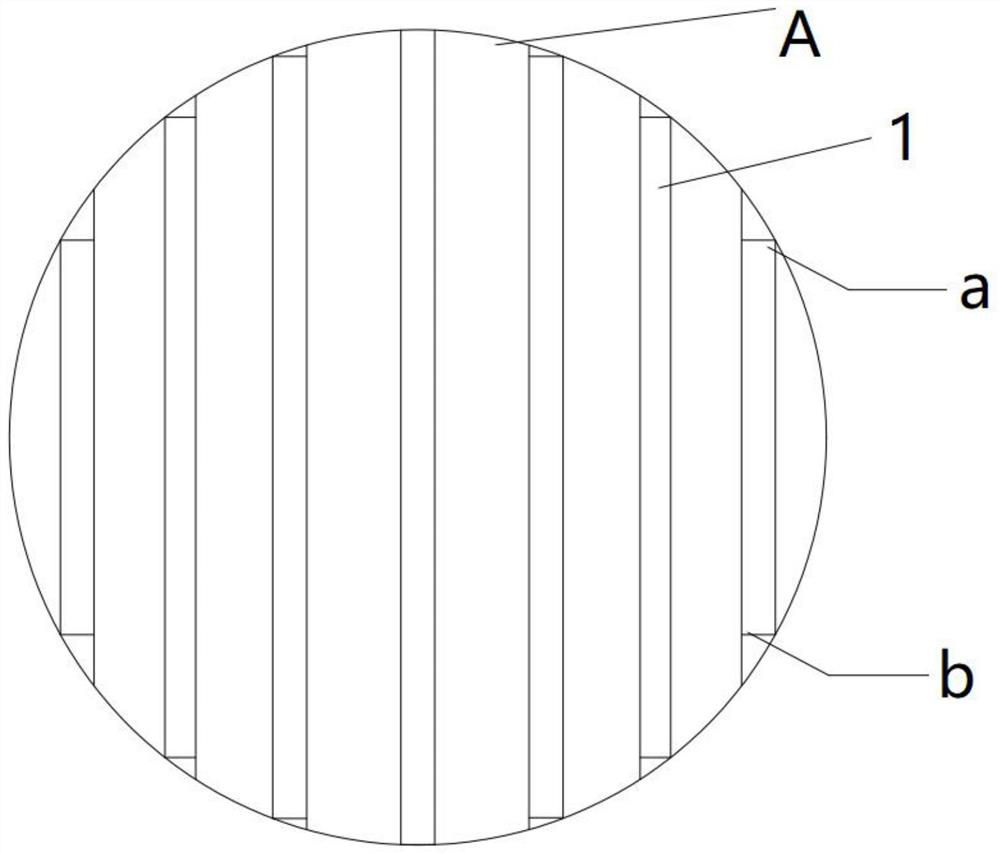

Constructing apparatus and method of guide line for road

ActiveUS20190093295A1Stable injection volumeImprove guide qualitySpraying vehiclesLiquid spraying apparatusIndustrial engineeringNozzle

Provided are an apparatus and a method of constructing a guide line for a road, and the apparatus includes a painting apparatus part that stores a lane paint, is driven by receiving power, and supplies the lane paint, a nozzle part that is installed in the painting apparatus part and sprays the lane paint supplied from the painting apparatus part on a road to form a guide line for a road including at least one of a directional mark and a lane, and an adjustment part that is installed in the painting apparatus part and adjusts at least one of a location and an interval of the lane paint sprayed from the nozzle part.

Owner:KOREA EXPRESSWAY CORPORATION

A kind of method and device for decrystallization of honey

ActiveCN105495071BImprove heat transfer efficiencyIncrease breaking speedFood scienceWater bathsBee products

The present invention discloses a honey decrystallization method and device and belongs to the technical field of bee product processing. The method includes the following steps: honey package barrel is washed clean and barrel lid is opened, the barrel is placed upside down in a crystal breaking chamber, and the air jet flow temperature is adjusted to 50-70 DEG C and the air flow speed is at 5-20 m / s to conduct air jet flow impact to break the crystal for 0.5-1.5 hours. After breaking the crystals, the honey flows into a honey melting chamber and the honey temperature is adjusted to a temperature of 40-60 DEG C to conduct crystal melting for 1-2 hours. The device includes: an air circulation channel (3), a heater (4), a fan (5), an air distribution pipe (6), a trailer (9), two sliding rails (10), two nozzles (11), a water bath heater (12), a steam heat exchanger (13), a stirring device (15), a heat exchange coil (16), a temperature sensor (17), and a temperature and air velocity sensor (19). The device is used to process the honey, which can effectively protect the biological activity of the honey, and the the device can save water and energy, is environmentally protective, and can achieve automatic control.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI +1

Method for rapidly adjusting smelting strength of blast furnace

The invention provides a method for quickly adjusting the smelting strength of a blast furnace, which is characterized in that a tuyere neck bush is made of a refractory material, and the tuyere neck bush is a hollow tube with two open ends in the length direction; when the smelting strength of the blast furnace needs to be reduced, the tuyere neck bush is inserted into a tuyere small sleeve embedded in the blast furnace after damping down, so that hot air finally flows out of the tuyere neck bush and enters a hearth of the blast furnace, and the inner diameter of an air supply channel is reduced; when the smelting strength of the blast furnace needs to be recovered, a steel chisel is used for crushing the tuyere neck bush embedded in the tuyere small sleeve, then crushed materials obtained after crushing are pushed into a hearth of the blast furnace, and the inner diameter of the tuyere small sleeve is recovered to supply air into the hearth; when the smelting strength of the blast furnace is adjusted, the tuyere small sleeve does not need to be replaced, primary blast furnace damping-down is reduced, the damping-down time is shortened, the amount of heat compensation and net coke during re-blowing is reduced, the yield loss is reduced, the purchase cost of the tuyere small sleeve is reduced, and the damping-down time of the blast furnace is shortened.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

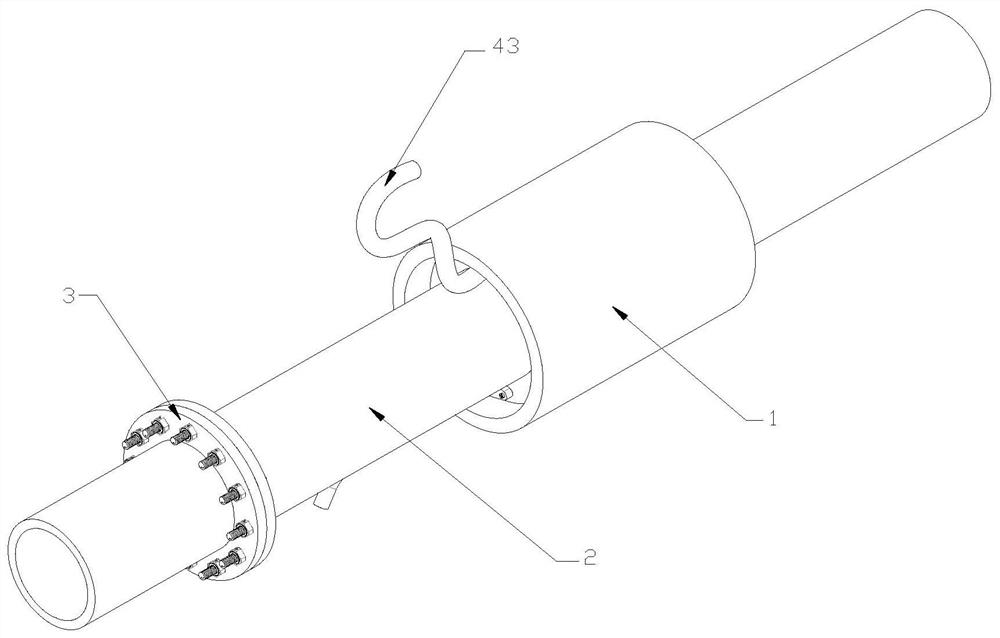

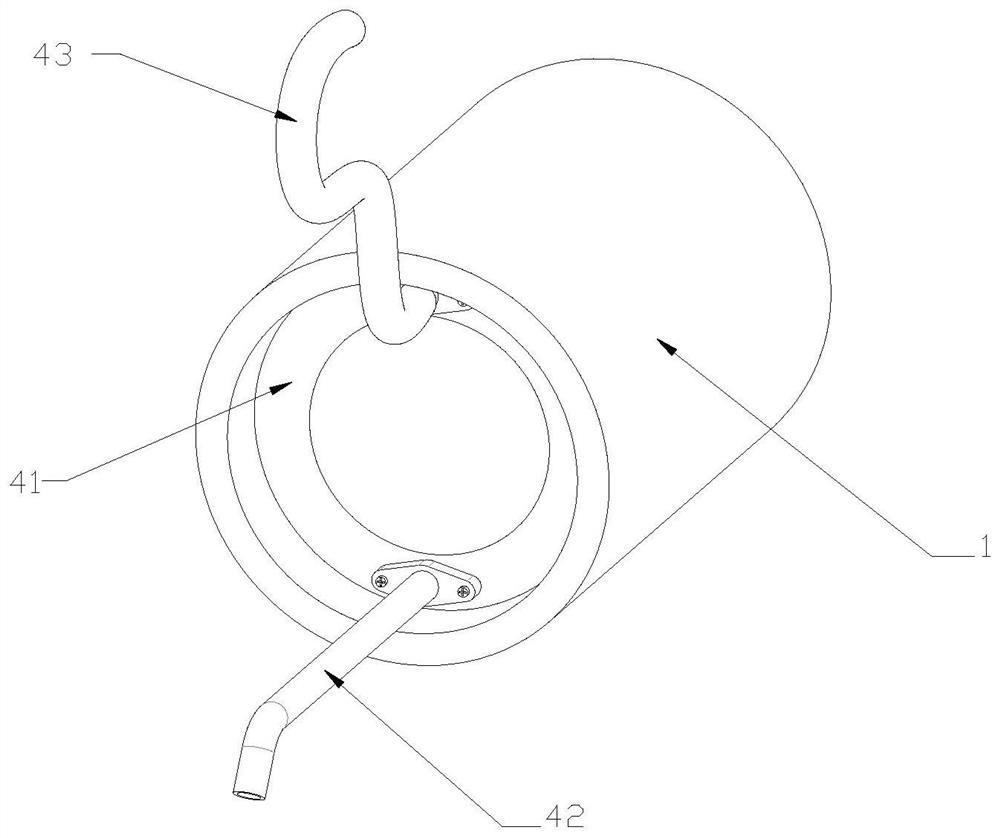

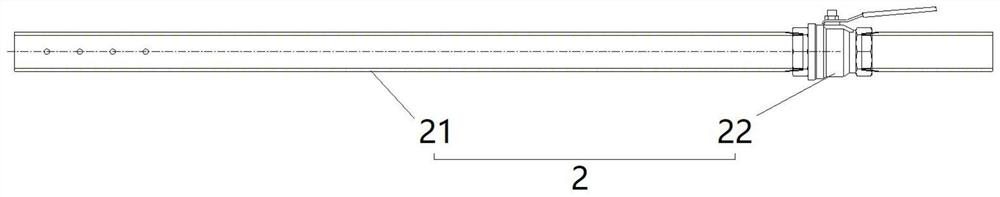

Wind port small sleeve cooling water pipe hard pipe transformed metal hose connector

PendingCN111676335AAdjustable lengthPrevent water leakageTuyeresCooling devicesThermodynamicsEngineering

The invention discloses a wind port small sleeve cooling water pipe hard pipe transformed metal hose connector. A middle sleeve, a straight blowing pipe, a transformed connection module and a flange are included. The transformed connection module comprises a small sleeve, a cooling water pipe hard pipe, a metal hose and a quick coupling. The metal hose can be adopted to replace a traditional cooling water hard pipe, the length of the metal hose can be freely adjusted, operation is convenient, deformation can be effectively absorbed, the phenomenon of pipe root water leakage is avoided, and theapplication effect is very good; the outer portion of the metal hose is wrapped by high-temperature asbestos, high-temperature damage is prevented, and the service life is prolonged; and the damping-down time is shortened, and potential safety hazards are eliminated. The problems that in the prior art, due to the furnace interior pressure, deformation or displacement is generated due to temperature changes, consequently, the cooling water hard pipe directly makes contact with the middle sleeve or the straight blowing pipe for extrusion, the hard pipe is bent and deforms after being stressed,the seal face of the pipe root and the small sleeve is damaged, a large amount of water leaks, when the condition is serious, damping-down needs to be conducted for replacement, and adverse influencesare brought to blast furnace production are solved.

Owner:安徽长江钢铁股份有限公司

Removing construction method for shield machine to reach tunnel door

InactiveCN111980715ASmall amount of workShorten the construction periodTunnelsSlagArchitectural engineering

The invention provides a removing construction method for a shield machine to reach a tunnel door. The method comprises the following steps that S1, when the shield machine reaches a certain distancefrom the tunnel door, tunnelling is stopped, and a plurality of exploration holes are drilled at determined positions of the tunnel door; S2, inspection tubes with valves are inserted into the exploration holes and fixed, and the valves are opened to check water flow in the tunnel door; S3, a working platform is set up, piles in the tunnel door are cut in the horizontal direction at the tops of the piles until all the piles are cut, and the cutting depth of each pile is greater than half of the pile diameter; S4, the piles in the tunnel door are completely cut in the same cutting direction asstep S3 at the roots of the piles; S5, the shield machine tunnels forwards until the piles in the tunnel door are pushed out of the tunnel door, and concrete at the tops of pile holes are removed; S6,the piles are fixed to prevent the piles from moving, remaining steel bars at the tops of the piles are cut until complete cutting off, and the piles are transferred out of the tunnel door until allthe piles are transferred; and S7, after remaining slag soil in the tunnel door is removed, the shield machine reaches the tunnel door to carry out complete removing.

Owner:CHINA RAILWAY 11TH BUREAU GRP

Low-voltage circuit breaker with rapid lock-jumping function

InactiveCN1245731CImprove breaking capacityShorten break timeSwitches with electrothermal and electromagnetic releaseProtective switch operating/release mechanismsLow voltage circuitsJumping function

The invention discloses a low-voltage circuit breaker having quick-acting tripping function, wherein an open-end flange is arranged on at least one side surface of the contact device, a corresponding force bearing member is arranged on the bottom of the rotation shaft of the chassis, the force bearing member receives the overpressure wind current escaped from the open-end flange of the contact apparatus, which is then magnified at the actuation member position through the rotation shaft transmission, then striking the shackle quickly, producing a tripping operation. The invention can substantially improve the tripping capability for the breaker.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

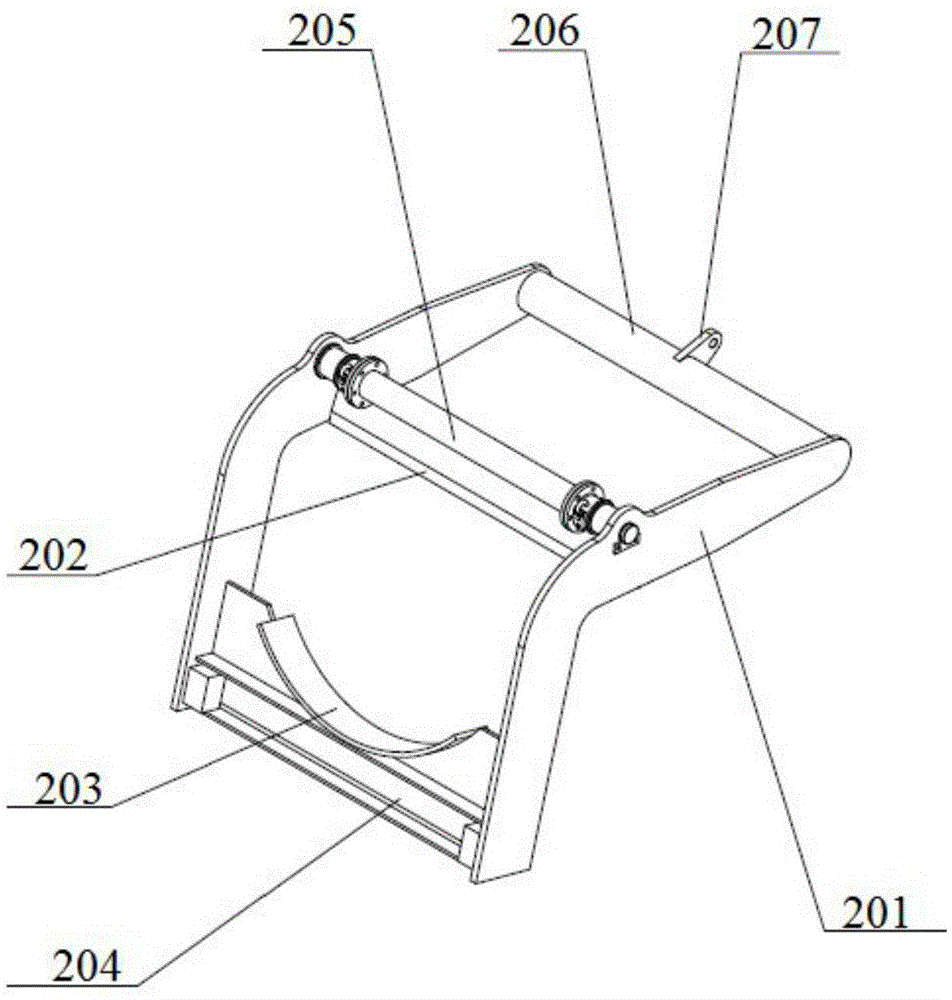

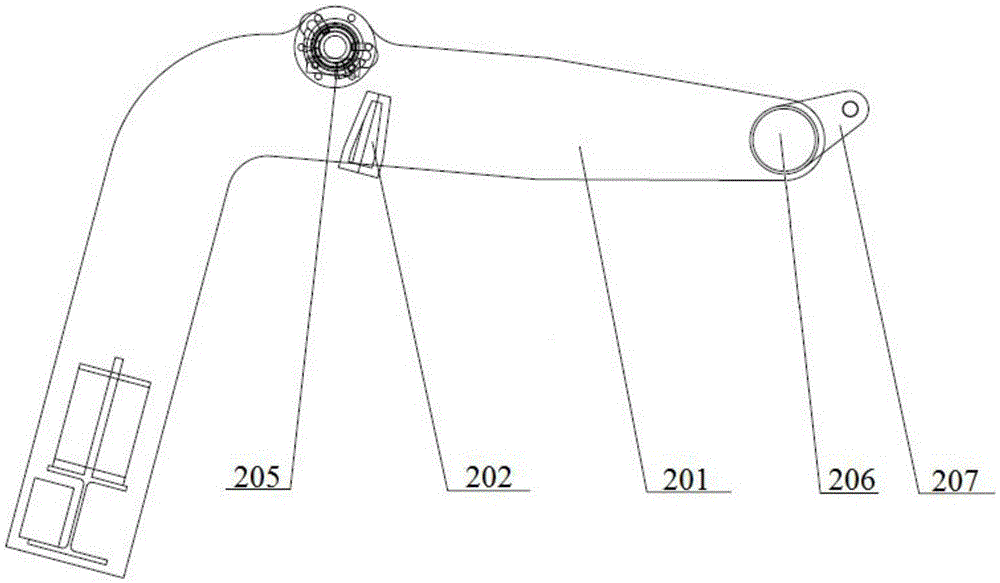

Rapid mounting and dismounting mechanism used for distribution chute replacing device and distribution chute replacing system

ActiveCN105603141AImprove replacement efficiencyReduce replacement timeBell-and-hopper arrangementEngineeringBlast furnace

The invention relates to a rapid mounting and dismounting mechanism used for a distribution chute replacing device. A fixed support of the distribution chute replacing device is blocked and hung on an access door by arranging a blocking and hanging structure, then the fixed support is locked on the access door by virtue of a locking structure, and the fixed support can be rapidly unlocked, so that rapid mounting and dismounting of the distribution chute replacing device are realized. The invention also relates to a distribution chute replacing system. The distribution chute replacing system comprises the distribution chute replacing device and the rapid mounting and dismounting mechanism, wherein the distribution chute replacing device is used for clamping a distribution chute by virtue of a clamping mechanism and a driving mechanism, and rapid dismounting and mounting of the distribution chute can be realized. By combining the distribution chute replacing device with the rapid mounting and dismounting mechanism, time for replacing the distribution chute can be obviously shortened, so that damping-down time of a blast furnace is shortened, and production efficiency is effectively improved.

Owner:WISDRI ENG & RES INC LTD

High-efficiency germination accelerating method of daphne giraldii nitsche seed

InactiveCN107046849AShorten break timeGood repeatabilitySeed immunisationSeed dormancyDistilled water

The invention discloses a high-efficiency germination accelerating method of a daphne giraldii nitsche seed. The high-efficiency germination accelerating method comprises the following steps of picking a daphne giraldii nitsche fruit which is mature when pericarp is carmine, scrubbing the daphne giraldii nitsche fruit to remove the pericarp and pulp, then indoors drying seeds in shade, and totally using three days from the picking to the drying in shade; selecting and putting a full seed into a kraft bag for later use; standing the full seed for 15 days in an incubator at 25 DEG C; standing the full seed for 15 days in the incubator at 30 DEG C; soaking the seed for 24 hours by using a 150mg.L<-1> of GA3 solution, and replacing the solution once per 8 hours; afterwards, cleanly flushing the full seed by using distilled water and then indoors drying the full seed in shade for 12 hours; soaking and disinfecting the full seed for 10 minutes by using a 5 percent of potassium permanganate solution, and afterwards, cleanly flushing the full seed by using the distilled water; taking river sand and the treated seed, and uniformly mixing the river sand and the treated seed according to a proportion of 1 to 5 in a germination box; putting the germination box in a refrigerator at 7 DEG C for 25 days. The high-efficiency germination accelerating method has the beneficial effects that treatment steps are simple; the operation is easy; the repeatability is high; the popularization is convenient; a needed device and a needed reagent are common; the price is low; more importantly, the efficiency of breaking seed dormancy is high; a required time is short.

Owner:HEXI UNIV

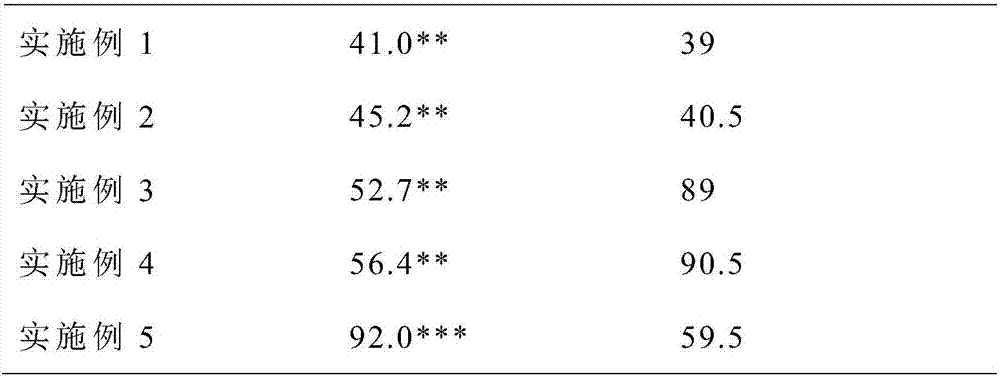

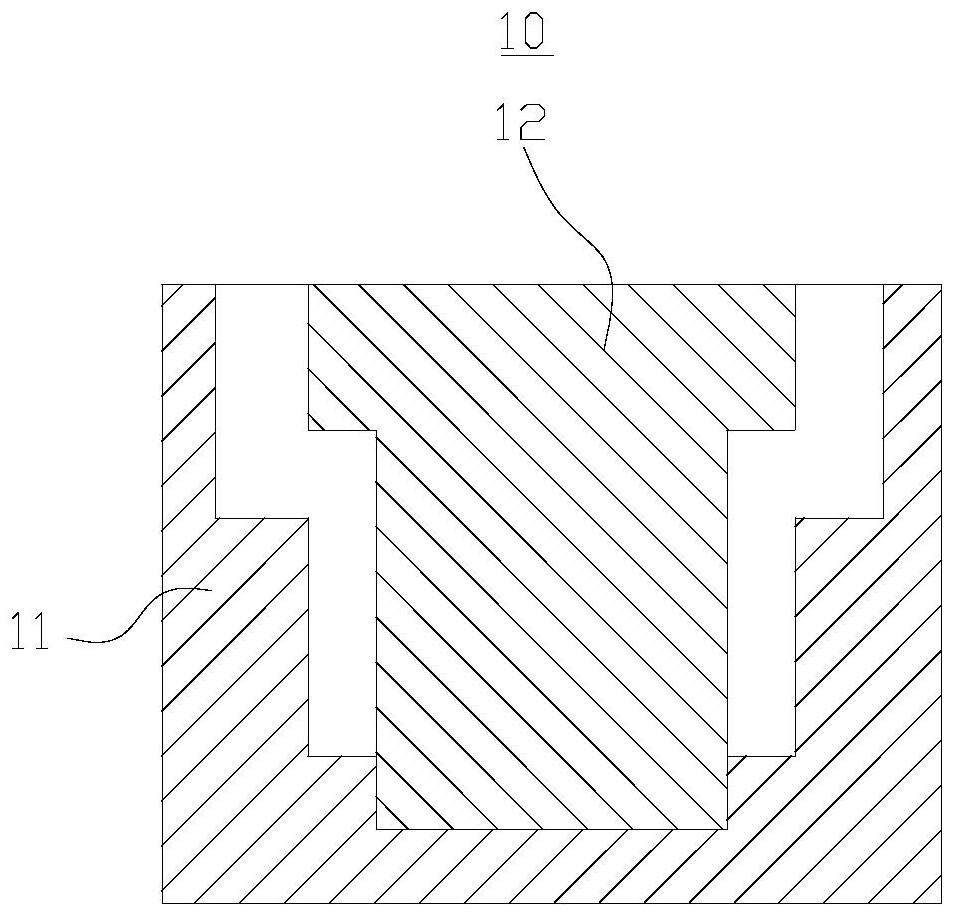

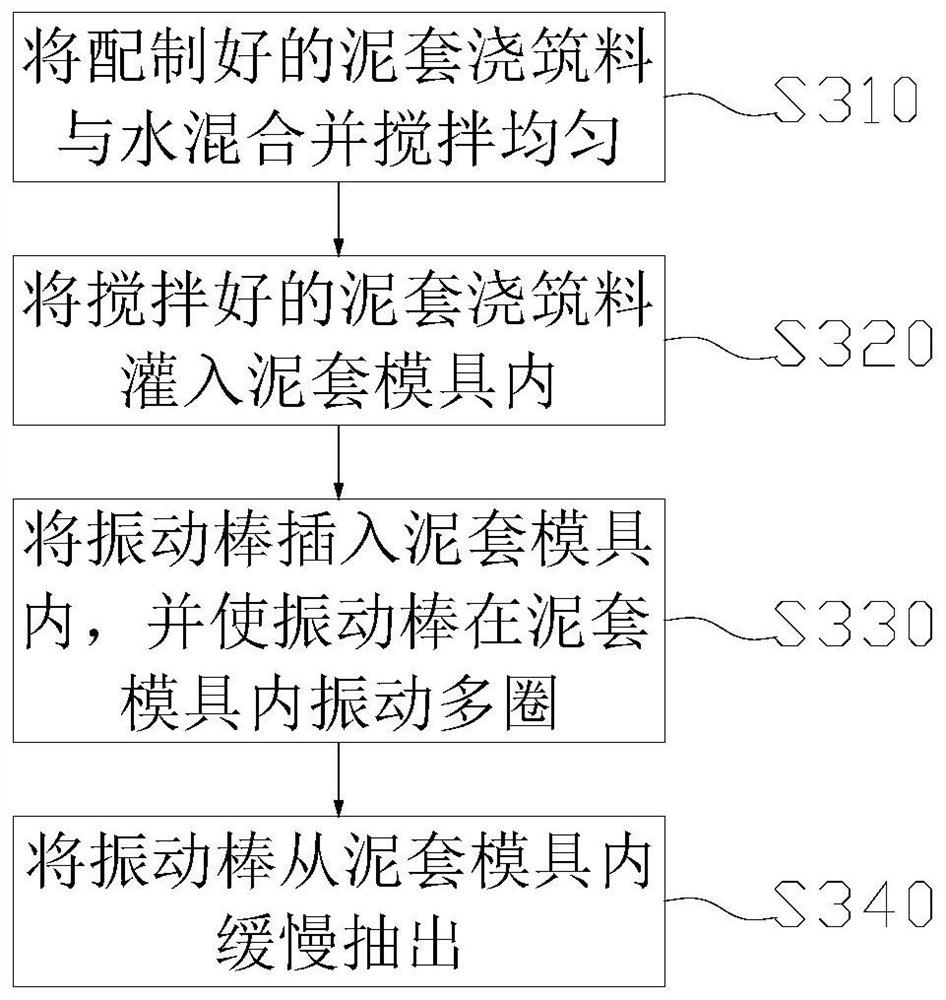

Integral taphole clay jacket pouring installation method and blast furnace taphole structure

ActiveCN111676337AQuick changeShorten break timeBlast furnace componentsBlast furnace detailsAdhesiveStructural engineering

The invention provides an integral taphole clay jacket pouring installation method and a blast furnace taphole structure, and belongs to the technical field of blast furnaces. The integral taphole clay jacket pouring installation method comprises the steps that a clay jacket mold is manufactured; clay jacket pouring forming is carried out by means of the clay jacket mold; a clay jacket is taken out of the clay jacket mold and dried; clay jacket old material is cleared to form a clay jacket frame; the periphery of the clay jacket frame is coated with an adhesive; and the dried clay jacket is putted into the clay jacket frame to be bonded with the adhesive. According to the method, the integral clay jacket is subjected to offline pouring, and then the clay jacket is bonded in the clay jacketframe through the adhesive so that the operation of quickly replacing the clay jacket can be realized, the blowing-down time of a blast furnace is shortened, the blowing-down rate of the blast furnace is greatly reduced, the productivity of the blast furnace is improved, and the production cost is reduced.

Owner:SGIS SONGSHAN CO LTD

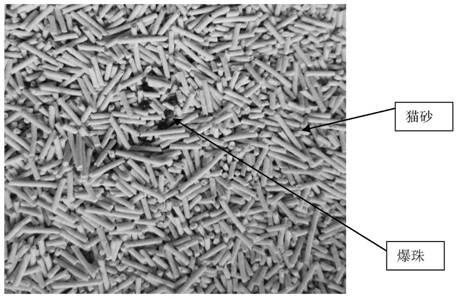

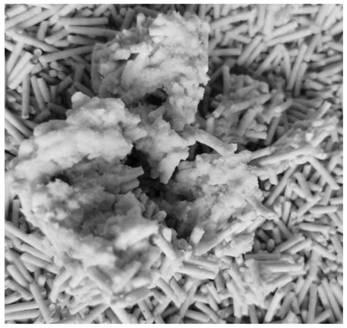

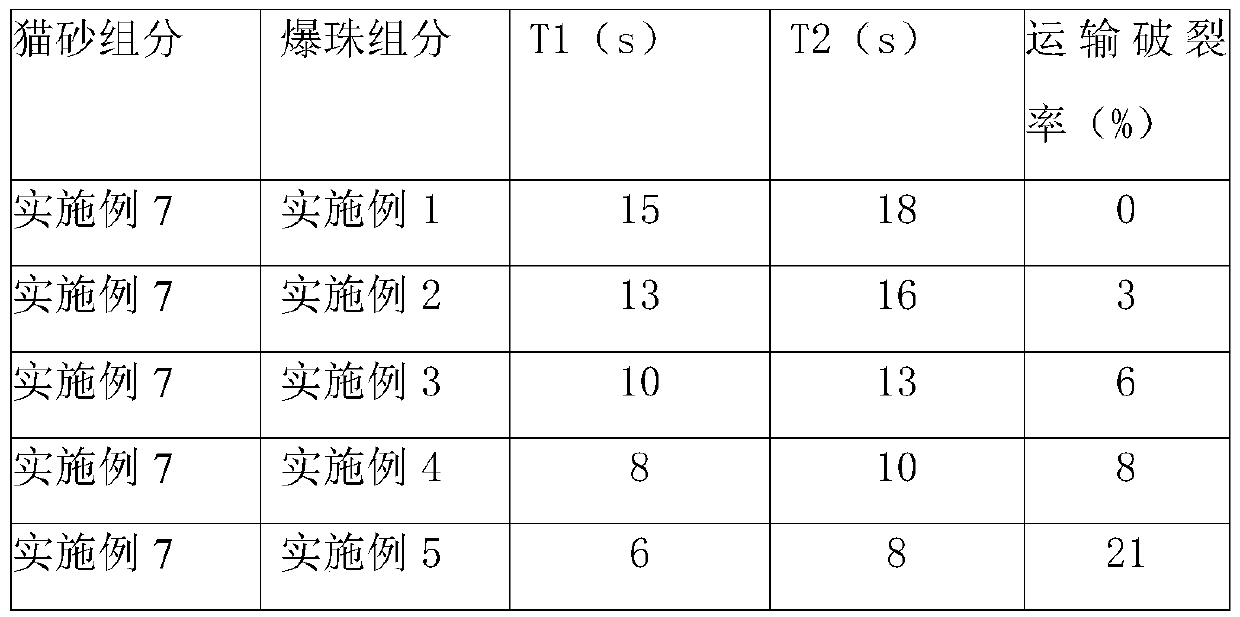

Deodorization blast bead, deodorization animal sand and manufacturing method thereof

ActiveCN111498920AQuality is not affectedAchieve deodorizing effectSpecific water treatment objectivesAnimal housingCarrageenanMedicine

The invention relates to a deodorization blasting bead, a deodorization cat litter and a manufacturing method thereof; the deodorization blasting bead comprises a rubber skin and a wrapping liquid, and the compressive strength of the deodorization blasting bead is 0.4-1 Pa; the rubber skin comprises konjac glucomannan or guar gum or agar or carrageenan or xanthan gum or the like, and the deodorizing blast bead is applied to deodorizing animal sand. After encountering urine, the blasting bead is broken, the liquid in the bag is released for deodorization, and the effect is good. By controllingthe pressure resistance of the blasting bead, the blasting bead is broken when encountering urine, the urine is dissolved and absorbed within 15-20 s, then the deodorization effect is achieved, and meanwhile breakage cannot be caused in the transportation process, so that the product quality is not affected.

Owner:宜昌市宠冠宠物用品有限公司

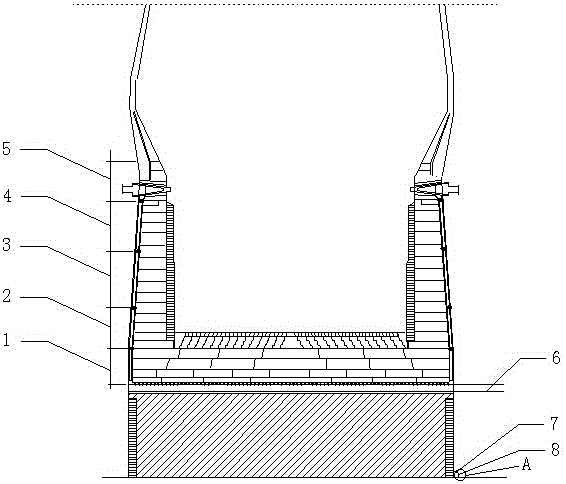

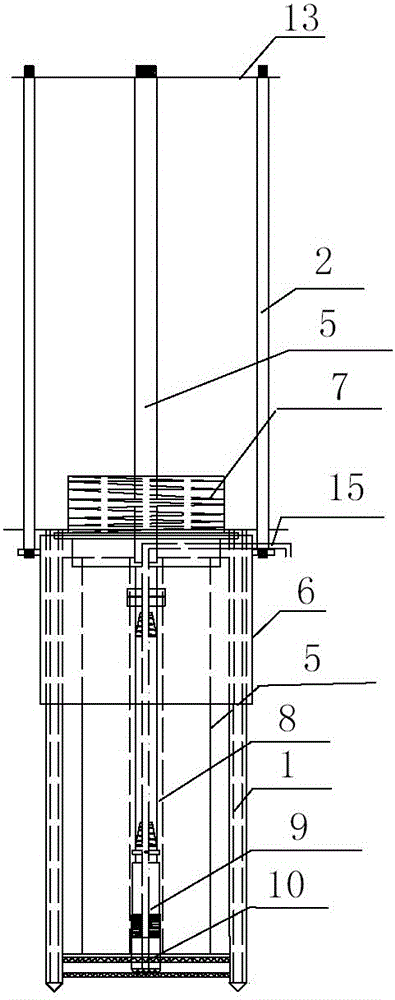

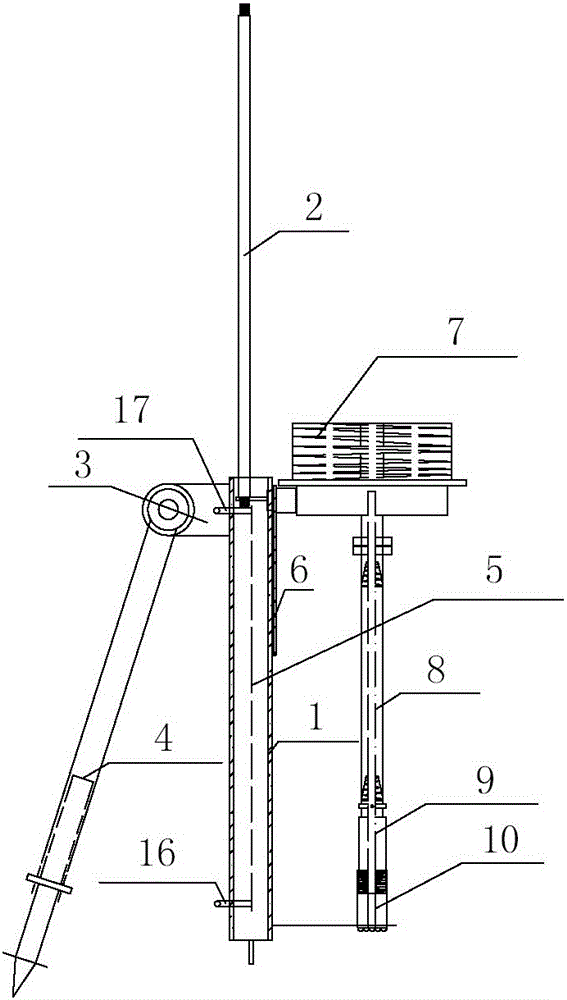

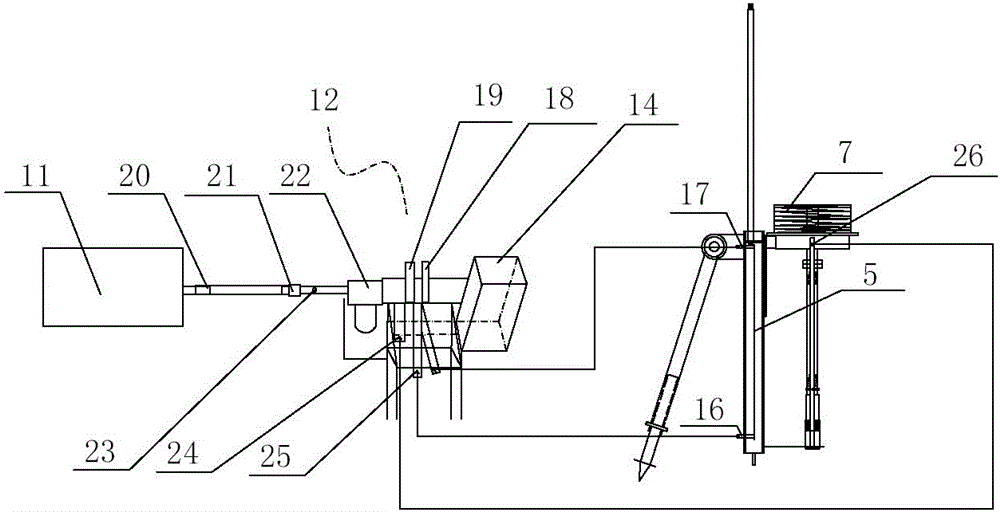

A down-the-hole drilling rig for breaking through pilot holes in granite road cuttings and its application method

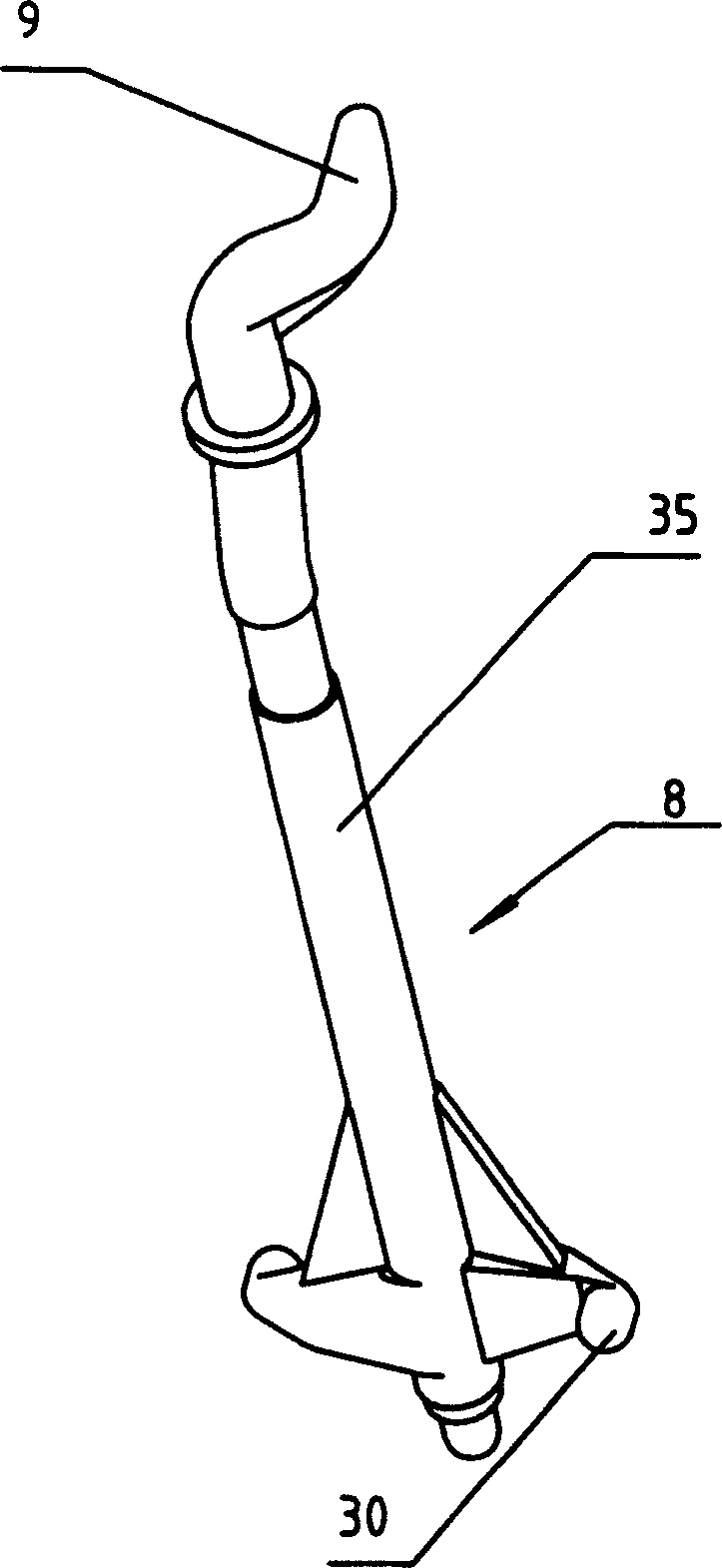

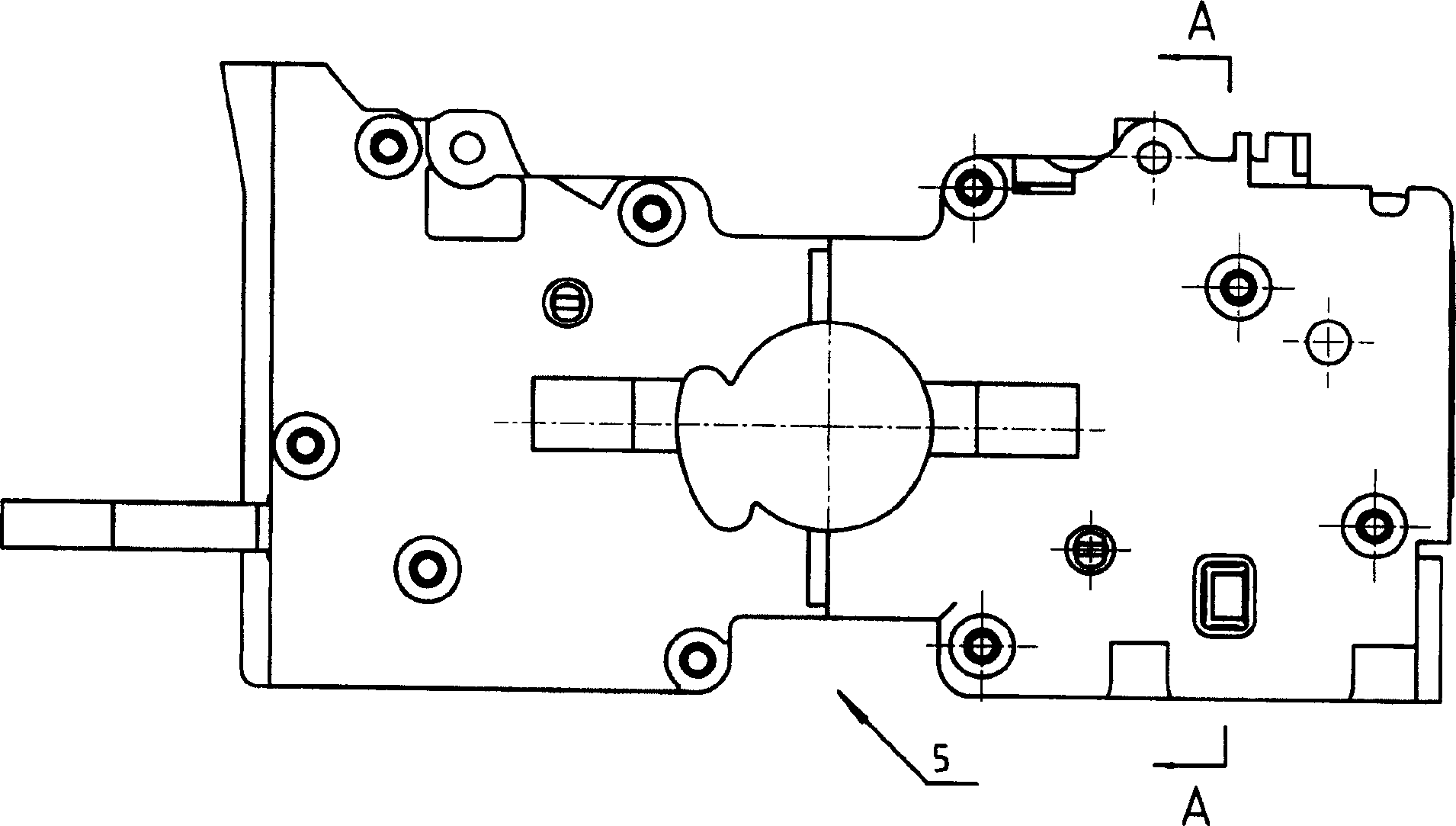

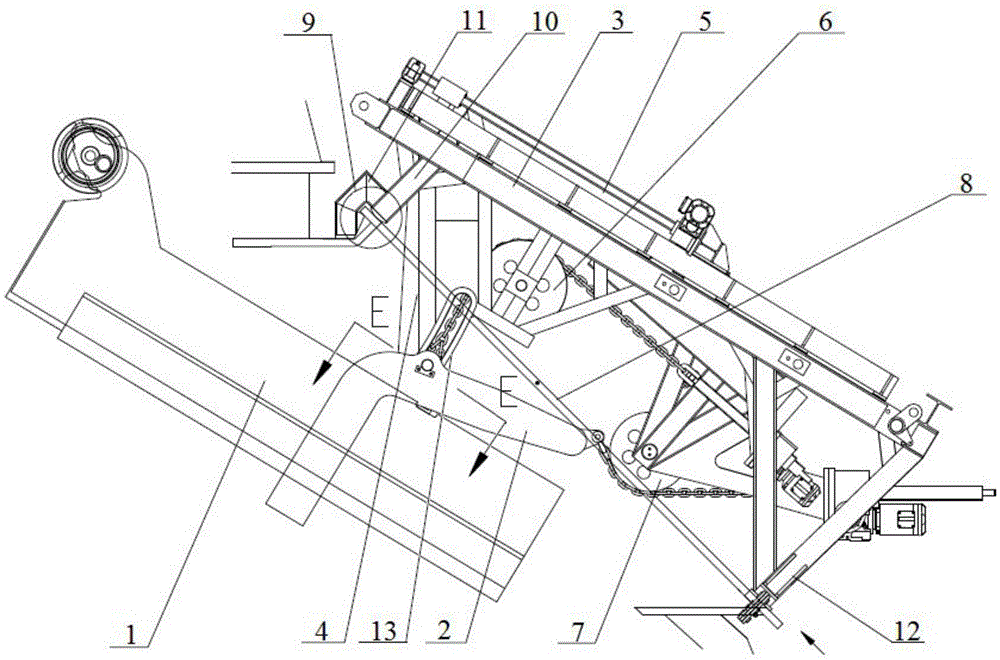

A downhole drill for granite cutting guide hole breaking comprises a drilling rack, a rotation motor, a drill rod, a controller and an air compressor, and is characterized in that the drill rack (1) is a rectangular frame, a connecting plate (3) and a supporting rack (4) welded at the two ends above one side of the rectangular frame are connected through bolts; the rotation motor (7) is connected with a sliding plate (6) through a side surface of a connecting flange base; one end of the drill rod (8) is vertically mounted on a connecting flange at the bottom of the rotation motor (7), the other end of the drill rod is connected with an impacter (9) which is further connected with a drill bit (10); one end of the controller (12) is connected with the air compressor (11) through an air tube, and the other end of the controller is connected with the connecting flange of the rotation motor (7) through the air tube and is also connected with a jack (5) through an impacter (9) head; the mobile screw air compressor (11) is connected with the jack and the controller through the air tube.

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com