Blast furnace cooling wall water pipe repairing method

A repair method and stave technology, applied in the direction of cooling devices, etc., can solve the problems of reduced cooling water volume of cooling equipment, affecting the cooling strength of staves, and H1 inflow water flow reduction, so as to ensure water flow, shorten wind break time, and reduce The effect of small resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

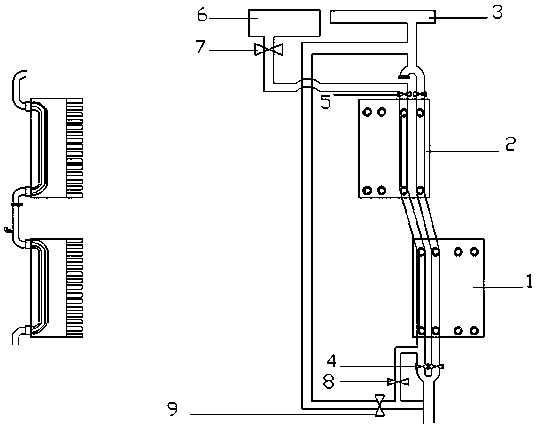

[0024] Such as figure 1 Shown, a kind of repair method of blast furnace stave water pipe, comprises the following steps:

[0025] Step 1. Add pipe-through return water bag 6: Before the wind breaks, the maintenance personnel will place 315°-360°, 0°-45°, 45°-90°, 90°-135°, 135° on the 19m platform at an elevation of 22m Five directions of °-180 ° have added five pipe-through return water bags 6. Each backwater bag is 3 meters long, welded with Φ114×7 seamless steel pipe, and effectively fixed with brackets. On the return water ring pipe of the copper cooling plate, press the water belt to open 5 holes with an inner diameter of Φ100, connect the pipe return water bag 6 with the copper cooling plate drainage ring pipe, and install a DN100 gate valve in the middle. There are 7 holes spaced apart on the return water bag, the hole spacing is 300-450mm, the inner diameter of the hole is Φ32mm, the hole position is directly below the pipe, and the distance between the inner diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com