Drop-out fuse for power construction

A drop-type fuse, power construction technology, applied in circuits, electrical components, emergency protection devices, etc., can solve the problem of inability to display the size of the fusing current, and achieve the effects of ensuring fusing sensitivity, accelerating fusing, and shortening the breaking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

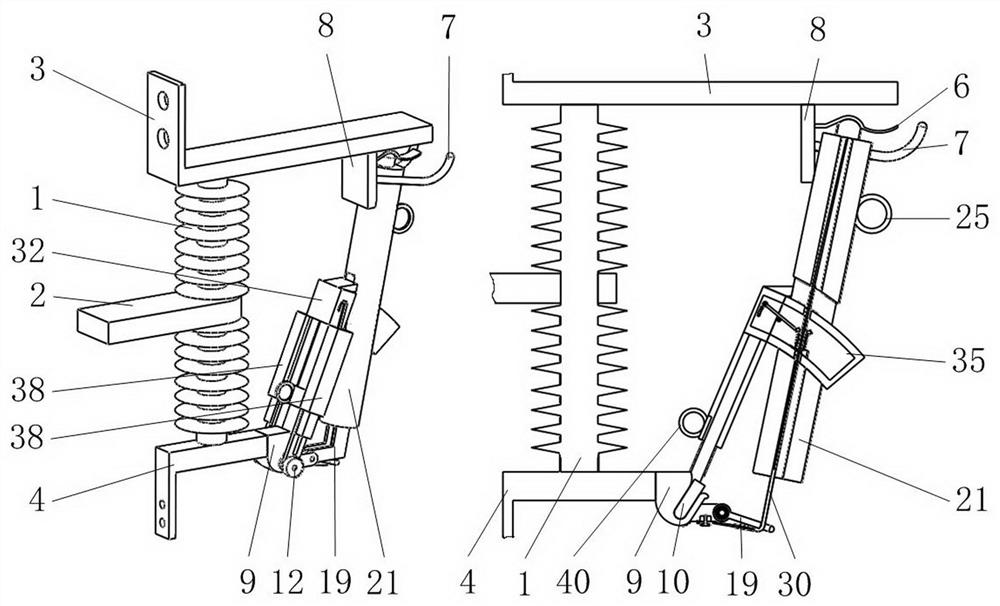

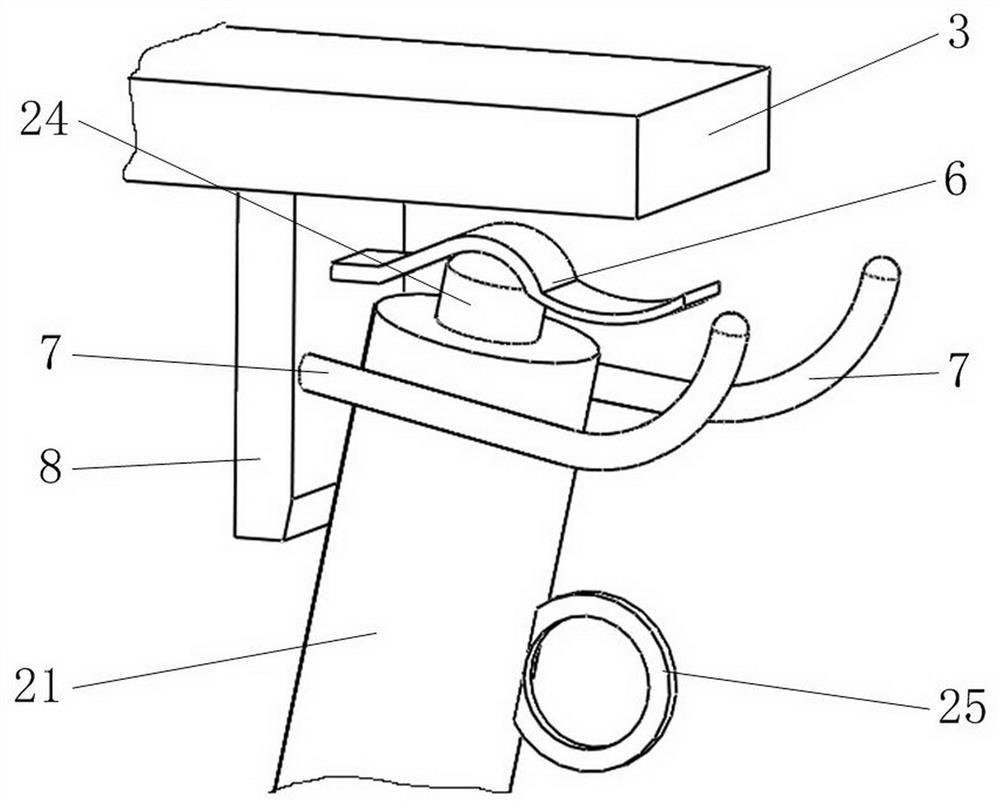

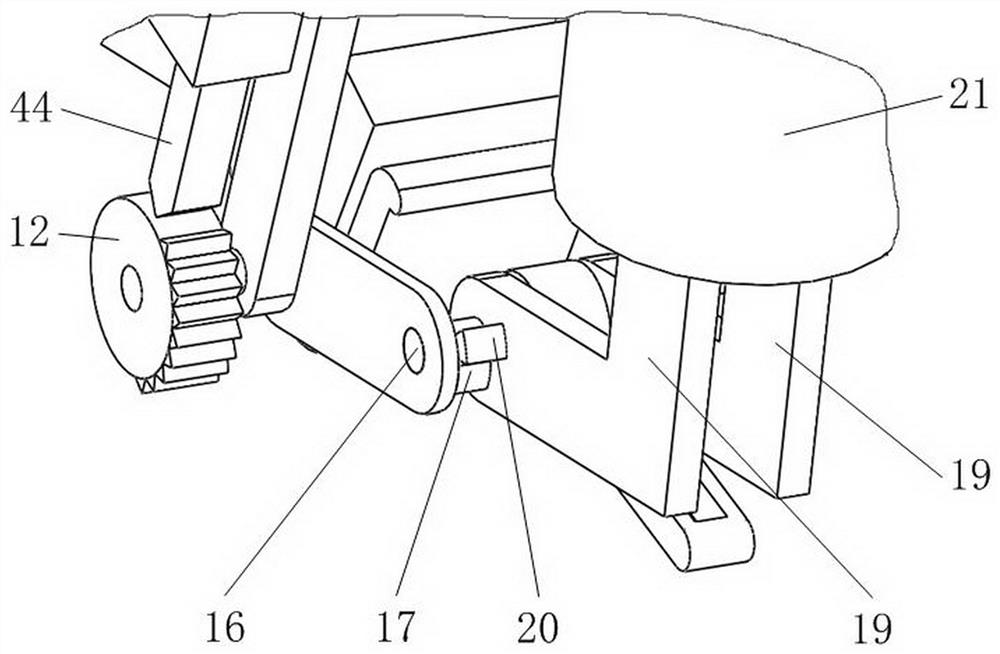

[0035] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0036] Such as figure 1 , 8 , 12, it includes insulator 1, mounting bracket 2, compression spring 6, hook socket 9, mounting plate 10, pin A11, incomplete gear 12, connecting plate A14, pin B16, connecting plate B19, fuse Tube 21, contact 24, pendulum plate 26, scroll spring 29, fuse 30, connecting plate C31, fixed block 32, arc-shaped block 35, telescopic rod 41 composed of outer cover 42 and inner rod 44, limit spring 46 , connecting rod 47, pin C48, swing bar 49, pin D50, memory alloy spring 52, limit block 53, wherein as figure 1 , 8 As shown, the insulator 1 is installed on the pole through the installation bracket 2, and the outlet terminal 4 installed at the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com