A down-the-hole drilling rig for breaking through pilot holes in granite road cuttings and its application method

A technology for down-the-hole drilling rigs and granite, which is applied in drilling equipment, earthwork drilling, automatic control systems for drilling, etc., can solve the problems of numerous auxiliary equipment, delaying construction progress, and spending a lot of time, reducing labor intensity and low cost. , the effect of shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

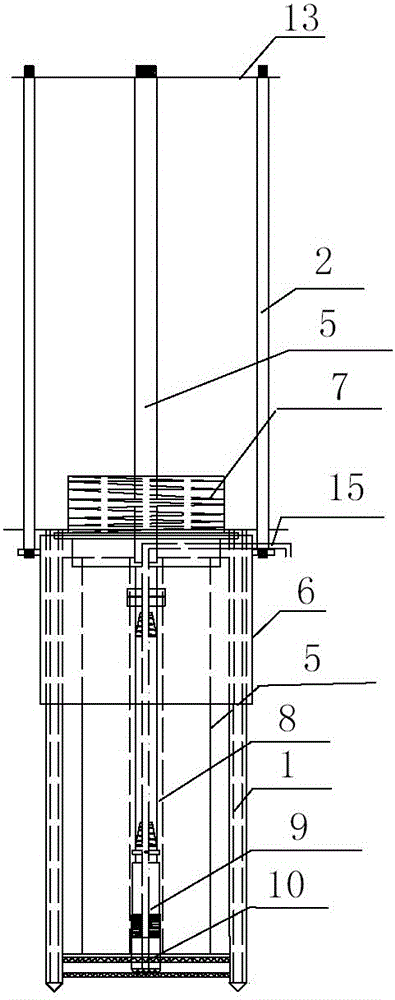

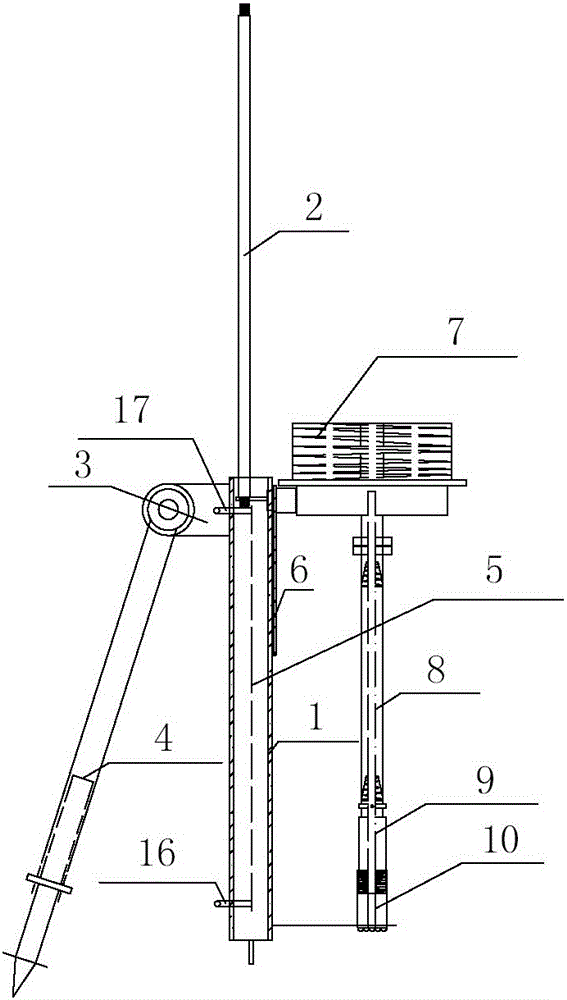

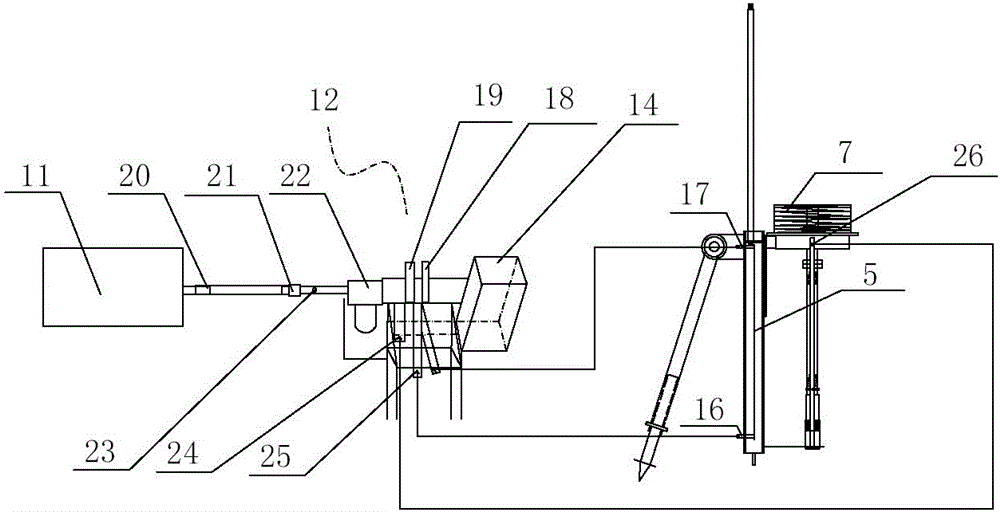

[0031] A down-the-hole drilling rig for breaking through pilot holes in granite road cuttings

[0032] In this embodiment, the specifications and technical requirements of each component are as follows:

[0033] 1) Support frame: Weld a 30mm thick steel plate with a DN51 steel pipe, pass through another DN45mm steel pipe with a pin and connect it to the drill stand.

[0034] 2) The connecting plate between the support frame and the drilling frame: it is processed by a 40mm thick steel plate and welded on the drilling frame.

[0035] 3), jack: according to image 3 The relevant dimensions are checked and calculated by the design institute, processed by relevant manufacturers, and welded together with the drill stand.

[0036] 4) Drill stand: 20a I-beam and 30mm thick steel plate are used for assembly and welding.

[0037] 5) Telescopic rod: ¢30mm round steel is used, and the two ends are processed into ¢20mm threaded buttons, a total of 2 pieces.

[0038] 6) Sliding plate: ...

Embodiment 2

[0052] A method for using a down-the-hole drilling machine for breaking through pilot holes in granite road cuttings, characterized in that it includes the following steps:

[0053] a. Assemble the down-the-hole drilling rig, wherein the installation of the drill pipe, impactor and drill bit should be completed by stretching the jack rod after the air compressor works.

[0054] b. The drill frame and the support frame can be freely adjusted according to the actual situation of the construction site; the drill bit 10, the impactor 9, and the drill pipe 8 are connected in sequence, and the principle of lifting up and down is that the jack 5 is connected with the sliding plate 6, and the sliding plate 6 is connected with the drill Frame 1 and telescopic rod 2 are connected to form a propulsion mechanism. Compressed air enters the cylinder through the pipeline to act on the piston, and the piston rod drives the slide plate through the bracket to perform rock drilling.

[0055] c. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com