Honey decrystallization method and device

A technology of honey and crystal breaking, which is applied in application, food preparation, food science, etc. It can solve the problems of small color change, less loss of biologically active substances, and short processing time, so as to reduce the loss of honey biologically active substances and improve crystallization. Speed, the effect of shortening the crystal breaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

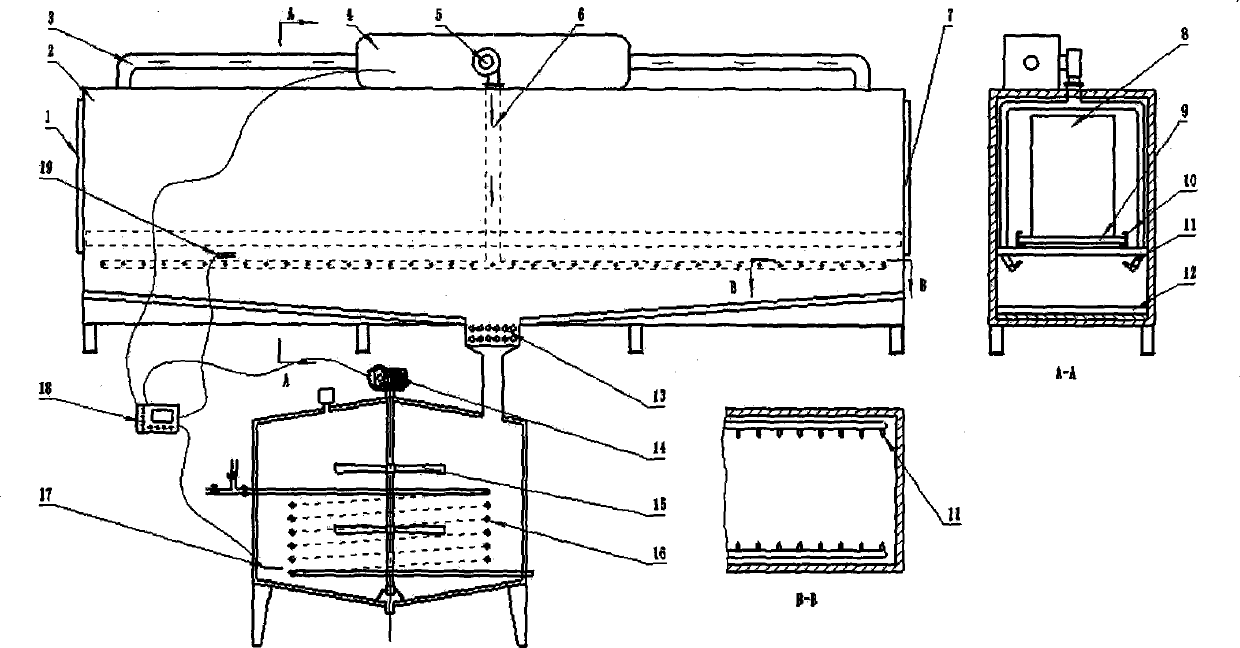

[0024] Open hatch 1, clean 10 barrels of Vitex twig honey (crystallization rate greater than 80%) outer packaging barrels, put them upside down successively on the trailer 9 in the crystal breaking room, close hatch 1; Adjust it to 60°C, adjust the airflow speed to 15m / s, and set the honey temperature in the crystal melting chamber to 45°C; ③Open the valve 12 of the water bath heater, set the water temperature to 65°C, connect the steam heat exchanger 13, and control the steam pressure 0.25MPa, after 0.5 hours all crystallized honey has been completely broken and flowed into the crystal melting chamber. ④ When the crystal breaking starts for 15 minutes, according to the signal fed back by the temperature sensor 17, open the heat exchange coil 16 cold water valve to the crystal melting chamber. The honey is cooled so that the honey temperature drops to 45°C, and the honey temperature remains constant. ⑤ 20 minutes after the start of crystal breaking, the honey in the crystal me...

Embodiment 2

[0026]Open hatch 1, clean 10 barrels of linden bar honey (crystallization rate is greater than 80%) outer packaging barrels, put upside down successively on the trailer 9 of crystal breaking room, close hatch 1; 2. gas is discharged by automatic control box The jet temperature is adjusted to 55°C, the airflow speed is adjusted to 20m / s, and the honey temperature in the crystal melting chamber is set to 50°C; ③Open the water bath heater 12 valve, set the water temperature to 60°C, connect the steam heat exchanger 13, and steam The pressure is controlled at 0.2 MPa. After 35 minutes, all the crystallized honey has been completely broken and flowed into the crystal melting chamber. ④ When the crystal breaking starts for 20 minutes, according to the signal fed back by the temperature sensor 17, open the hot water valve of the heat exchange coil 16 for melting. The honey in the crystal chamber is heated to make the honey temperature rise to 50°C, and the honey temperature remains co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com