Patents

Literature

32results about How to "Stable injection volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

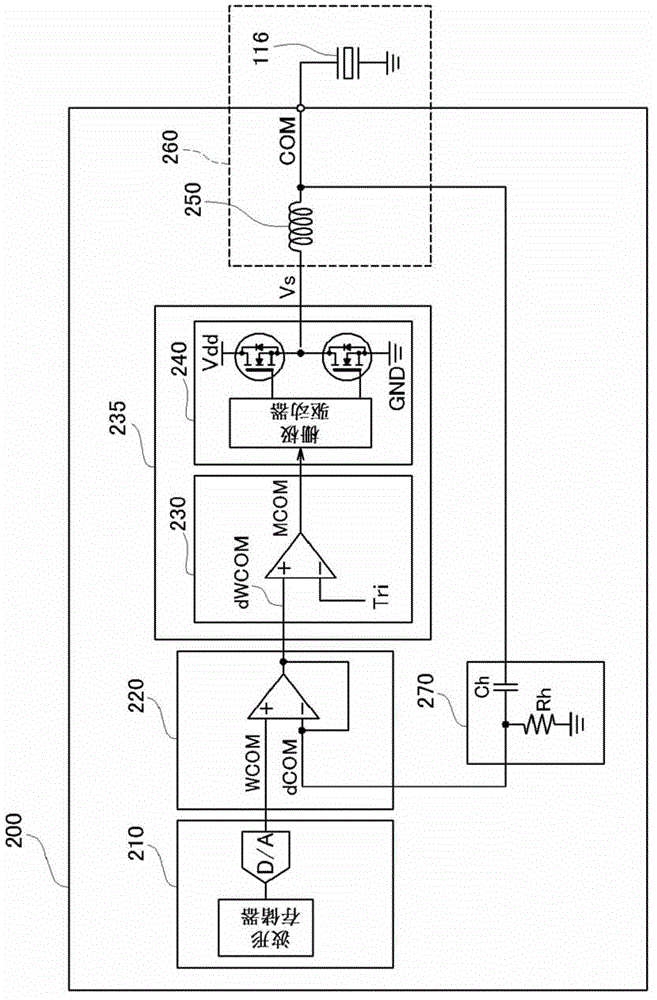

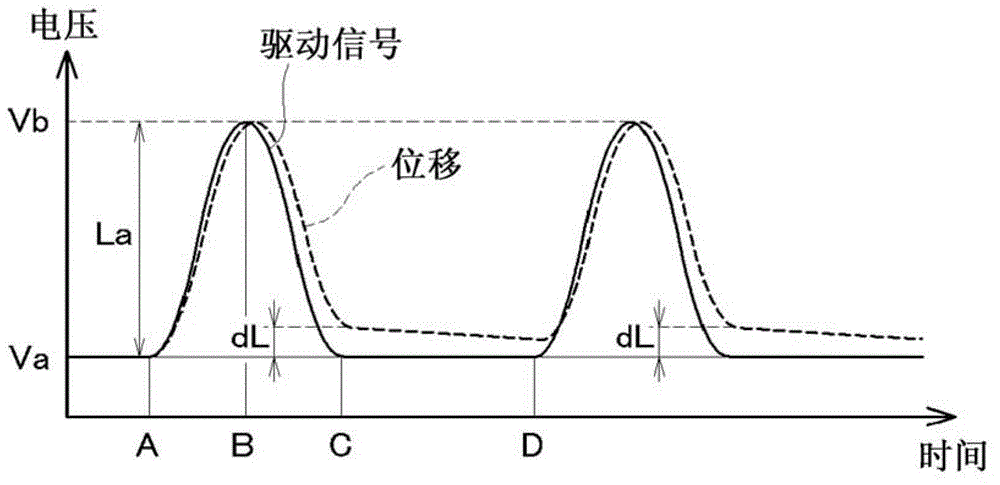

Piezoelectric element drive circuit and liquid ejecting apparatus

InactiveCN102862388AStable injection volumeGuaranteed deformationSurgeryIntravenous devicesNegative feedbackElectricity

A drive waveform signal as a reference of a drive signal to be applied to a piezoelectric element is power-amplified, and the drive signal after passing through a coil is applied to the piezoelectric element. A resonant circuit is formed of the coil and the piezoelectric element, and a resonant peak is suppressed by performing a phase advance compensation of the drive signal and by performing a negative feedback. At this time, the degree of suppression of the peak is adjusted so that a slight reverse voltage is generated. Since this can eliminate residual distortion of the piezoelectric element by the reverse voltage, even when driving is performed at a high repetition frequency, the original amount of deformation can be ensured. Besides, the circuit does not become complicated.

Owner:SEIKO EPSON CORP

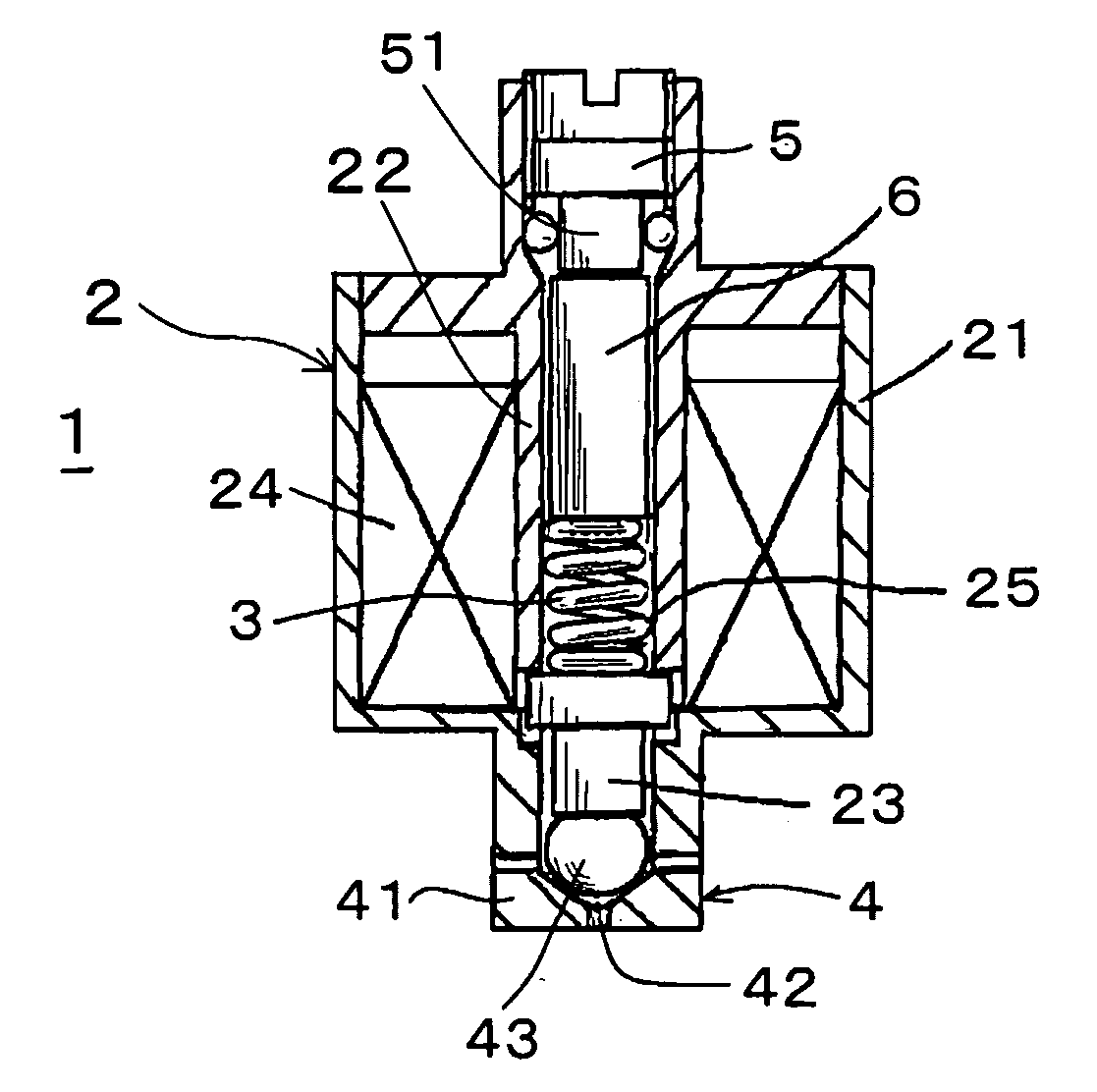

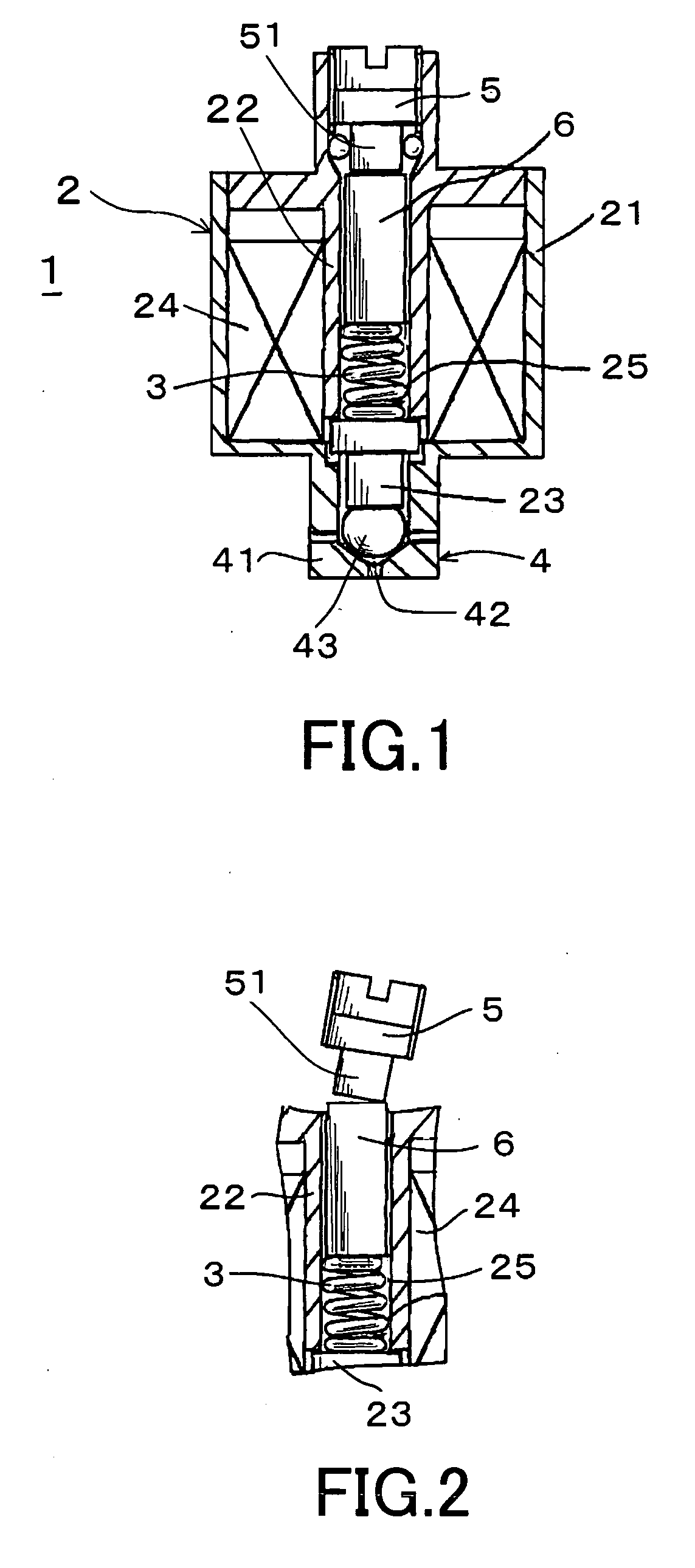

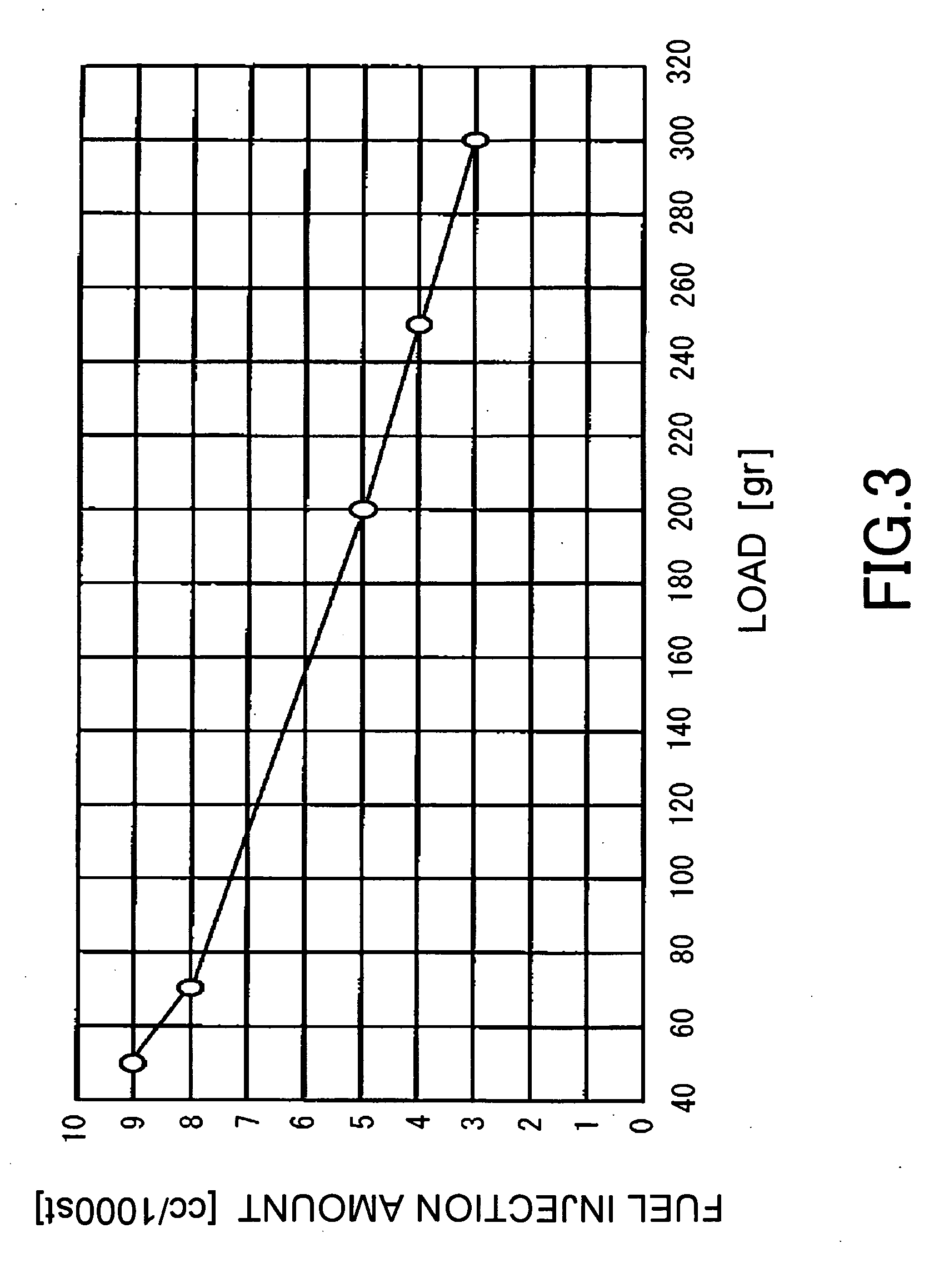

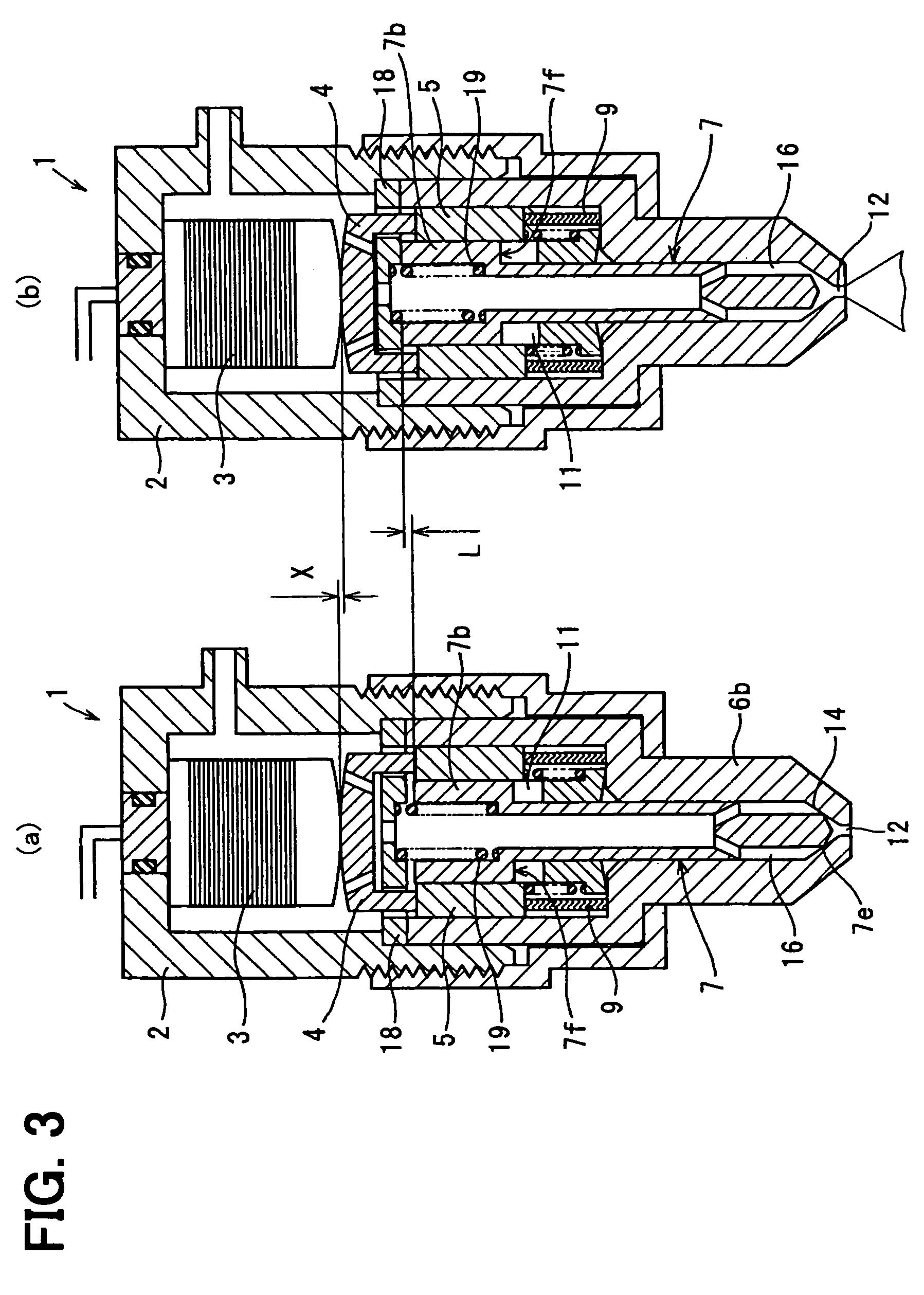

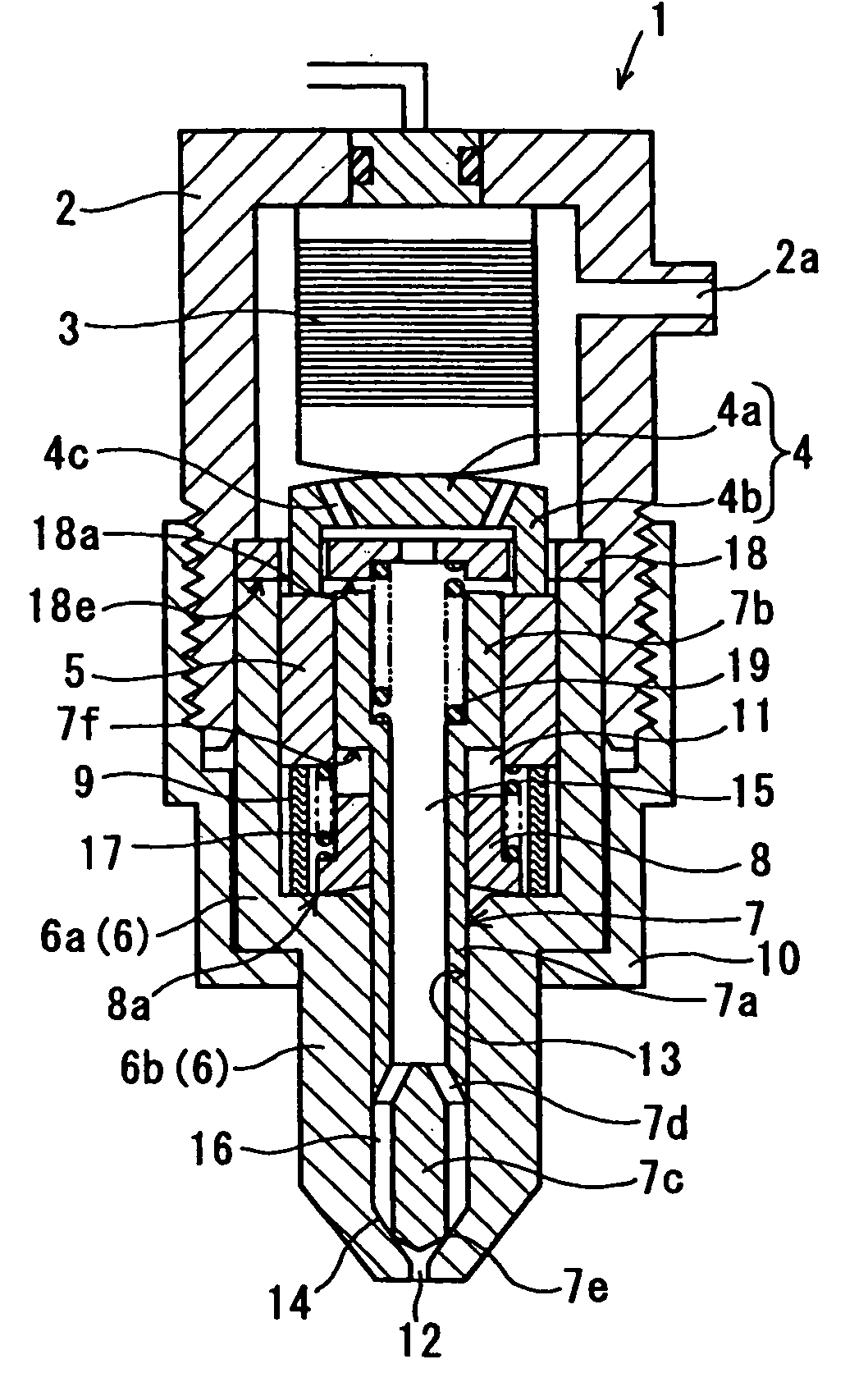

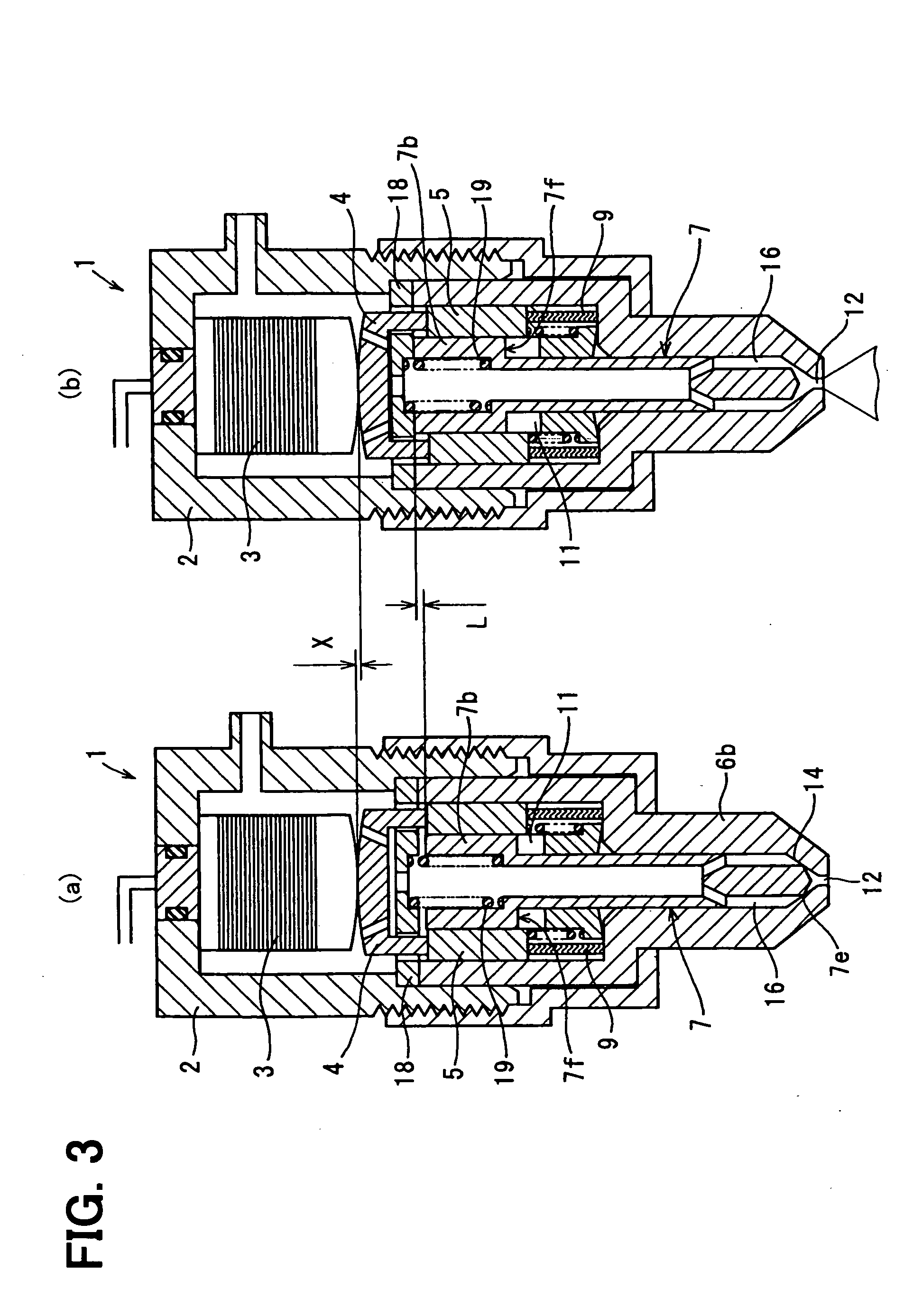

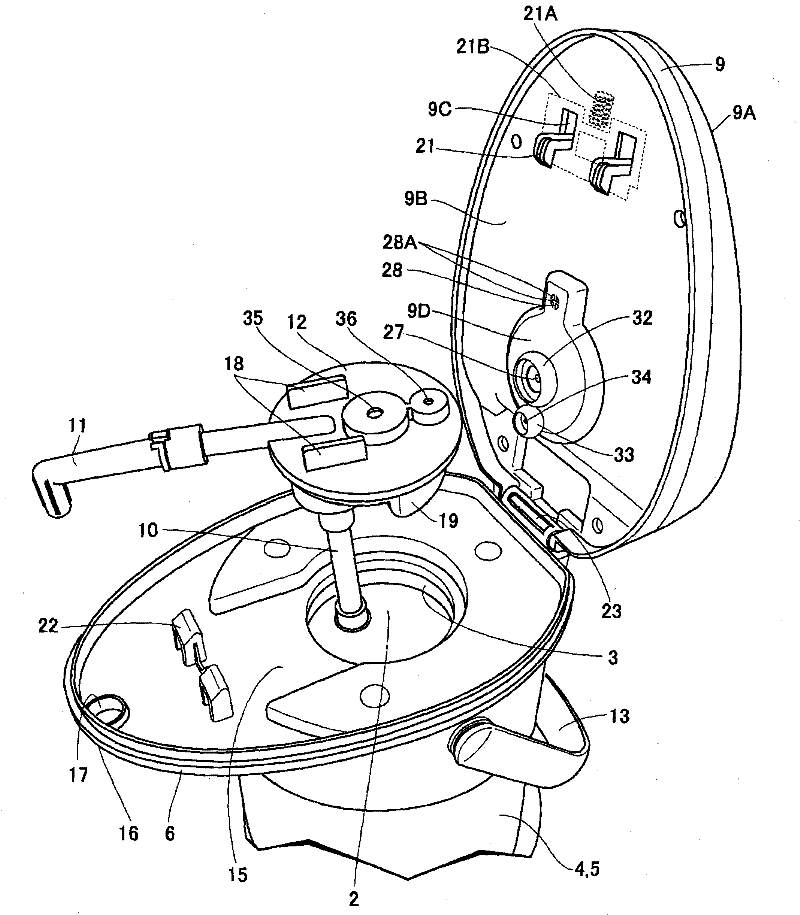

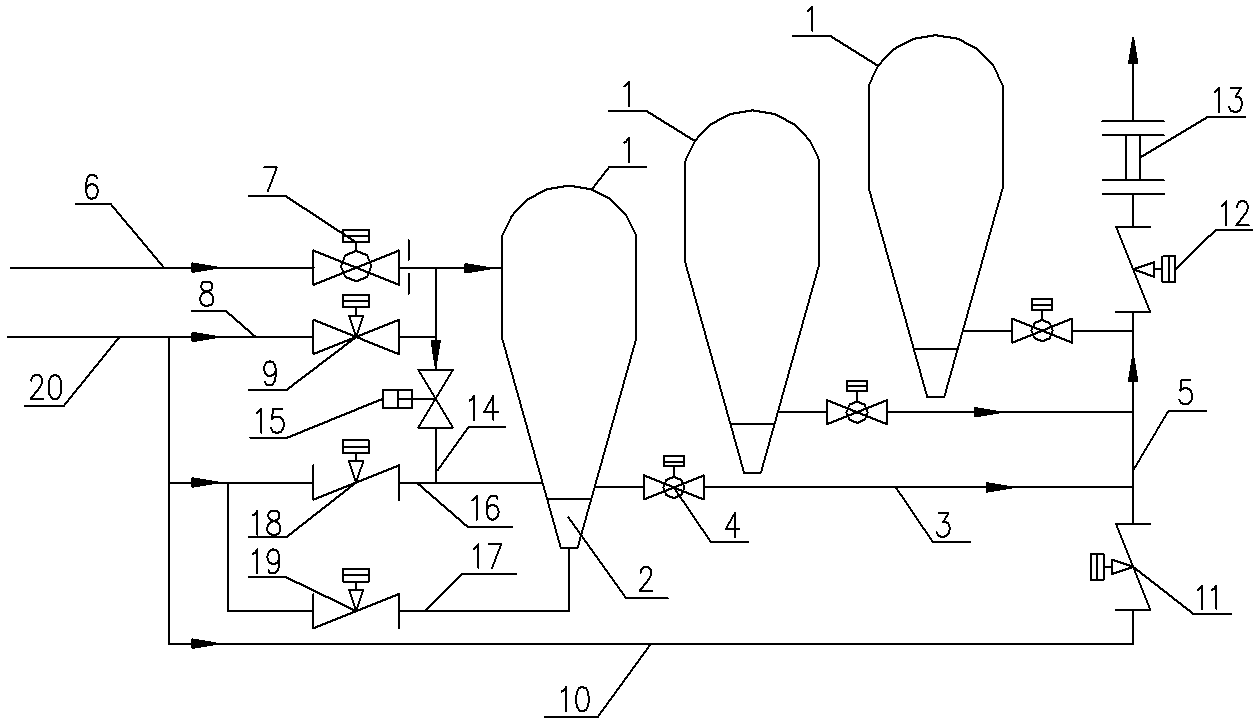

Electromagnetic fuel injection valve

InactiveUS20070145165A1Increased durabilityStable injection volumeSpray nozzlesFuel injection apparatusInjection portSolenoid valve

The invention provides an electromagnetic fuel injection valve which is operated extremely normally, is excellent in a durability, can always obtain a stable injection amount, and can reduce an influence by a fuel, an atmospheric temperature and the like. In an electromagnetic fuel injection valve (1) in which an electromagnetic valve (2) corresponding to a drive source is constituted by a yoke (21), a core (22) and a movable valve (23), an injection nozzle (41) interiorly provided with a ball valve (43) and having an injection port (42) for injecting a fuel is arranged in a leading end of the movable valve (23) so as to form an injection valve (4), and a return spring (3) bonded to the movable valve (23) and an adjusting screw (5) pressure supporting the return spring (3) are arranged in an axial hole (25) of the core (22) by being fitted and inserted to the axial hole (25) of the core (22) from an opening in a base end side, a connection lever (6) is slidably interposed between the adjusting screw (5) in the axial hole (25) of the core (22) and the return spring (3).

Owner:NIKKI CO LTD

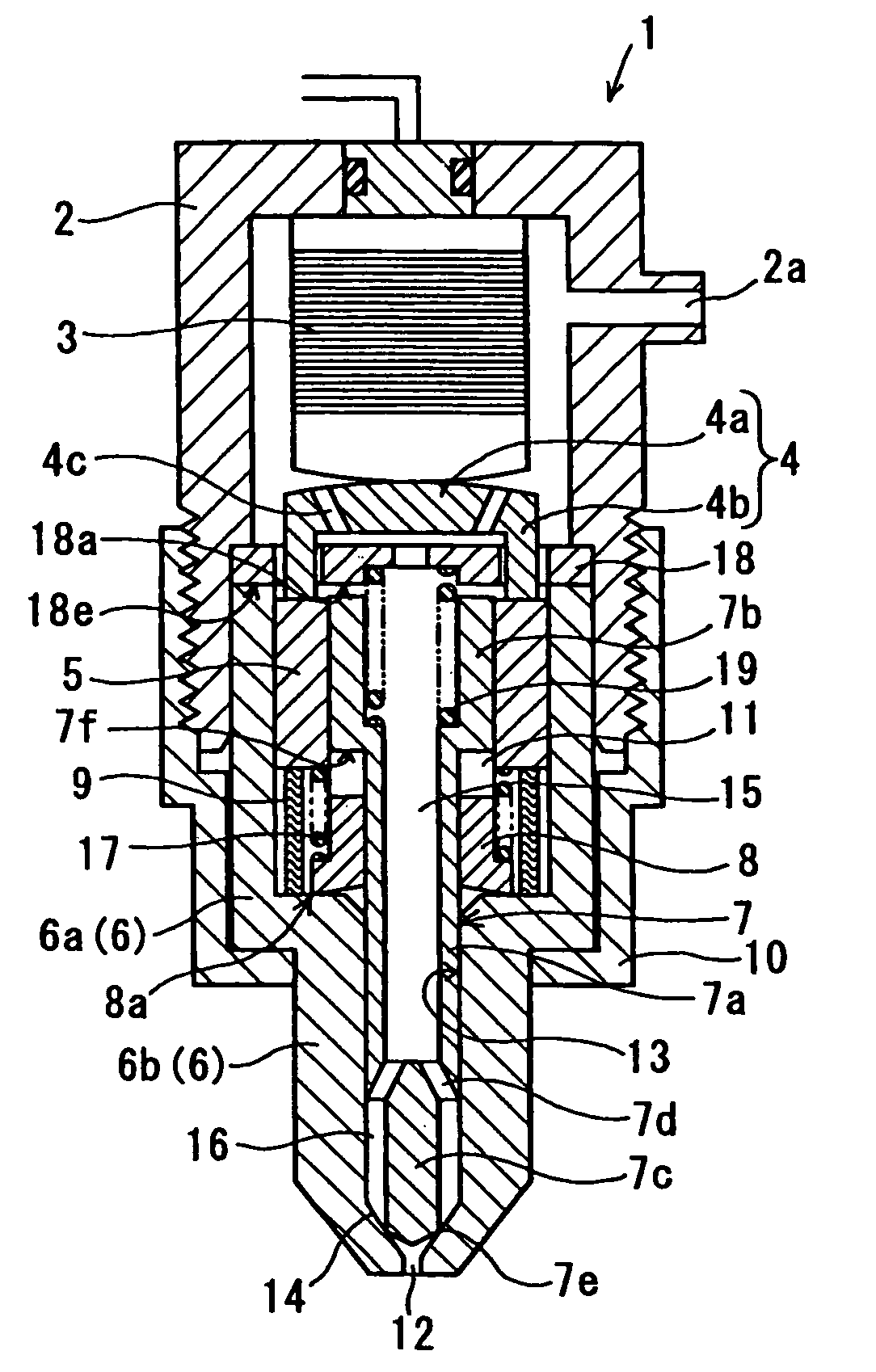

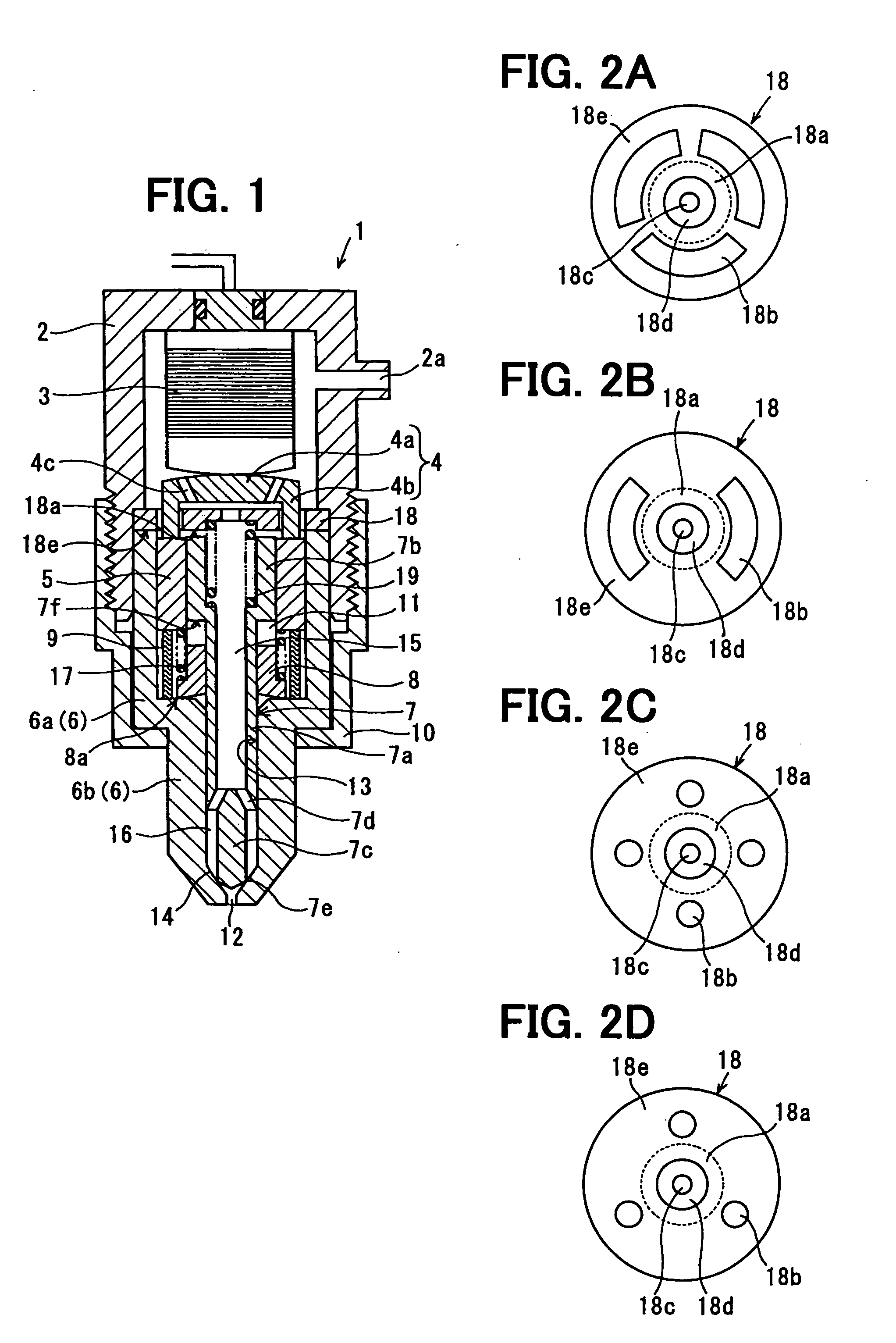

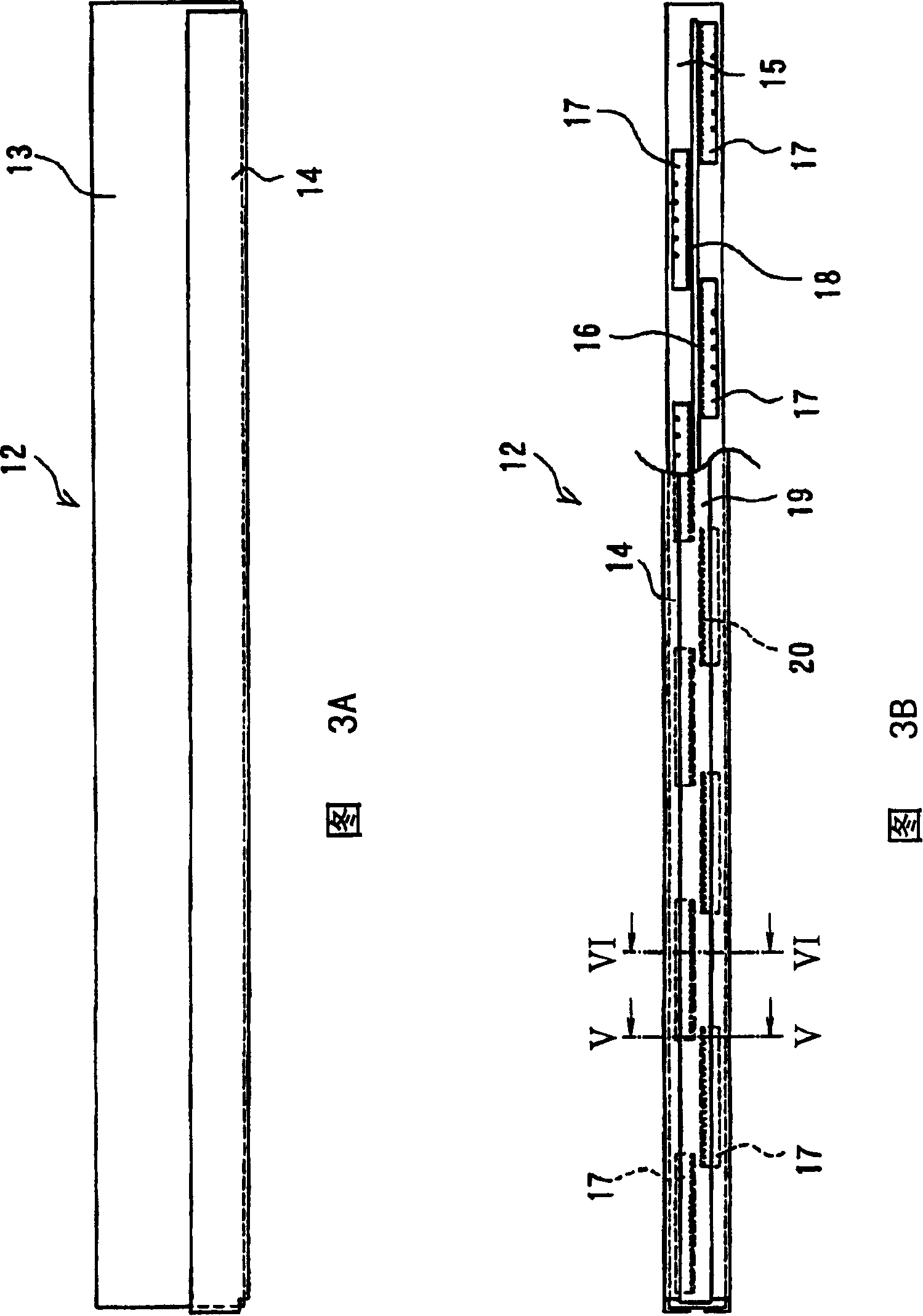

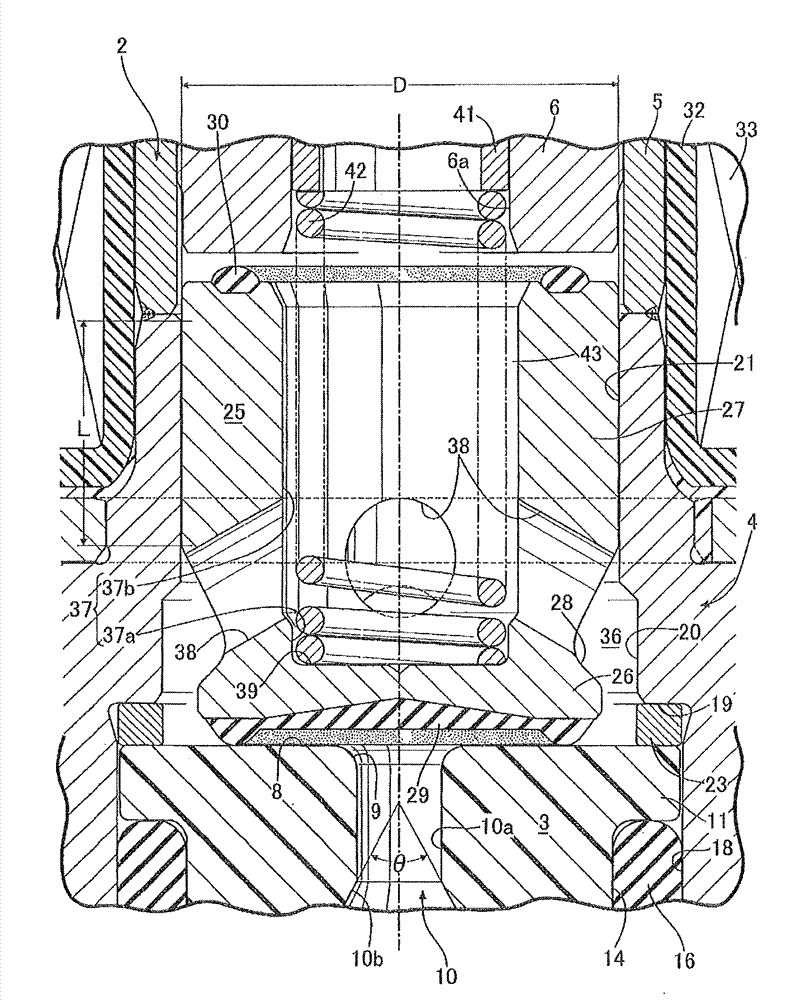

Injector

InactiveUS7699242B2Stable injection volumeIncrease in sizeMovable spraying apparatusSpray nozzlesSingle plateHigh pressure

An injector has a lift limiting member provided by a single plate member. The plate member has a stopper face, multiple hole sections, a flow passage hole, and a spring seat face. An axial end face of a needle head section of a needle contacts the stopper face when the needle lifts by a predetermined amount. Transmitting sections of a pressurizing piston are loosely inserted in the hole sections. High pressure fuel can pass through the flow passage hole. The spring seat face receives an end portion of a spring that biases the needle in a valve closing direction. The lift limiting member limits a valve opening lift position of the needle, so a stable injection quantity is obtained. Thus, a surface area of the single plate member can be used in multiple functions.

Owner:DENSO CORP

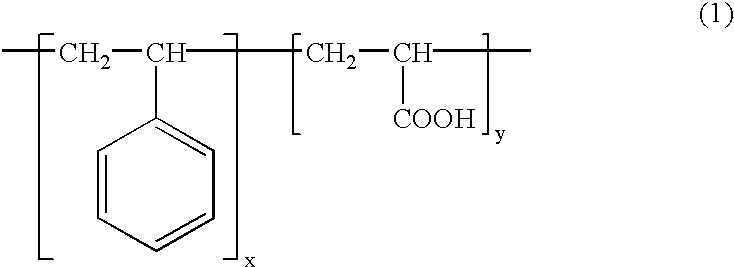

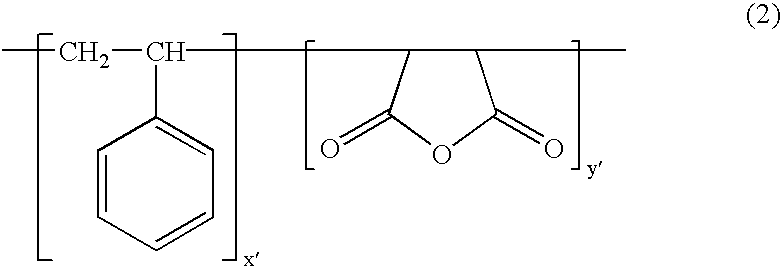

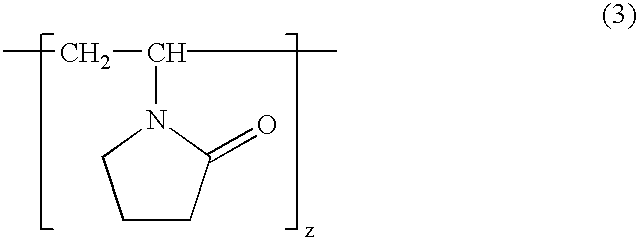

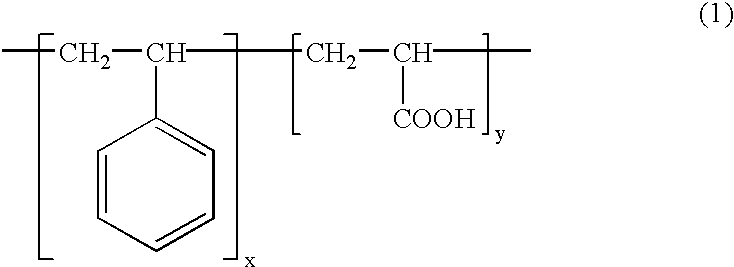

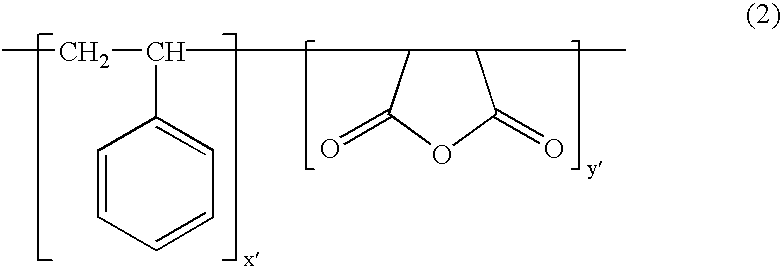

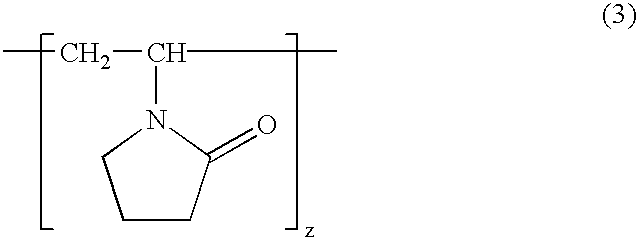

Dispersant composition used for preparing aqueous pigmented ink for ink-jet

InactiveUS6838521B2Quality improvementImprove disadvantagesTransportation and packagingInksPolymer scienceOrganic chemistry

Owner:SEJONG UNIVERSITY

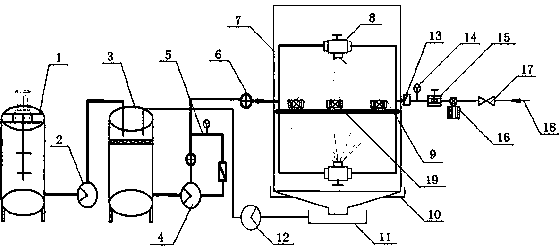

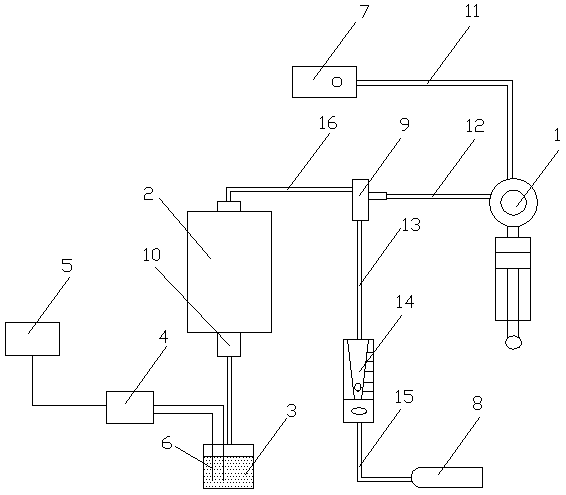

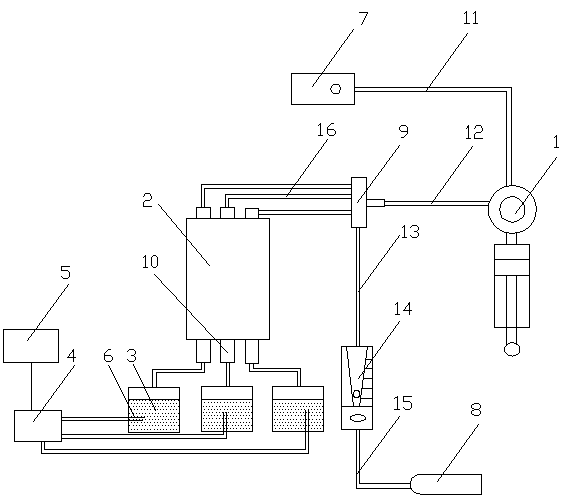

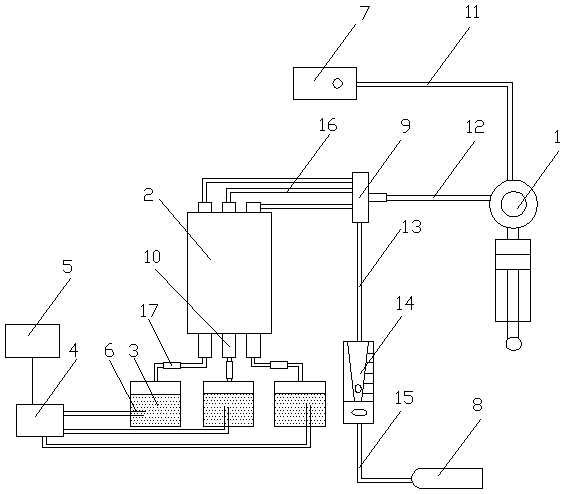

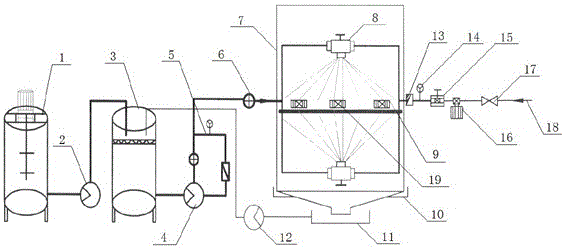

Baked food surface spraying system

The invention discloses a baked food surface spraying system which comprises a feeding mechanism, an air supply mechanism, at least two atomizing nozzles connecting the feeding mechanism with the air supply mechanism, and a blank conveying belt; the atomizing nozzles are mounted on the upper side and the lower side of the blank conveying belt respectively; the feeding mechanism comprises a feed liquid mixer, a delivery pump, a filter storage bucket, a spraying pump, a feed liquid pressure stabilization device and a feed liquid throttle valve which are connected with one another sequentially; the air supply mechanism comprises an anti-backflow device, an air pressure regulating valve, an air filter and an gas source valve, which are connected with one another through connecting pipes in sequence. The baked food surface spraying system is simple in structure and reasonable in design; the feed liquid throttle valve is regulated to stabilize the spraying amount according to feed liquid different in flavor, so that the plurality of sets of atomizing nozzles can work normally; the system is particularly suitable for spraying the surface of fried blank to form different flavors through baking, and solves the problems of flavor component loss, higher acid value of frying oil, rancid grease, higher oil content of finished products, and the like caused by the reason that the blank is tasty in a sprayed manner and dewatered in a fried manner.

Owner:HUAIBEI SHUNFA FOOD

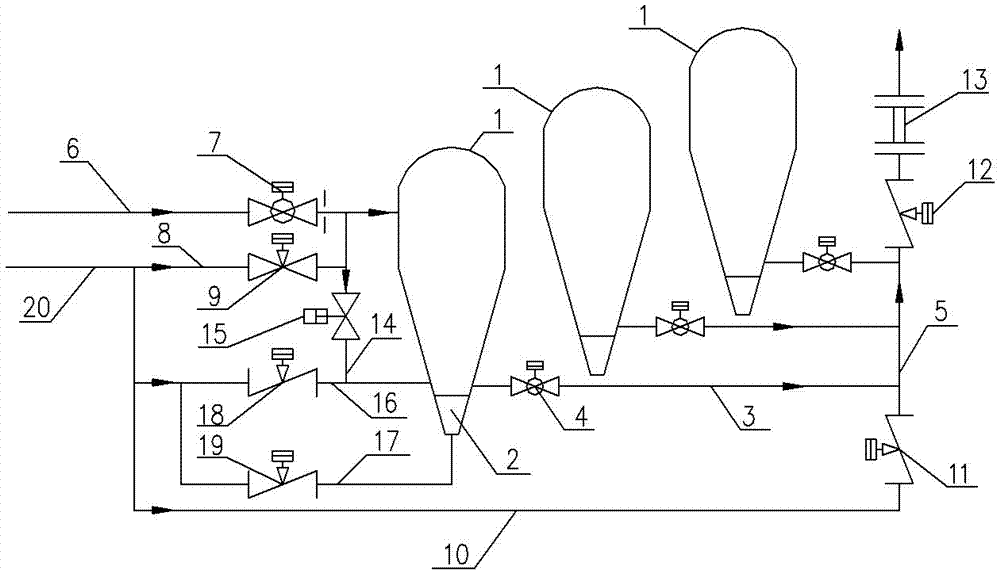

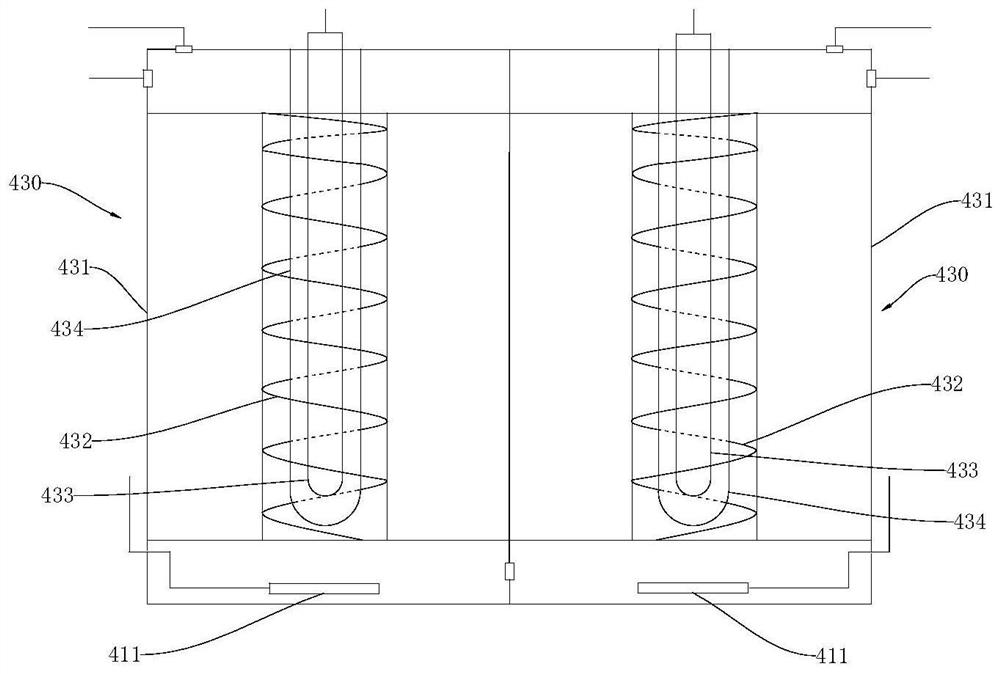

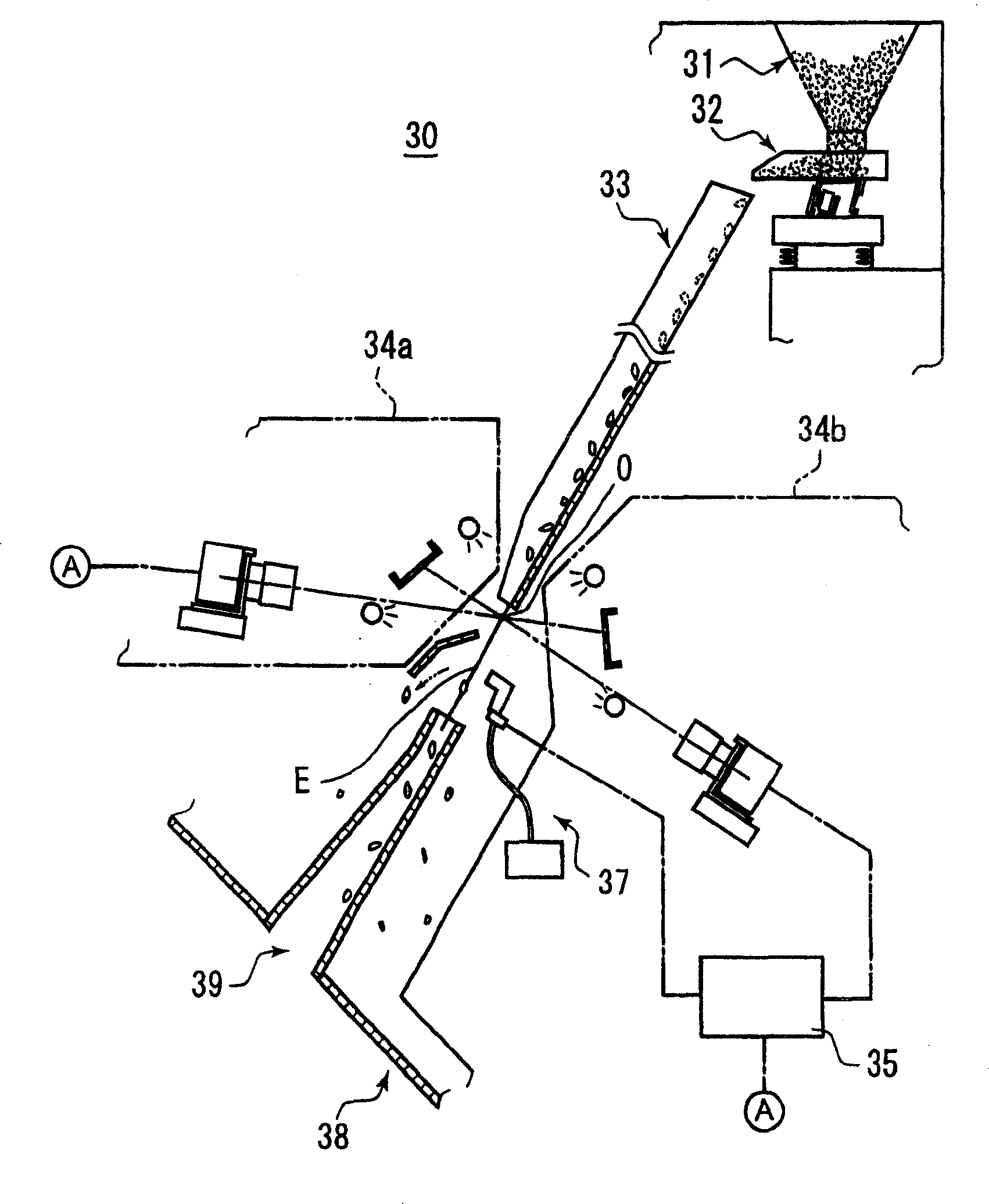

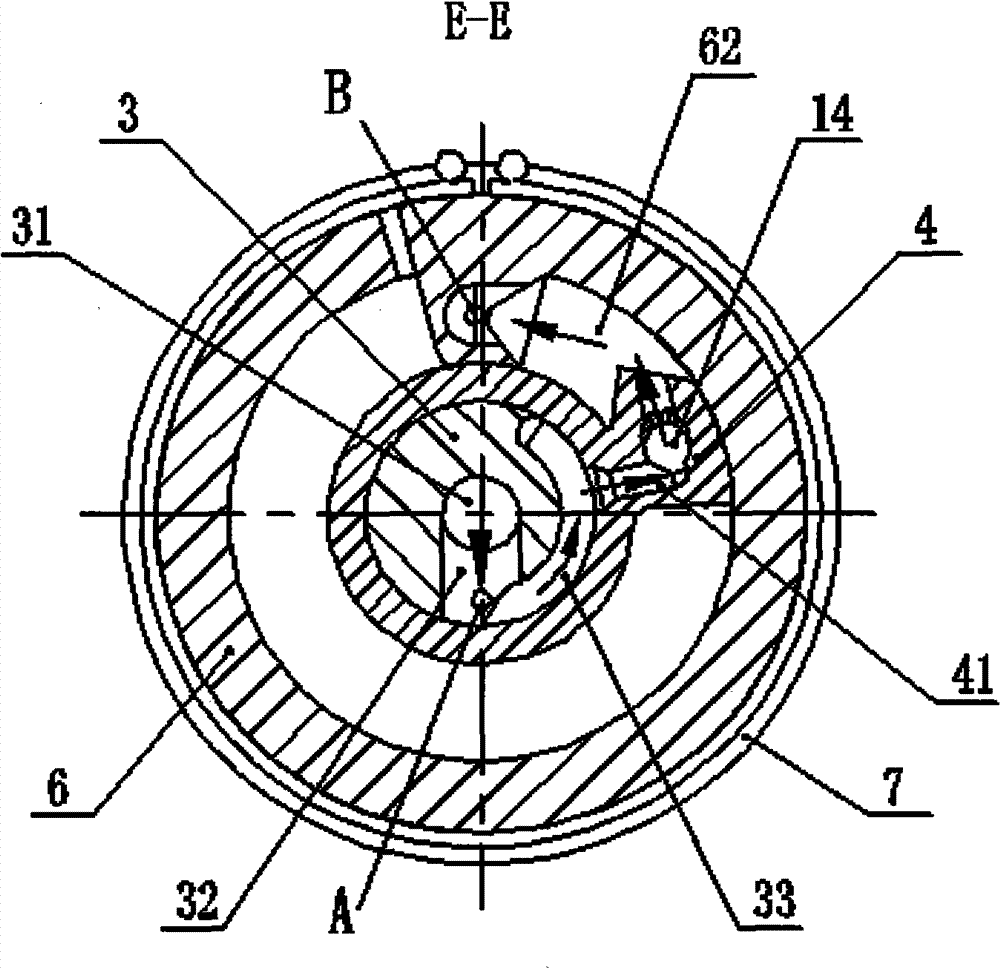

System and process for pulverized coal injection of blast furnace

ActiveCN102787191AEvenly distributedGuaranteed gas adjustment functionBlast furnace componentsBlast furnace detailsEngineeringTransportation technology

The invention provides a system and a process for pulverized coal injection of a blast furnace. The system comprises a plurality of parallel injection tanks, fluidization tanks, injection branch pipes, coal injection valves, an injection main pipe, a charging pipeline, a charging valve, a pressure stabilizing pipeline, a pressure stabilizing valve, a gas supplementing pipeline, a gas supplementing regulating valve, a pulverized coal flow regulating valve and a pulverized coal flow meter, wherein one fluidization tank is arranged at the bottom of each injection tank, one injection branch pipe is connected with an outlet of each injection tank, one coal injection valve is arranged on each injection branch pipe, the charging pipeline and the pressure stabilizing pipeline are connected with each injection tank, the injection main pipe is vertically arranged, the pulverized coal flow regulating valve and the pulverized coal flow meter are arranged on the injection main pipe from bottom to top, the gas supplementing pipeline is connected to the bottom end of the injection main pipe, and the gas supplementing regulating valve is arranged on the injection main pipe and below the joints of the injection branch pipes and the injection main pipe. By the aid of the system and the process, pulverized coal can be uniformly and stably injected, injection quantity is accurately controlled, pulverized coal dense phase transportation technology can be realized, gas consumption is low, and pipeline abrasion is less.

Owner:WISDRI ENG & RES INC LTD

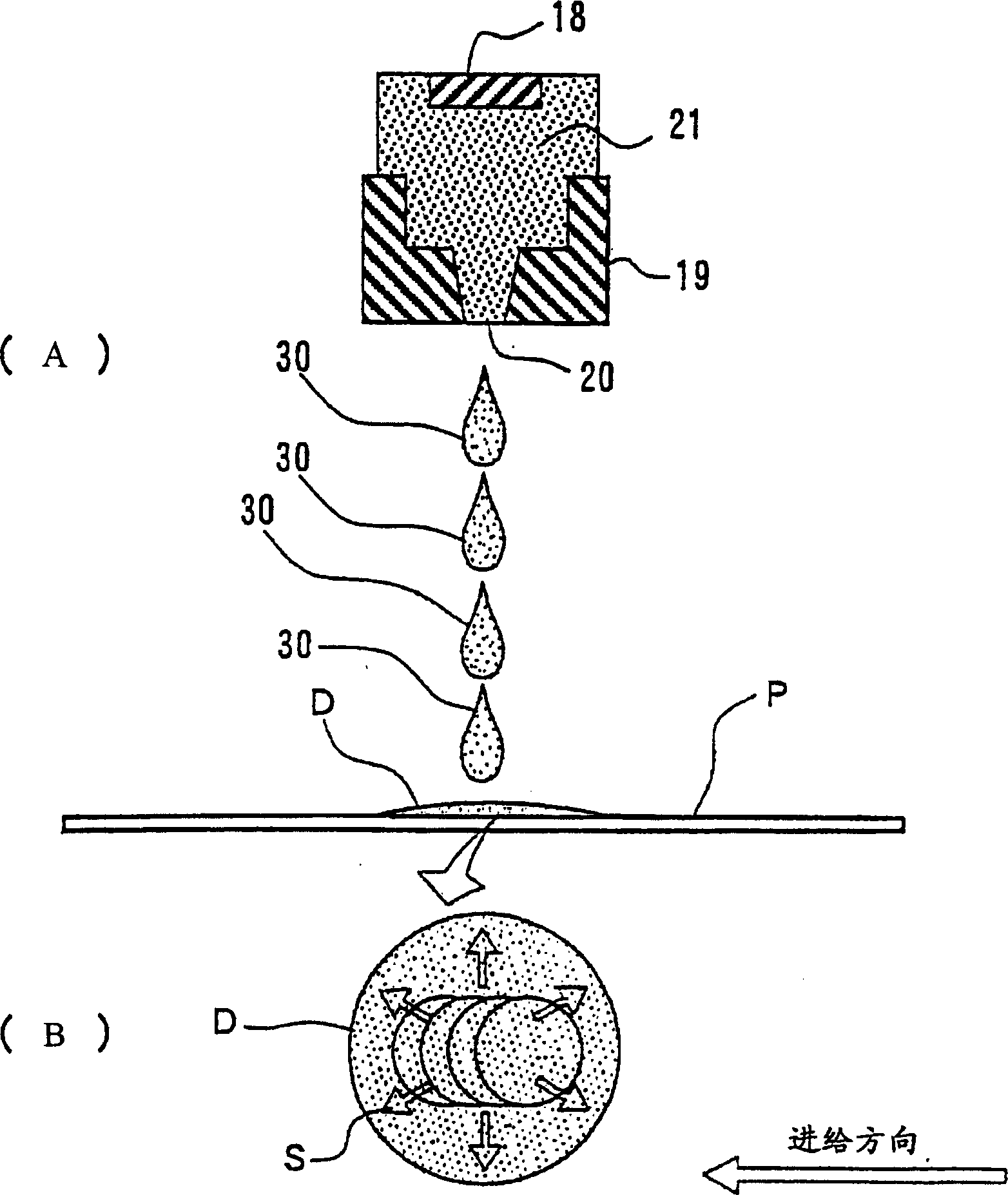

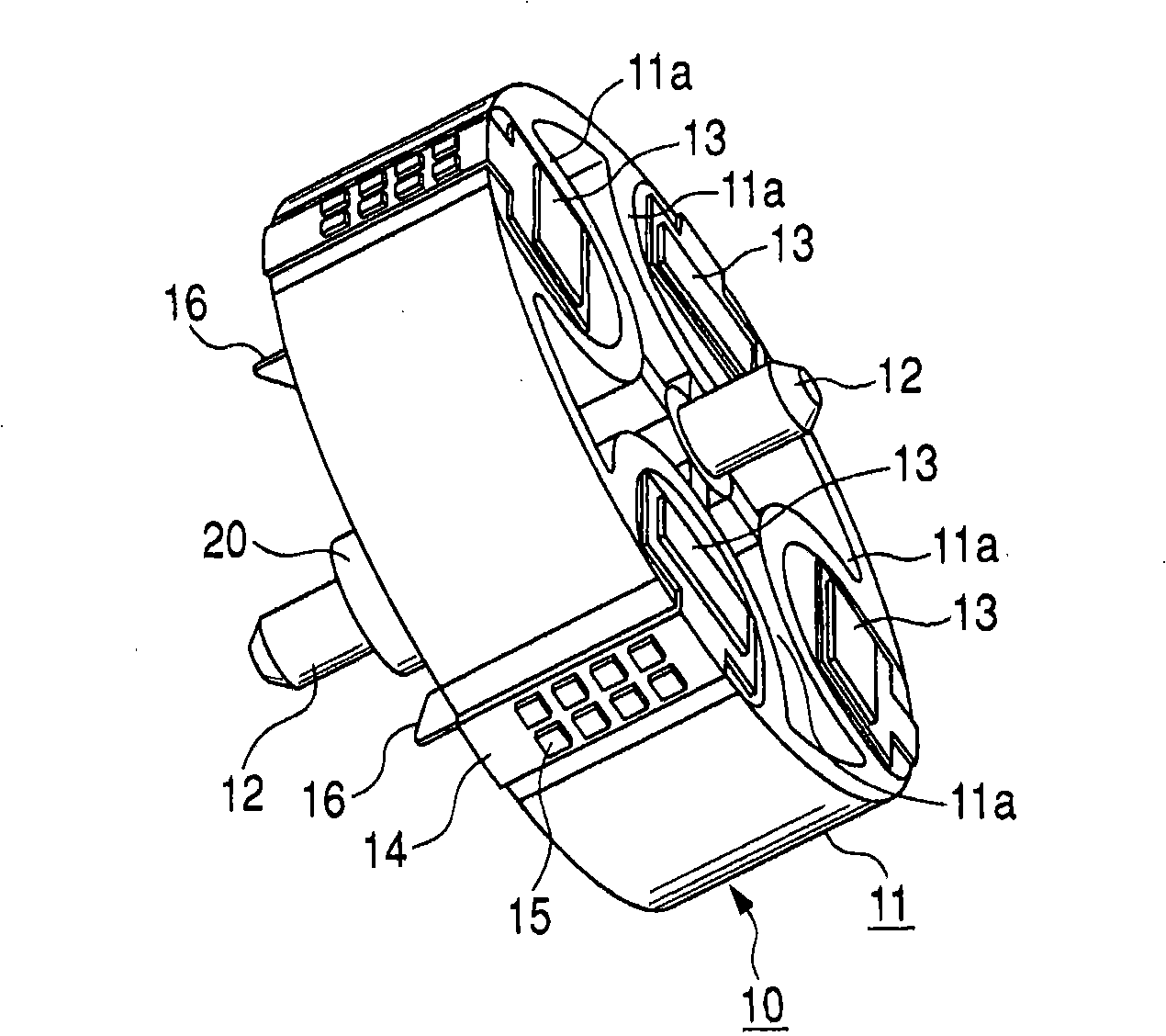

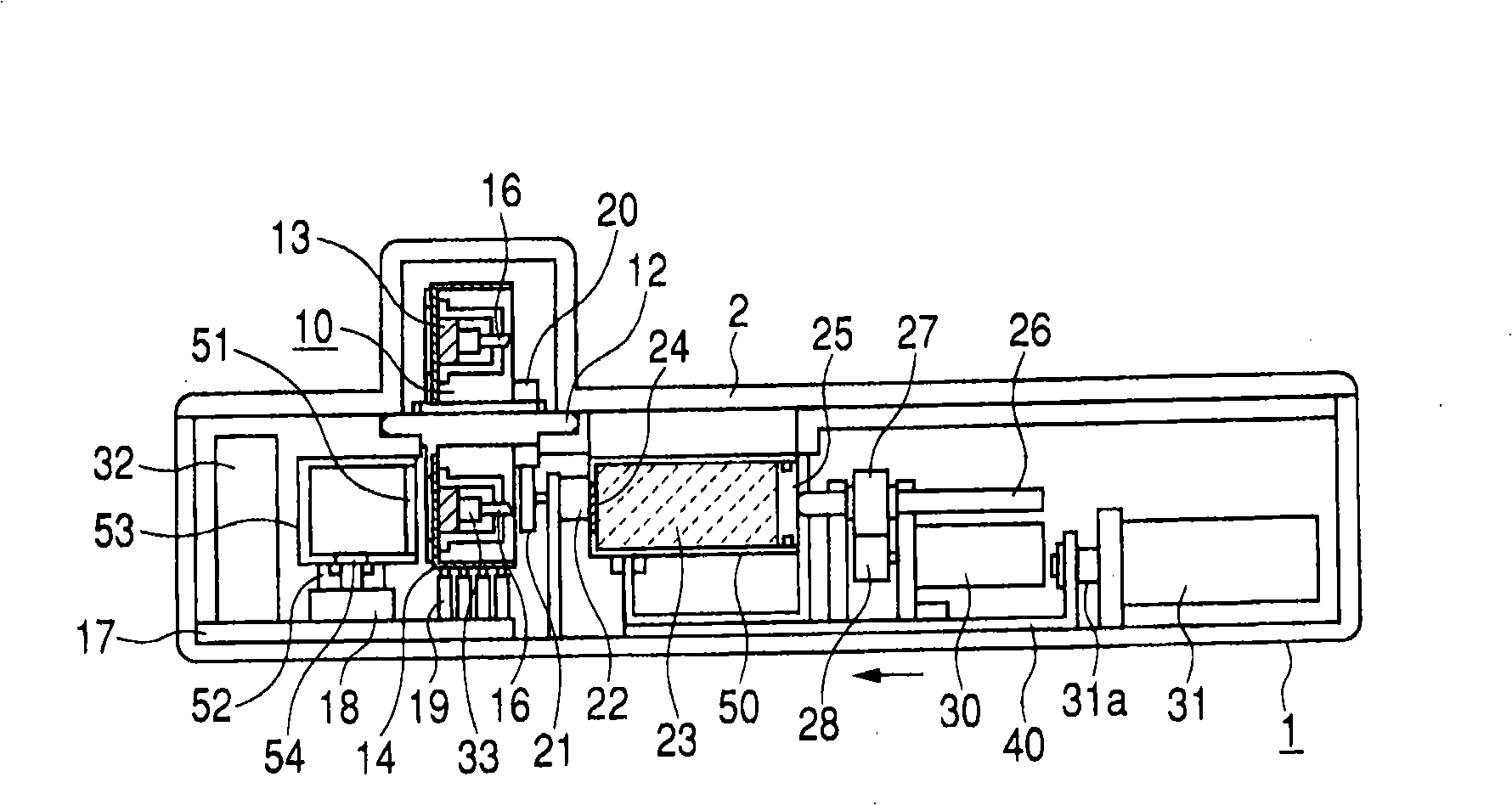

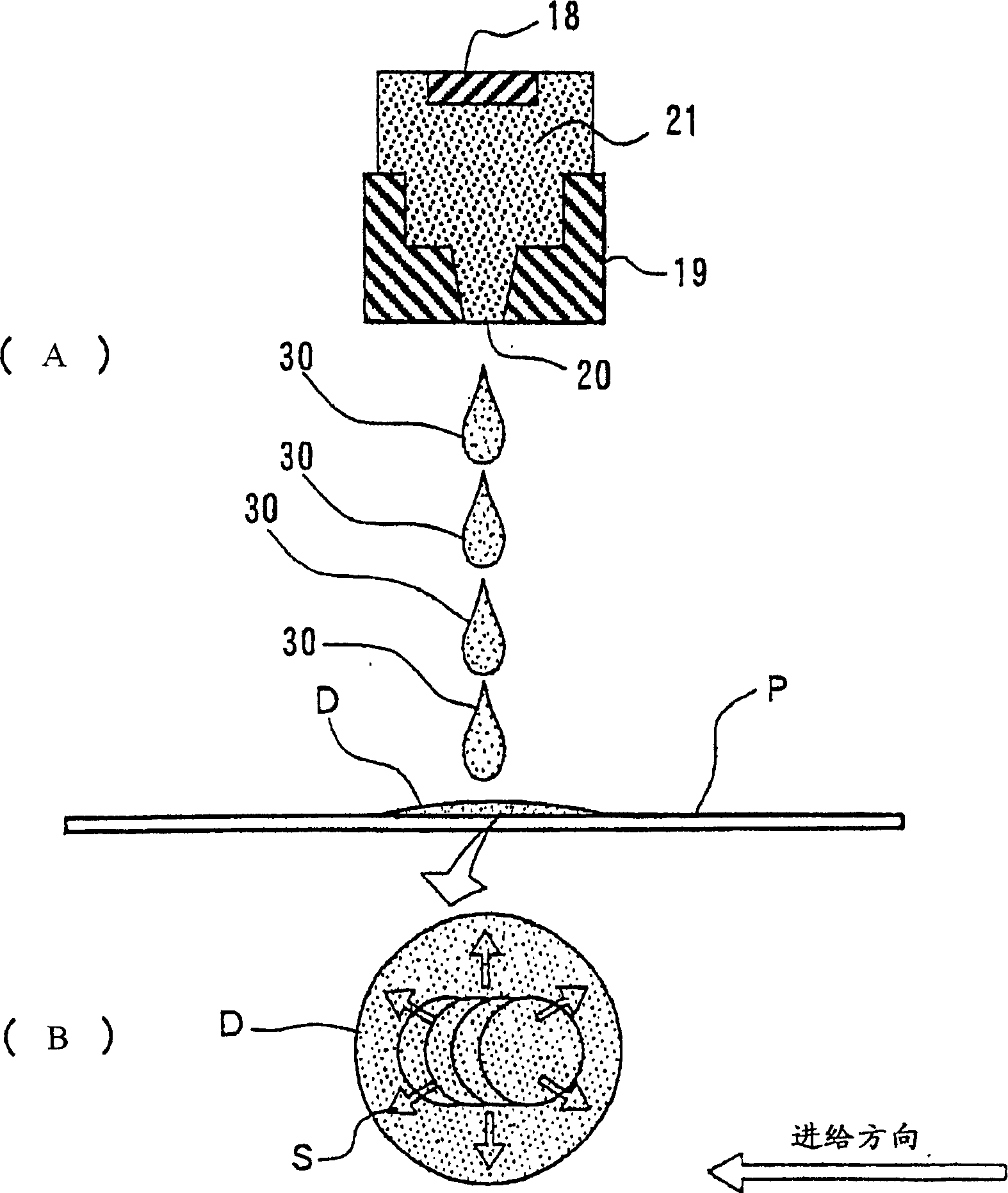

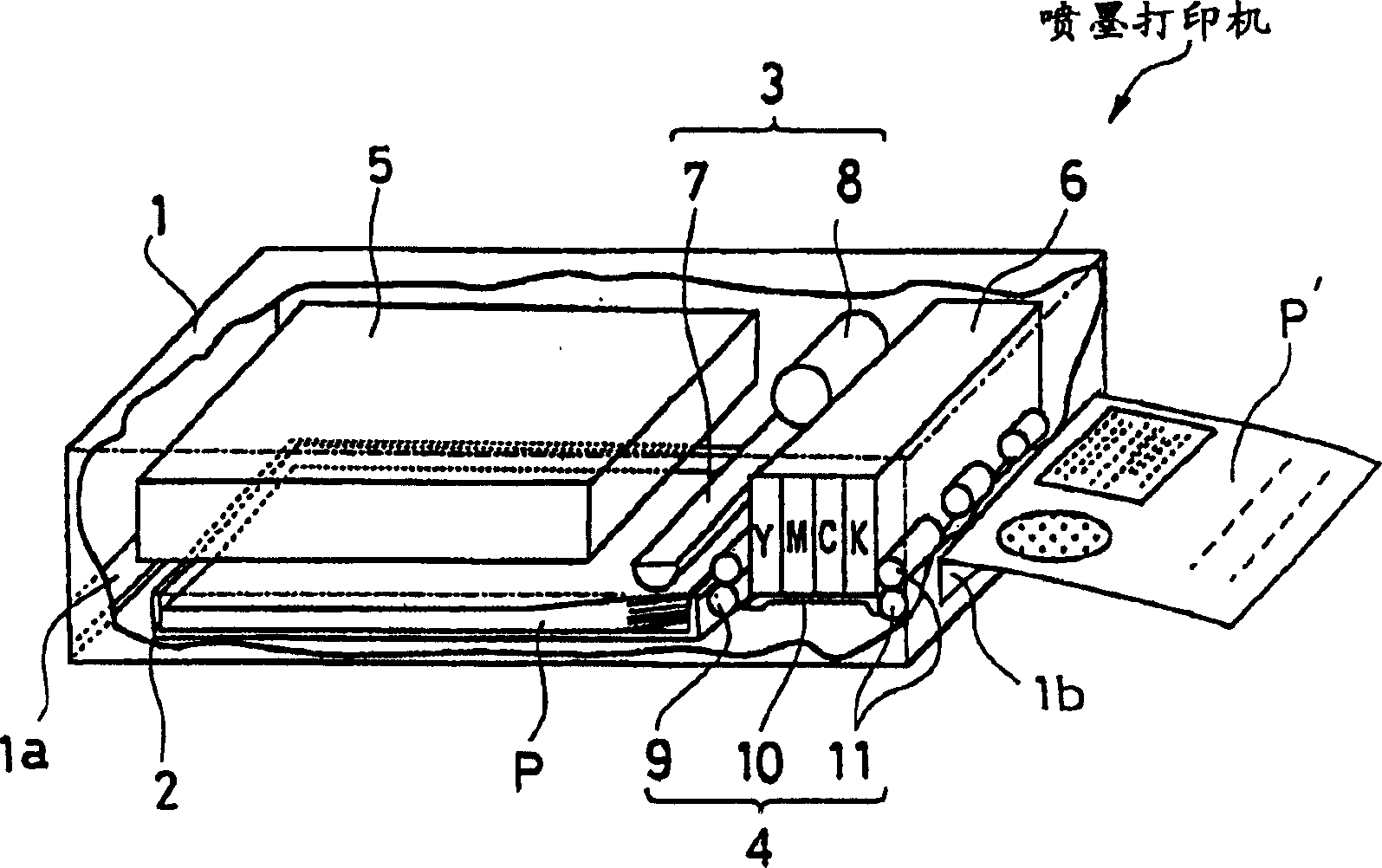

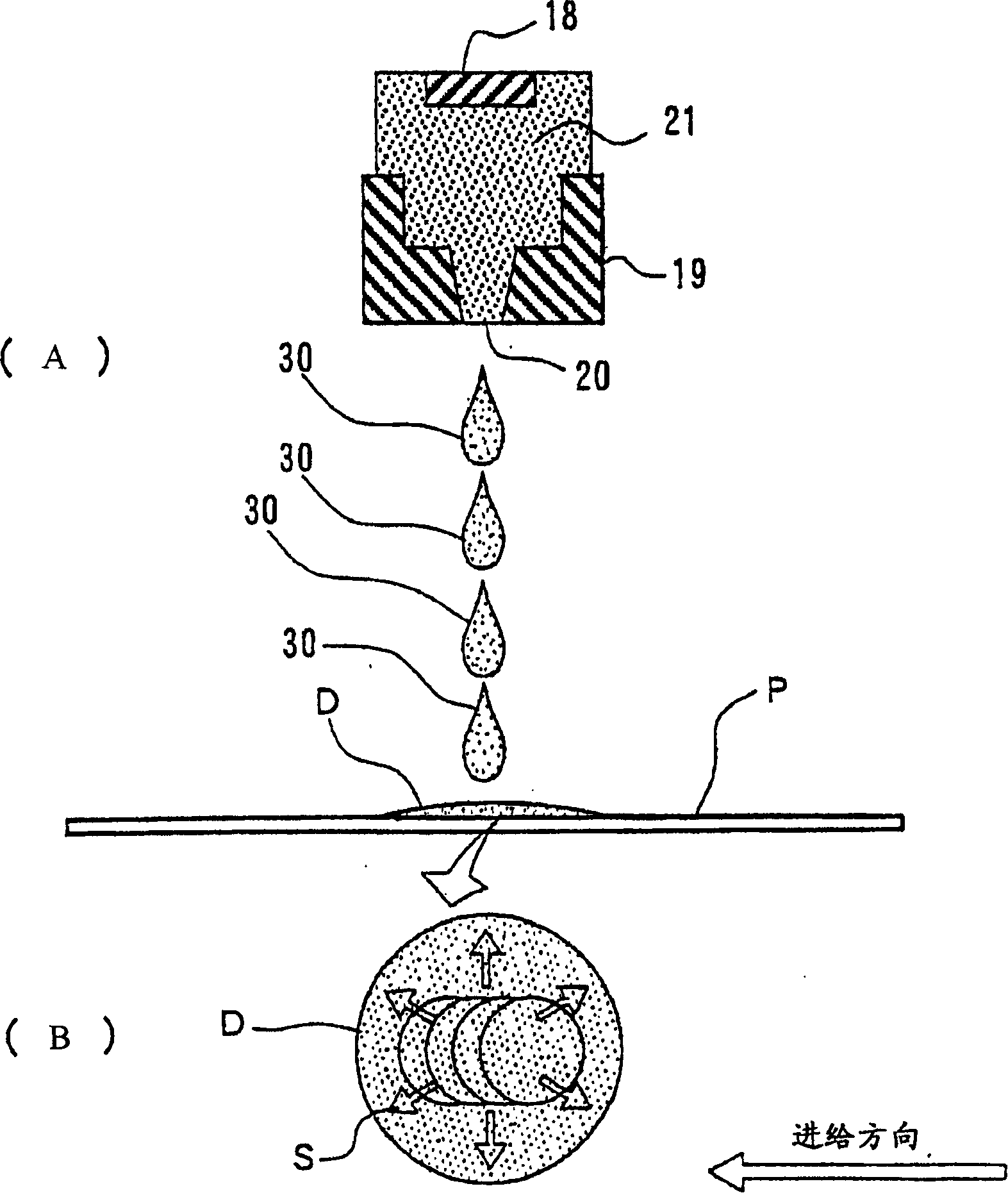

Liquid injecting method and injector

InactiveCN1509872AStable injection volumeQuality improvementInking apparatusImaging qualityEngineering

In a liquid-ejecting method for ejecting liquid contained in a liquid chamber from a nozzle as a liquid droplet group, the ejection amount of each liquid droplet of the continuously ejected liquid-droplet group can be stabilized corresponding to a wide frequency band of a pulse signal. Also, when one pixel is formed with a plurality of liquid droplets using a head capable of deflecting the ejecting direction of the liquid droplet, the image quality is improved by reducing the landing positional displacement between plural liquid droplets for forming the one pixel.

Owner:SONY CORP

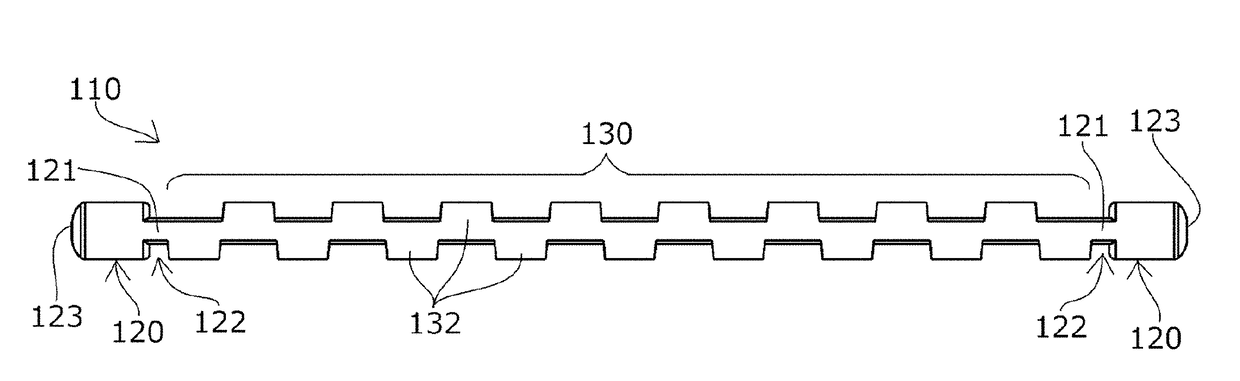

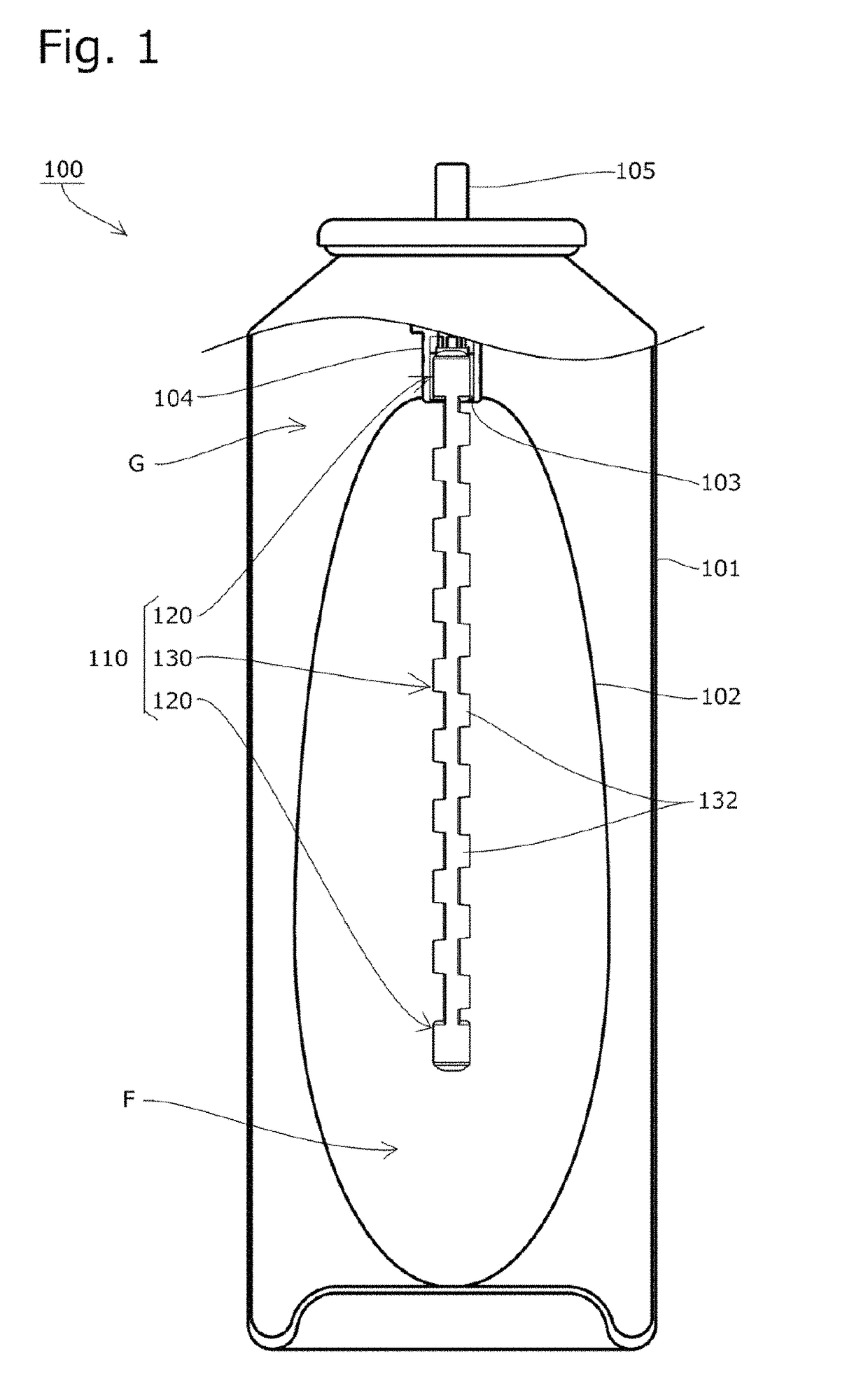

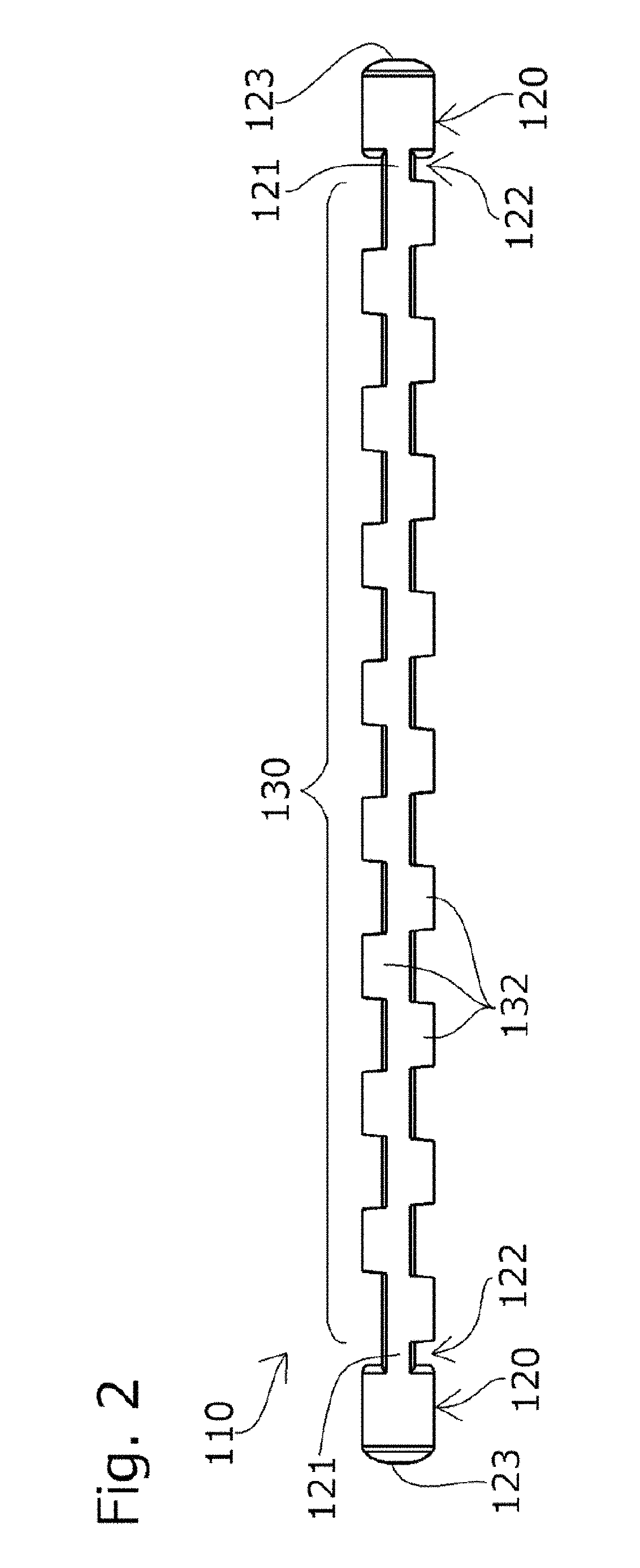

Remaining-amount reduction member

ActiveUS9932167B2Avoid it happening againStable injection volumeLiquid dispensingFlexible containersEngineeringMechanical engineering

Owner:TOYO AEROSOL IND CO LTD

Dispersant composition used for preparing aqueous pigmented ink for ink-jet

InactiveUS20030051632A1Improve disadvantageGood particle stabilityTransportation and packagingInksPolymer chemistryPigment particle

Owner:SEJONG UNIVERSITY

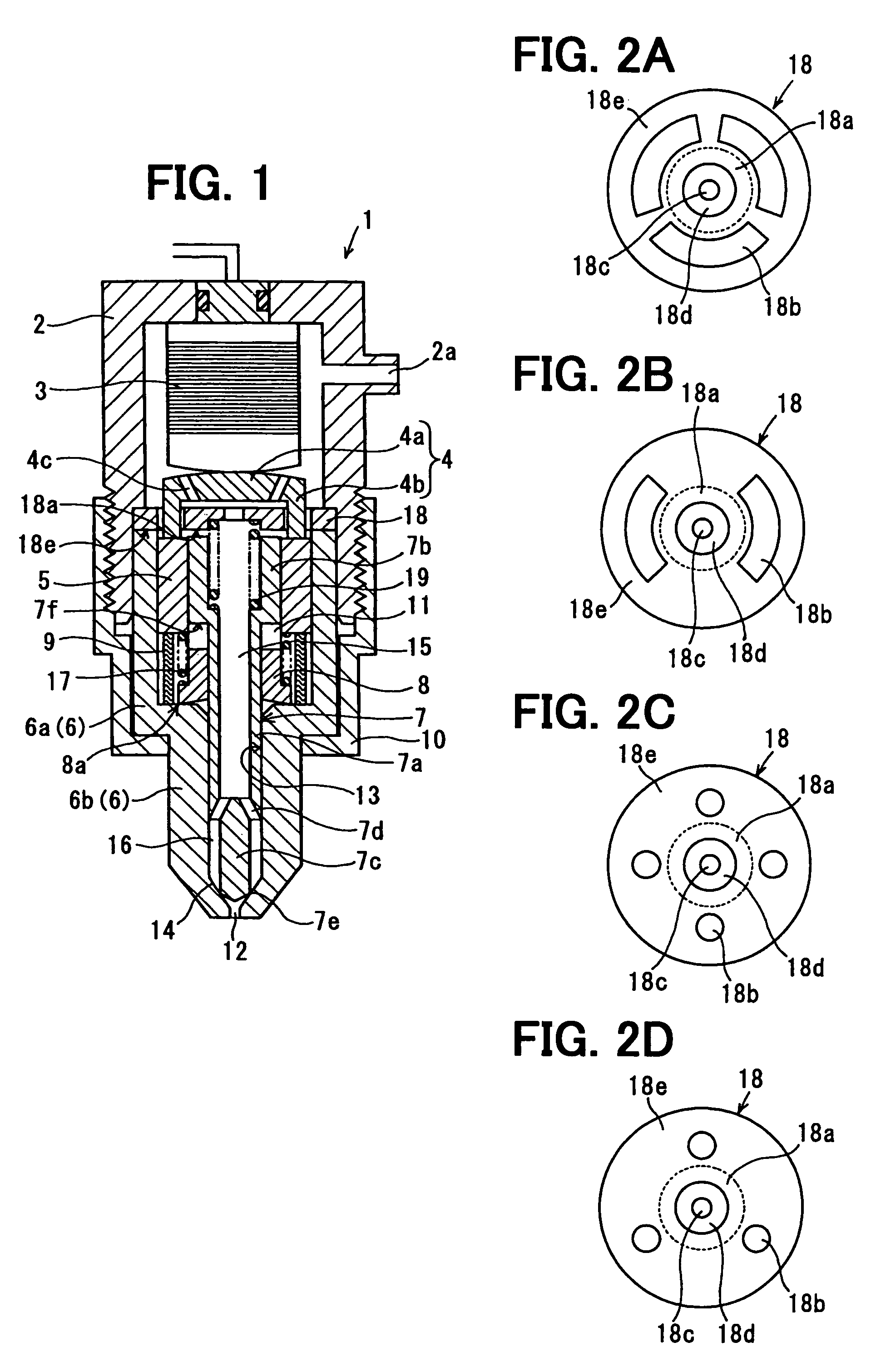

Injector

InactiveUS20080217441A1Improve accuracyLift position can be limitedMovable spraying apparatusSpray nozzlesSingle plateEngineering

An injector has a lift limiting member provided by a single plate member. The plate member has a stopper face, multiple hole sections, a flow passage hole, and a spring seat face. An axial end face of a needle head section of a needle contacts the stopper face when the needle lifts by a predetermined amount. Transmitting sections of a pressurizing piston are loosely inserted in the hole sections. High pressure fuel can pass through the flow passage hole. The spring seat face receives an end portion of a spring that biases the needle in a valve closing direction. The lift limiting member limits a valve opening lift position of the needle, so a stable injection quantity is obtained. Thus, a surface area of the single plate member can be used in multiple functions.

Owner:DENSO CORP

Electric pressurization outpouring type liquid container

ActiveCN102197955AInjection volume is stableReduce running waterWater-boiling vesselsNon-pressured vesselsEngineeringMechanical engineering

Owner:THERMOS CHINA HOUSEWARES

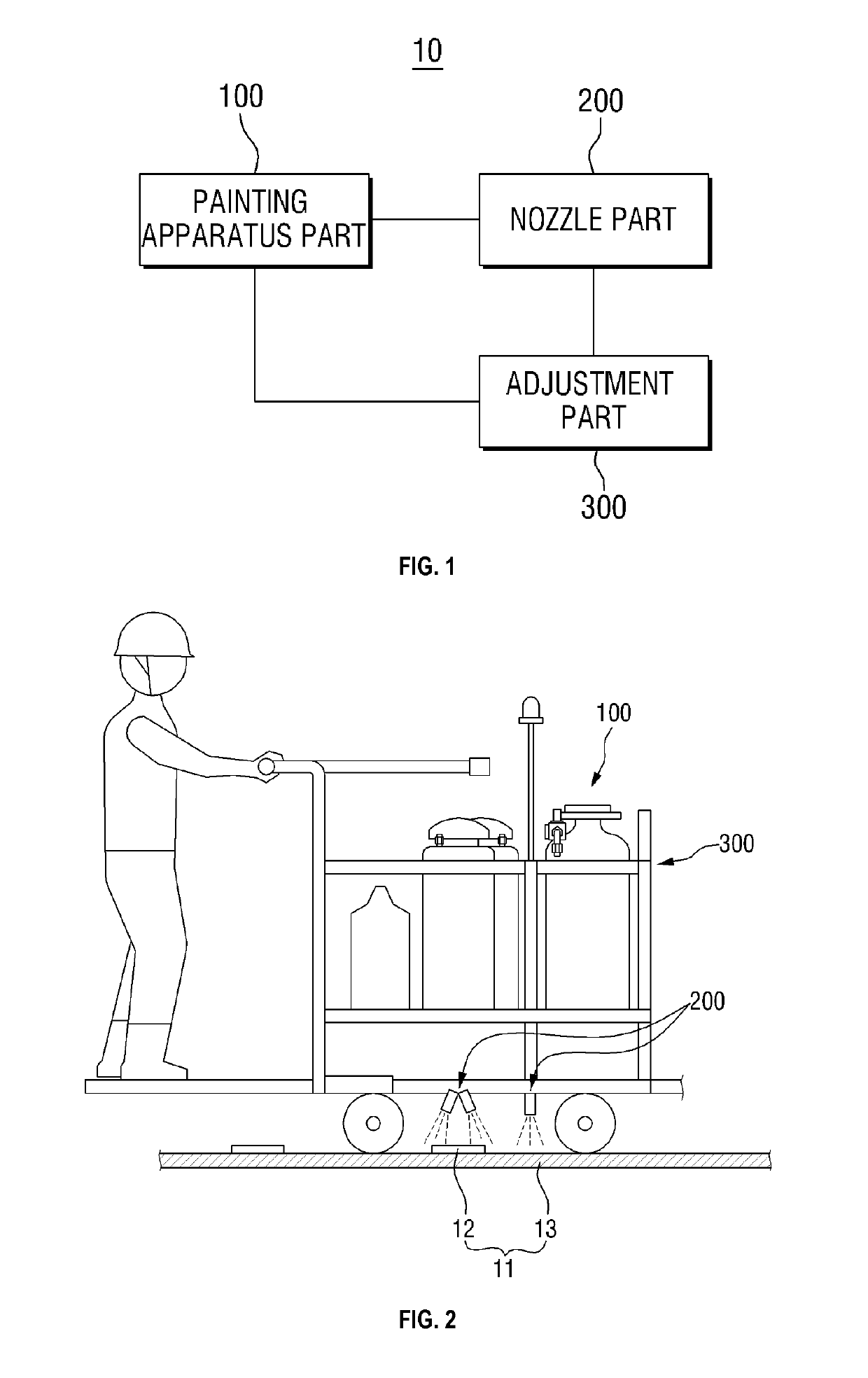

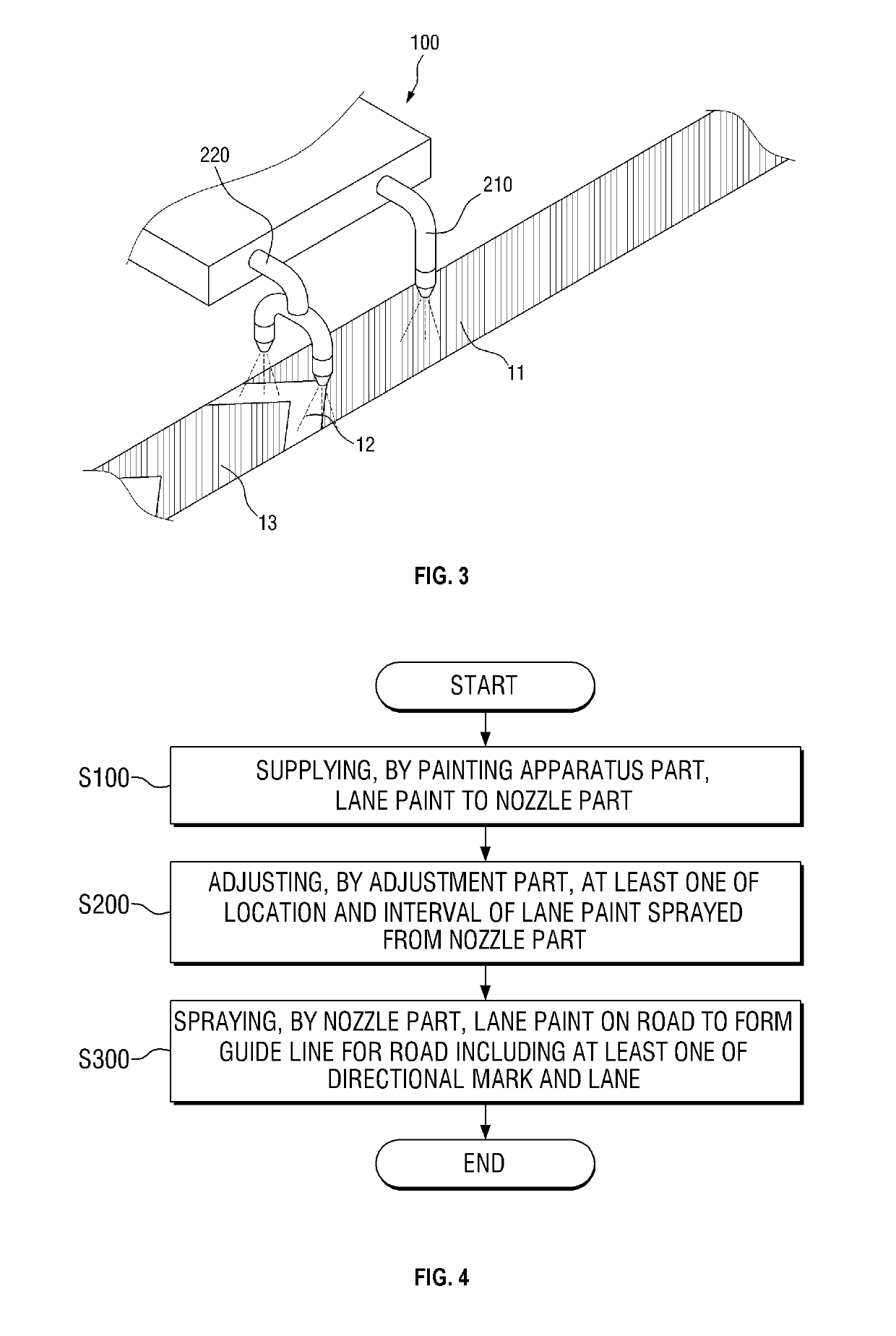

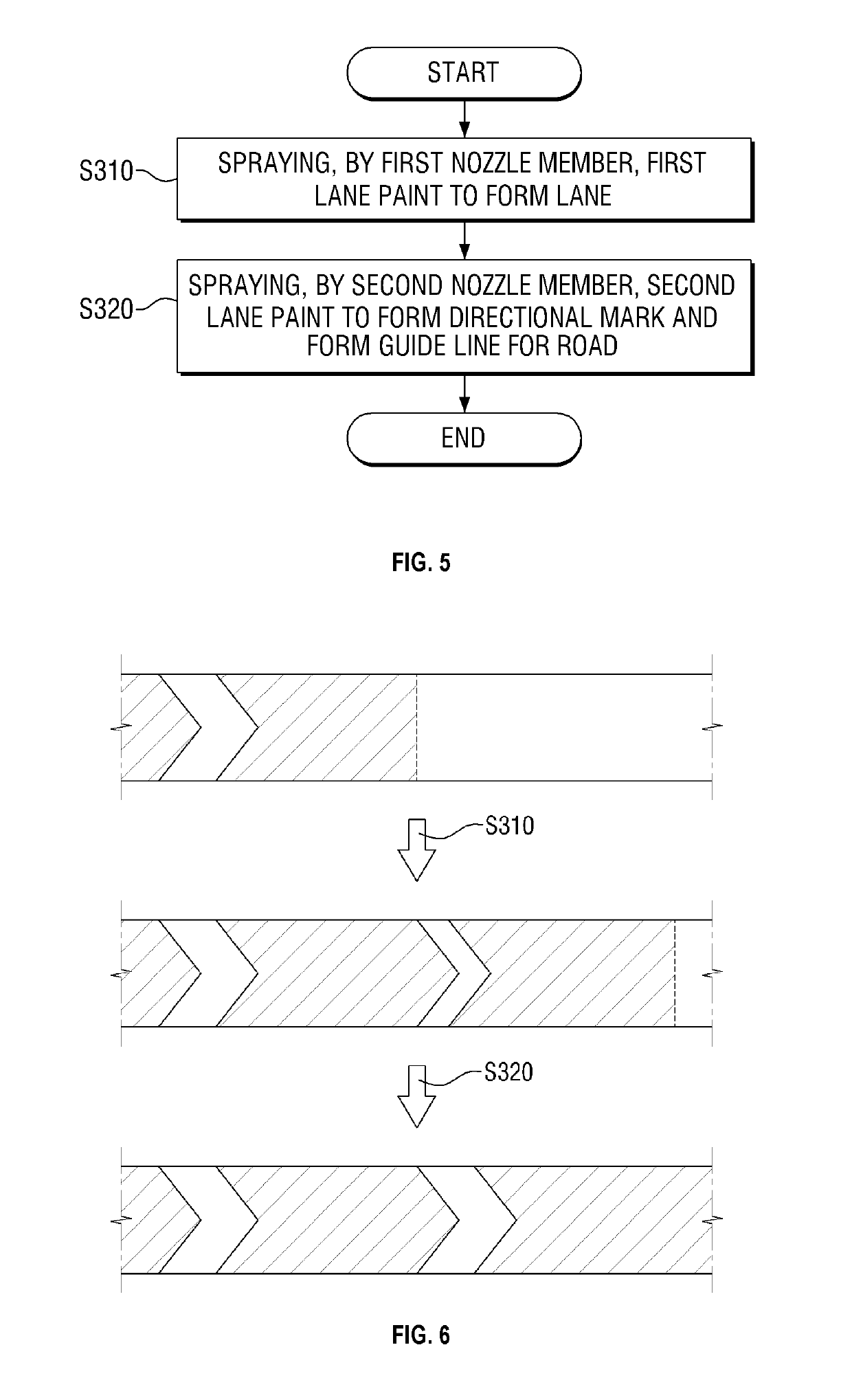

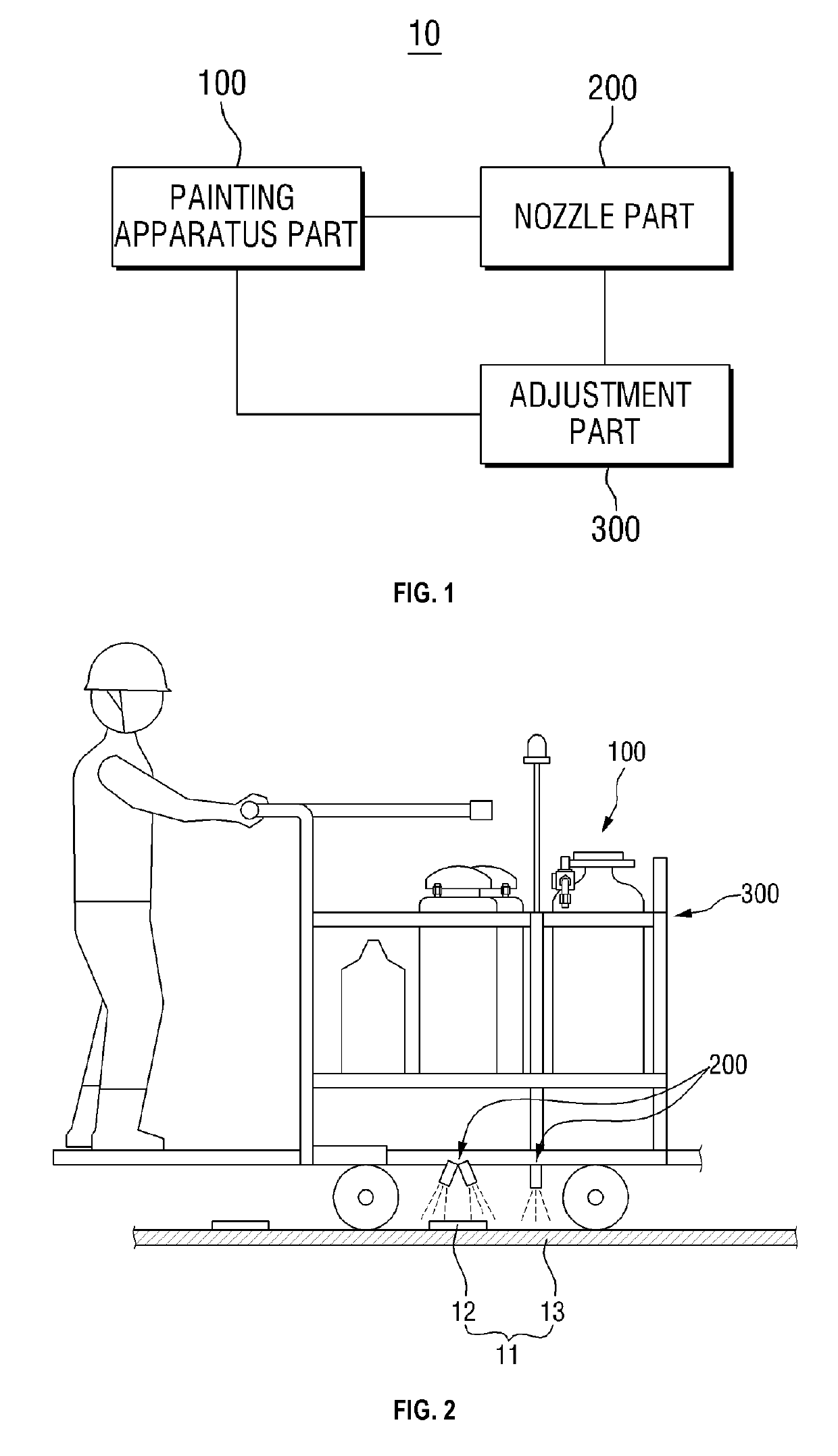

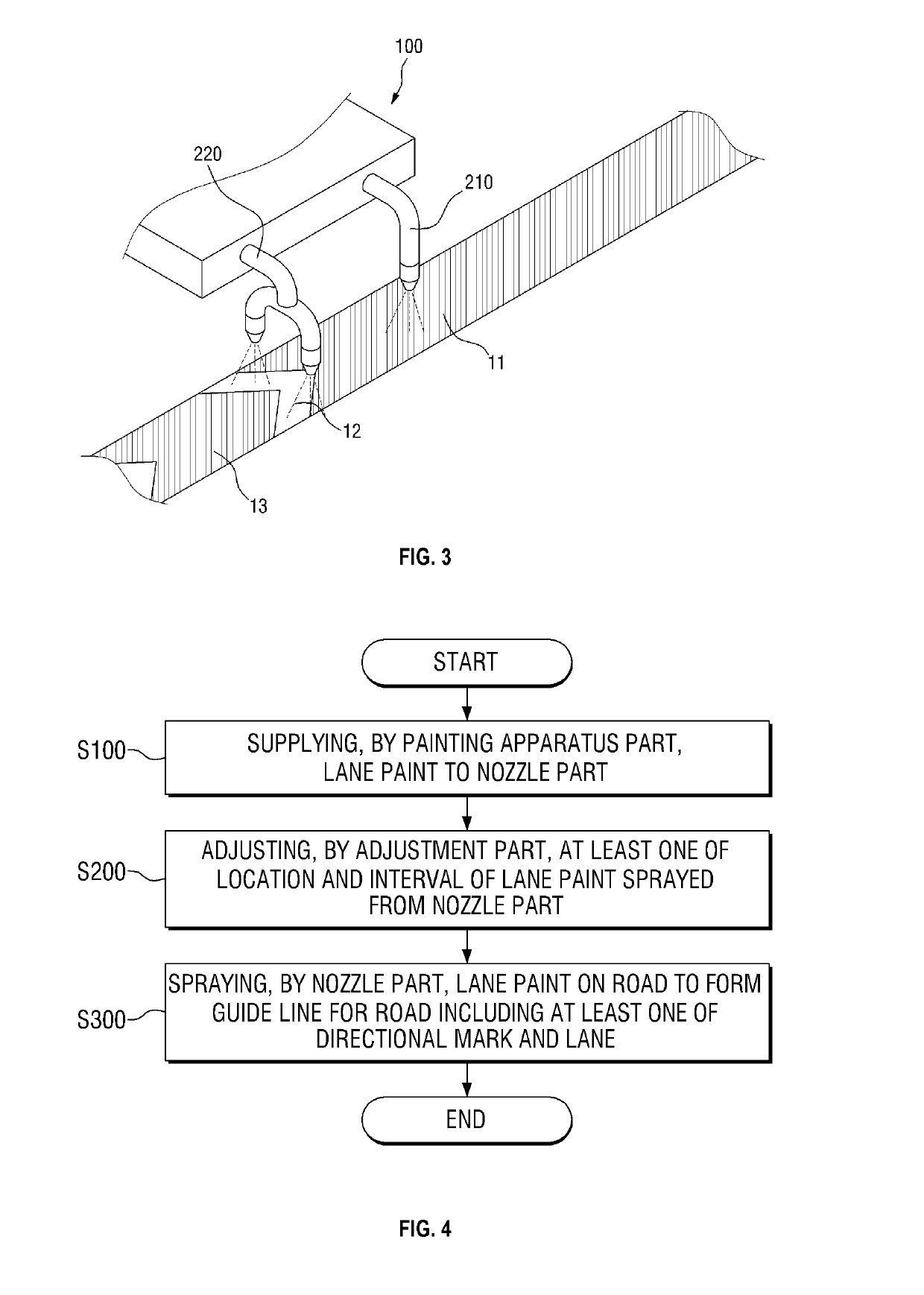

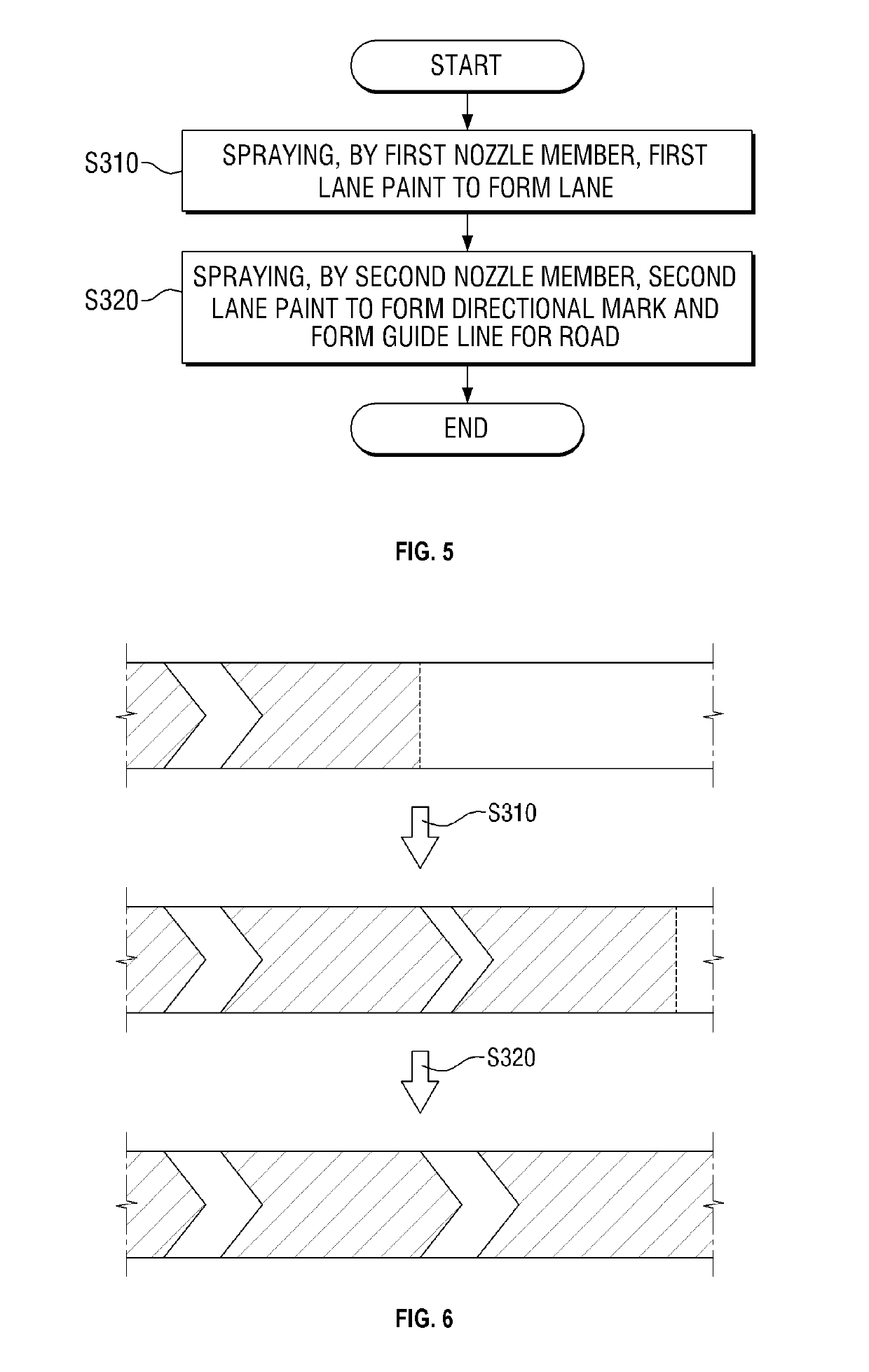

Constructing apparatus and method of guide line for road

ActiveUS10364537B2Improve guide qualityStable injection volumeSpraying vehiclesLiquid spraying apparatusSpray nozzleEngineering

An apparatus is for constructing a guide line for a road. The apparatus includes a painting apparatus part that stores a lane paint, is driven by receiving power, and supplies the lane paint. A nozzle part is installed in the painting apparatus part and sprays the lane paint supplied from the painting apparatus part on a road to form a guide line for a road including at least one of a directional mark and a lane. An adjustment part is installed in the painting apparatus part and adjusts at least one of a location and an interval of the lane paint sprayed from the nozzle part.

Owner:KOREA EXPRESSWAY CORPORATION

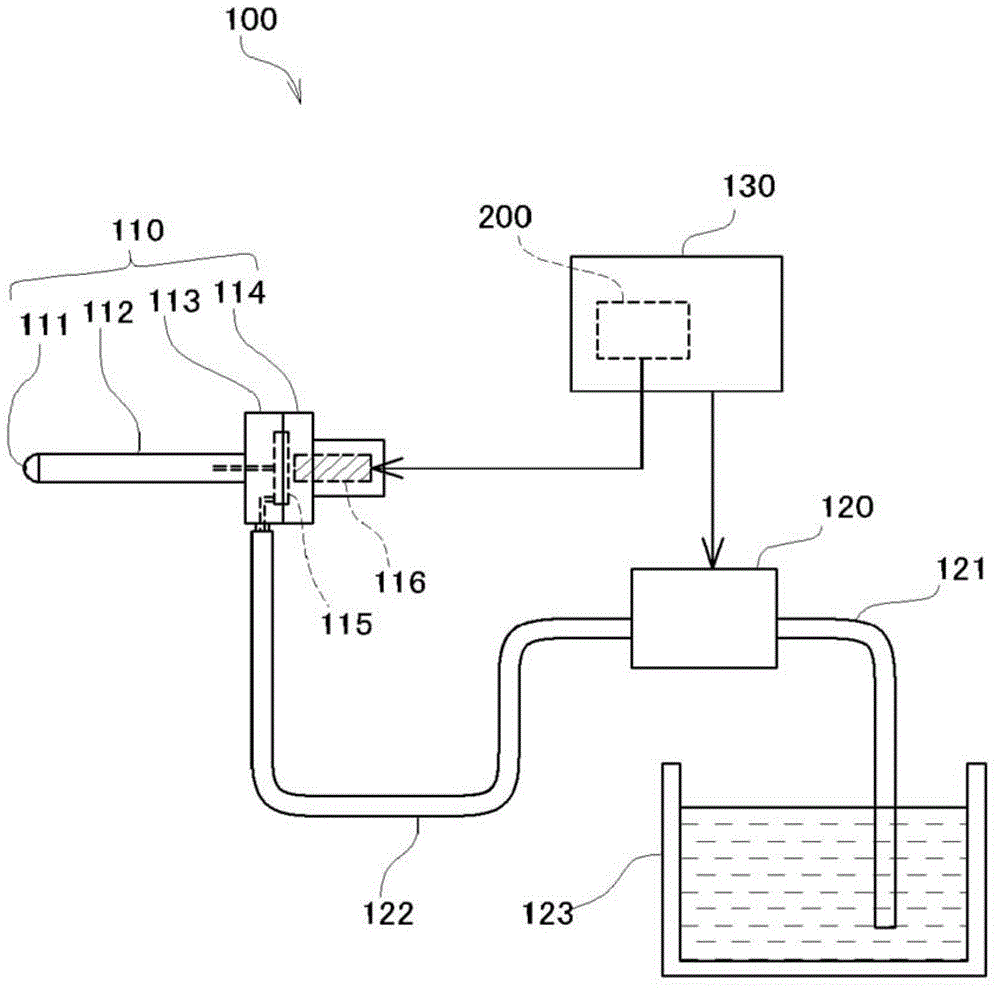

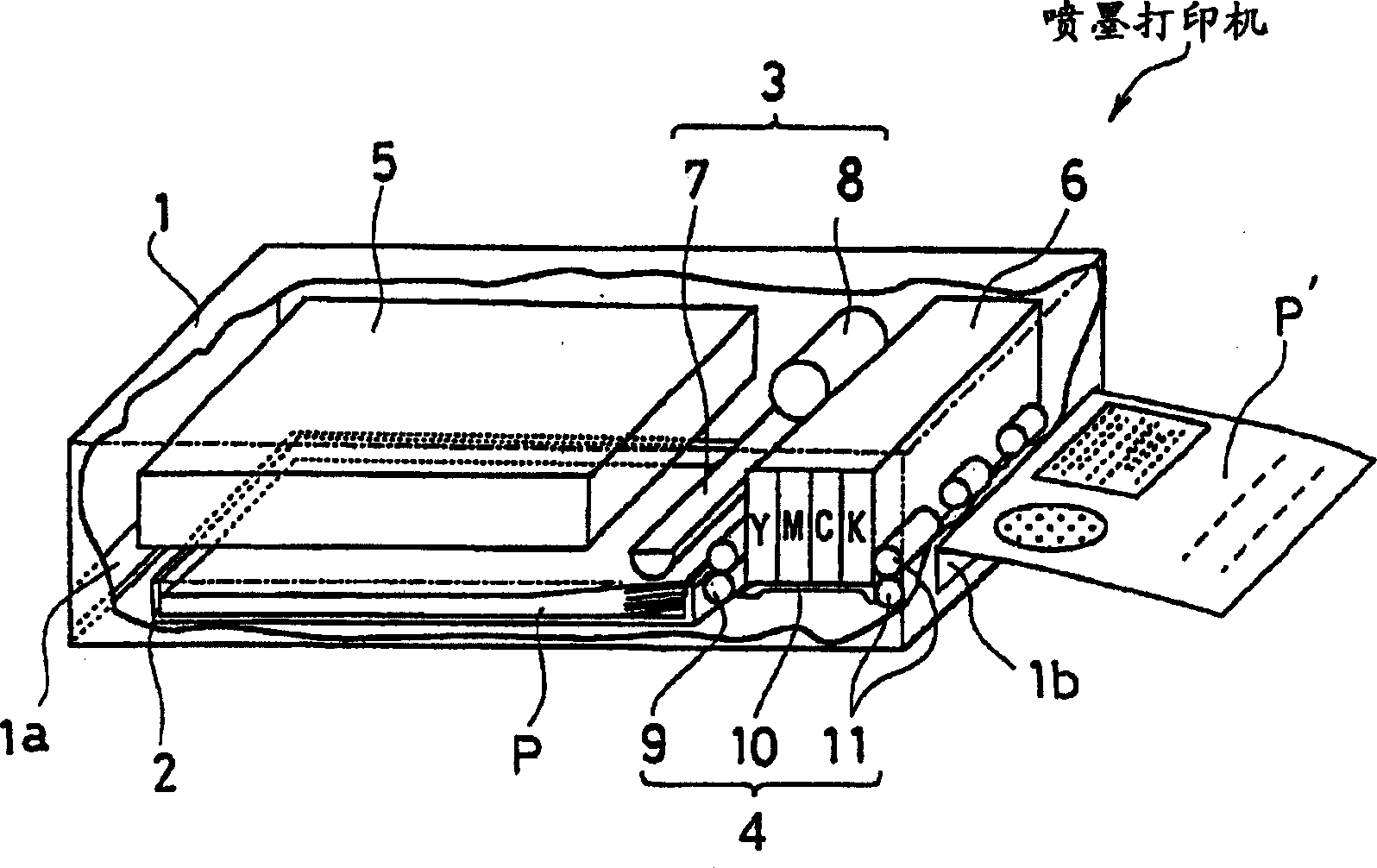

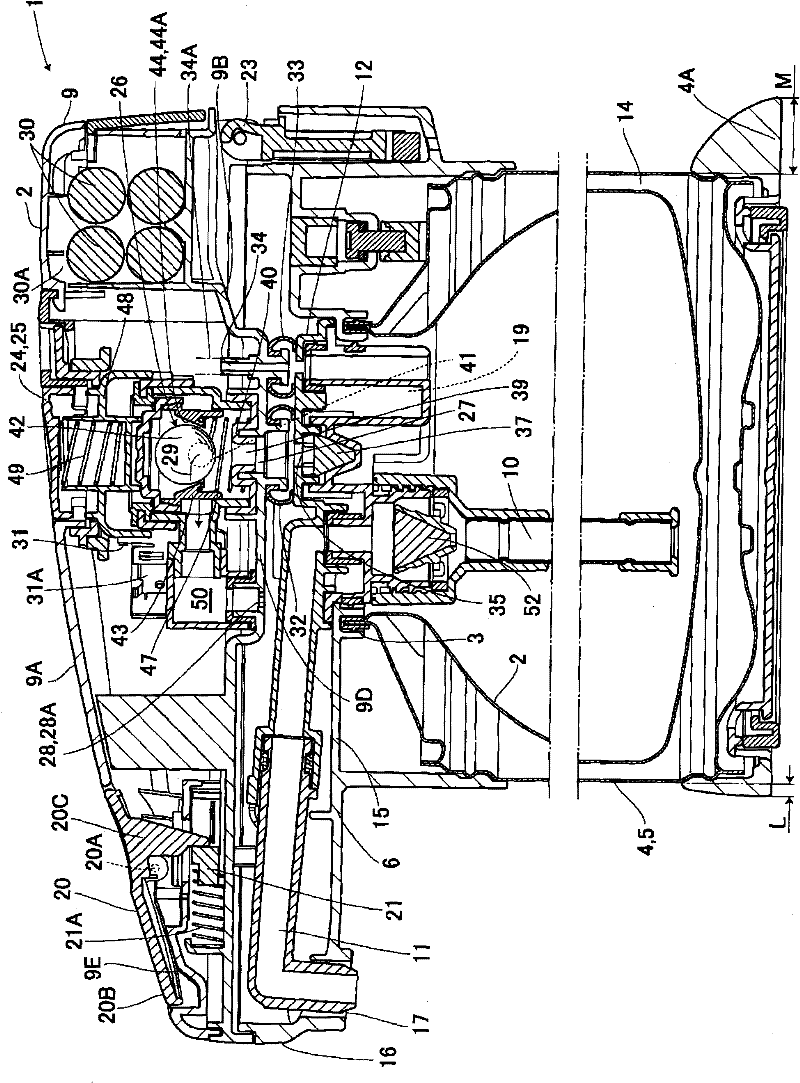

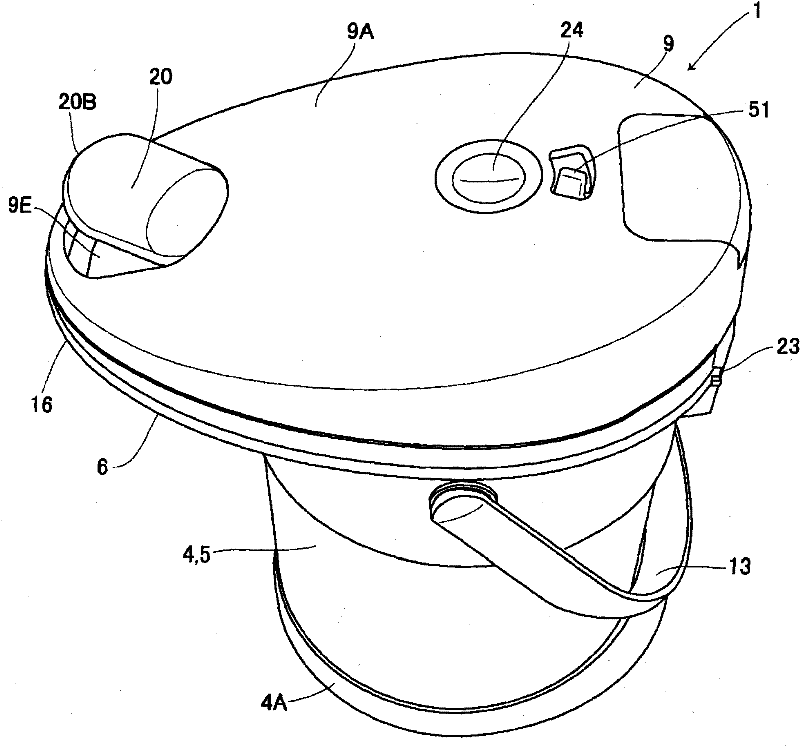

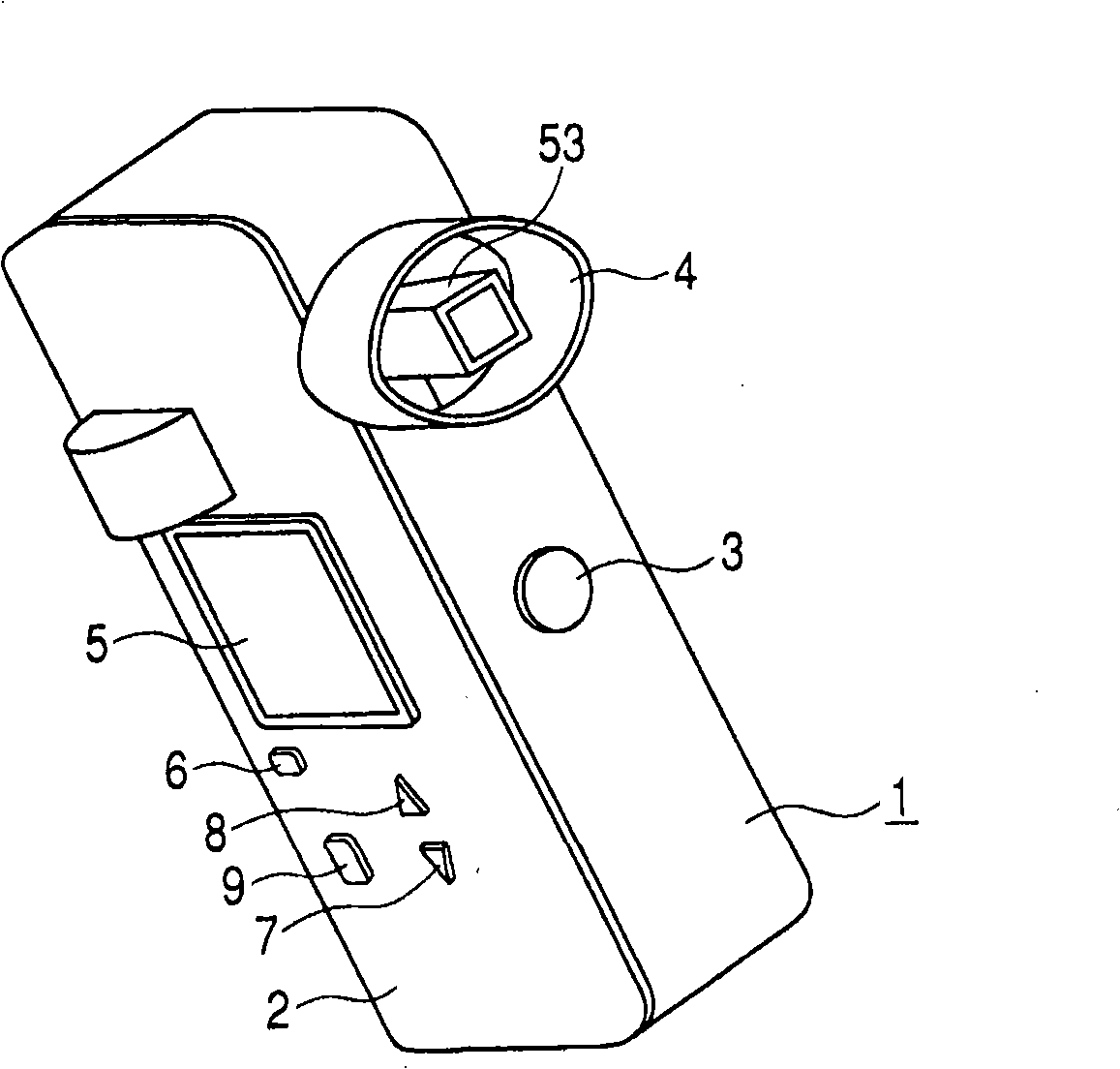

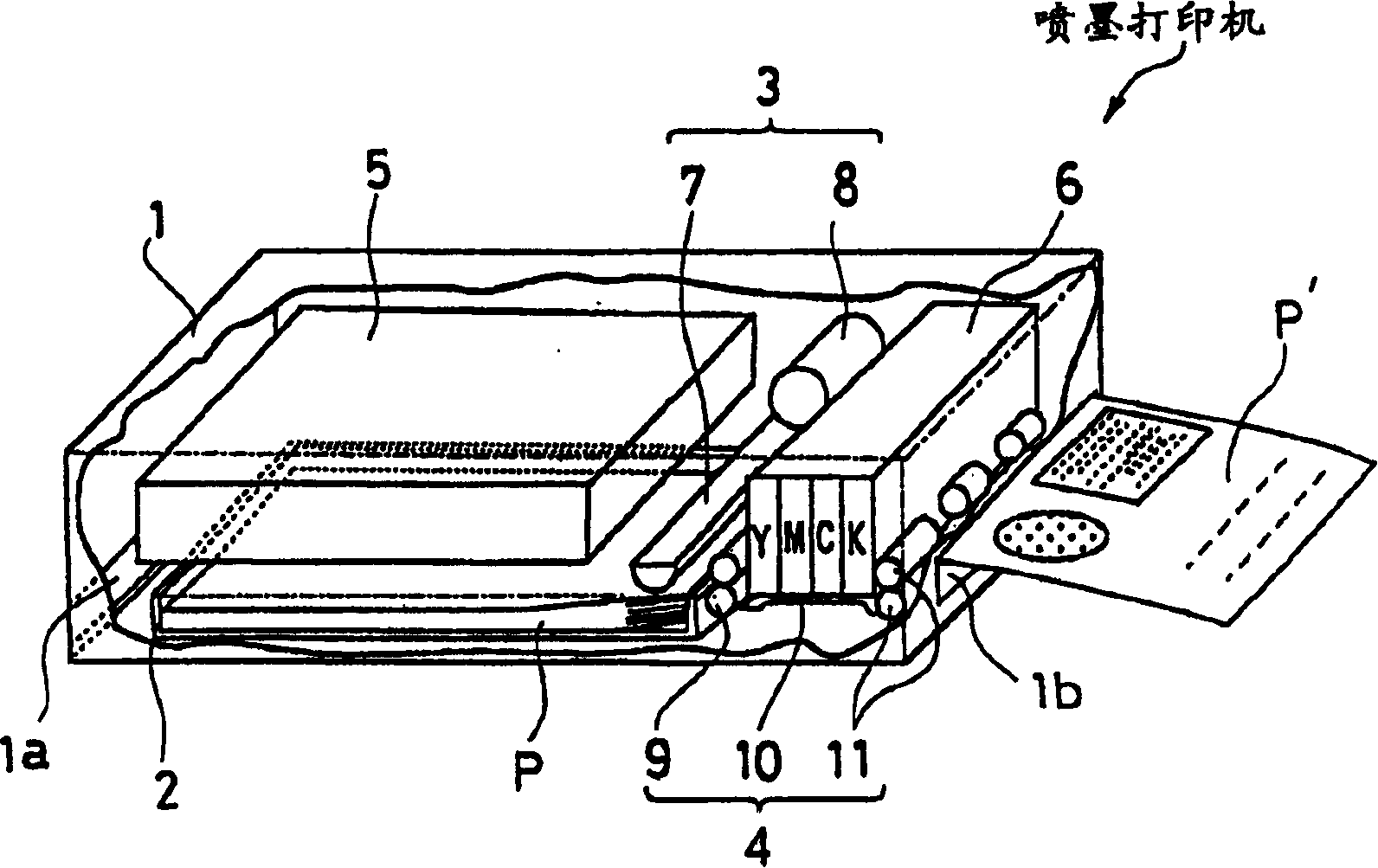

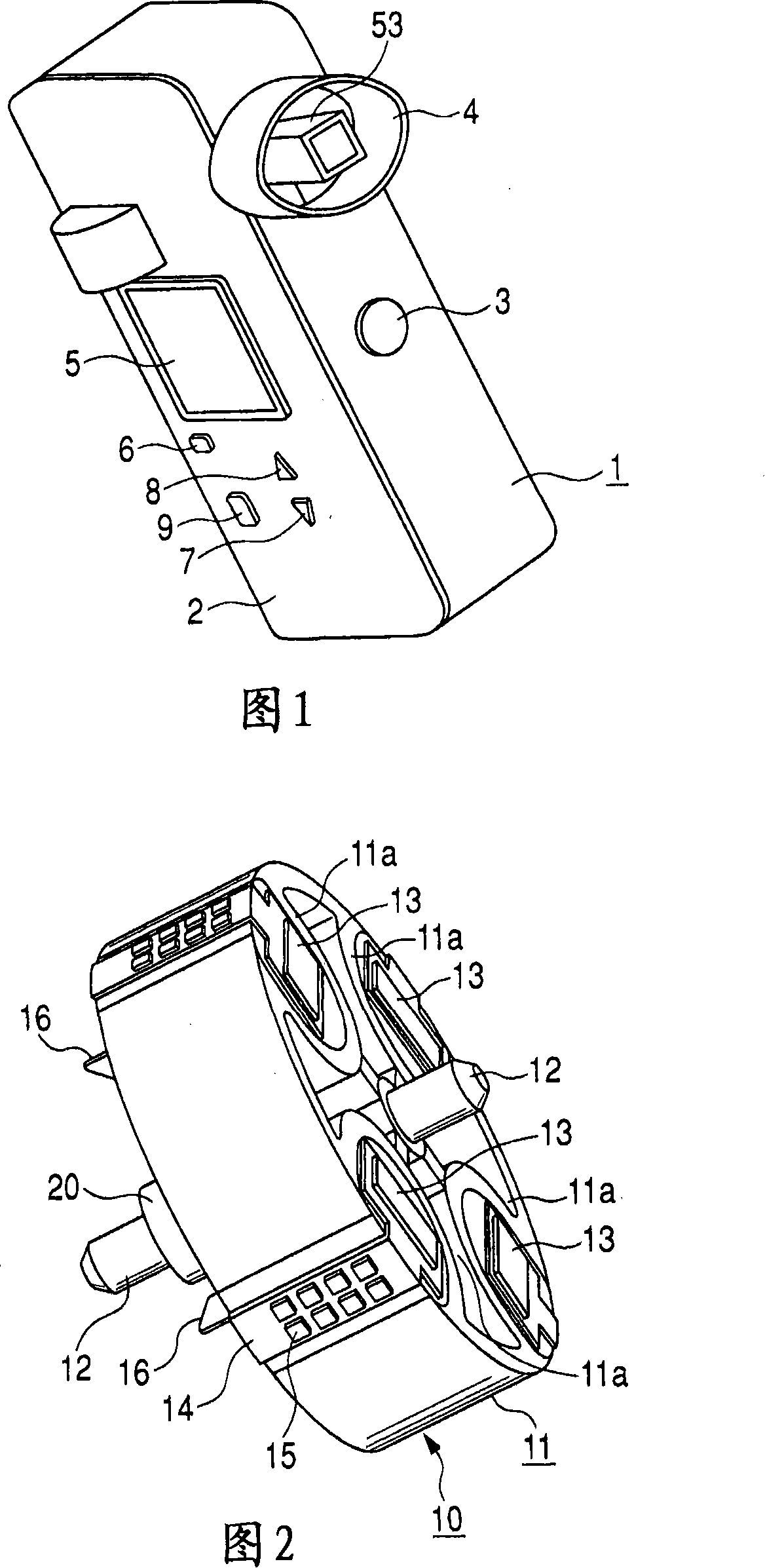

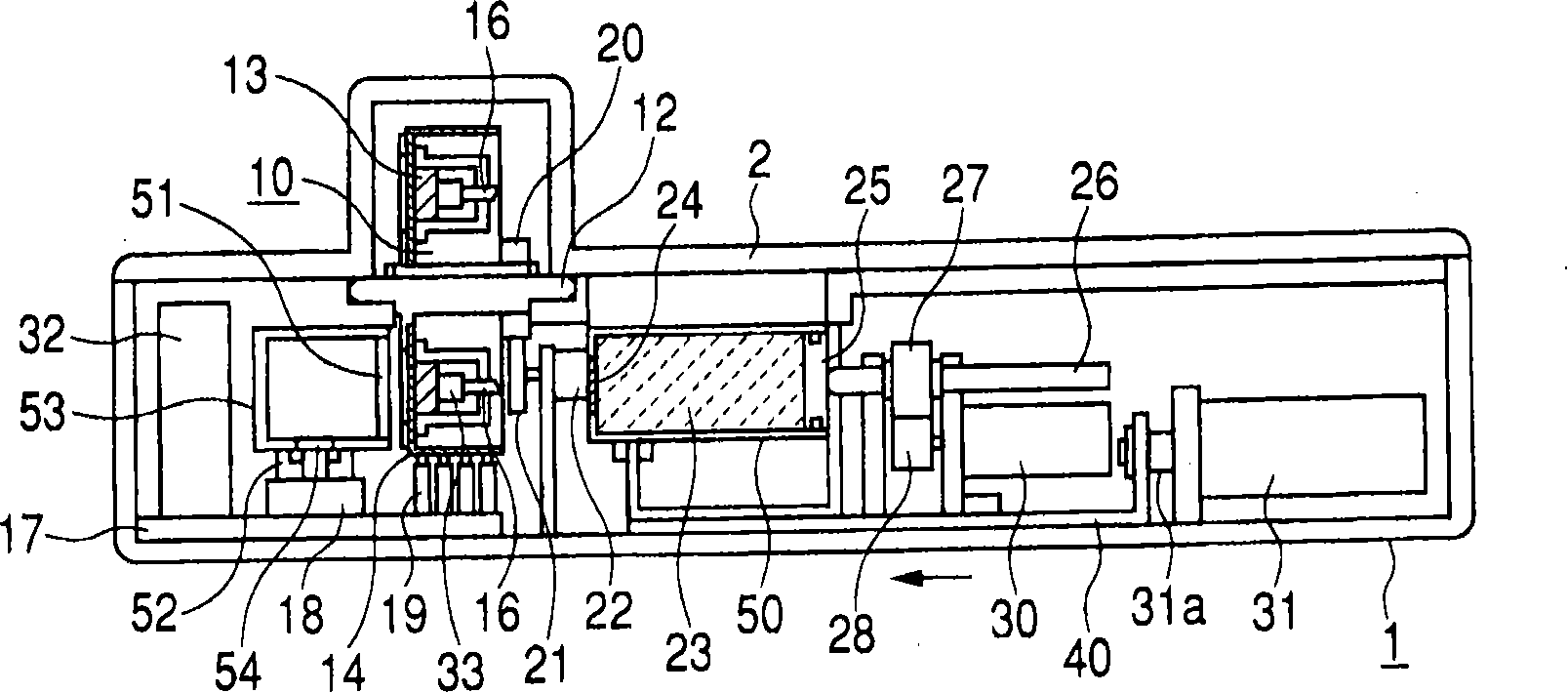

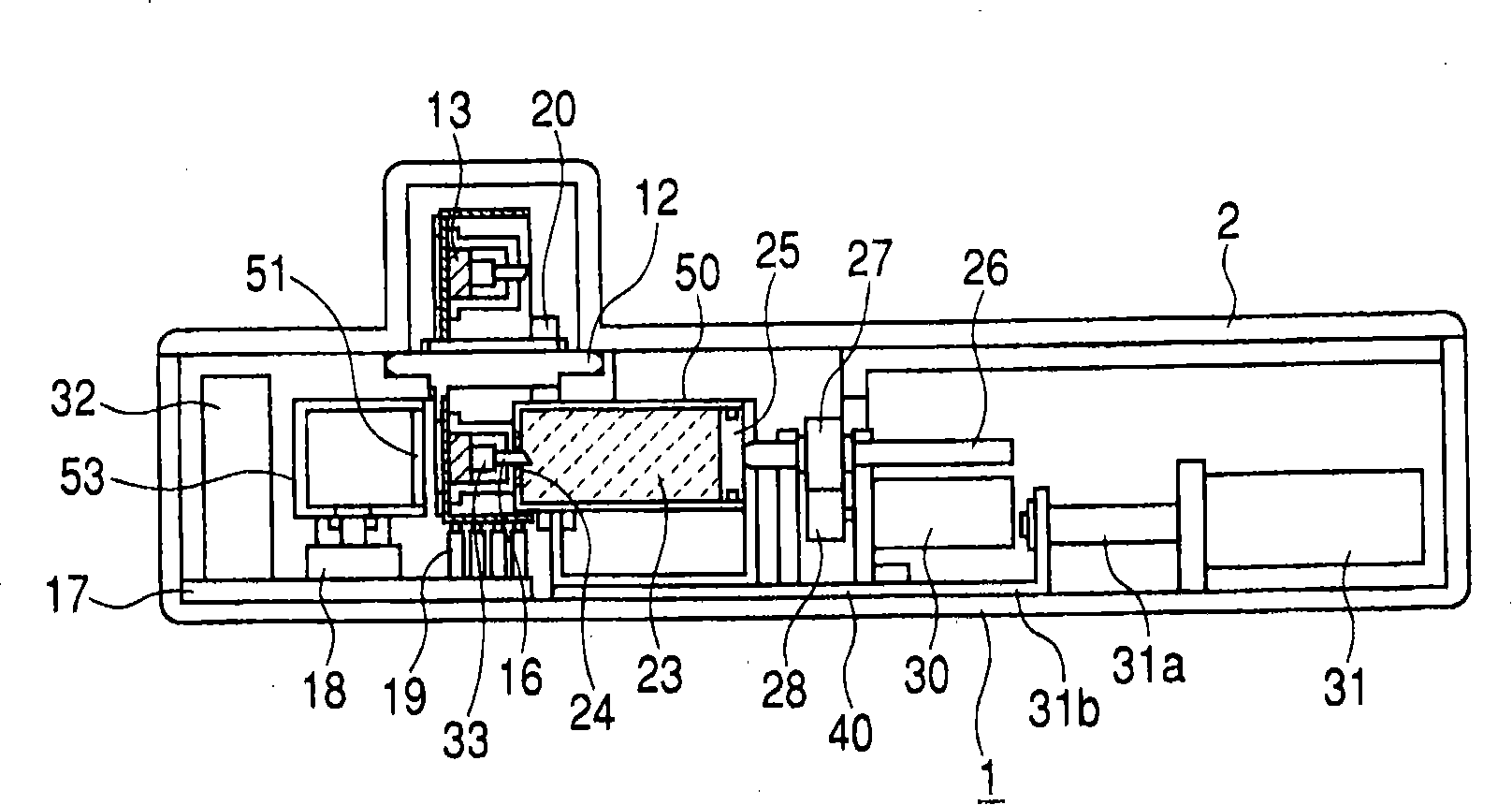

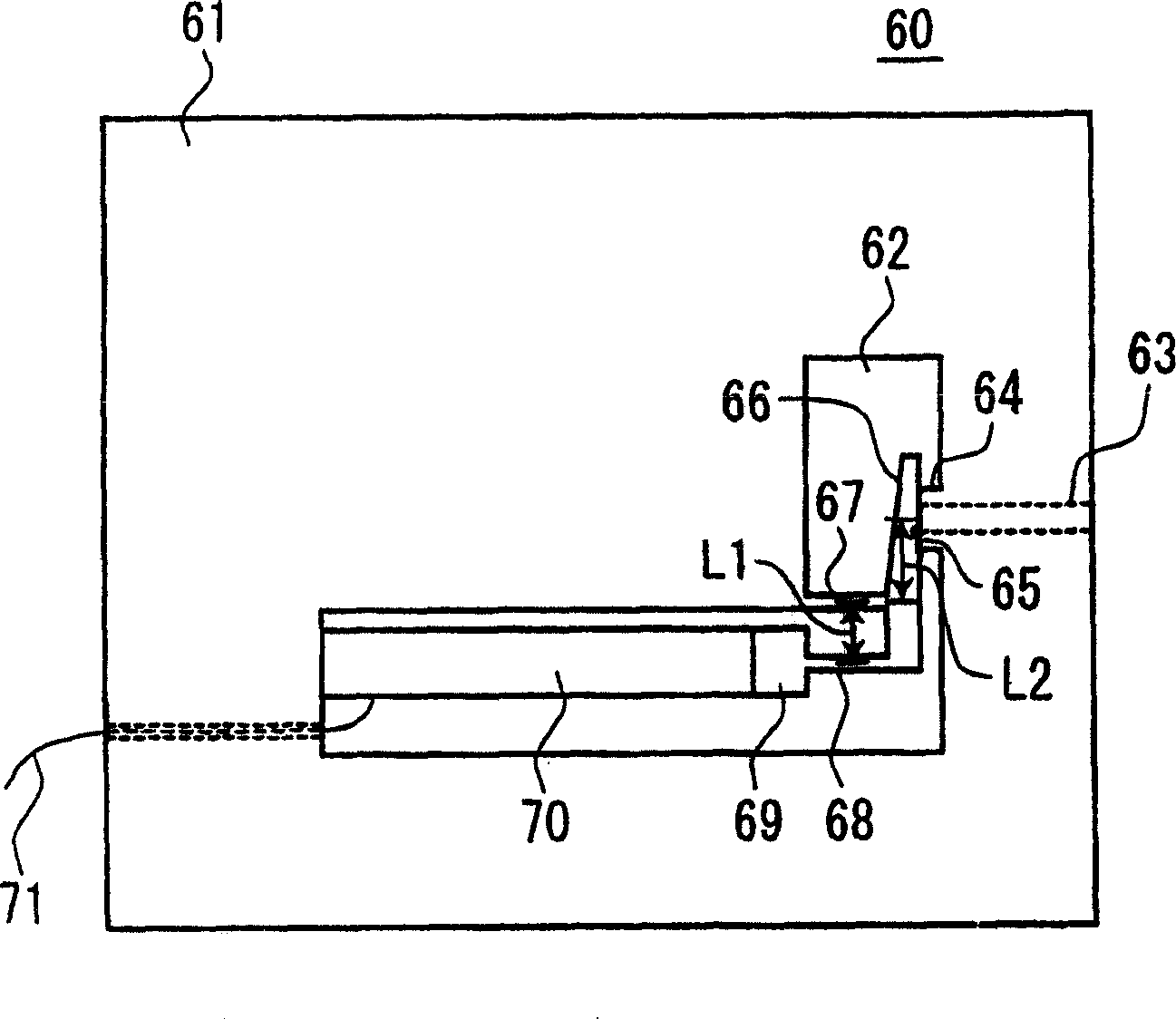

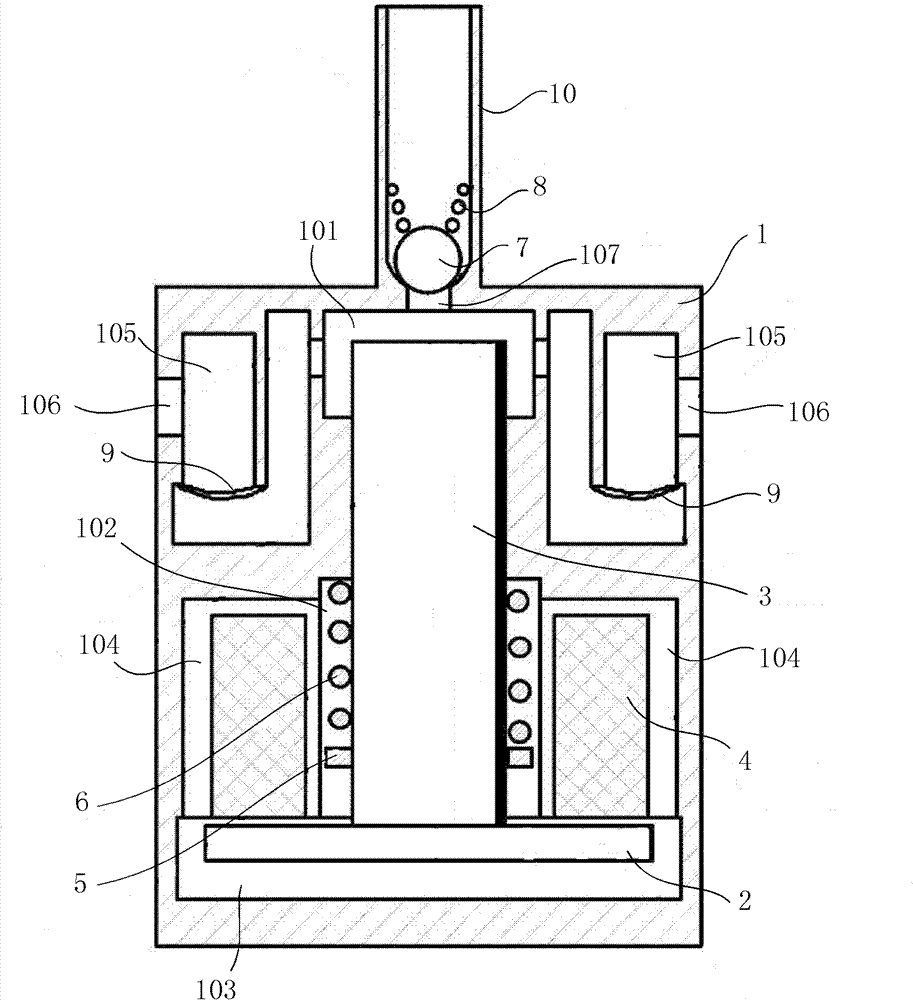

Inhaler and ejection head unit attachable to the inhaler

InactiveCN101264363AStable injection volumeReduce inconvenienceMedical atomisersInhalatorsInhalationBiomedical engineering

An ejection head unit being attachable to an inhaler for ejecting a medicine to cause a user to inhale the medicine has a plurality of ejection heads having an element generating energy for ejecting the medicine, and a plurality of ejection nozzles through which the medicine is ejected by the element. An inhaler for ejecting a medicine to allow inhalation thereof by a user has an air flow path guiding a medicine that is inhaled accompanying inspiration by the user to a suction port, an ejection head unit having a plurality of ejection heads including an element generating energy for ejecting the medicine and a plurality of ejection nozzles through which the medicine is ejected by the element, and a positioning unit for positioning a single ejection head among the plurality of ejection heads at an opening provided in one portion of the air flow path.

Owner:CANON KK

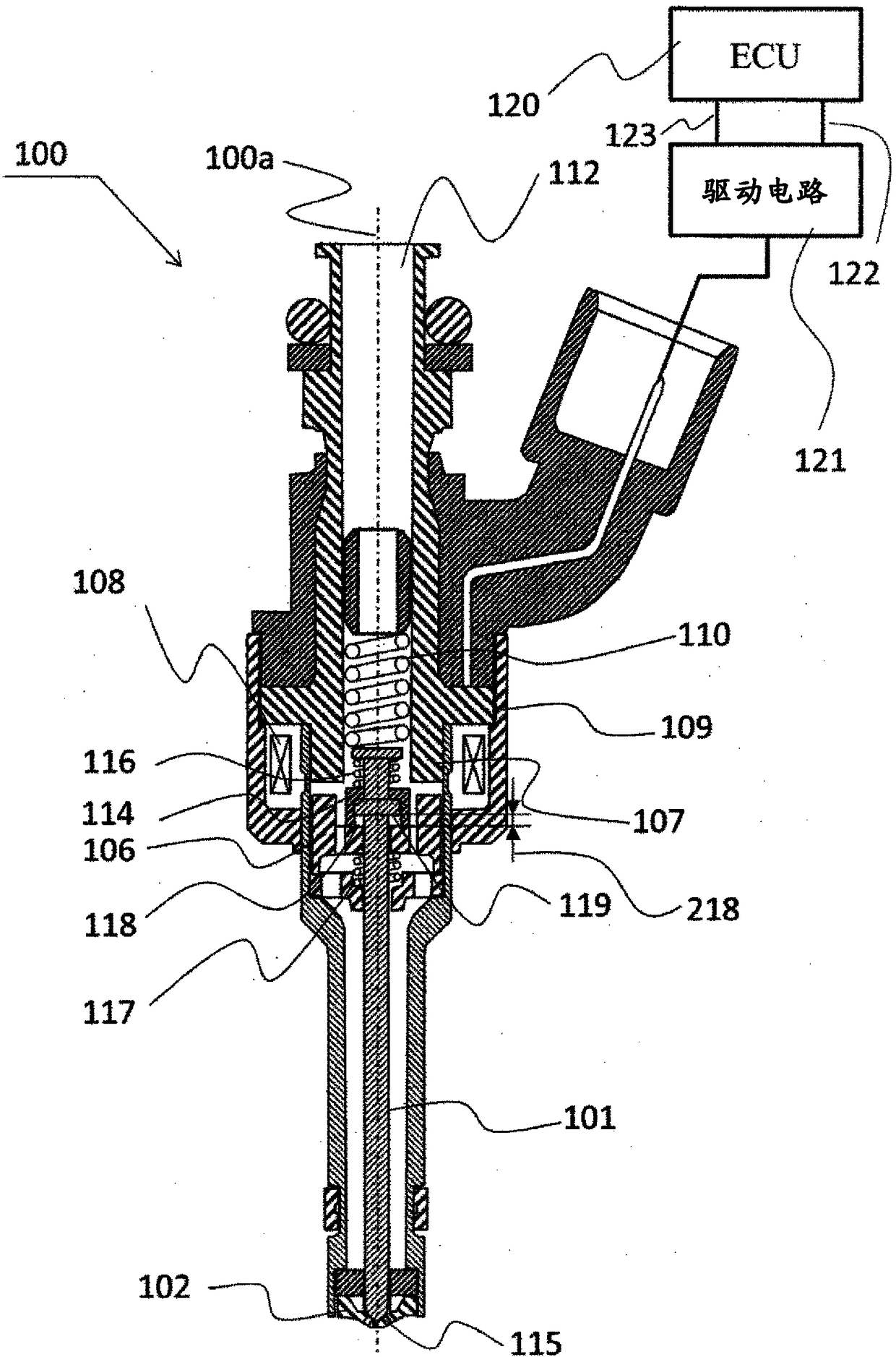

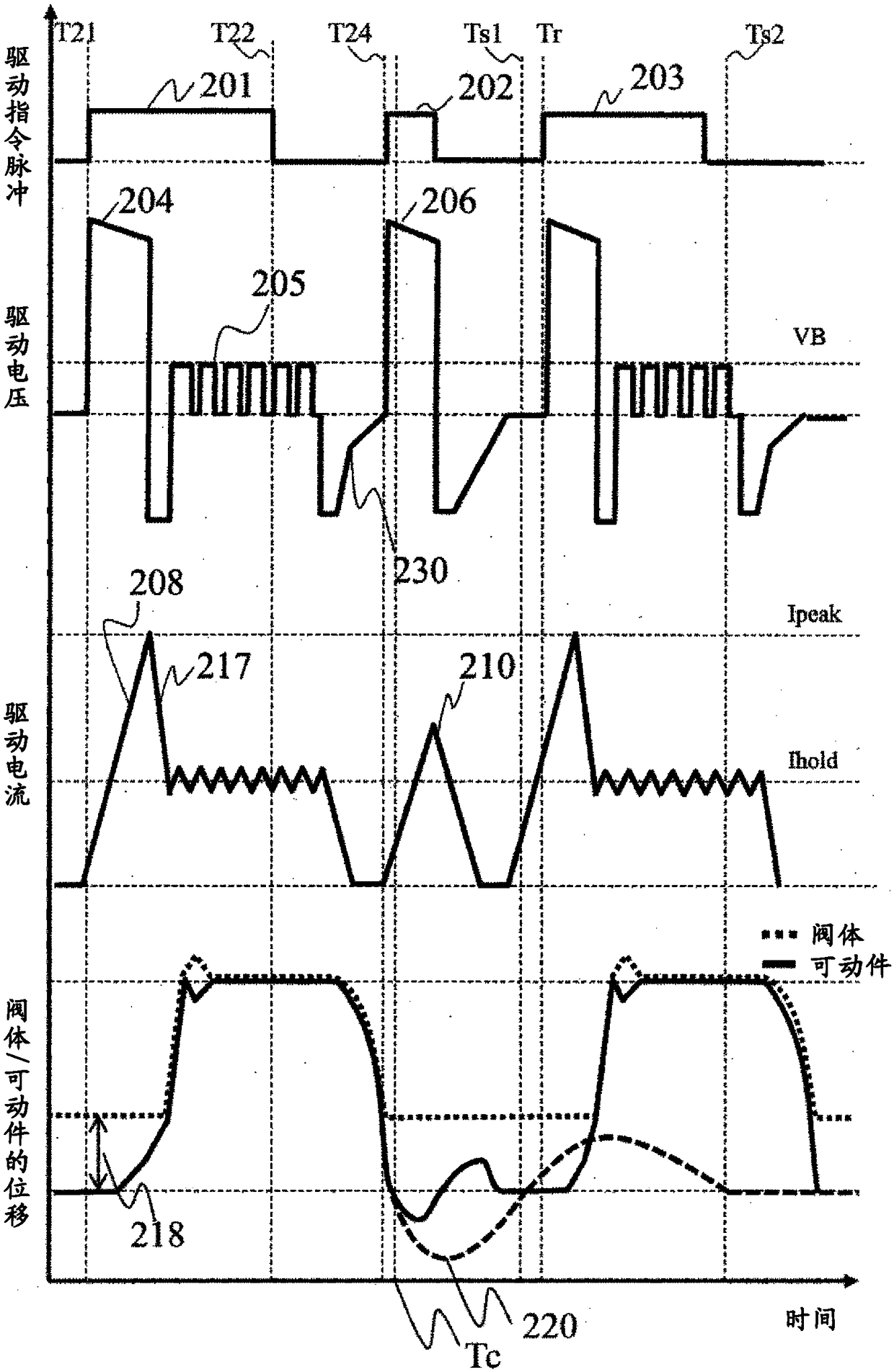

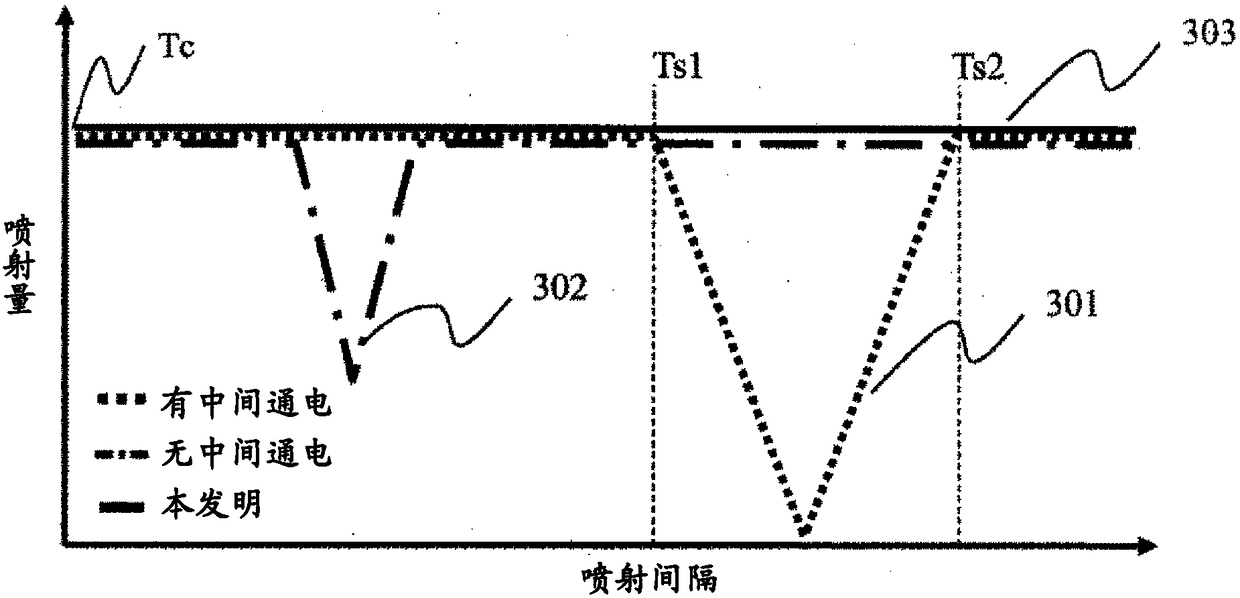

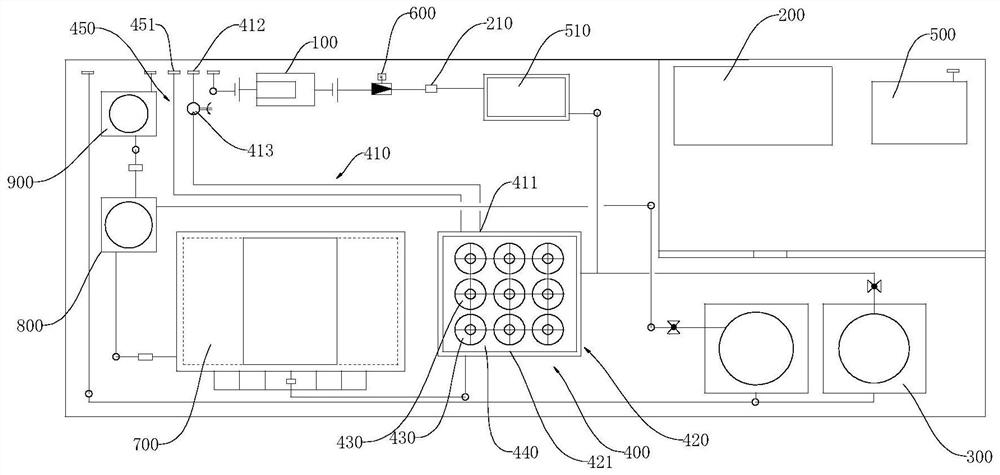

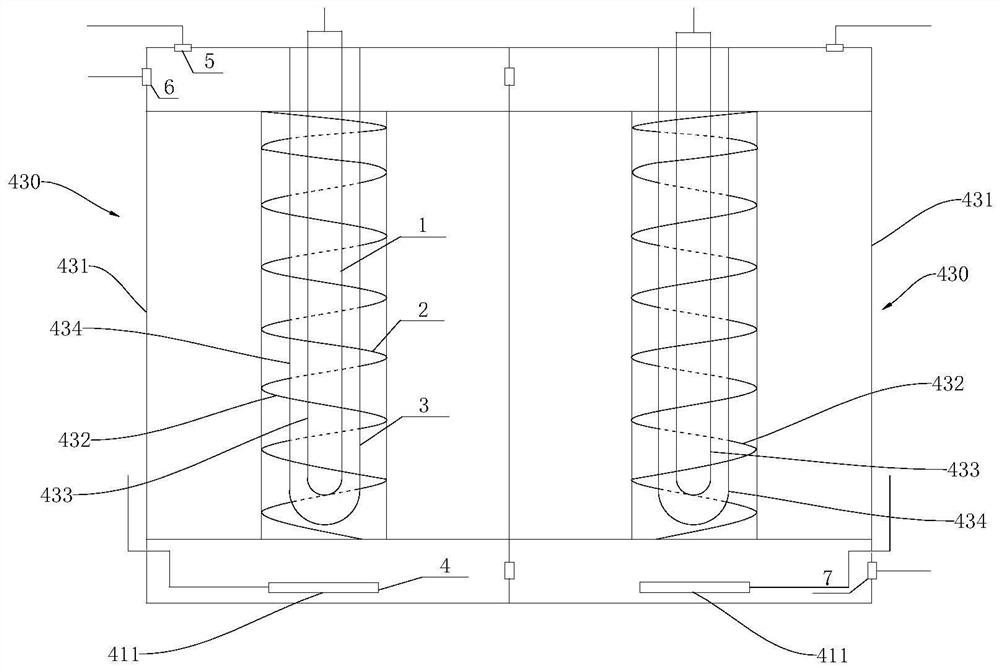

Control device for fuel injection device

ActiveCN108474316AImprove stabilityStable injection volumeElectrical controlInternal combustion piston enginesFuel injectionValve seat

The present invention provides a control device for a fuel injection device, said control device improving the operational stability of a valve during valve opening and stabilizing the injection amount even when the interval between an earlier fuel injection (first fuel injection) and a subsequent fuel injection (second fuel injection) has changed. Provided is a control device for a fuel injectiondevice that is provided with a valve, which opens a fuel passage by moving away from a valve seat, a movable iron core, which implements a valve opening / closing operation, and a fixed iron core, which draws the movable iron core thereto due to the flow of a current through a coil, wherein the control device is provided with a control unit that, when energization of the coil is cut off and the movable iron core moves in the direction of separation from a fixed iron core after the coil has been energized to draw the movable iron core to the fixed core, performs intermediate energization to re-energize the coil, said control unit controlling whether or not to perform the intermediate energization in accordance with the injection interval of the fuel injection device.

Owner:HITACHI ASTEMO LTD

Equipment for treating unsymmetrical dimethylhydrazine-containing wastewater

PendingCN113716769AEasy to handleReduce trafficWater treatment parameter controlWater/sewage treatment by irradiationPtru catalystEnvironmental engineering

The invention relates to equipment for treating unsymmetrical dimethylhydrazine-containing wastewater. The equipment comprises a wastewater conveying mechanism, a flow detection mechanism, a concentration detection mechanism, a catalyst sampling mechanism, a degradation reaction mechanism and a control mechanism. The degradation reaction mechanism is respectively communicated with the wastewater conveying mechanism and the catalyst sampling mechanism through pipelines, and the degradation reaction mechanism is used for degrading unsymmetrical dimethylhydrazine in the wastewater; and the control mechanism is electrically connected with and controls the wastewater conveying mechanism and the catalyst sampling mechanism, and is used for adjusting the flow of the wastewater and the sampling amount of the catalyst according to the concentration of unsymmetrical dimethylhydrazine in the wastewater. When the concentration of unsymmetrical dimethylhydrazine in the wastewater is large, the flow of the wastewater can be properly reduced and the sampling amount of the catalyst can be increased, and on the contrary, the flow of the wastewater can be properly increased and the sampling amount of the catalyst can be properly reduced. Therefore, the unsymmetrical dimethylhydrazine amount treated in unit time in the degradation reaction mechanism is relatively stable, so that the fluctuation of each discharge index of the treated wastewater is relatively small.

Owner:TSINGHUA UNIV +1

Liquid-ejecting method and liquid-ejecting apparatus

The invention relates to a liquid-ejecting method and liquid-ejecting apparatus. In a liquid-ejecting method for ejecting liquid contained in a liquid chamber from a nozzle as a liquid droplet group, the ejection amount of each liquid droplet of the continuously ejected liquid-droplet group can be stabilized corresponding to a wide frequency band of a pulse signal. Also, when one pixel is formed with a plurality of liquid droplets using a head capable of deflecting the ejecting direction of the liquid droplet, the image quality is improved by reducing the landing positional displacement between plural liquid droplets for forming the one pixel.

Owner:SONY CORP

Spot plating electrode module and spot plating device

The invention discloses a spot plating electrode module and a spot plating device, and relates to the field of electroplating. The device comprises an insulating upper cover and an insulating lower cover, wherein the insulating upper cover and the insulating lower cover are encircled to form a cavity, a through hole for plating liquid pressed into the cavity is formed in the insulating upper cover, the butt joint surface of the insulating lower cover and the insulating upper cover is provided with a liquid outlet communicating with the cavity, the liquid outlet comprises a plurality of liquidspraying grooves extending outwards along the butt joint surface, and anode coating is coated on the inner walls of the liquid spraying grooves. The insulating upper cover and the insulating lower cover encircle to form a cavity, the plating liquid is pressed into the cavity through the through hole, liquid spraying grooves extending outwards is arranged on the butt joint surface of the insulatinglower cover, and the liquid spraying grooves communicate with the cavity; when the plating liquid is pressed into the cavity, the liquid is sprayed outwards through the liquid spraying grooves, and then the liquid is accurately sprayed onto the material belt through the liquid spraying grooves, the redundant plating liquid is not needed to be removed, so that the plating liquid is saved, the working procedures are reduced, and the electroplating efficiency is improved; the anode coating coated on the inner walls of the liquid spraying grooves can enhance the conductivity of the inner walls ofthe liquid spraying grooves and accelerate the electron flow speed, and the spot plating is high in adhesion degree, fast in speed and is more uniform.

Owner:安徽永基电子科技有限公司

Constructing apparatus and method of guide line for road

ActiveUS20190093295A1Stable injection volumeImprove guide qualitySpraying vehiclesLiquid spraying apparatusIndustrial engineeringNozzle

Provided are an apparatus and a method of constructing a guide line for a road, and the apparatus includes a painting apparatus part that stores a lane paint, is driven by receiving power, and supplies the lane paint, a nozzle part that is installed in the painting apparatus part and sprays the lane paint supplied from the painting apparatus part on a road to form a guide line for a road including at least one of a directional mark and a lane, and an adjustment part that is installed in the painting apparatus part and adjusts at least one of a location and an interval of the lane paint sprayed from the nozzle part.

Owner:KOREA EXPRESSWAY CORPORATION

A method to improve the accuracy of total sulfur analysis

ActiveCN106153699BImprove accuracyGood repeatabilityMaterial electrochemical variablesHigh concentrationCarbonyl sulfide

The invention discloses a method capable of improving total sulfur analysis accuracy and belongs to the technical field of petrochemical industry. The method includes following steps: a, selecting standard sample gas including hydrogen sulfide, carbonyl sulfide, methyl mercaptan, ethyl mercaptan, propyl mercaptan, isopropyl mercaptan, carbon disulfide and thiophene; b, filling a tin foil bag at normal pressure with the standard sample gas, connecting the tin foil bag onto a first gas incoming pipe, determining sample feeding volume of a correction point, respectively measuring repeatedly, and calculating an average value to obtain a total sulfur value; c, measuring total sulfur values under different sample feeding volumes, and establishing a standard curve; d, filling an empty normal-pressure tin foil bag with to-be-measured sample gas, calling the standard curve, starting a total sulfur analysis device, repeating sample feeding for three times, and acquiring an average value which is content of total sulfide in the to-be-measured sample gas. Through the method, accurate and quantitive analysis of total sulfur content in natural gas can be realized; no matter for high-concentration samples or complex samples, analysis errors can be reduced, and total sulfur analysis accuracy can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid-ejecting method and liquid-ejecting apparatus

The invention relates to a liquid-ejecting method and liquid-ejecting apparatus. In a liquid-ejecting method for ejecting liquid contained in a liquid chamber from a nozzle as a liquid droplet group, the ejection amount of each liquid droplet of the continuously ejected liquid-droplet group can be stabilized corresponding to a wide frequency band of a pulse signal. Also, when one pixel is formed with a plurality of liquid droplets using a head capable of deflecting the ejecting direction of the liquid droplet, the image quality is improved by reducing the landing positional displacement between plural liquid droplets for forming the one pixel.

Owner:SONY CORP

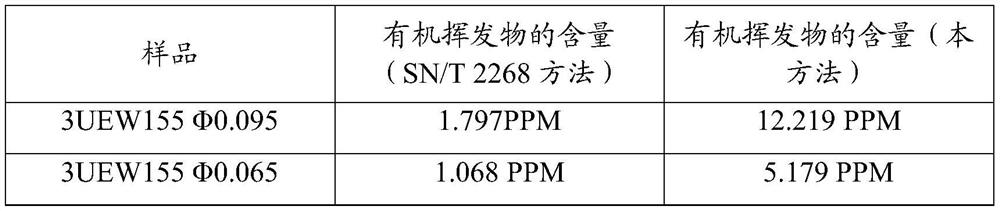

Enameled wire organic volatile matter content detection method

PendingCN114414693AFacilitated releaseShort retention timeComponent separationPhysical chemistryMass analyzer

The invention provides a method for detecting the content of organic volatile matters in an enameled wire. The method comprises the following steps: S1, preparing a target organic volatile matter standard substance into mixed standard substance solutions with different concentrations; s2, taking one mixed standard substance solution, and injecting the mixed standard substance solution into a headspace sample injection bottle of a gas chromatography-mass spectrometer; s3, introducing the solution into a non-polar chromatographic column for separation; s4, the separated gas enters a mass spectrometer, a component table and a test method are established according to qualitative results, and then quantitative scanning is performed; s5, repeating the steps S2-S4 to test mixed standard solutions with other concentrations, and drawing an external standard method standard curve; and S6, adding ethanol into the enameled wire sample, putting the enameled wire sample into a headspace bottle, and testing the enameled wire sample according to the conditions of the steps S2 to S4 to obtain the content of each target organic volatile matter. The method has the advantages that ethanol is added into the enameled wire sample, so that the sample size can be kept stable, and the release amount of organic volatile matters is increased; due to the weak-polarity chromatographic column, the overall chromatographic retention time is shortened, and the detection speed is increased.

Owner:ZHUHAI GREE ELECTRIC ENTERPRISES +4

Inhaler and ejection head unit attachable to the inhaler

InactiveCN101264363BStable injection volumeReduce inconvenienceMedical atomisersInhalatorsMedicineInhalation

An ejection head unit being attachable to an inhaler for ejecting a medicine to cause a user to inhale the medicine has a plurality of ejection heads having an element generating energy for ejecting the medicine, and a plurality of ejection nozzles through which the medicine is ejected by the element. An inhaler for ejecting a medicine to allow inhalation thereof by a user has an air flow path guiding a medicine that is inhaled accompanying inspiration by the user to a suction port, an ejection head unit having a plurality of ejection heads including an element generating energy for ejecting the medicine and a plurality of ejection nozzles through which the medicine is ejected by the element, and a positioning unit for positioning a single ejection head among the plurality of ejection heads at an opening provided in one portion of the air flow path.

Owner:CANON KK

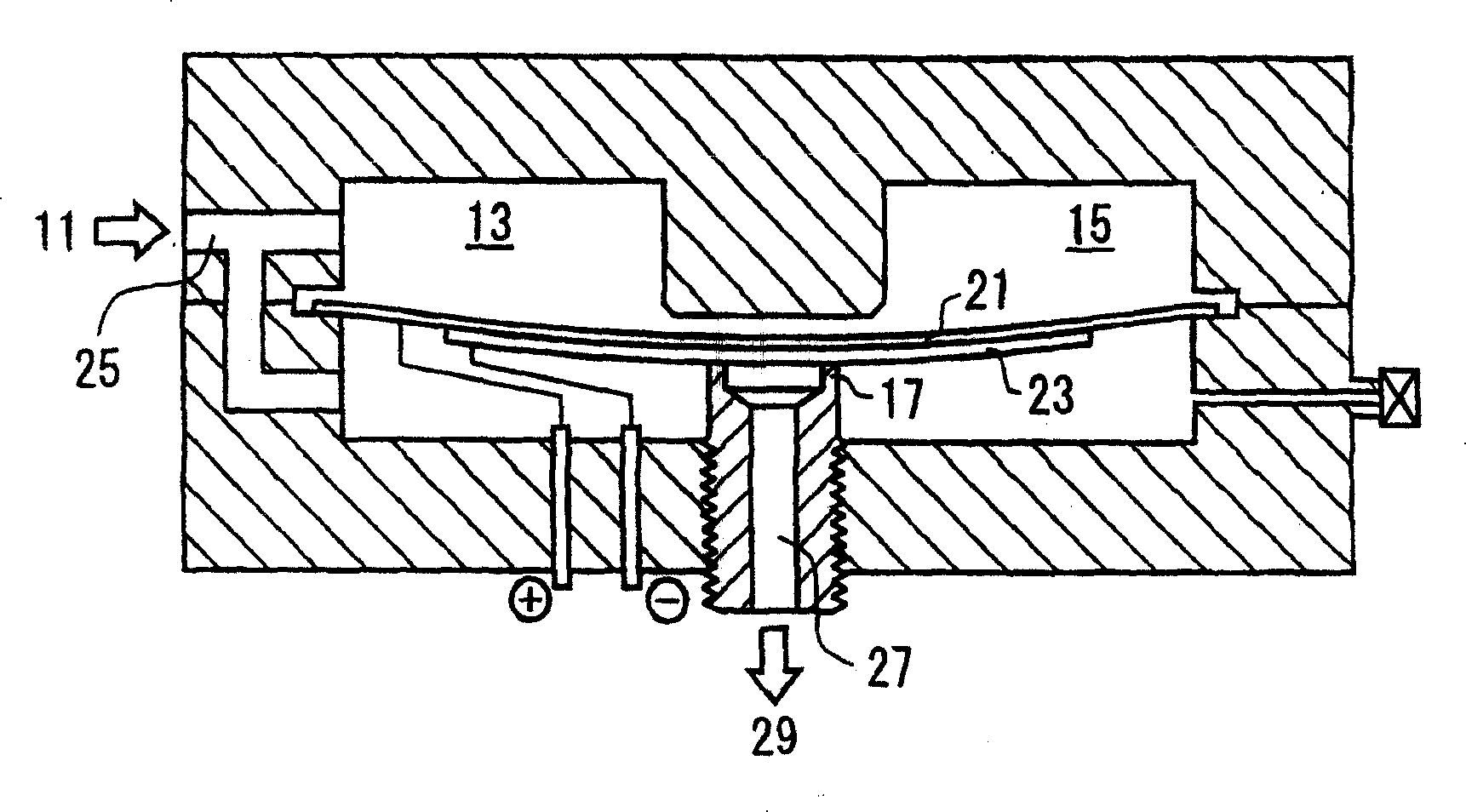

Piezoelectric air valve and multi-valve type piezoelectric air valve

InactiveCN100396975CStable generationStable injection volumeOperating means/releasing devices for valvesMultiple way valvesMulti-valveElectricity

The air valve includes a valve body for controlling operations to open and close the communication between an air pressure chamber and an air outlet, a piezoelectric element for generating driving force in the form of displacements, and a displacement enlarging mechanism for enlarging the small displacements generated by the piezoelectric element by the principle of a pry and applying the enlarged displacements to the valve body. The enlarged displacements cause a large and sufficient gap to be developed between the air pressure chamber and the air outlet when a voltage is applied to the piezoelectric element. When the applying of voltage to the piezoelectric element is stopped, the resetting force of the piezoelectric element itself causes the gap to be closed quickly.

Owner:SATAKE CORP +1

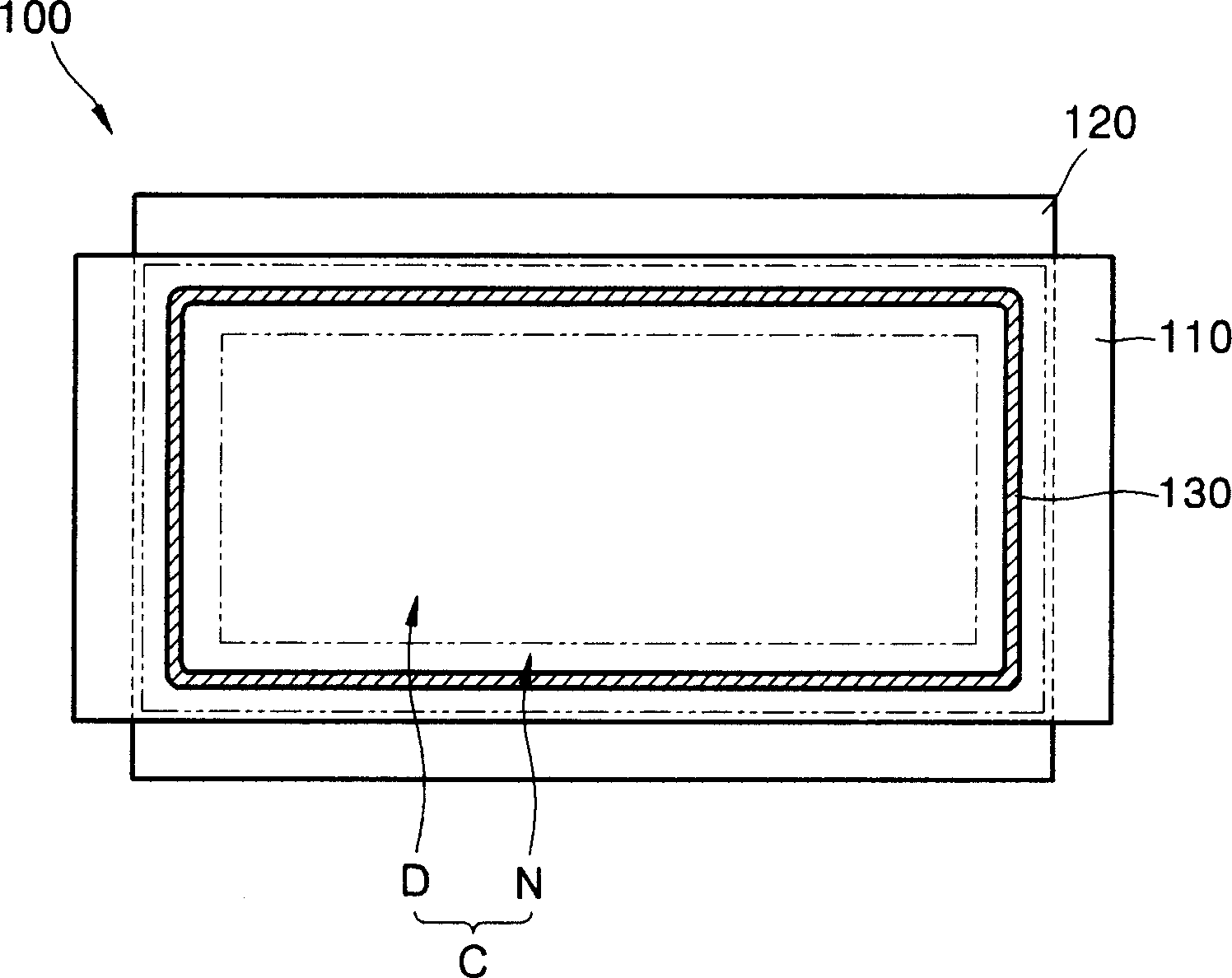

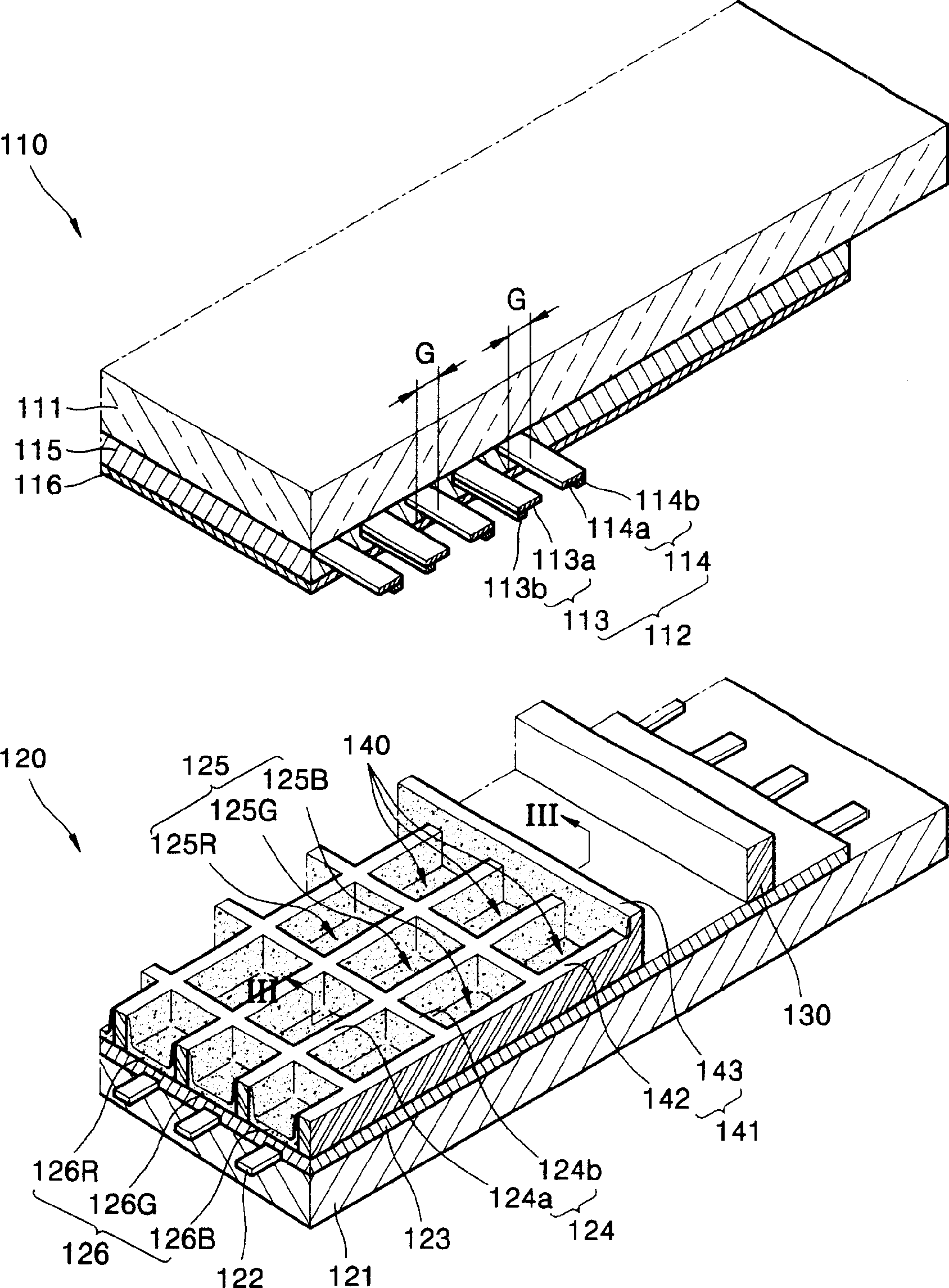

Plasma display panel

InactiveCN1744262ASimple designSolve the lack of spaceSustain/scan electrodesAlternating current plasma display panelsInjection pressureForeign matter

Owner:SAMSUNG SDI CO LTD

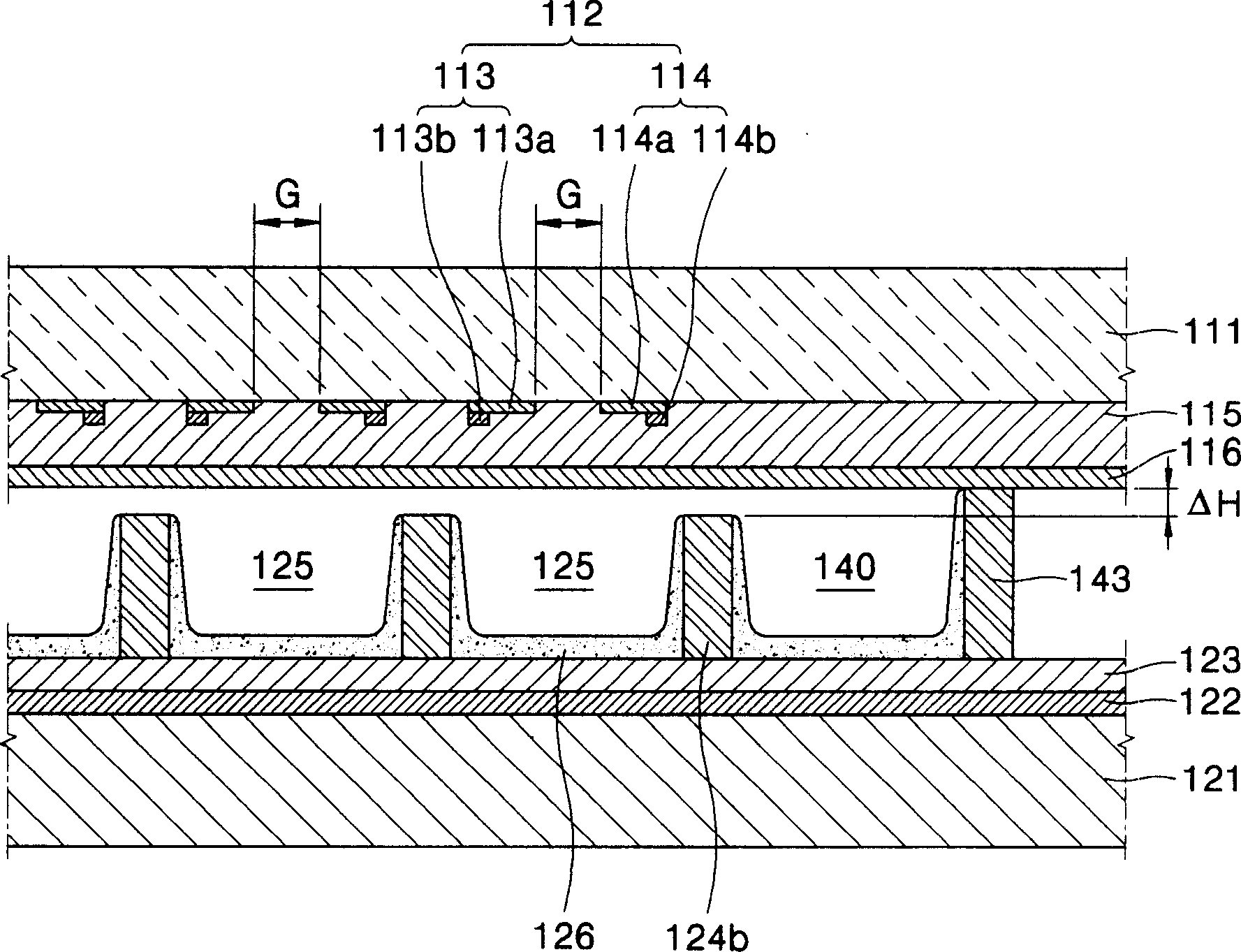

Large pressure difference real-time adjustment water distributor

InactiveCN104563983BHigh precisionImprove water injection development effectFluid removalDifferential pressureUpper joint

The invention discloses a high-pressure-difference real-time adjusting water distributor. The high-pressure-difference real-time adjusting water distributor comprises a central pipe, a water distribution core and a working drum, wherein the upper end of the central pipe is connected with an upper joint through an upper short joint; the water distribution core is arranged in the central pipe; the working drum covers the central pipe; the inner side of the lower end of the working drum is connected with a lower joint; a water distribution adjusting device is arranged between the central pipe and the working drum; and a spit preventing device is arranged at the outer side of the upper short joint at the upper end of the water distribution adjusting device. The spit preventing device comprises a counter preventing piston and a counter preventing spring; the counter preventing piston can vertically slide along the outer surface of the upper short joint; the counter preventing spring covers the outer side of the upper short joint at the upper end of the counter preventing piston; and a pressure transfer through hole is formed in the middle wall of the upper short joint. The high-pressure-difference real-time adjusting water distributor not only can satisfy the high-leakage layer throttle requirement under high interlayer water injection pressure difference, but also can realize stable water injection under the condition of pressure fluctuation, and can effectively reduce the measurement and adjustment workloads and improve the water injection precision.

Owner:CHINA PETROLEUM & CHEM CORP +1

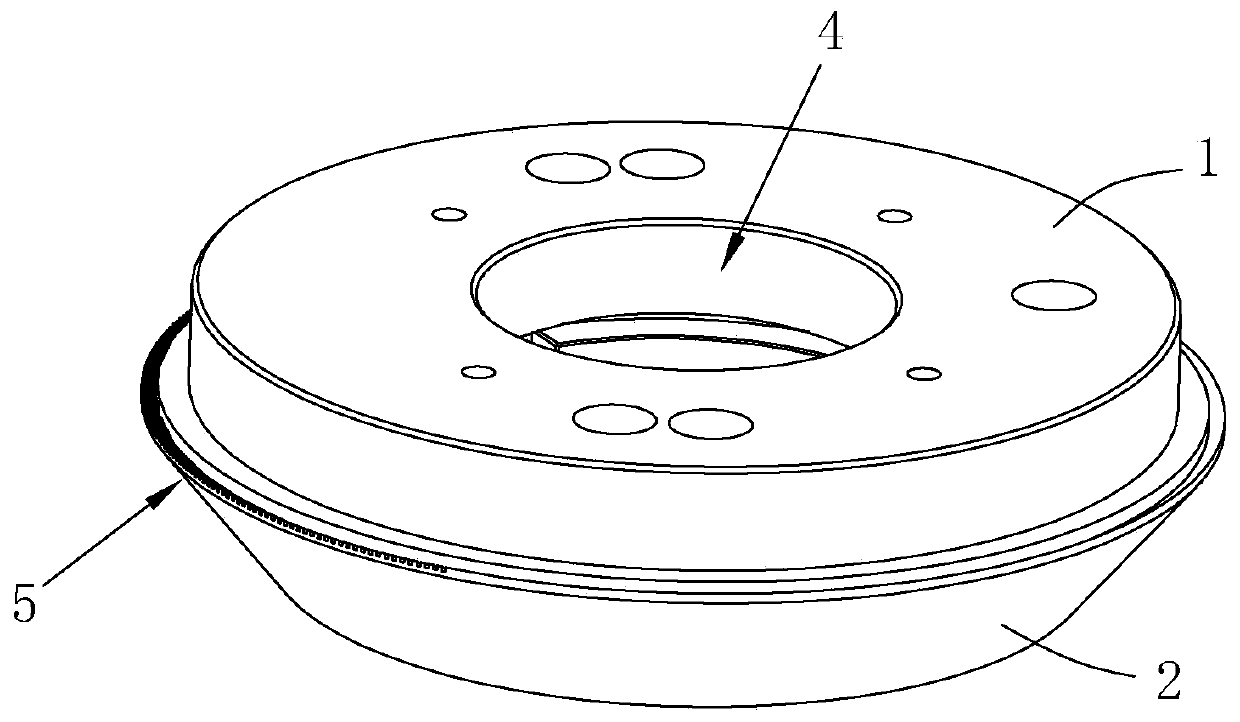

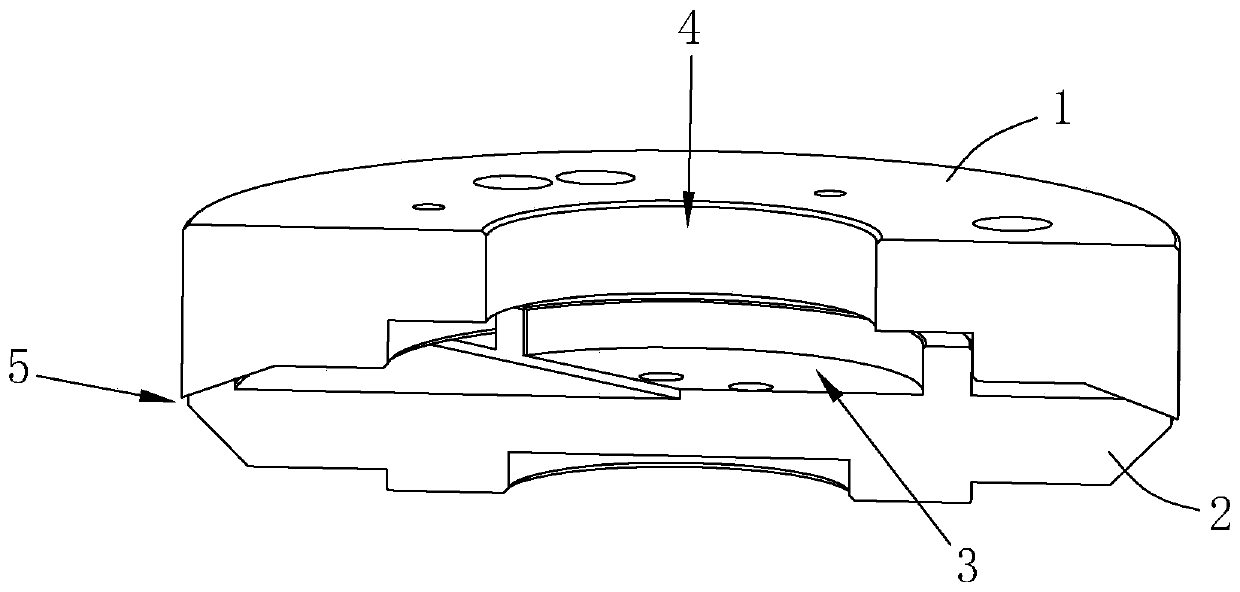

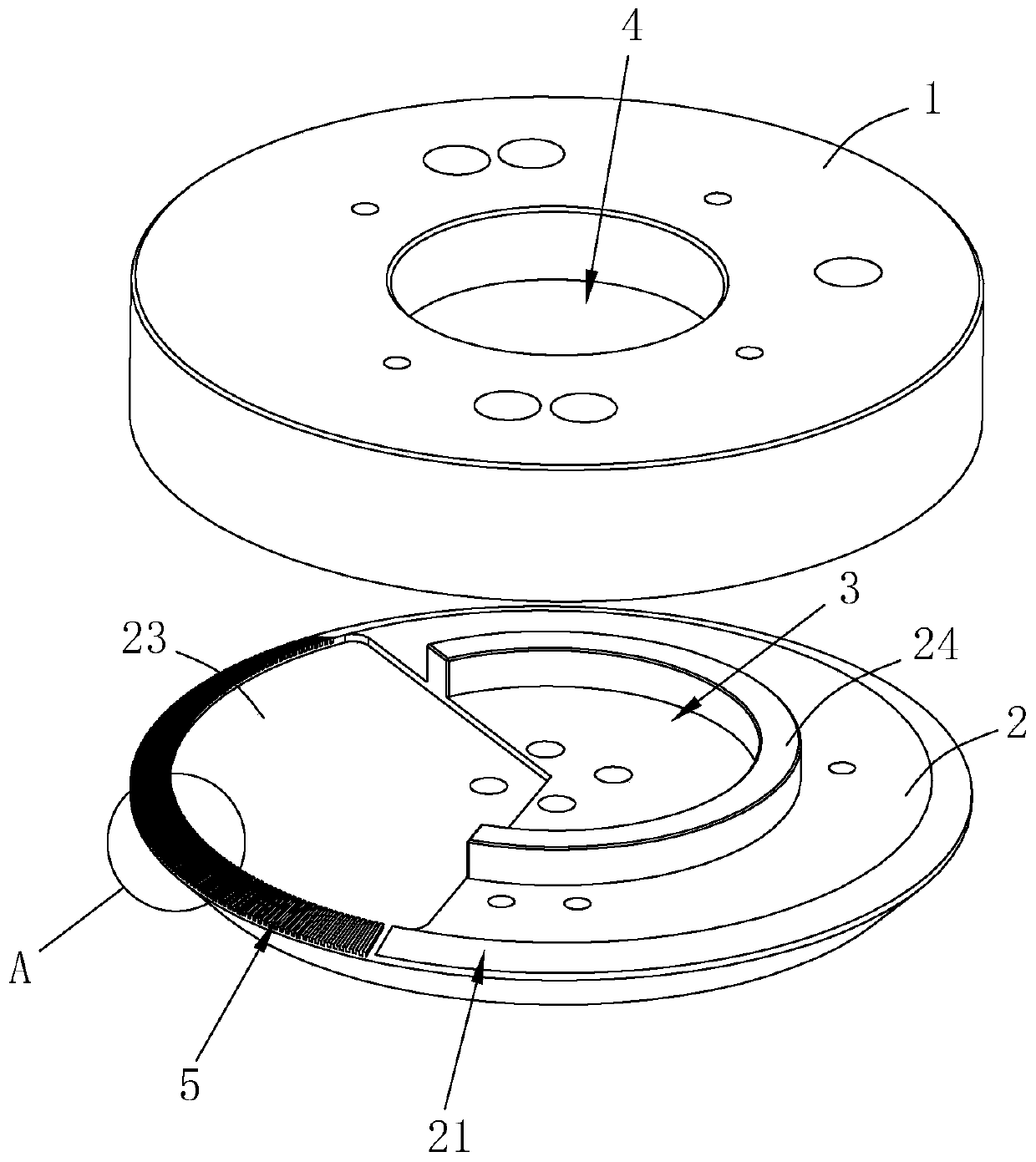

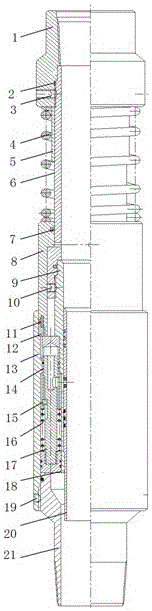

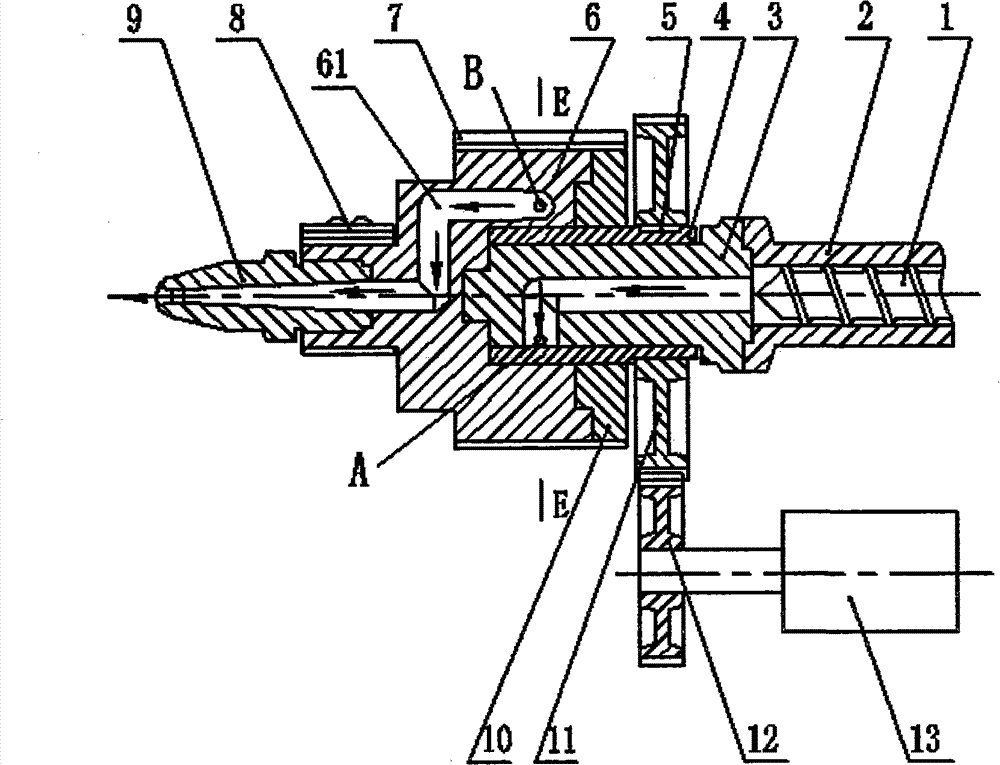

Screw-free plastic disc type rotary injection method and device

ActiveCN101920547BSimple structureReduce volumeLiquid surface applicatorsCoatingsPlastic materialsSpray nozzle

Disclosed are a non-screw plate type rotary plastic injection method and the apparatus thereof. A piston which is arranged in circular groove of a round plate and rotatable about center of the plate is used to complete the processes of plastic feeding, injection and pressure holding. The plate type rotary injection apparatus consists of a plate type storage cavity (4) having a circular groove on its round plate, an injection piston (1) rotatable about the plate type storage cavity (4), a support shaft (3), a nozzle (5) and so on. To complete the process of filling plastic materials, the plastic melt enters the plate type storage cavity (4) propelling the injection piston rotates and enlarges the storage cavity. An external force is applied to drive the injection piston (1) to rotate reversely, so as to eject the material in the plate type storage cavity out through the nozzle (5) and into the mould cavity. The torque of the injection piston (1) is maintained, so that the pressure in the mould cavity is maintained and the material shrinkage is compensated. The injection apparatus is featured in its small scale, accurate measurement of material to be stored, low energy consumption of injection and low inertia in injection movement.

Owner:SOUTH CHINA UNIV OF TECH +1

System and process for pulverized coal injection of blast furnace

ActiveCN102787191BEvenly distributedGuaranteed gas adjustment functionBlast furnace componentsBlast furnace detailsThermodynamicsProcess engineering

Owner:WISDRI ENG & RES INC LTD

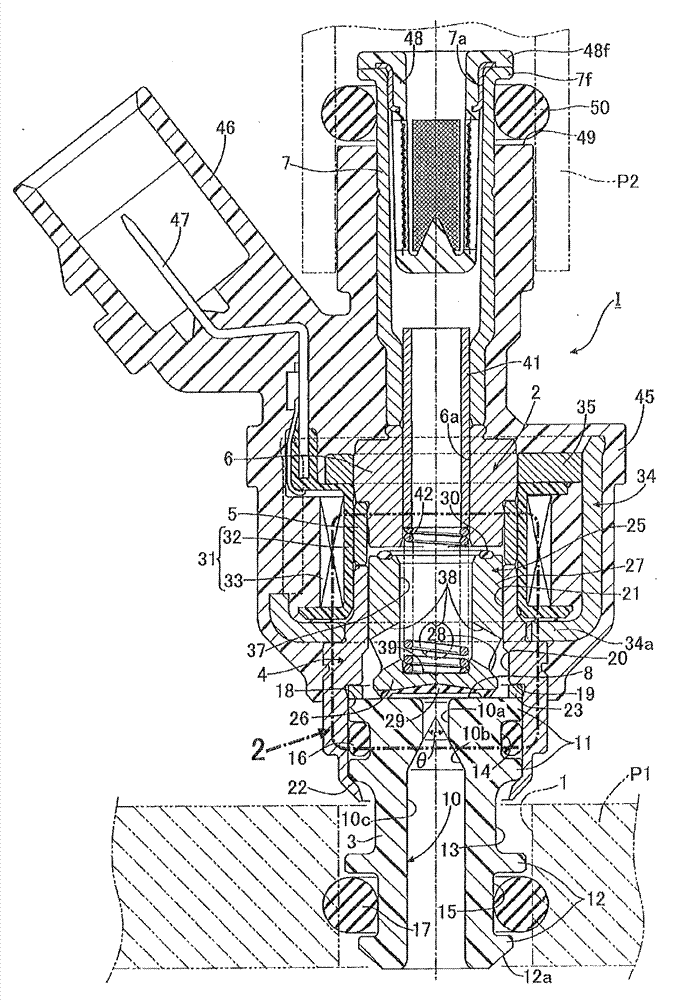

Gas fuel injection valve

InactiveCN102105671BPrevent leakageReduce the numberInternal combustion piston enginesFuel supply apparatusEngineeringSynthetic resin

A gas fuel injection valve wherein a valve housing (2) is provided with a nozzle member (3) having a flat valve seat (8) and a nozzle hole (10) penetrating through the center of the valve seat, and also with a magnetic circular tube body (4) joined to the nozzle member (3). The nozzle member (3) consists of a synthetic resin, and on the outer periphery of the nozzle member (3) are formed a first fitting section (11) fitted in a fitting connecting hole (18) in a front end section of the magnetic circular tube body (4), a second fitting section (12) fitted in a mounting hole (1) in an air intake path member (P1) of an engine, and a connecting recess (13) located between both the fitting sections (11, 12). A staking tube section (22) formed at the front end of the magnetic circular tube body(4) is staked to the connecting recess (13) side to join the magnetic circular tube body (4) and the nozzle member (3) together. An annular seal groove (15) in which a seal (17) is mounted is formed in the outer periphery of the second fitting section (12), and the seal (17) makes close contact with the inner peripheral surface of the mounting hole (1) in the air intake path member (P1). Thus, the seal groove in which the seal (17), which makes close contact with the inner peripheral surface of the mounting hole (1) in the air intake path member (P1), is mounted can be formed without using a special ring member.

Owner:KEIHIN CORP

A spraying system on the surface of baked food

Owner:HUAIBEI SHUNFA FOOD

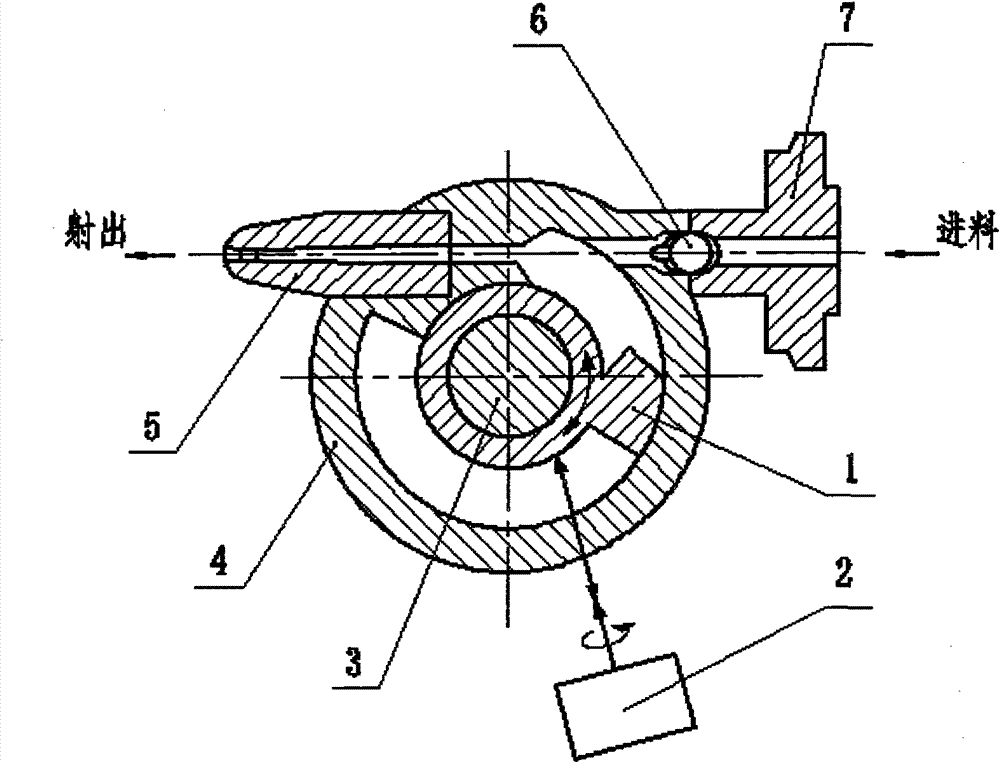

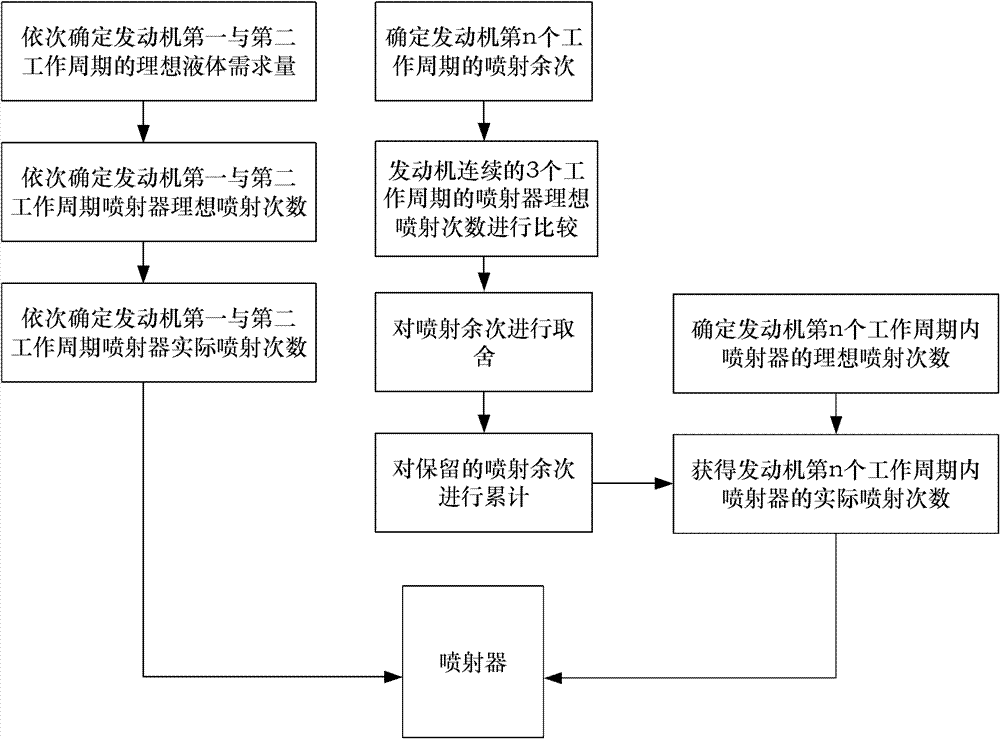

Liquid measure ejector and spraying control method thereof

ActiveCN102213167BHighly integratedGuaranteed atomization effectElectrical controlFuel injection apparatusAviationEngineering

The invention discloses a liquid measure ejector and a spraying control method thereof and belongs to the fields of miniature aviation piston engine fuel spraying, wherein the ejector comprises a shell, a limit disc, a piston, a solenoid, a spring clamp seat, a bias spring, a unidirectional loading valve, a cone spring, an oil pumping diaphragm and a spray passageway; and the liquid ejector can deliver a specific amount of liquid through operating the solenoid, the liquid spraying quantity of each system operating cycle can be controlled through controlling the spraying times. The invention also discloses an ejector control method based on the quantitative liquid spraying function of the ejector, the spraying times required for the engine in each cycle can be confirmed by the method.

Owner:北京领动国创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com