Baked food surface spraying system

A material spraying and food technology, applied in the field of baking food surface spraying systems, can solve the problems of the pressure drop of the atomizing nozzle, the inability to overcome the influence, the inability to balance the balance between the air intake and the feed, etc. The effect of increasing acid value and overcoming the loss of flavor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

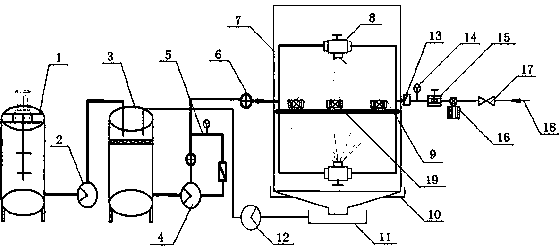

[0016] like figure 1 A baked food surface spraying system shown includes a feeding mechanism, an air supply mechanism, an atomizing nozzle 8 connecting the feeding mechanism and the air supply mechanism, and a raw material conveyor belt 9, and the atomizing nozzle 8 is provided with at least two Each is installed on the upper and lower sides of the billet conveyor belt 9 respectively; the feeding mechanism includes a feed-liquid mixer 1, a feed pump 2, a filter storage tank 3, a feed pump 4, and a feed-liquid pressure stabilization device 5 connected in sequence. . Feed-liquid throttle valve 6; the air supply mechanism includes an anti-backflow device 13, an air pressure regulating valve 15, an air filter 16, and an air source valve 17 connected in sequence through a connecting pipeline 18.

[0017] The air supply mechanism also includes an air pressure gauge 14 installed on the connecting pipeline between the backflow prevention device 13 and the air pressure regulating valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com