Control device for fuel injection device

A technology for a fuel injection device and a control device, which is applied in the directions of fuel injection device, fuel injection control, special fuel injection device, etc., can solve problems such as deterioration of exhaust performance, and achieve the effect of improving stability and stable injection quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

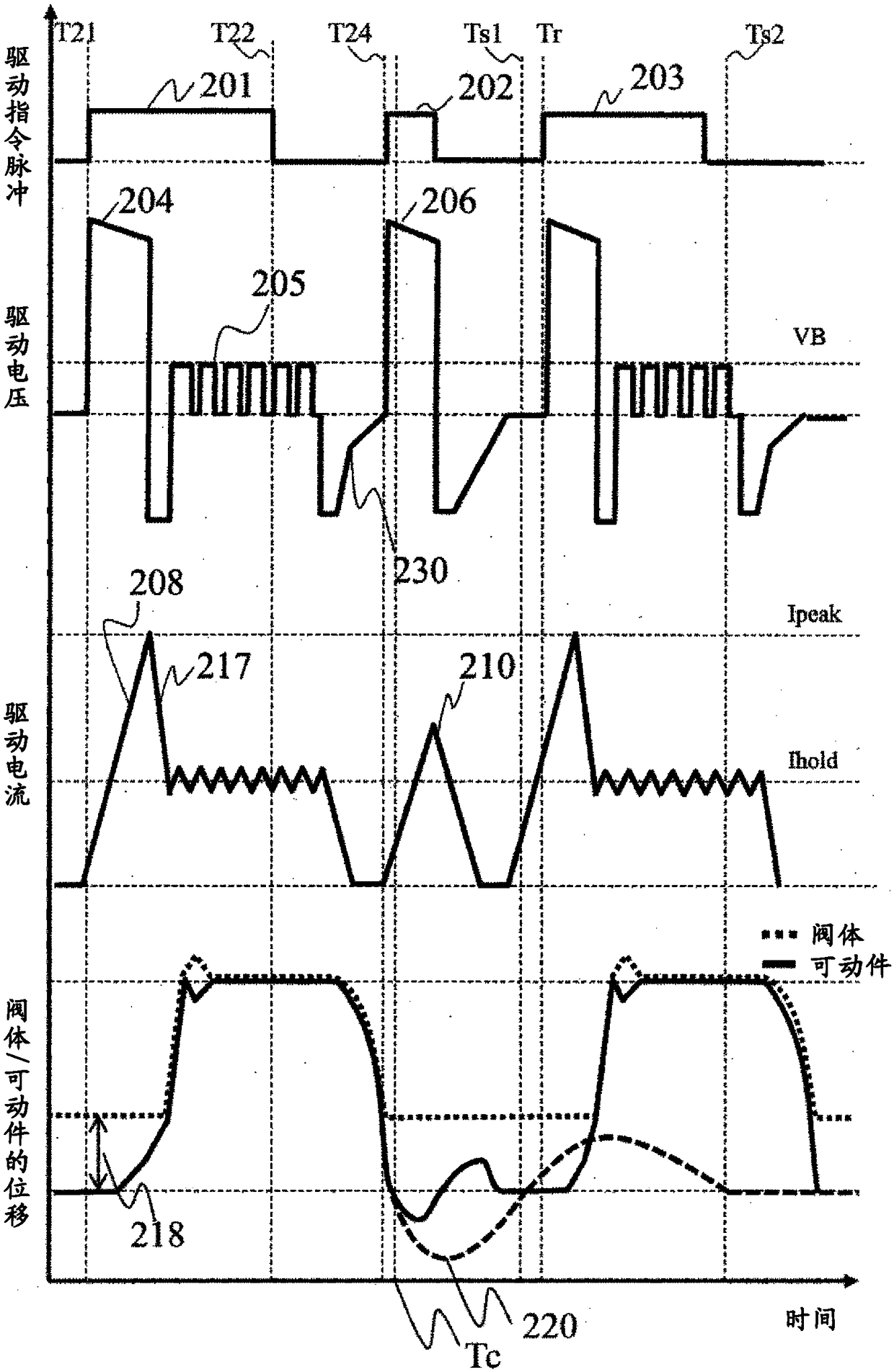

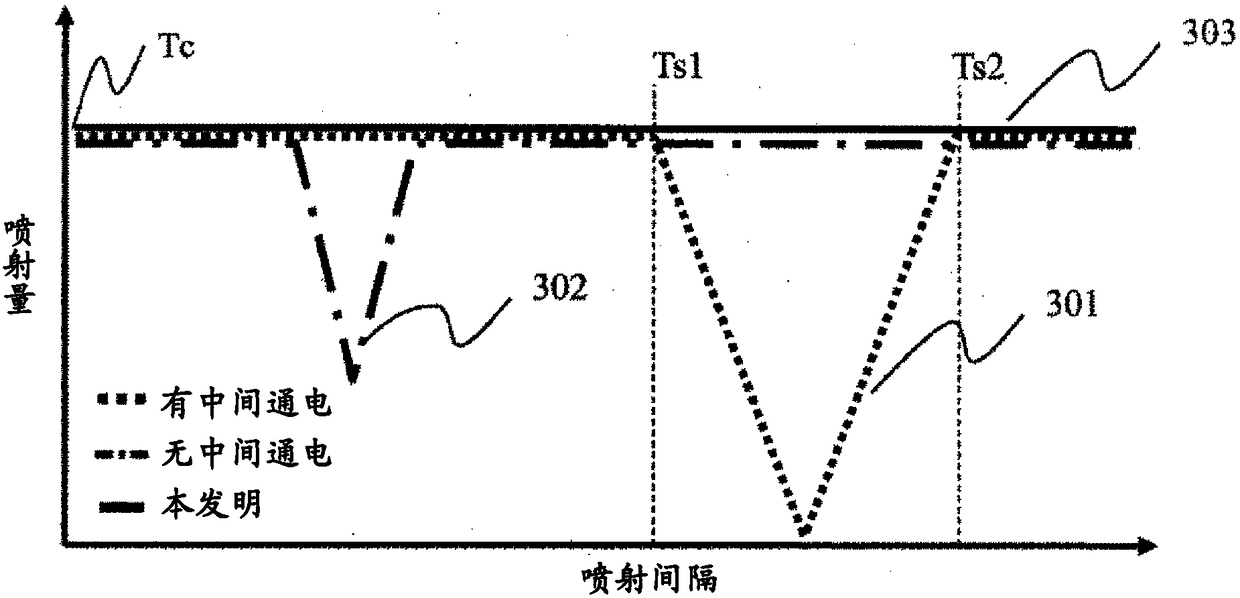

[0024] Hereinafter, Embodiment 1 of the present invention will be described. This embodiment is a control device for controlling a fuel injection device for an internal combustion engine, and involves generating magnetic flux in a magnetic circuit including a movable iron core and a fixed iron core by passing a current through a coil to attract the movable iron core to the side of the fixed iron core. The control device of the electromagnetic fuel injection device that acts on the magnetic attraction force of the iron core to open and close the valve body.

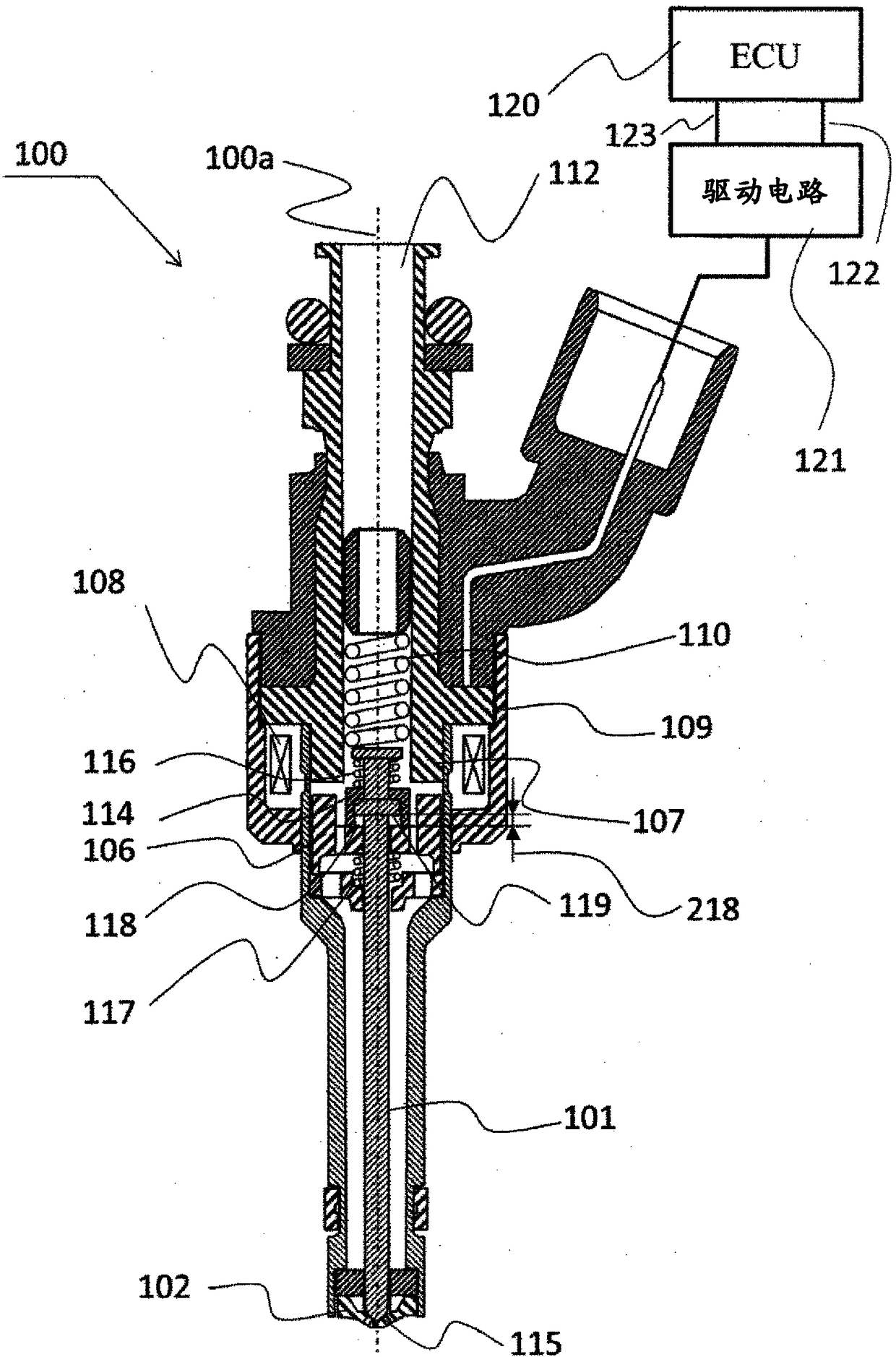

[0025] figure 1 It is a longitudinal cross-sectional view of the fuel injection device 100 in this embodiment and a diagram showing an example of a configuration of a drive circuit 121 for driving the fuel injection device 100 and an ECU (Engine Control Unit) 120 that controls the fuel injection device 100 through the drive circuit 121 . The driving circuit 121 is called "EDU".

[0026] exist figure 1 Here, the longitu...

Embodiment 2

[0060] Below, use Figure 4 ~ Figure 6 The structure and operation of the fuel injection device according to the second embodiment of the present invention will be described.

[0061] Initially, use Figure 4 The structure and basic operation of the fuel injection device of this embodiment will be described. Figure 4 It is a longitudinal cross-sectional view of the fuel injection device 400 of this embodiment and a diagram showing an example of the configuration of a drive circuit 421 and an ECU (Engine Control Unit) 420 for driving the fuel injection device 400 . Furthermore, ECU 420 and drive circuit 421 may be configured as an integral component. At least the driving device of the fuel injection device (electromagnetic fuel injection valve) is a device that generates the driving voltage of the fuel injection device, which may be a device in which the ECU and the driving circuit are integrated, or a single driving circuit.

[0062] The ECU 420 reads signals indicating th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com