Piezoelectric element drive circuit and liquid ejecting apparatus

A piezoelectric element and drive circuit technology, applied in the direction of electrical components, circuits, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of large-scale drive circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Next, in order to clarify the contents of the present invention described above, examples will be described in the following order.

[0034] A. Device structure:

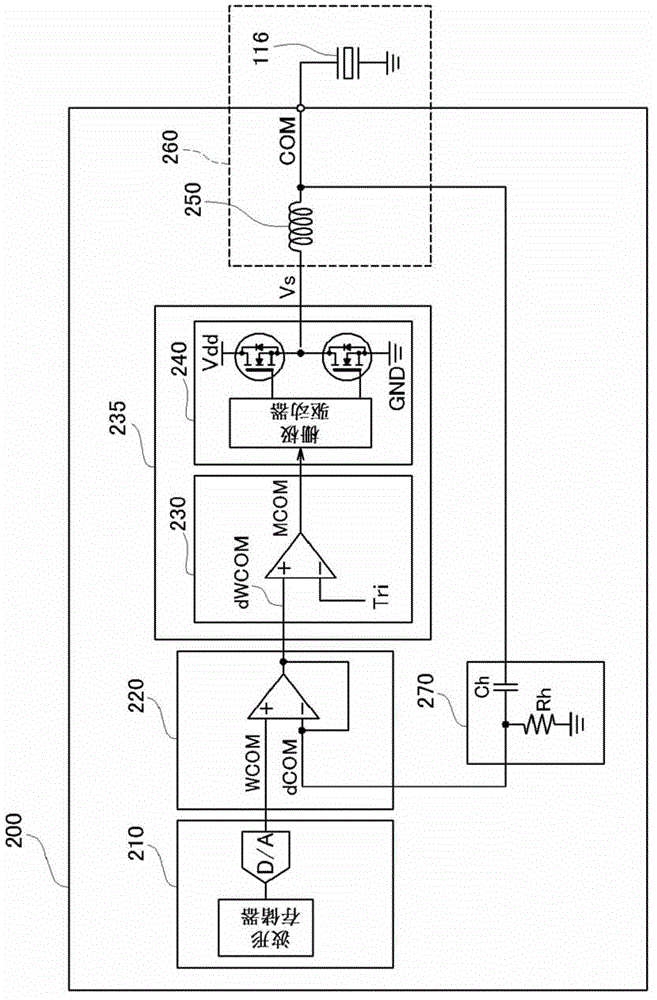

[0035] B. The circuit structure of the piezoelectric element drive circuit:

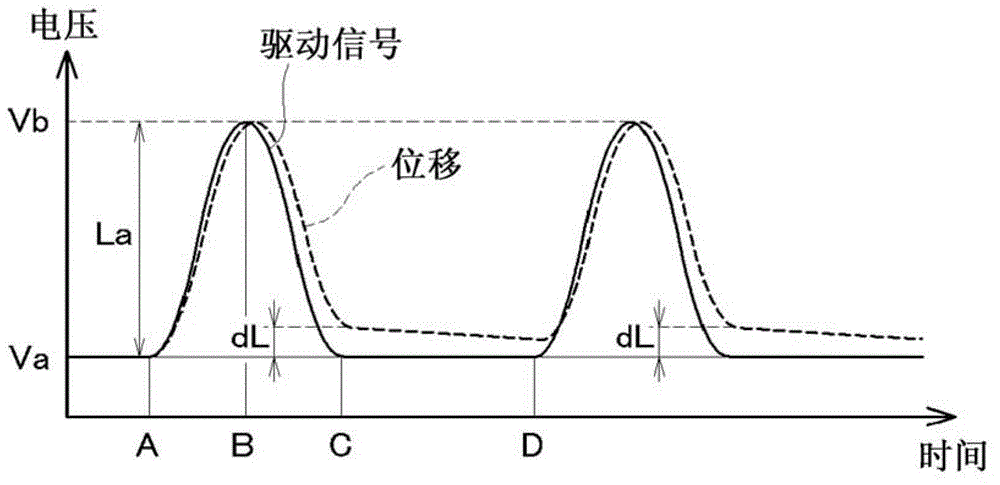

[0036] C. Action of piezoelectric element drive circuit:

[0037] D. Variations:

[0038] A. Device structure:

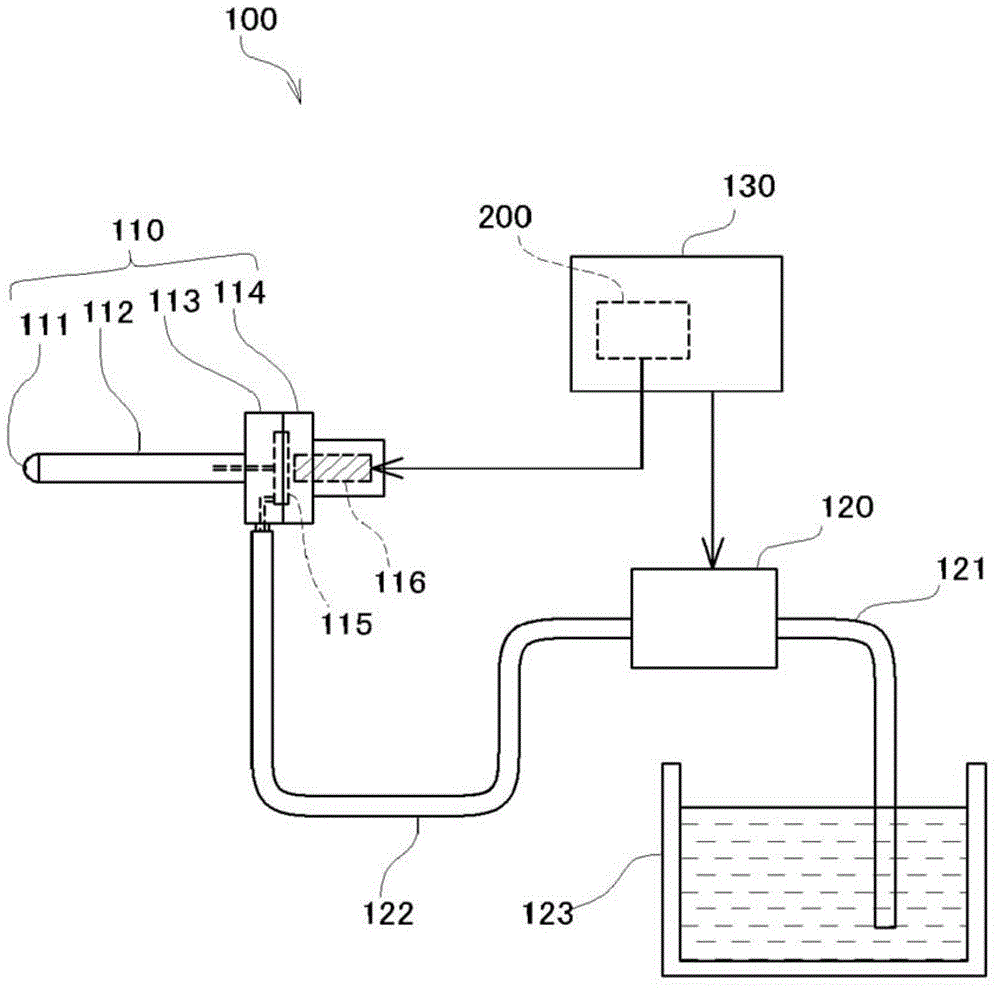

[0039] figure 1 It is an explanatory diagram showing the configuration of the fluid ejection device 100 incorporating the piezoelectric element drive circuit 200 of the present embodiment. As shown in the figure, the fluid injection device 100 is roughly divided into the following parts: an injection unit 110 that injects fluid, a fluid supply unit 120 that supplies the fluid injected from the injection unit 110 to the injection unit 110, and controls the injection unit 110 and the fluid injection unit 110. The control unit 130 and the like for the operation of the supply unit 120 .

[0040] The injection unit 110 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com