Screw-free plastic disc type rotary injection method and device

A plastic disc and disc type technology, which is applied to devices and coatings for coating liquid on the surface, can solve the problems of low storage metering accuracy, large injection motion inertia, and high injection energy consumption, and achieve accurate storage metering, The effect of low manufacturing cost and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

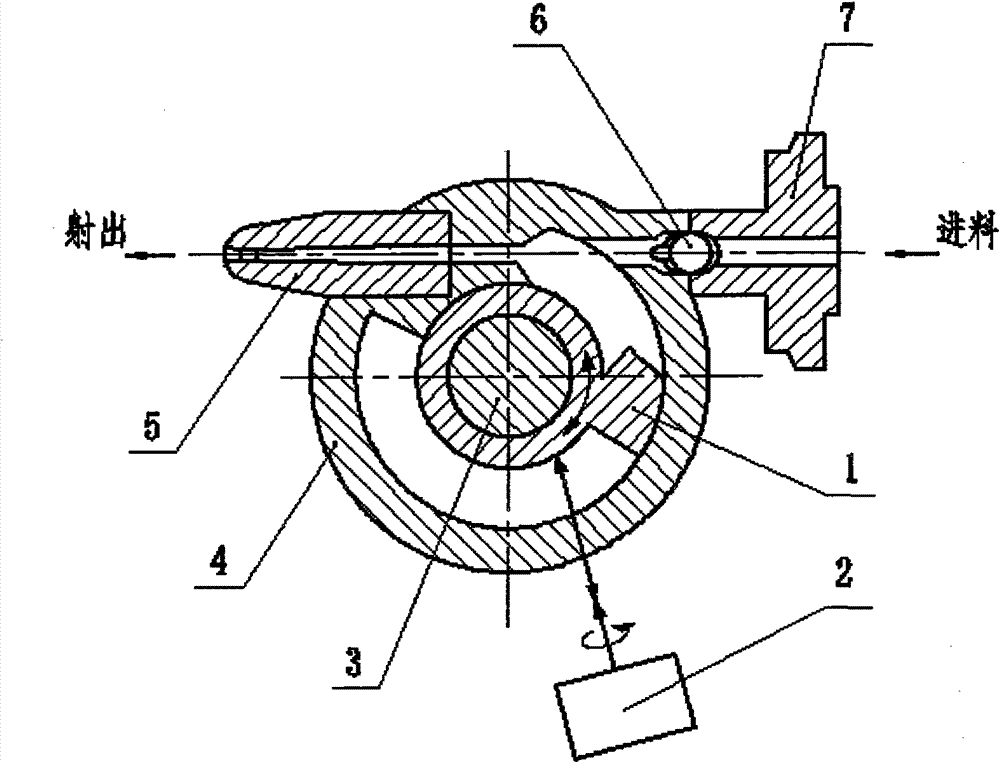

[0022] As shown in Figure 1, the plastic disc rotary injection device includes an injection piston 1, a motor 2, a support shaft 3, a disc storage cylinder 4, a nozzle 5, a control valve 6 and a connecting flange 7; the disc storage cylinder 4 There is an annular groove, the injection piston 1 is set on the support shaft 3, and connected with the motor 2, the piston head of the injection piston 1 is placed in the annular groove, and can be rotated at a certain angle around the center of the disc storage cylinder 4 in the annular groove. Rotational movement. A nozzle 5 is provided on the peripheral edge of the disc storage cylinder 4, and the channel of the nozzle 5 communicates with the annular groove; a channel is also provided on the peripheral edge of the disc storage cylinder 4, and the channel is connected with the connecting flange 7. On the channel, A control valve 6 is provided.

[0023] The working process of this embodiment is:

[0024] When storing material, open ...

Embodiment 2

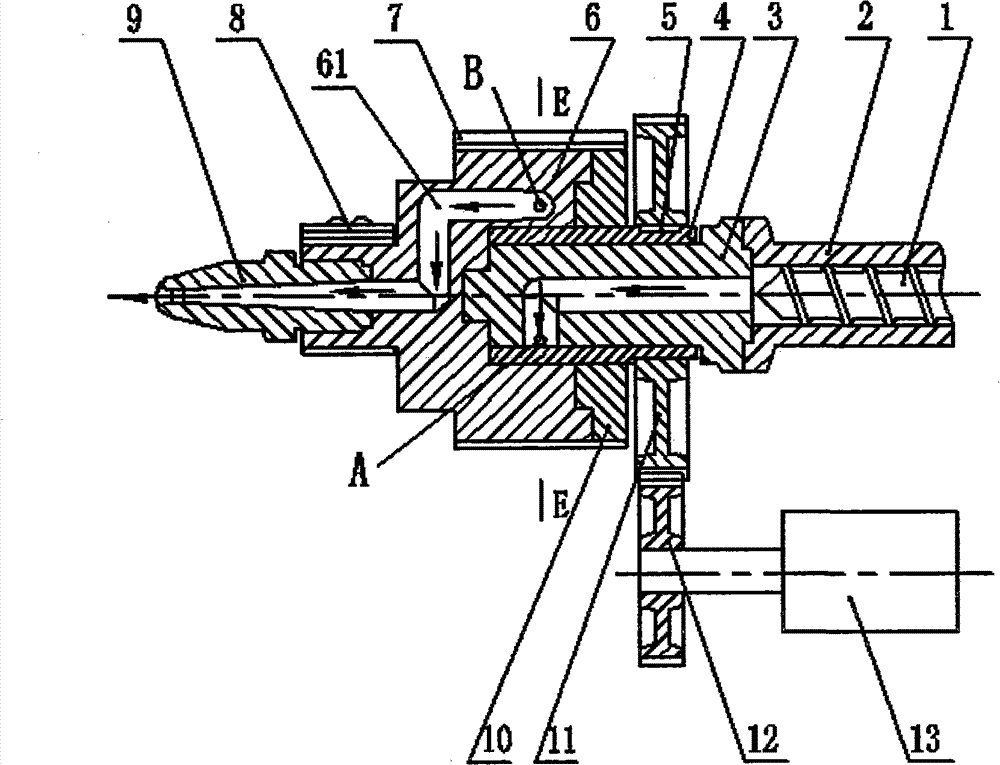

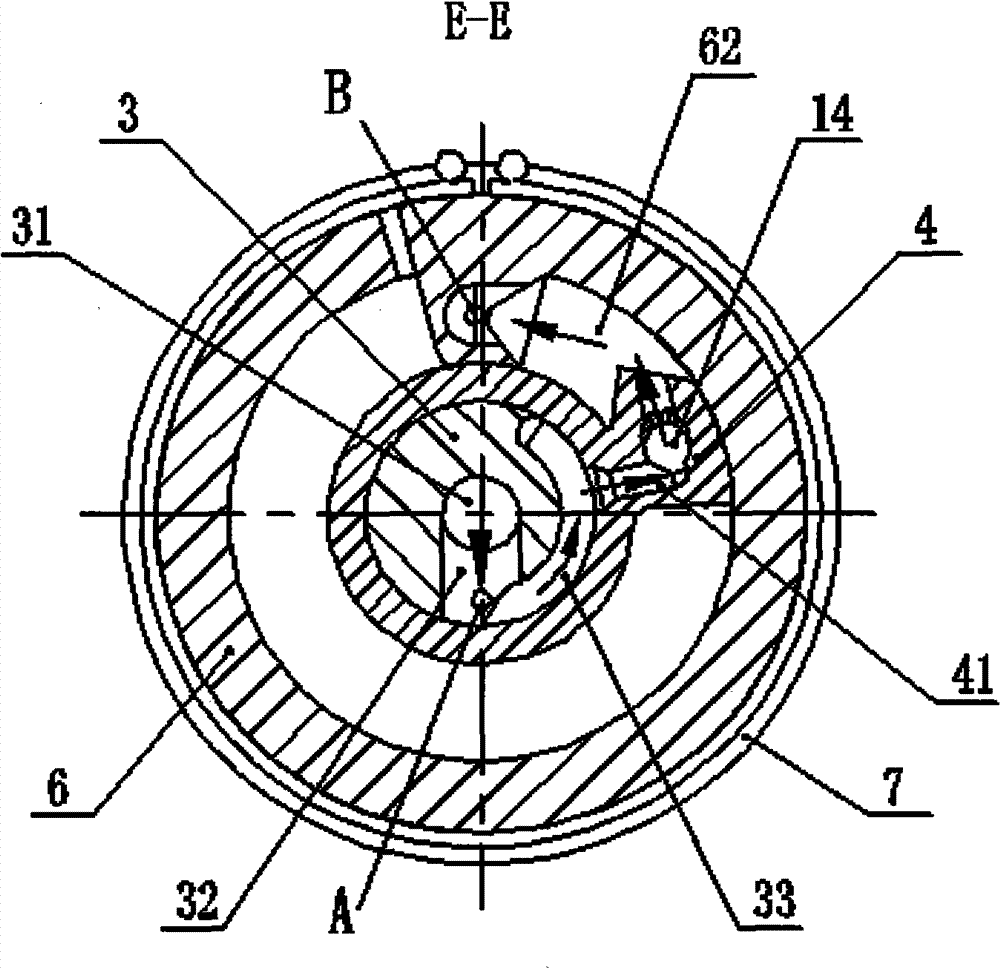

[0028] Such as figure 2 , 3 As shown, the screwless plastic disc rotary injection device includes a support shaft 3, an injection piston 4, a key 5, a disc storage cylinder 6, a metering heating ring 7, a nozzle heating ring 8, a fixed flange 10, and a driven gear 11, driving gear 12, motor 13 and check ball 14. The outer periphery of the injection piston 4 is provided with a disc storage cylinder 6, a fixed flange 10 and a driven gear 11 in sequence; the driven gear 11 is connected with the injection piston 4 through a key 5, the driven gear 11 meshes with the driving gear 12, and the driving gear 12 is connected with the output shaft of motor 13. The support shaft 3 is located in the injection piston 4, and the support shaft 3 is provided with such Figure 4 As shown in the axial flow channel 31, the radial flow channel 32 and the circumferential flow channel 33, one end of the support shaft 3 is connected to the barrel 2, and the other end of the support shaft 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com