Gas fuel injection valve

A gas fuel and injection valve technology, applied in the direction of low pressure fuel injection, low pressure fuel injection, fuel injection device, etc., can solve problems such as hindering cost reduction, increase in the number of parts and assembly man-hours, etc., and achieves reduction of assembly man-hours and zero reduction. Number of parts and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

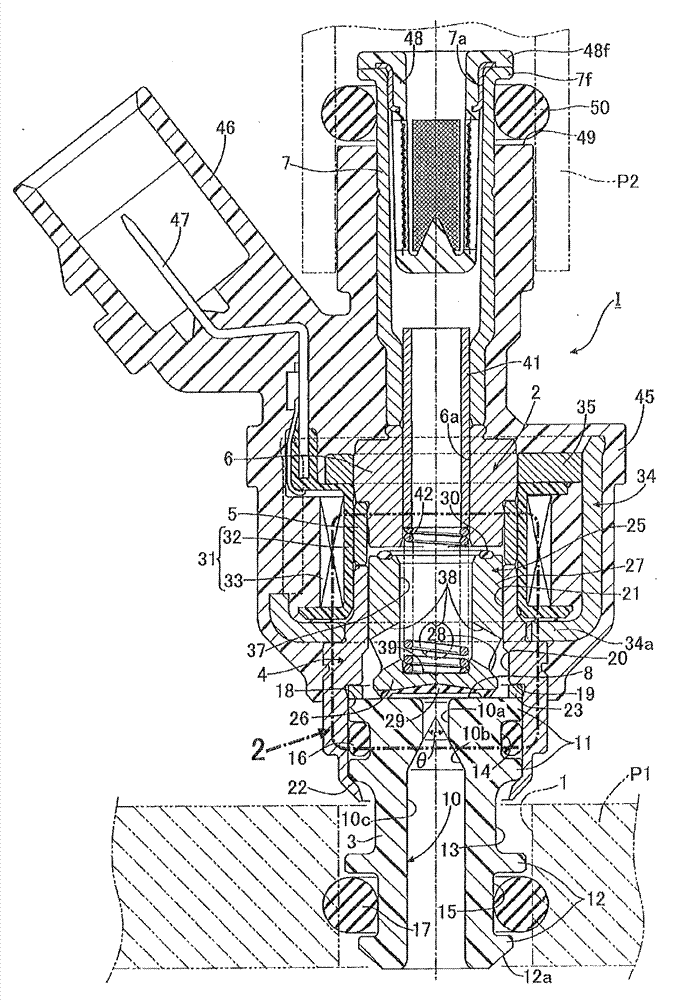

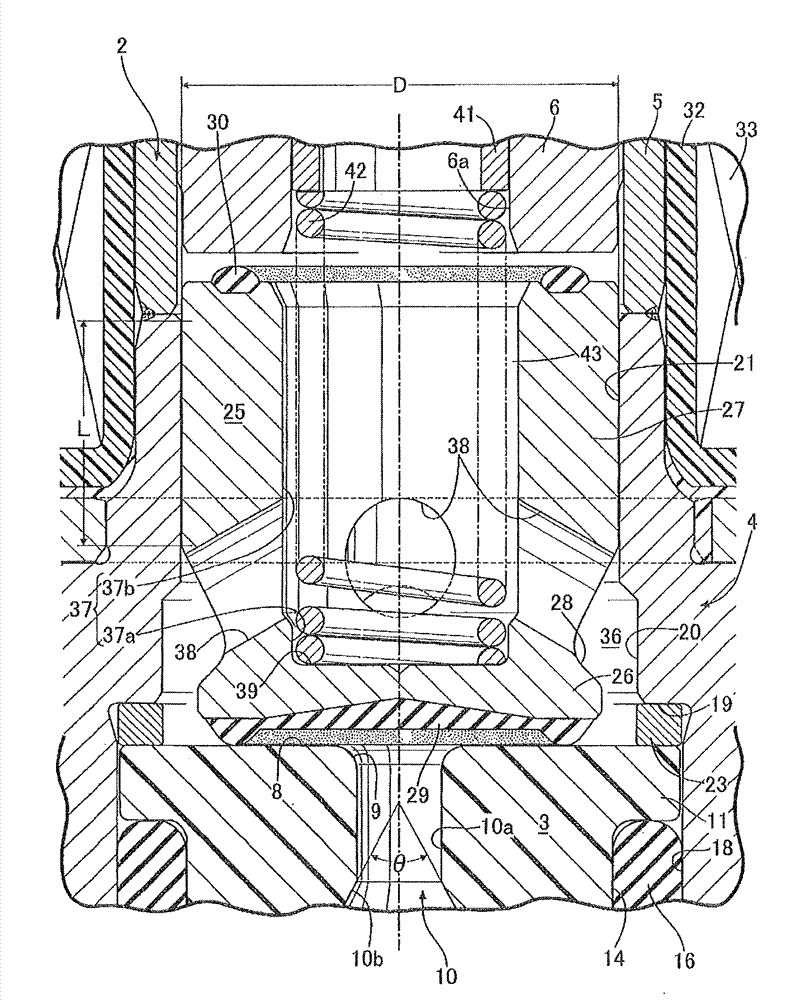

[0024] exist figure 1 Among them, the front end portion of the gas fuel injection valve I is installed in the mounting hole 1 provided in the intake passage member P1 of the engine, and the gas fuel injection valve I can be inserted into the intake passage member P1 during the intake stroke of the engine. Inject gaseous fuel.

[0025] The valve sleeve 2 of the injection valve 1 is formed by coaxially arranging the nozzle member 3, the magnetic cylinder 4, the non-magnetic collar 5, the fixed iron core 6 and the fuel inlet cylinder 7 sequentially from the front end side thereof, and making them interact with each other. Composed of liquid-tight combination.

[0026] The nozzle member 3 is made of synthetic resin, and a nozzle hole 10 is formed in the center of the nozzle member 3 , and the rear end surface of the opening of the nozzle hole 10 is formed on the flat valve seat 8 . On the outer periphery of the nozzle member 3, a first fitting portion 11 located at the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com