Piezoelectric air valve and multi-valve type piezoelectric air valve

一种空气阀、空气压力的技术,应用在升阀、阀细节、多通阀等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

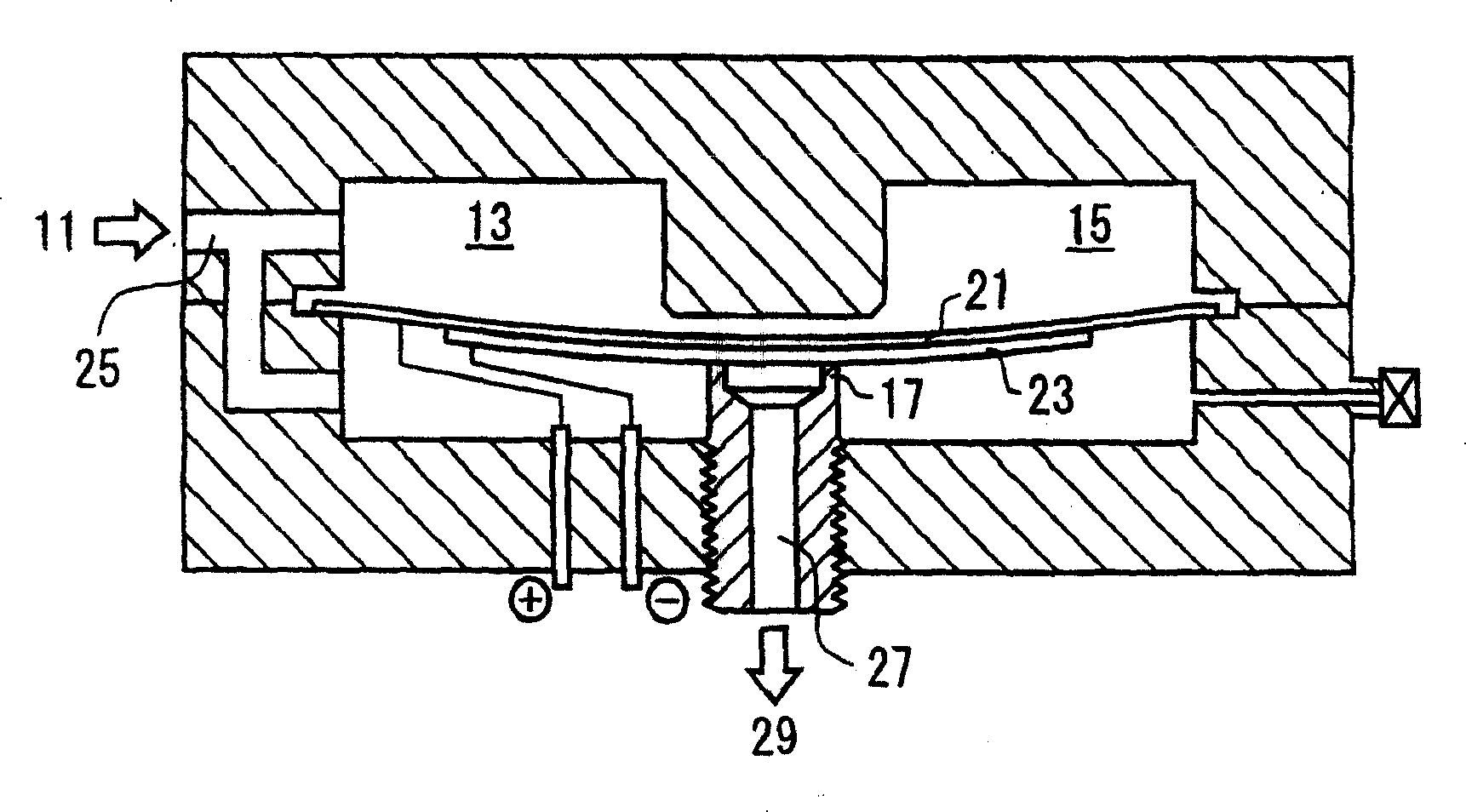

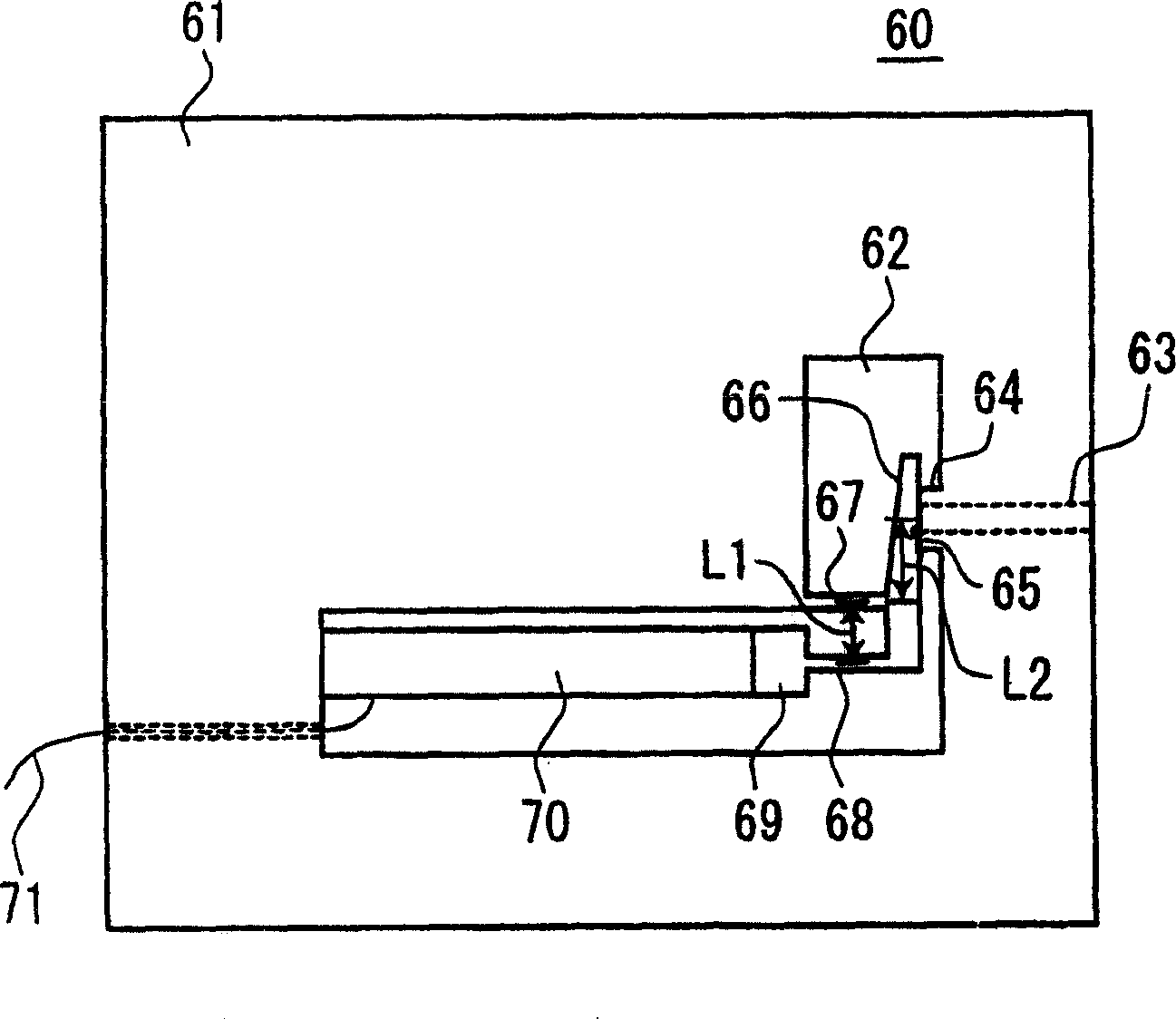

[0036] Now, the piezoelectric air valve and the multi-valve piezoelectric air valve according to the present invention will be described in detail below with reference to the accompanying drawings.

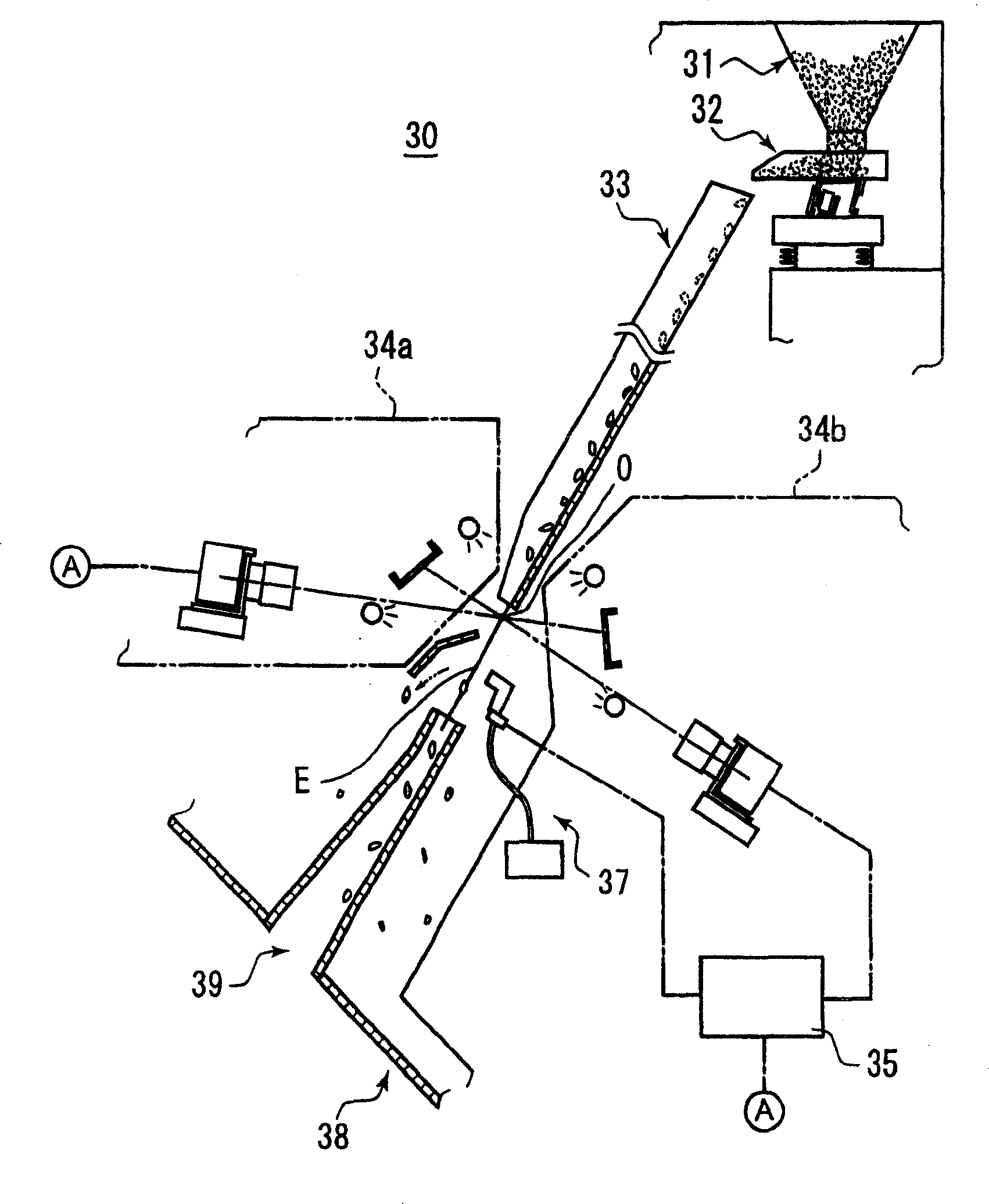

[0037] First refer to figure 2 An overview of a particulate material sorting machine that can use the piezoelectric air valve according to the present invention will be described to help understand the present invention. figure 2 is a schematic side sectional view of the main part of the granular material sorting machine 30 and its internal structure. The granular material sorter 30 includes a granular material supply part including a bin 31 and a vibratory feeder 32 at an upper portion thereof. The granular material supplied from the granular material supply part sequentially falls naturally through the chute 33, and then is released into the air from the lower end portion thereof along a given falling trajectory.

[0038] At least one pair of optical detection means 34a, 34b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com