A method to improve the accuracy of total sulfur analysis

An accuracy and analysis device technology, applied in the field of improving the accuracy of total sulfur analysis, can solve the problems of impact on results, cumbersome operation, low analysis accuracy, etc., and achieve improved accuracy, good repeatability and accuracy, and full conversion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

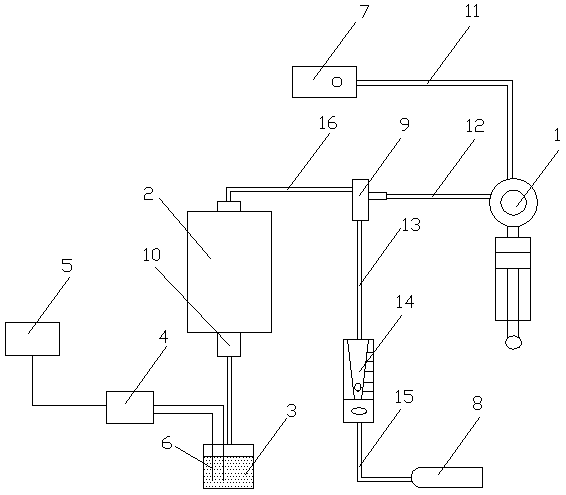

[0043] A method for improving the accuracy of total sulfur analysis, comprising the following steps:

[0044] a. Select the standard sample gas with the same composition and content as the actual natural gas sample. The standard sample gas includes hydrogen sulfide, carbonyl sulfide, methyl mercaptan, ethanethiol, propylene mercaptan, isopropyl mercaptan, carbon disulfide and thiophene;

[0045] b. First put the standard sample gas into the normal-pressure tin foil bag 7, then connect the tin foil bag 7 to the first air inlet pipe 11 of the total sulfur analysis device, determine the sample volume of the calibration point, and the standard sample gas is in the cracking furnace The quartz high-temperature combustion tube 10 of 2 is burned together with oxygen, and the sulfur dioxide converted into the titration cell 3 along with the argon gas after combustion reacts with the electrolyte, and the total sulfide content in the standard sample gas is calculated by calculating the el...

Embodiment 2

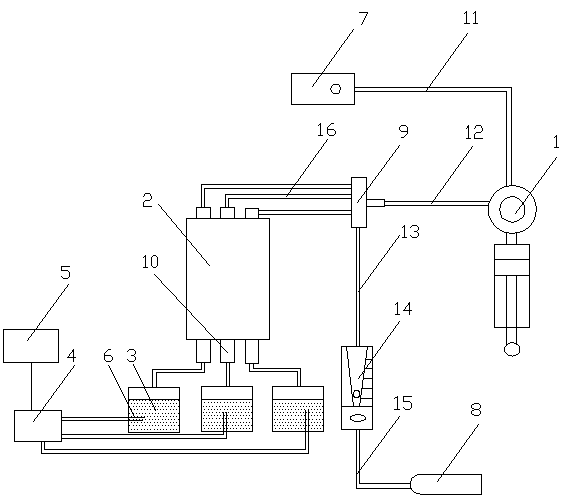

[0050] A method for improving the accuracy of total sulfur analysis, comprising the following steps:

[0051] a. Select the standard sample gas with the same composition and content as the actual natural gas sample. The standard sample gas includes hydrogen sulfide, carbonyl sulfide, methyl mercaptan, ethanethiol, propylene mercaptan, isopropyl mercaptan, carbon disulfide and thiophene;

[0052] b. First put the standard sample gas into the normal-pressure tin foil bag 7, then connect the tin foil bag 7 to the first air inlet pipe 11 of the total sulfur analysis device, determine the sample volume of the calibration point, and the standard sample gas is in the cracking furnace The quartz high-temperature combustion tube 10 of 2 is burned together with oxygen, and the sulfur dioxide converted into the titration cell 3 along with the argon gas after combustion reacts with the electrolyte, and the total sulfide content in the standard sample gas is calculated by calculating the el...

Embodiment 3

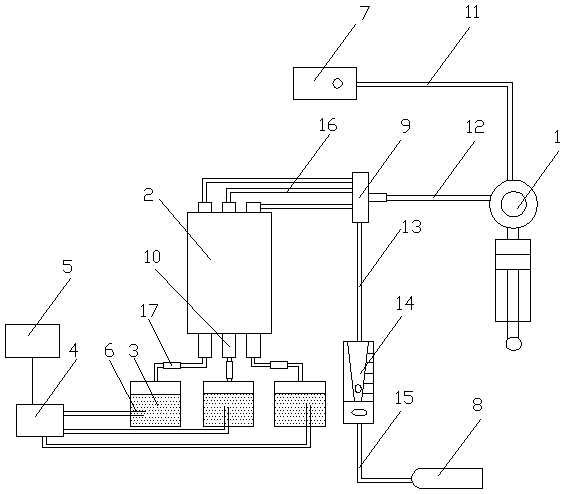

[0062] A method for improving the accuracy of total sulfur analysis, comprising the following steps:

[0063] a. Select the standard sample gas with the same composition and content as the actual natural gas sample. The standard sample gas includes hydrogen sulfide, carbonyl sulfide, methyl mercaptan, ethanethiol, propylene mercaptan, isopropyl mercaptan, carbon disulfide and thiophene;

[0064] b. First put the standard sample gas into the normal-pressure tin foil bag 7, then connect the tin foil bag 7 to the first air inlet pipe 11 of the total sulfur analysis device, determine the sample volume of the calibration point, and the standard sample gas is in the cracking furnace The quartz high-temperature combustion tube 10 of 2 is burned together with oxygen, and the sulfur dioxide converted into the titration cell 3 along with the argon gas after combustion reacts with the electrolyte, and the total sulfide content in the standard sample gas is calculated by calculating the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com