Large pressure difference real-time adjustment water distributor

A technology of real-time adjustment and water distribution, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of increasing the number of deployment operations and production costs, sensitive to changes in the pressure of the water injection layer, and inability to deploy on-site, etc. Achieve the effect of preventing frequent deviation from the dosage amount, stabilizing the injection amount, and not increasing the injection amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

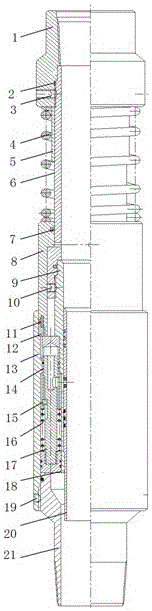

[0020] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0021] Such as figure 1 As shown, the water distributor is adjusted in real time with a large pressure difference. The upper joint 1 and the upper short joint 6 are connected by threads. The inner side of the lower part of the upper short joint 6 is threadedly connected with the central pipe 9, and a sealing ring is installed between the two, and is fastened with a set screw 10; the middle part of the upper short joint 6 has a pressure transmission hole, and the upper outer side is equipped with a limit sleeve 5. Anti-reverse piston 8 is installed on the outer side of the lower part. A sealing ring 7 is installed between the upper part of the anti-reverse piston 8 and the upper short joint 6, and a sealing ring 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com