Electric pressurization outpouring type liquid container

A liquid container, electric technology, used in non-pressure containers, gas/liquid distribution and storage, cooking utensils, etc., can solve the problems of reduced injection volume, easy air leakage, injection, etc., to achieve stable injection volume, reduce water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

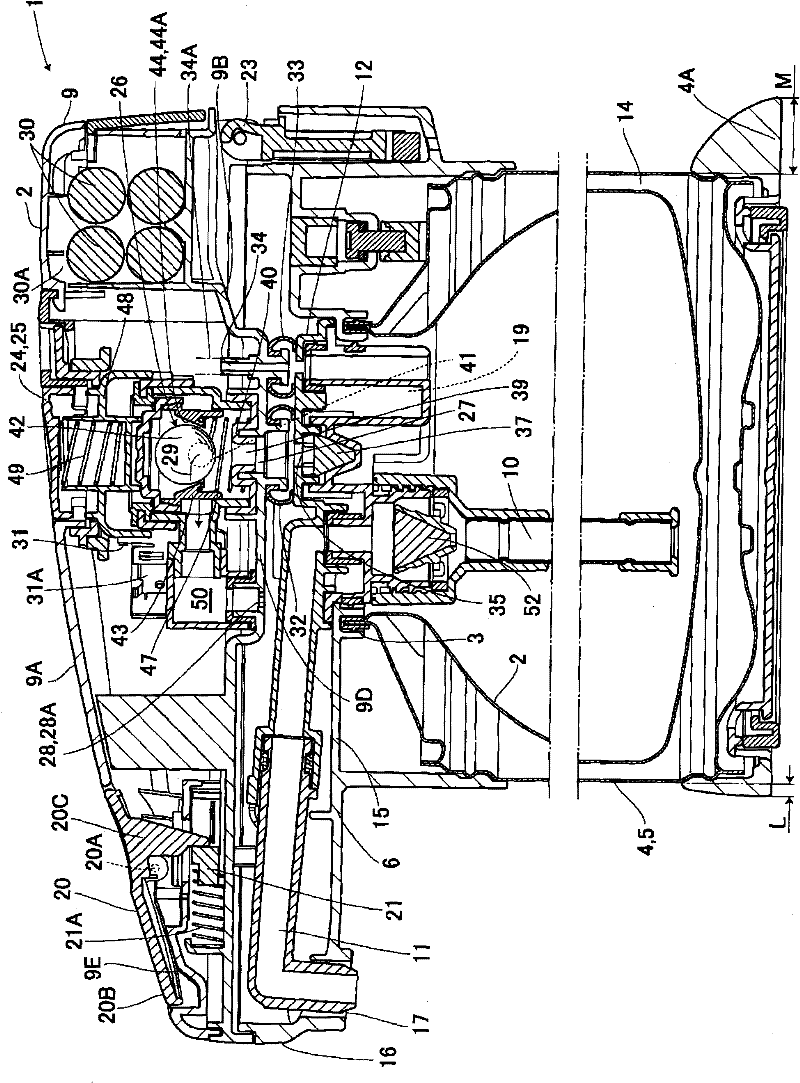

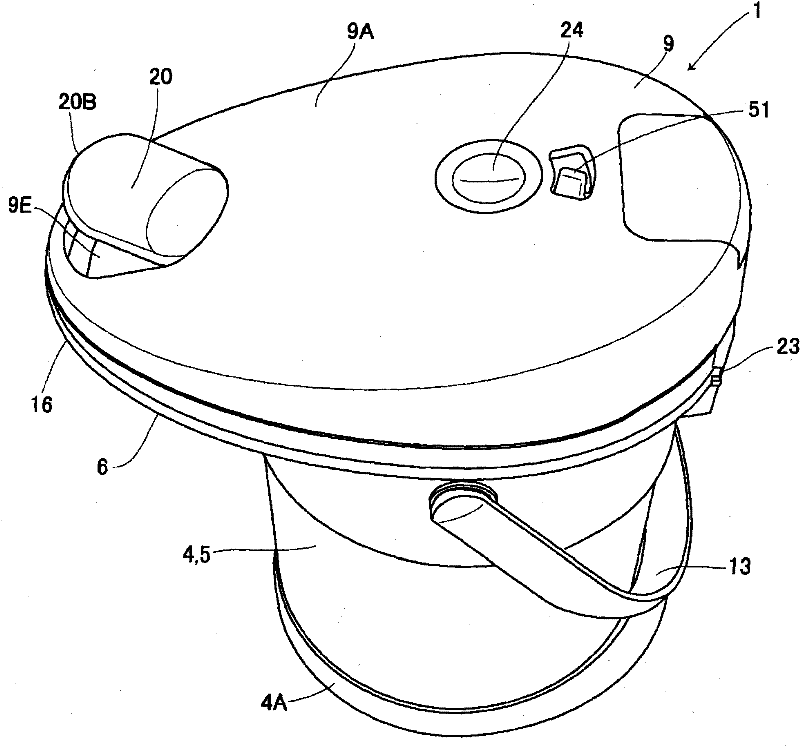

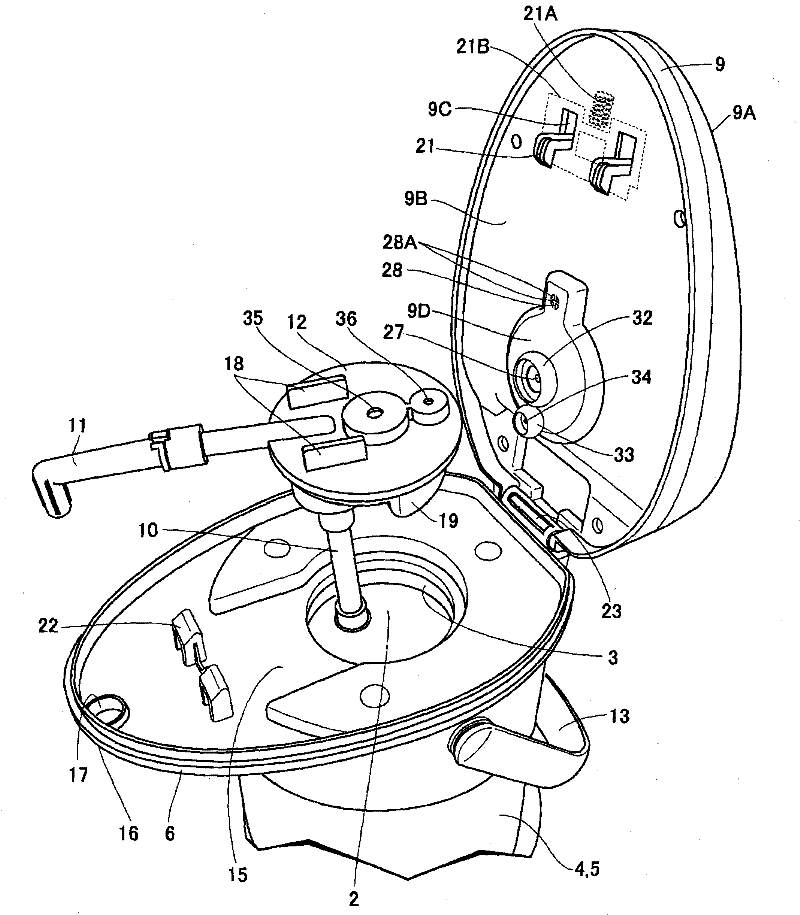

[0030] Figure 1 to Figure 10 Showing Embodiment 1, an electric kettle 1 is provided with: a container main body 5 having a bottomed inner tube 2 for accommodating liquids such as water; A bottomed outer cylinder 4 that is also used as an exterior; a substantially horizontal and substantially disc-shaped shoulder member 6, which is also called a water removal member, etc., is combined to form the outer peripheral upper end side of the outer cylinder 4 and the container body 5. The mouth 3 is covered; the hollow cover body 9 is provided with an electric diaphragm (not shown) air pump, that is, an electric pump 8, and is installed on the upper surface of the shoulder member 6 in a freely openable and closed manner; the middle plug 12, which is provided with a water pipe 10 for discharging the liquid in the inner cylinder 2 at the upper part, and is equipped with a water injection pipe 11 communicated with the water pipe 10 at the upper part, and seals the mouth 3 detachably; and...

Embodiment 2

[0063] Next, other examples will be described. However, the same reference numerals are assigned to the same parts as those in the first embodiment described above, and detailed description thereof will be omitted.

[0064] Figure 11 Example 2 is shown. In Example 2, the sealing members 32 and 33 of Example 1 are used together, and exhaust leakage and air leakage are provided on the lower surface of the cover 9 so as to surround the steam hole 27 and the exhaust hole 34 on the cover 12 side. The sealing member 32' serving as a leak prevention seal member 32' encloses the middle plug exhaust gas and the middle plug air which are also used as the middle plug exhaust path 35 and the middle plug air supply path 36 in the first embodiment. It is sent into the upper end of the dual-purpose road 35', and is arranged on the upper surface of the middle plug 12; the steam can be discharged through the middle plug exhaust and the middle plug air into the dual-purpose road 35', the seal...

Embodiment 3

[0066] Figure 12 Example 3 is shown, and the steam hole 27 on the side of the cover body 9 of Example 1, the lower end opening 27' of the exhaust hole 34 and the lower end opening 27' of the exhaust hole 34 are provided on the cover body so as to surround the lower end opening portion 27'. The lower surface of 9 is provided with exhaust leakage and air leakage preventing dual-purpose sealing member 32 ", and the inner side surrounded by the lower end of this sealing member 32 " will double as the middle plug exhaust passage 35 and the middle plug air of Embodiment 1 into The middle plug exhaust and the middle plug air of the road 36 are sent to the upper end of the double-purpose road 35 ′, and are arranged on the upper surface of the middle plug 12, and the steam can be sent into the double-purpose road 35 ′ and the sealing member 32 through the middle plug exhaust and the middle plug air. ", the lower end opening 27', and the steam hole 27 are discharged, and on the other h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com