Method for blocking gas spurt leakage of gas enclosing cover on furnace foundation of large-sized blast furnace

A blast furnace and gas technology, which is applied in the field of blocking large-scale blast furnace base gas cover gas leakage, and achieves the effects of obvious sealing effect, reduced maintenance engineering cost, and short wind break time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for blocking gas leakage from a large-scale blast furnace base gas cover, characterized in that it includes the gas cover sealing treatment and the grouting treatment steps from the gas cover to the tuyere section:

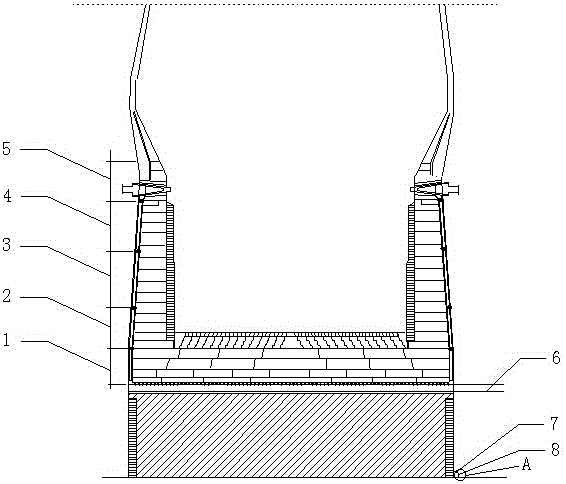

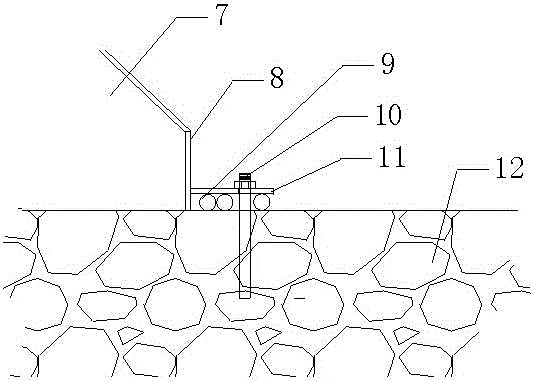

[0039] see now figure 1 and 2 , figure 1 It is a schematic structural view of a large blast furnace and a furnace-based gas enclosure in an embodiment of the present invention, figure 2 for figure 1 Enlarged view of part A in the middle.

[0040] (1) The sealing treatment of the gas cover includes the following steps:

[0041] a. Drill a hole of 150mm*Ø25mm at an interval of 1000mm on the outer concrete foundation of the gas enclosure at a distance of 100mm from the enclosure facade steel plate in the circumferential direction. Drill 220mm*Ø20mm expansion bolts in each hole;

[0042] b. Make an arc-shaped steel plate with a width of 150mm and a thickness of 8mm. The arc of the arc-shaped steel plate is consistent with the arc of the gas encl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com