Patents

Literature

103results about How to "Improve nail holding power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

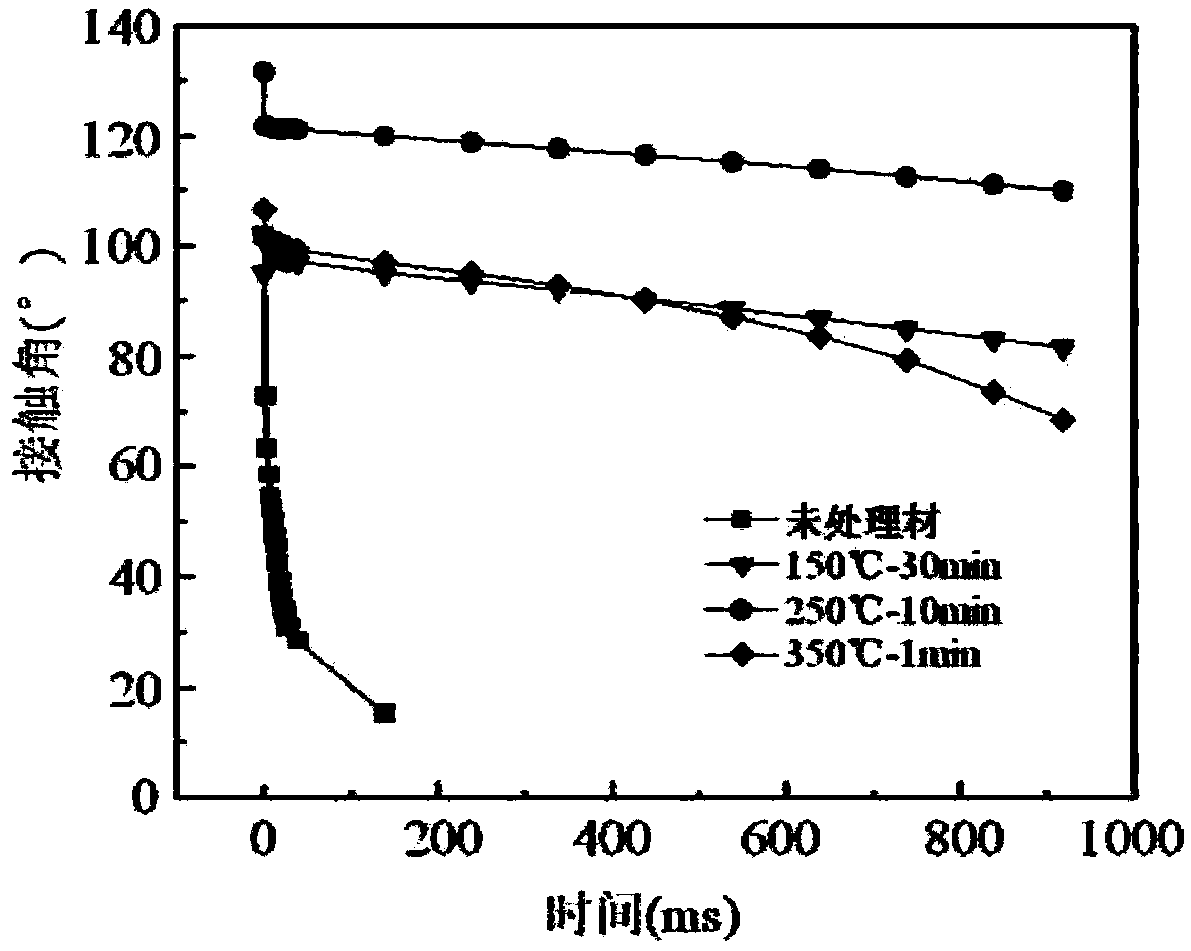

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

Multilayer composite plate for building templates and brick pallets and preparation process thereof

InactiveCN101633254AWith glazed effectEasy to demouldMouldsMixing operation control apparatusBrickSurface layer

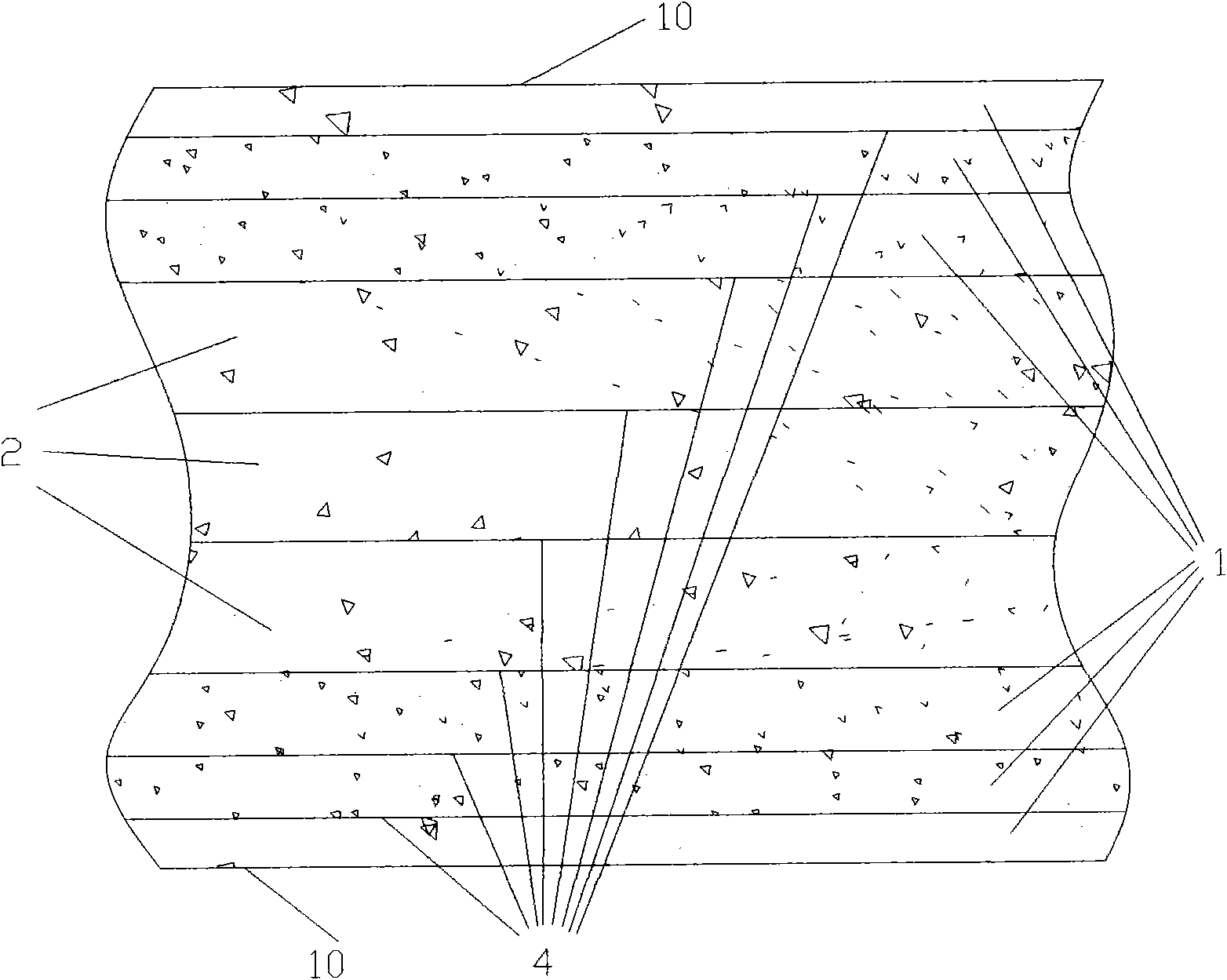

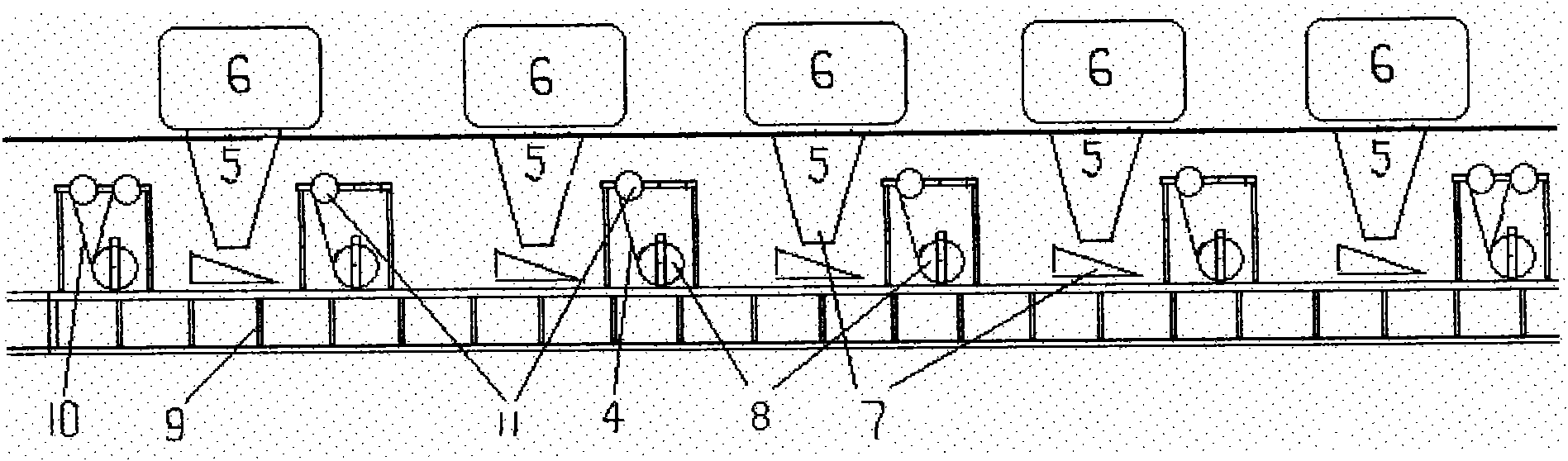

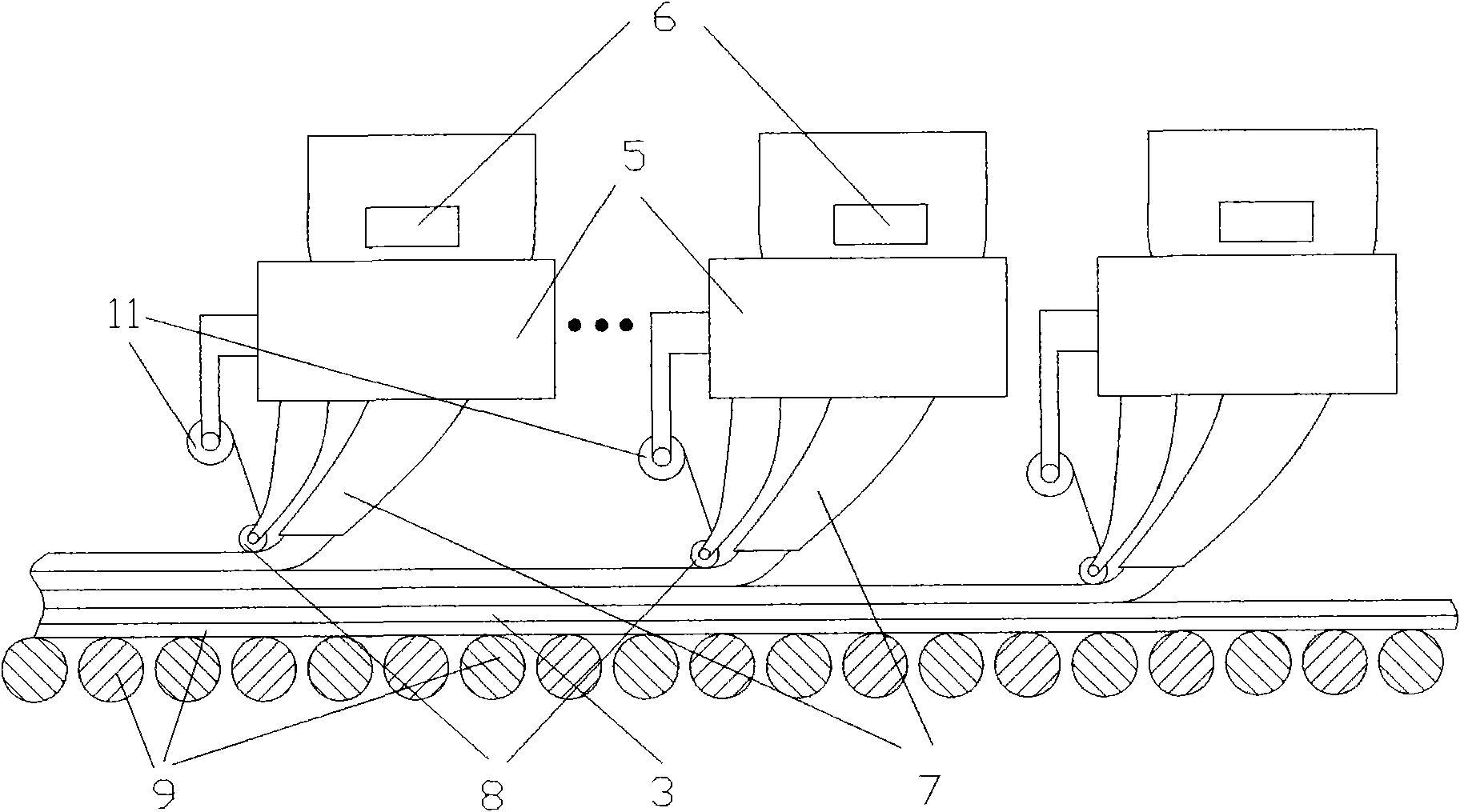

The invention discloses a multilayer composite plate for building templates and brick pallets, which is prepared from magnesium cement gel added with a reinforcing material and a filler, and comprises surface layers (1) and sandwich layers (2); the surface layers (1) or / and the sandwich layers (2) comprise the filler or / and the reinforcing material with even content or gradient change; the number of the sandwich layers (2) is totally between 1 and 5; and the reinforcing material is arranged between adjacent sandwich layers (2). The invention also comprises a preparation process for the multilayer composite plate, which comprises that: production equipment with the capacity of stirring and preparing materials at multiple positions and rolling at multiple positions orderly rolls the surface layers (1) or / and the sandwich layers (2) on a subplate (3); and the reinforcing material is used as a reinforced structure between adjacent surface layers (1) or / and sandwich layers (2). The products corresponding to the invention have the characteristics of strong applicability, good technical effect and suitability for mechanical continuous production, and have predictable great economic and social values.

Owner:LIAONING FENGCHENG INDAL TECH

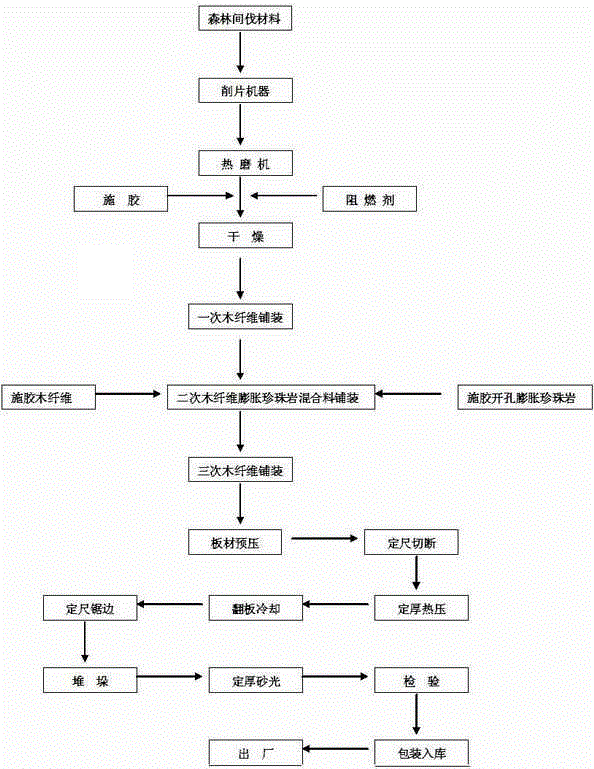

Method for manufacturing medium-density fiberboards

InactiveCN103192442AReduce manufacturing costStable internal structureWood working apparatusFlat articlesFiberManufacturing technology

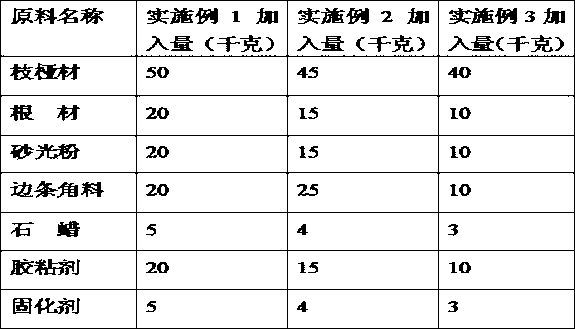

The invention relates to a method for manufacturing medium-density fiberboards, and belongs to the technical field of manufacture of fiberboards. The method includes proportionally cutting root-wood and brushwood to obtain 60X30X5mm wood chips; carrying out cleaning, cooking, hot-grinding and drying procedures for the wood chips to obtain fibers; proportionally and sufficiently mixing the fibers with sanding powder and sawdust-shaped edge strip and corner materials to obtain mixtures; and carrying out gluing, paving and hot-pressing procedures for the mixtures to manufacture finished medium-density fiberboard products. The method has the advantages that the manufacturing cost of the medium-density fiberboards is reduced to a certain extent; problems that sanding dust which is generated in existing fiberboard manufacturing procedures and edge strip and corner materials which are generated during blank plate cutting are discarded as rejected materials, environments are polluted, the manufacturing cost is increased and limited forest resources are wasted are solved; and the fiberboards manufactured by the method are stable in internal structure, low in deformation and good in physical and mechanical performance.

Owner:FOJON GRP

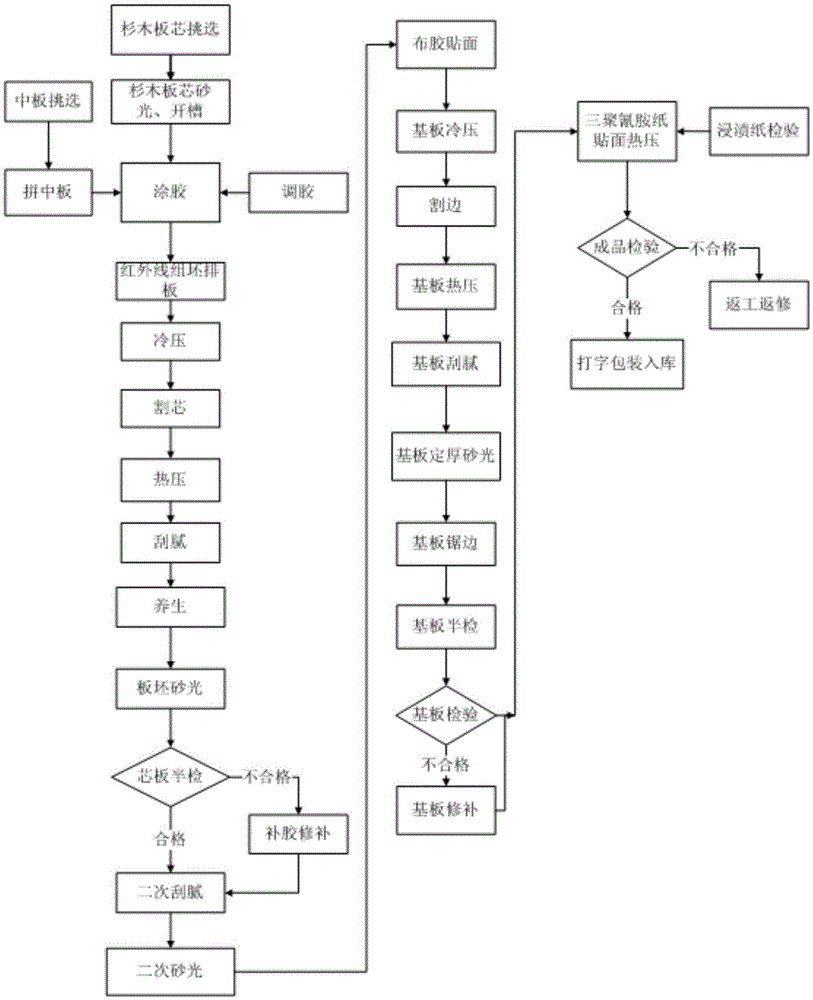

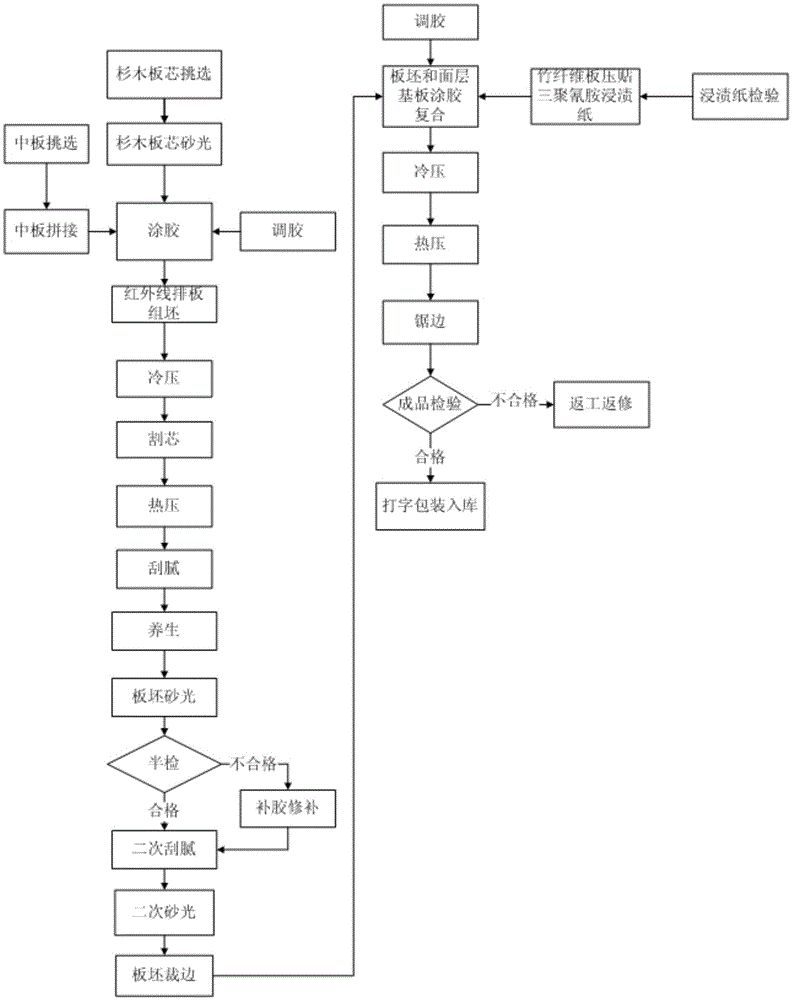

Production process of high-grade fir melamine ecological board

ActiveCN105459221AReduces surface white bloomsReduce defects such as carbonizationOther plywood/veneer working apparatusLaminationInfraredProduct inspection

The invention belongs to the field of board machining and particularly relates to a production process of a high-grade fir melamine ecological board. The process particularly includes the following steps of poplar middle plate selection, poplar middle plate splicing, fir core veneer selection, fir core veneer sanding, fir core veneer slotting, core veneer gluing, infrared ray board arrangement for forming a blank, cold pressing, core cutting, hot pressing, putty application, maintenance, sanding, semi-checking, secondary putty application, secondary sanding, gluing and veneering, base board cold pressing, base board edge cutting, base board hot pressing, base board putty application, base board fixed-thickness sanding, base board edge sawing, base board inspection, repairing, melamine impregnated paper hot pressing and finished product inspection, packaging and warehousing of finished products. The production process has the advantages that fir core veneers are adopted, the hardness, nail-holding ability and static bending strength of the board is improved; eucalyptus middle plates are replaced with poplar middle plates, and the defects that the surface of the finished products is stained and carbonized caused by multiple burrs and scabs on the surfaces of the gum wood are reduced effectively.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Fireproof marine-grade plywood

ActiveCN105643731AImprove fire and flame retardant performanceGood weather resistanceOther plywood/veneer working apparatusWood treatment detailsSolid woodGlass fiber

The invention relates to the technical field of composite artificial boards and discloses fireproof marine-grade plywood. The fireproof marine-grade plywood comprises a flame-retardant veneer, high-strength glass fiber meshes, flame-retardant solid wood core veneers and a flame-retardant bottom board, wherein the flame-retardant veneer is arranged on the uppermost layer, the flame-retardant bottom board is arranged on the bottommost layer, and one layer of high-strength glass fiber mesh, the three layers of flame-retardant solid wood core veneers and one layer of high-strength glass fiber mesh are sequentially arranged between the flame-retardant veneer and the flame-retardant bottom board from top to bottom; the layers are bonded through modified macromolecular WBP flame-retardant and waterproof glue. The fireproof marine-grade plywood has the functions of being resistant to fire, inflaming, water, moisture, insects and ants and absorbing sounds and shock, saves the energy, protects the environment and is high in strength.

Owner:GUANGZHOU YING ERAN FIRE MATERIAL CO LTD

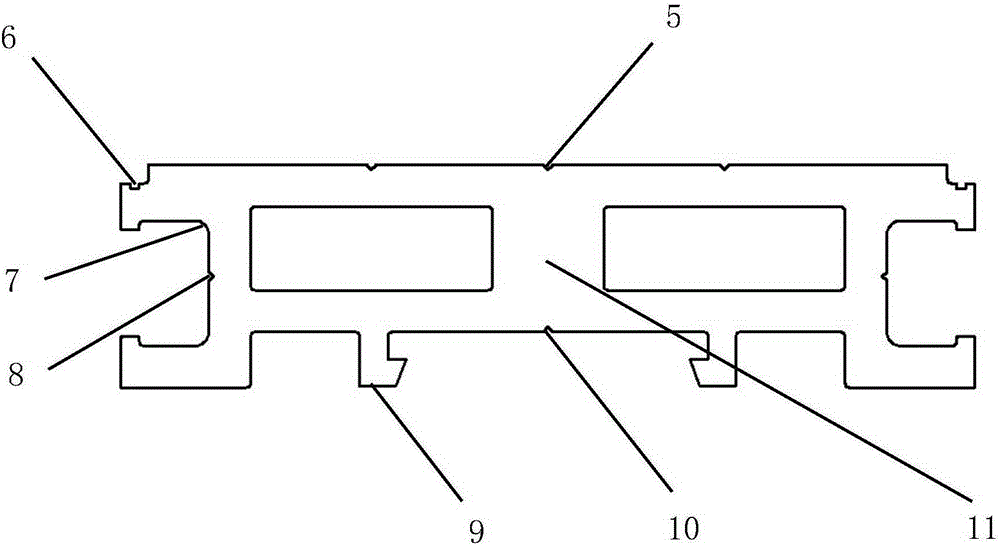

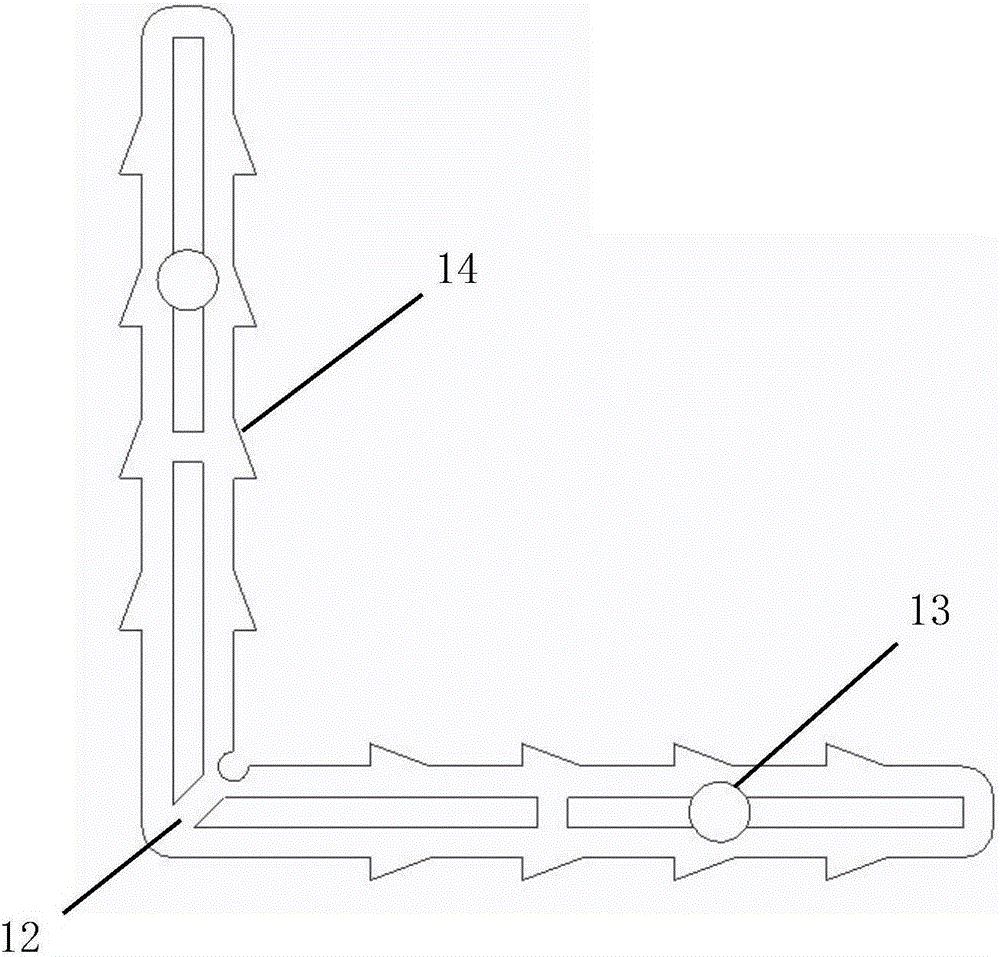

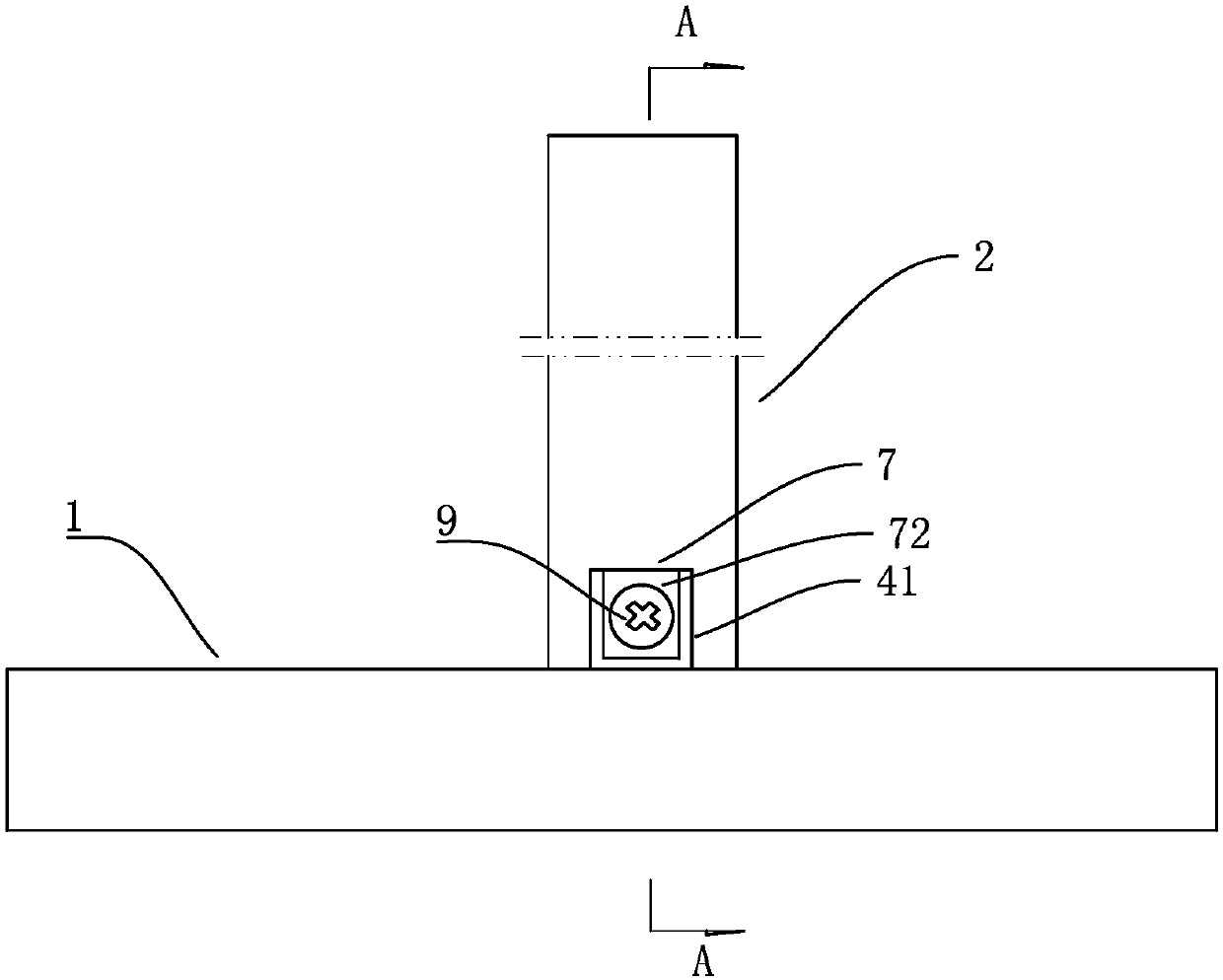

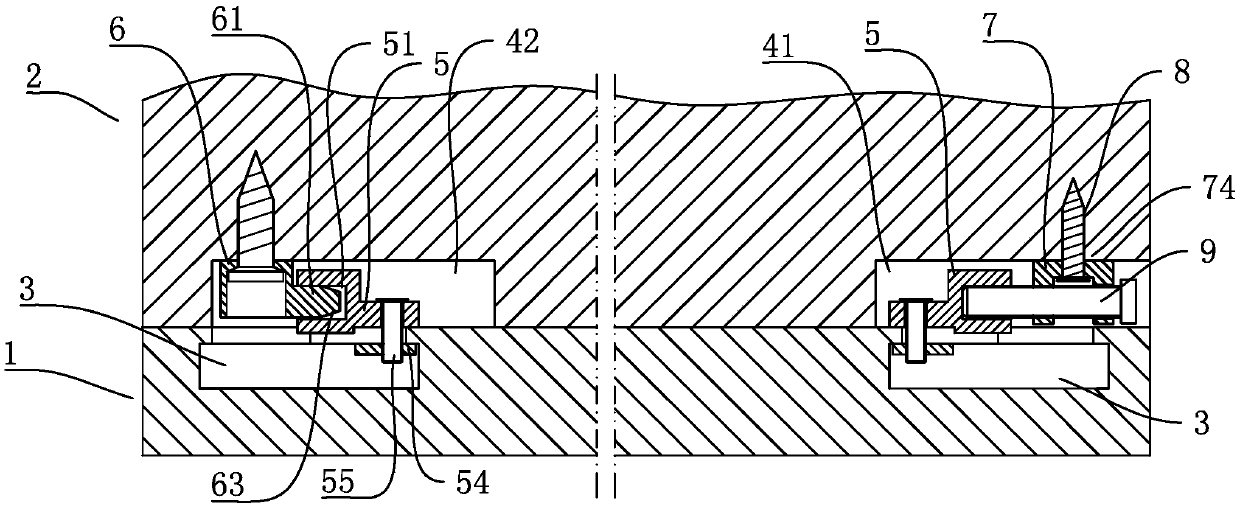

Door/window auxiliary frame and application method thereof

ActiveCN105275309AImprove insulation effectLow thermal conductivityFrame fasteningBase framesEngineeringOblique angle

The invention provides a door / window auxiliary frame, which comprises an upper frame plate, a lower frame plate, a left frame plate and a right frame plate, wherein the four frame plates are connected together. A corner formed between the two ends of each frame plate is in the form of an oblique angle with the cutting angle thereof to be 45 degrees. Adjacent frame plates are connected through the welding process. Inside each frame plate, a longitudinal slot is arranged to extend along the length direction of the frame plate. A right angle-shaped connector is inserted into the longitudinal slots of adjacent frame plates and the connector is provided with inverted teeth. The frame plates are the same in cross-sectional area. The middle part of the cross section of each frame plate is provided with a reinforcing rib and a longitudinal slot and the reinforcing rib is connected with a fixed sheet via a screw. The fixed sheet is connected with a wall body via an expansion bolt. The two sides of the cross section of each frame plate are respectively provided with a fixing slot. The lower side of the cross section of each frame plate is provided with a buckle for being connected with the fixed sheet. The application method comprises the steps of assembling the auxiliary frame, connecting the auxiliary frame with the wall body, and connecting the auxiliary frame with a door / window.

Owner:浙江中财型材有限责任公司

Compression molding fibre-reinforced straw plastic combined cabinet slab and preparation method thereof

The invention discloses a compression molding fibre-reinforced straw plastic combined cabinet slab which is prepared from the following raw materials according to parts by weight: 0.2-0.6 part of modified crop straw fibre or straw fibre wood powder thereof, 0.1-0.2 part of PET or nylon waste silk, 0.05-0.2 part of melamine, 0.05-0.2 part of modified talcum powder, 0.01-0.05 part of chemical assistant and 0.3-0.6 part of polyolefin thermoplastic resin. The invention also discloses a preparation method thereof. The cabinet slab of the invention is formaldehyde-free environment-protection material and has wood texture and handling characteristics, and the machinery mechanics strength thereof exceeds that of good-quality solid-wood slabs; and in addition, the cabinet slab does not adsorb water and has the functions of low coefficient of thermal expansion, moisture prevention, mildew prevention, aging prevention, combustion prevention, reuse and the like and is an ideal cabinet slab wood replacing material.

Owner:绍兴一普塑业有限公司

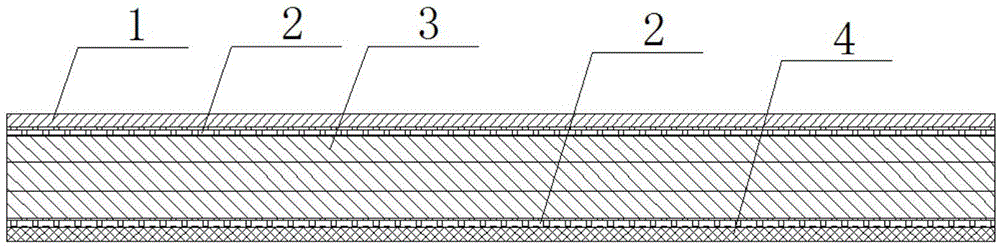

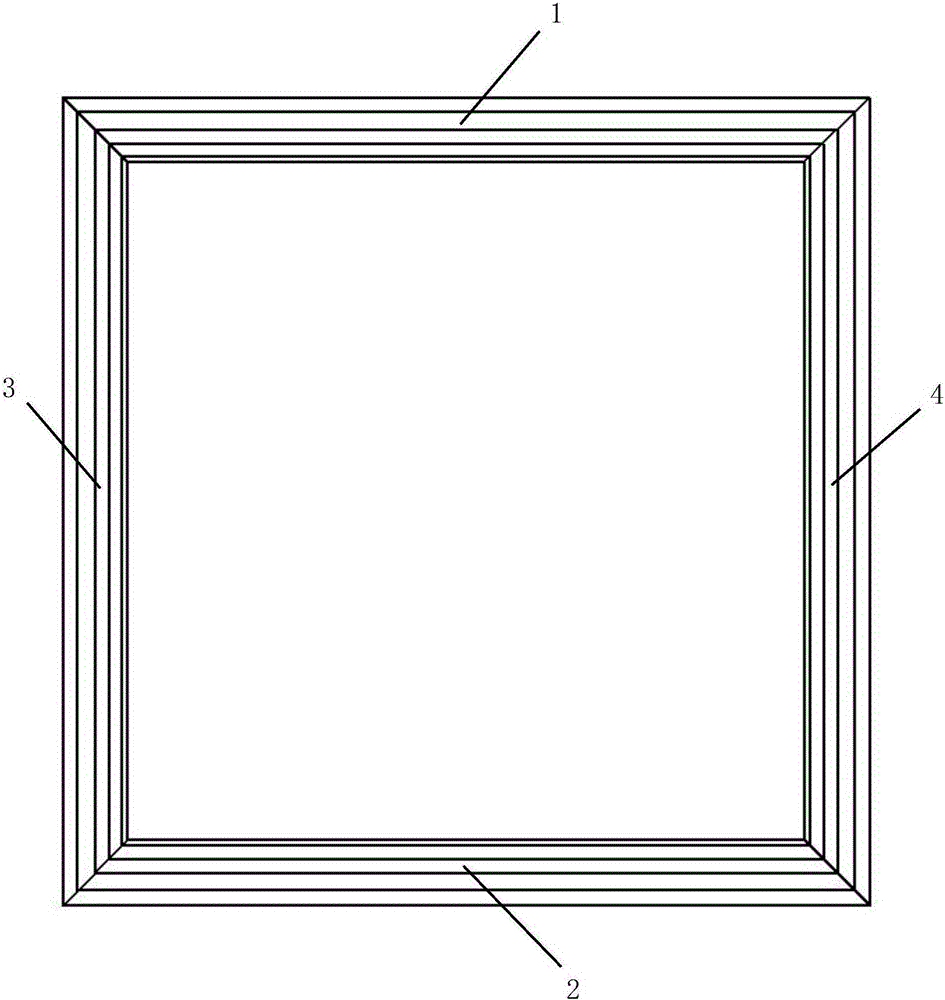

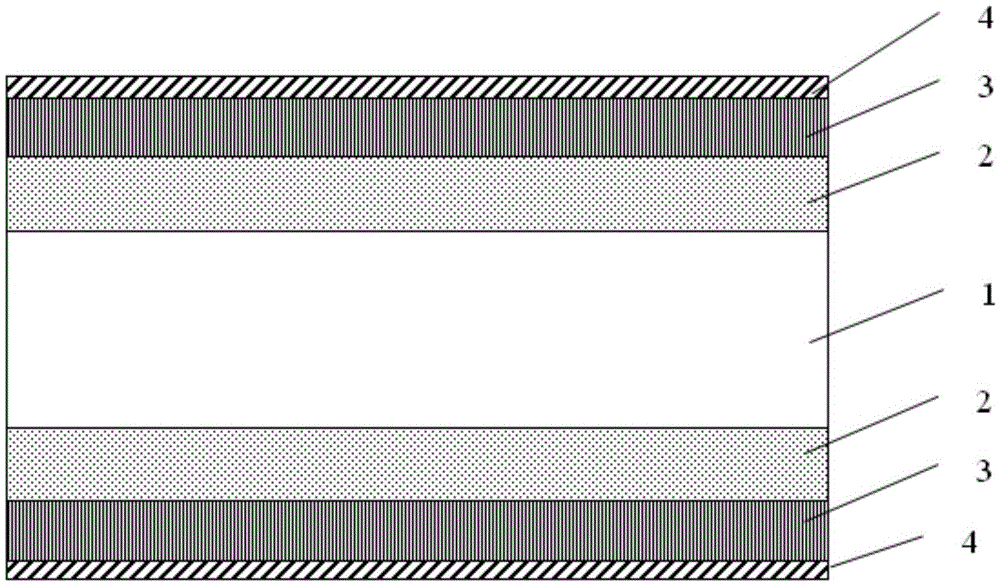

Novel solid ecological bamboo board and production process thereof

InactiveCN105415457AThe process is simple and reasonableShort production processOther plywood/veneer working apparatusWood veneer joiningEnvironmentally friendlySolid wood

The invention belongs to the field of board machining and provides a novel solid ecological bamboo board and a production process thereof. The novel solid ecological bamboo board comprises a cedarwood board core, middle boards, bamboo fiber boards and melamine impregnated paper. The upper surface and the lower surface of the cedarwood board core are covered with the middle boards through gluing and integrally pressed to form a board blank; the melamine impregnated paper is stuck to the bamboo fiber boards in a pressed mode to integrally form surface-layer substrates; the upper surface and the lower surface of the board blank are gelatinized and coated with the surface-layer substrates and integrally formed through hot pressing to obtain a finished product. The novel solid ecological bamboo board and the production process thereof have the advantages that 1, a novel assembly structure is adopted, and the hardness, nail-holding ability, static bending strength and surface evenness of the board are greatly improved; and 2, the bamboo fiber boards are adopted for the surface-layer substrates, the fracturing resistance and the thermocycling resistance of melamine ecological boards are greatly improved, and thus the melamine ecological board can meet the all-weather all-region using requirement; besides, the finished product is low in formaldehyde content, economical, environmentally friendly, and the advantages of water resistance, mould resistance, inflaming retarding, moth resistance and the like are achieved at the same time.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

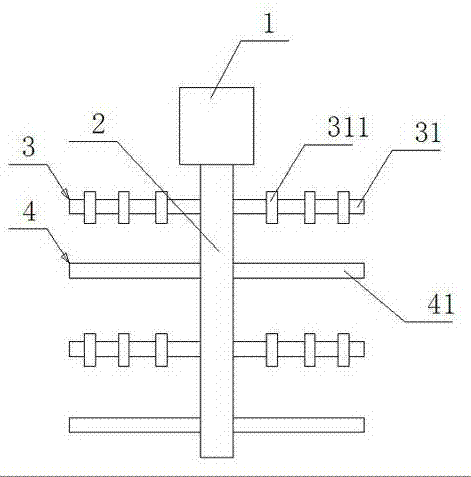

Long fiber reinforced polyolefin wood-plastic composite material and preparation method thereof

The invention discloses a long fiber reinforced polyolefin wood-plastic composite material and a preparation method thereof. The polyolefin wood-plastic composite material is composed of polyolefin resin, a long fiber reinforced polyolefin granular material or long fiber reinforced polyolefin strip material, a compatilizer, a coupling agent, wood powder and inorganic filler. The preparation method includes: subjecting the materials to mixing in a banbury mixer, then sending the material into an extruder to conduct extrusion and grain cutting or extrusion molding of product, or sending the material into an injection molding machine to perform injection molding. Adding of the long fiber reinforced polyolefin composite material provided by the invention can greatly improve the strength, stiffness, toughness, hardness and other mechanical properties of the wood-plastic composite material, thereby effectively enhancing the stiffness, toughness, surface hardness, nail-holding power and the like of wood-plastic boards and profile products. By means of the mixer, the long fiber reinforced polyolefin composite material or other recovered materials and wood powder, the inorganic filler and other materials can be mixed evenly. The wood-plastic material itself is reinforced, and has better performance and wider scope of application.

Owner:SHANDONG UNIV OF TECH

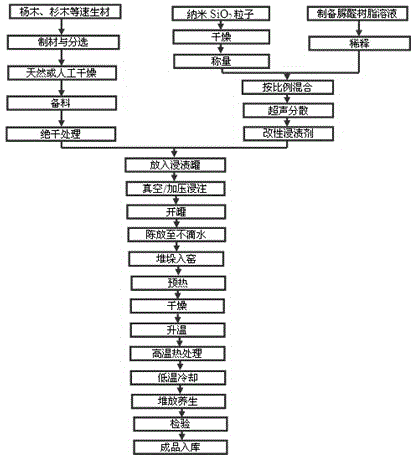

Modified fast growing wood impregnating agent and impregnation high-temperature integrated treatment method

InactiveCN105563578AThe modification effect is good in hardnessHigh hardnessPretreatment apparatusPressure impregnationHardnessAdditional values

The invention relates to a modified fast growing wood impregnating agent and impregnation high-temperature integrated treatment method. The method comprises the following steps: (1) preparing a modified urea-formaldehyde resin impregnating agent; (2) preparing the fast growing wood and treating at a preparation stage; (3) absolutely drying at a high temperature; (4) performing the impregnation and high-temperature integrated treatment; (5) aging, maintaining, inspecting and warehousing. The modified fast growing wood impregnating agent and impregnation high-temperature integrated treatment method has the advantages that: (1) a modified impregnating agent is made into a suspension by adding a nano material on the basis of the conventional urea-formaldehyde resin impregnating agent and ultrasonically stirring, the modification effect of the modified impregnating agent on the aspects such as hardness, abrasion resistance, size stability and the like is better than that of the conventional urea-formaldehyde resin impregnating agent, and the preparation process is simple, moderate in conditions and convenient to operate; (2) the physical and mechanical properties of the fast growing wood such as poplar and cedar can be well improved; the wide application of the fast growing wood can be realized, the consumption of top-grade wood can be reduced, the wood application range can be enlarged, the additional value and technical content of the fast growing wood can be increased, and the optimal application of poor wood can be realized.

Owner:GUANGDONG YIHUA TIMBER IND

Ecological wood and preparation method thereof

The invention relates to the field of ecological wood and provides ecological wood and a preparation method thereof. The ecological wood has the advantages of good waterproof and moisture-proof effects, no harmful substances such as formaldehyde, methylbenzene and the like, good flame-retardant effect, small smoke production volume, good ductility, toughness and impact resistance, recyclability, acid / alkali corrosion resistance and long service life. The ecological wood comprises the following ingredients in parts by weight: 60-70 parts of chloride-vinegar copolymer resin, 9-11 parts of impact modifier, 20-30 parts of plant fiber, 1-3 parts of coupling agent, 10-20 parts of smoke inhibitor, 5-15 parts of activated clay, 0.5-1.5 parts of lubricant, 4-6 parts of activator, 8-10 parts of environment-friendly flame retardant, 4-8 parts of heat stabilizer, 0.5-1.5 parts of odorless crosslinker, 1-5 parts of foaming agent and 1-5 parts of deammoniation agent. The ecological wood is prepared in a manner that all the ingredients are subjected to pretreatment by the plant fiber, mixing by a closed mixer, cooking by an open mixer, tabletting by a tabletting machine and closed-pore foaming in a mold, cooling and mold stabilizing.

Owner:YIBAO FUJIAN POLYMER MATERIALS

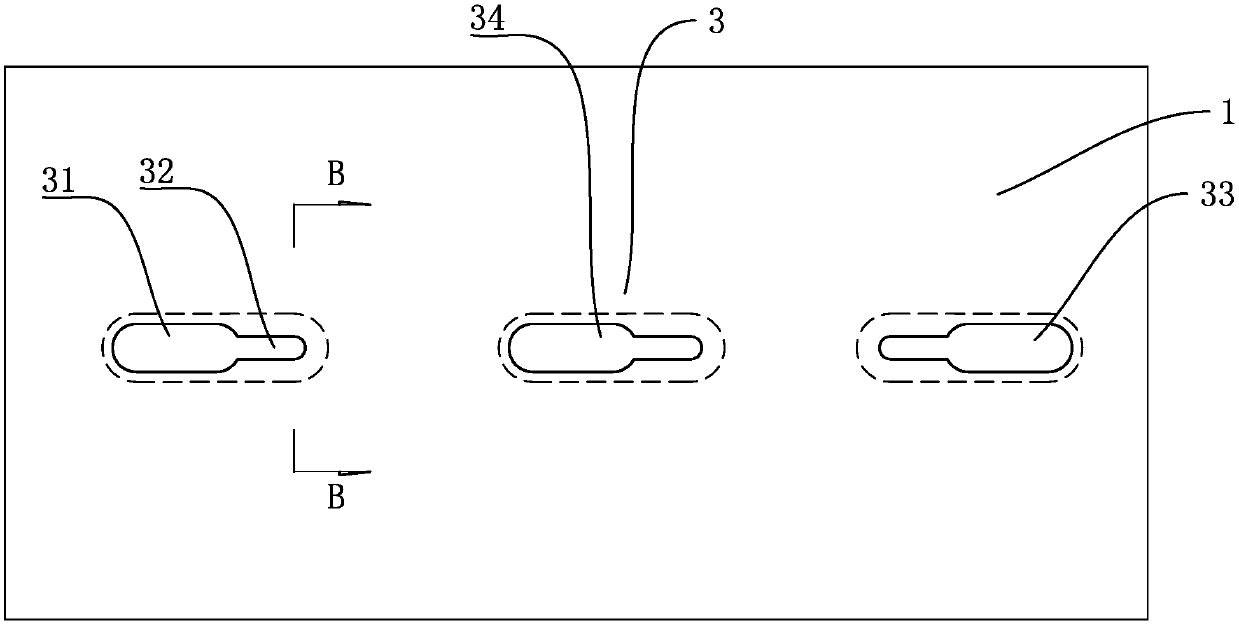

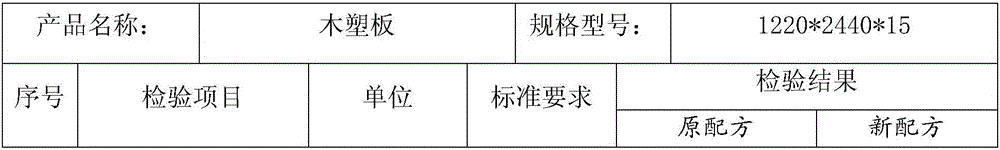

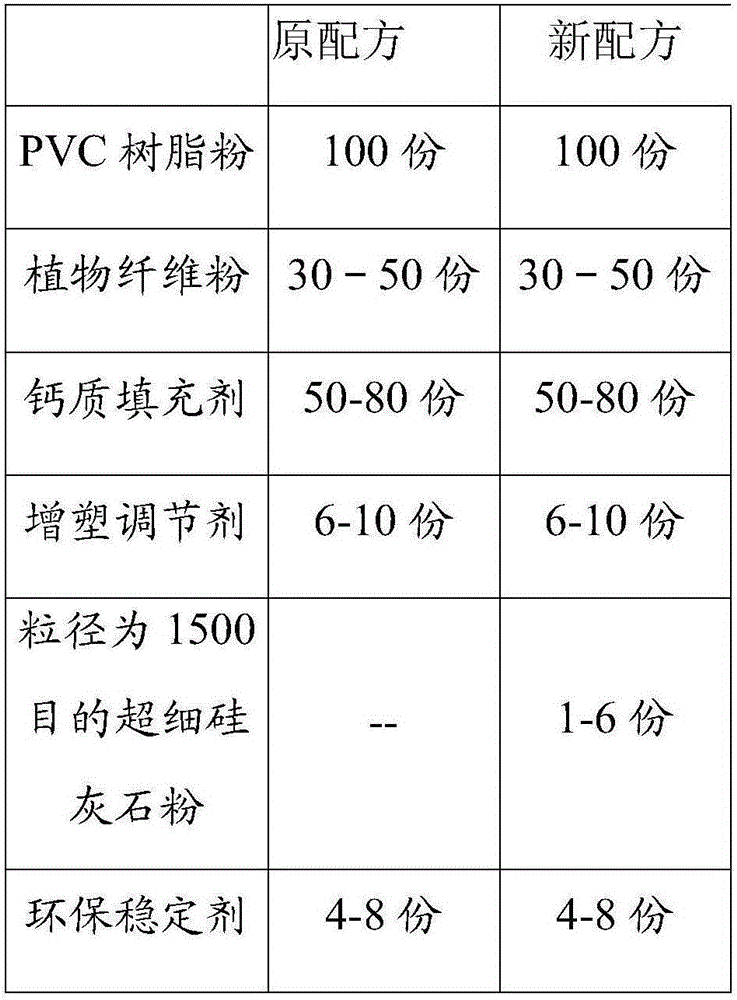

Wood-plastic plate and production process

The invention discloses a wood-plastic board, which is composed of raw materials in the following weight ratios: PVC resin powder: 100 parts; plant fiber powder: 25-60 parts; calcium filler: 40-90 parts; plasticizing regulator: 0.5 ‑5 parts; processing aid superfine wollastonite powder: 0.5‑5 parts; environmental stabilizer: 3‑9 parts; ACR processing aid: 3‑12 parts; foaming agent: 0.5‑4 parts; internal and external lubricants: 0.5-3.5 parts, the particle size of the superfine wollastonite powder is at least 1500 mesh, and the upper material is mixed, heated, shaped and cut. The invention also discloses a production process. It is environmentally friendly, low in cost, and the cut surface of the product is neat, dense and free of pores, and its hardness, strength, and nail holding force are higher than the national standard, which can meet the effects of various post-processing requirements of the product.

Owner:SHANDONG XIAGUANG INDAL

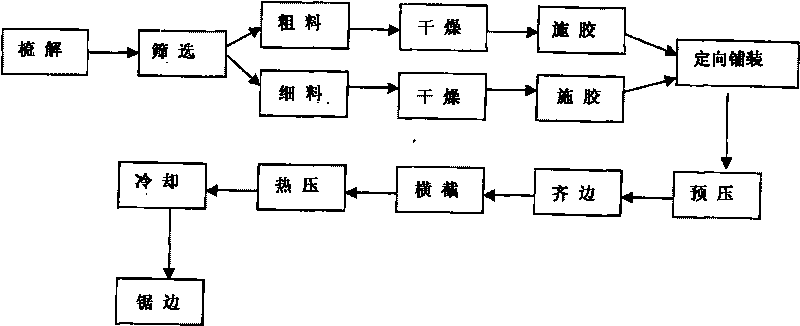

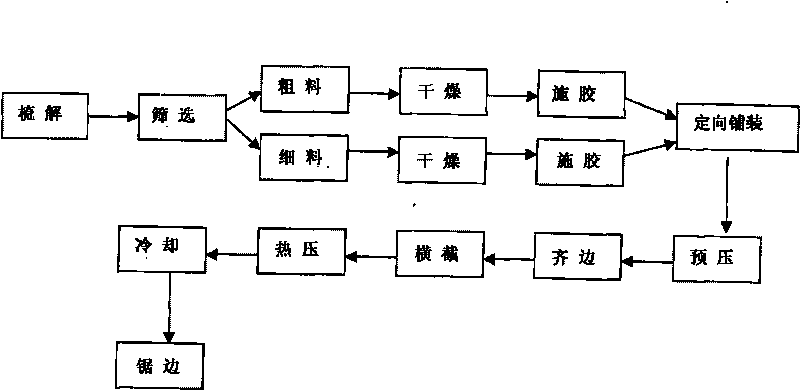

Technology for manufacturing glulam

InactiveCN101745964AGuaranteed flatnessIncrease usageDomestic articlesFlat articlesPulp and paper industryHigh intensity

The invention discloses a technology for manufacturing glulam, comprising the following steps: scrimming; sieving fine material and coarse material; drying fine material and coarse material respectively and glue blending; orientated lay-up, respectively laying up two fine wood stick layers on front face and back face of a coarse wood stick layer to manufacture a slab; and hot-pressing the slab to form a sheet. According to the technology, leftover material of waste wood is rolled and scrimmed to the fine wood stick layers and the coarse wood stick layer, which are then dried, glue-blended and orientated-laid, respectively, the two fine wood stick layers are laid up on the front and back faces of the coarse wood stick layer, which can not only ensure flatness on the surface of the sheet, but can also make full use of the leftover material of waste wood, thus the utilization rate of woods is enhanced; in addition, the technology with simple production process can manufacture integrated sheet having high strength and nail-holding ability, without paying attention to the processing precision of wood sticks.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

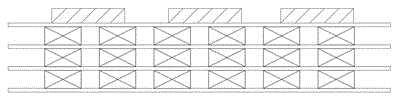

Three-layer structure wooden composite board material and mfg method

InactiveCN1502464AGood board qualityThe product has high environmental protection performanceWood layered productsStructural unitAdhesive

The present invention relates to a three-layer structure wooden composite plate material and its production method, belonging to the field of building decorative technology. Said composite plate material is formed from surface layer and core layer, in which the core layer material formed from flat structure unit adopts wood material, bamboo material and straw, and said flat structure unit size is: length 45-110 mm, width 10-50 mm and thickness is 0.1-1 mm, and the thickness of core layer is 21-91% of that of plate material. Said surface layer material is made up by selecting fibre or particle structure unit, and adopting the procedures of preparing material, laying-forming, pre-pressing and hot-pressing. The adhesive used by core layer is isocyanate adhesive. Said invention also provides the steps of laying, forming process.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Timber wood hot pressing charing intensification method

ActiveCN101214675BUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationMechanical property

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

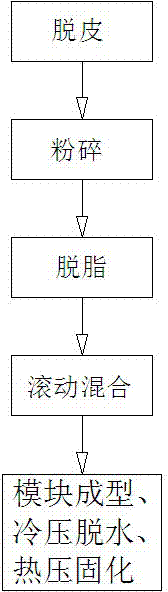

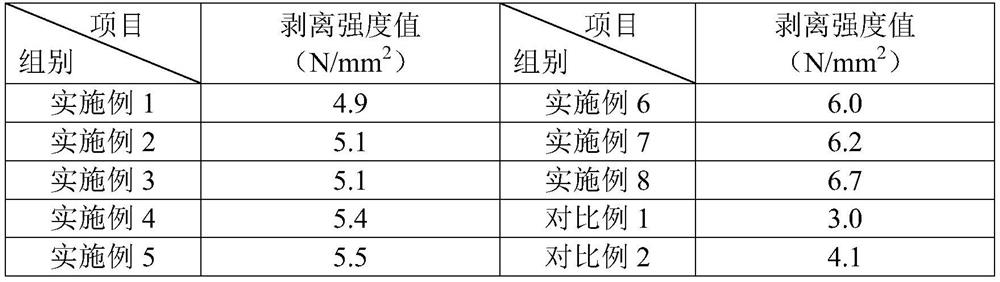

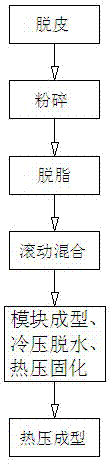

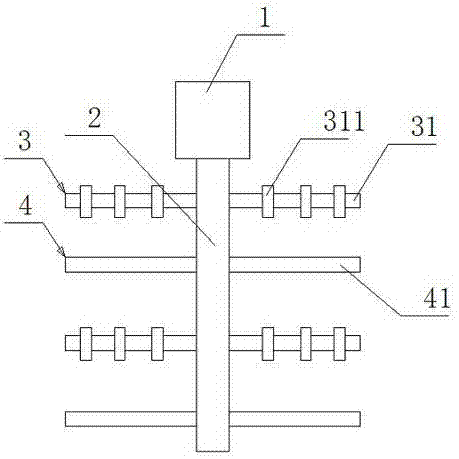

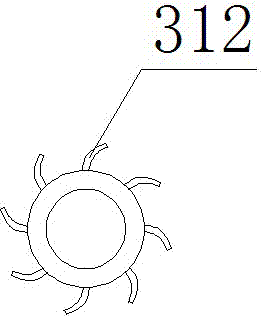

Recyclable environment-friendly mulberry fiber board

The invention relates to the board technology, in particular to a recyclable environment-friendly mulberry fiber board. Mulberry fibers and sheet-shaped mulberry trunks are in hot press molding through adhesives. The production method comprises the steps that (1) a mulberry tree is peeled, so that mulberry bark and a mulberry trunk are obtained; (2) the mulberry bark is smashed after being dehydrated to obtain the mulberry fibers, and the mulberry trunk is smashed after being dehydrated to obtain the sheet-shaped mulberry trunks; (3) the mulberry fibers and the sheet-shaped mulberry trunks are subjected to ungrease treatment, and then washing, filtering and drying are conducted; (4) the degreased mulberry fibers and the sheet-shaped mulberry trunks are mixed in a rolling mode, acrylic emulsion is added, rolling mixing and preheating are conducted, and then an anti-caking modifying agent and a curing agent are added; (5) modularization forming is conducted on the mixture in the fourth step, and then cold pressing dehydration and hot pressing solidifying are carried out. According to the recyclable environment-friendly mulberry fiber board, raw material supply of goods is sufficient, collecting is convenient, cost is low, the processing technology is simple, compared with a fiber plate in the current market, the nail-holding ability is improved substantially, the moisture proof performance is obviously improved, the board can be recycled after being smashed, and the board is more economical and environmentally friendly.

Owner:HUZHOU YOULUO NEW MATERIAL TECH

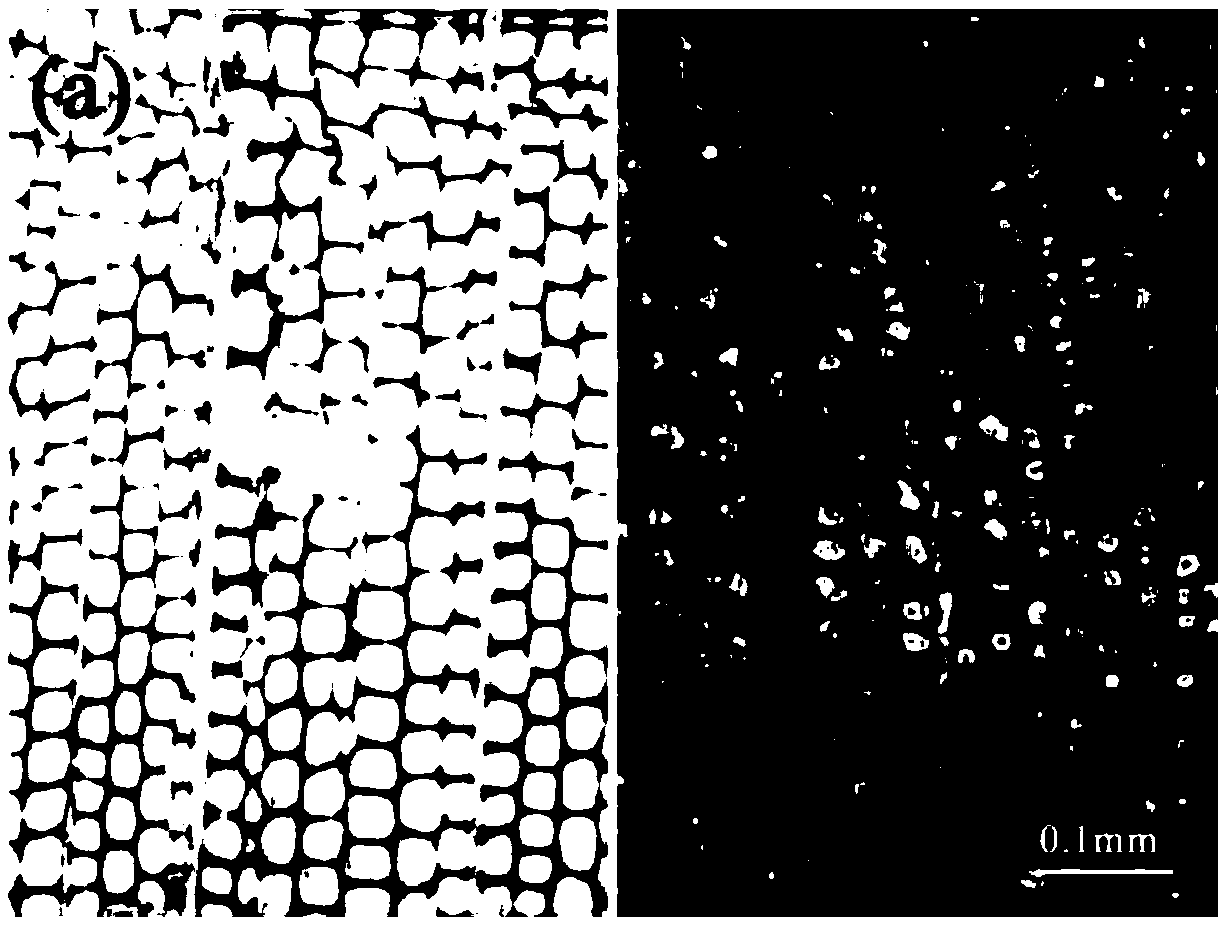

Ultra-light-weight composite environment-friendly fiber board and preparing method of ultra-light-weight composite environment-friendly fiber board

The invention discloses an ultra-light-weight composite environment-friendly fiber board and a preparing method of the ultra-light-weight composite environment-friendly fiber board, and belongs to the technical field of an ultra-light-weight fiber board. The ultra-light-weight composite environment-friendly fiber board is characterized by comprising an upper flame-retardant wood fiber layer, a lower flame-retardant wood fiber layer and a wood fiber and expanded perlite mixing layer arranged between the upper and lower flame-retardant wood fiber layers. The invention also discloses the preparing method of the ultra-light-weight composite environment-friendly fiber board. The ultra-light-weight composite environment-friendly fiber board has a series of advantages that the supporting capacity of a high-rise building partition wall is effectively reduced; the strength of the wall surface is enhanced; the properties such as the impact-resistant property, the folding-resistant property and the nail holding force are good; the heat insulation function, the fireproof function, the sound isolation function, the anti-seismic function and the aging-resistant effect are achieved; the secondary wall surface decoration is convenient; and the attaching force of a decoration surface is strong, and the like.

Owner:河南鑫饰板业有限公司

Treatment method of enhancing wood performance by quick dense carbonization

PendingCN109366670ANo deformationNo crackingWood treatment detailsWood charring/burningCarbonizationVolumetric Mass Density

The invention relates to a treatment method of enhancing wood performance by quick dense carbonization. The treatment method comprises the following steps: (1) drying wood; and (2) placing the wood toa stainless steel electric heating plate, placing a perforated metal plate on the wood, heating, pressing and compacting the wood, wherein the compaction ratio of the wood is controlled at 6-25%, keeping the pressure state for thermal treatment for 1-30 min, and cooling and depressurizing the wood to obtain the dense carbonization enhanced wood. According to the treatment method provided by the invention, compact densification of the wood is achieved while the wood is carbonized, and the density of the wood is increased, so that the surface hardness and the bending strength of wood are enhanced, that is, the mechanical properties of the wood are improved.

Owner:贵州省林业科学研究院 +1

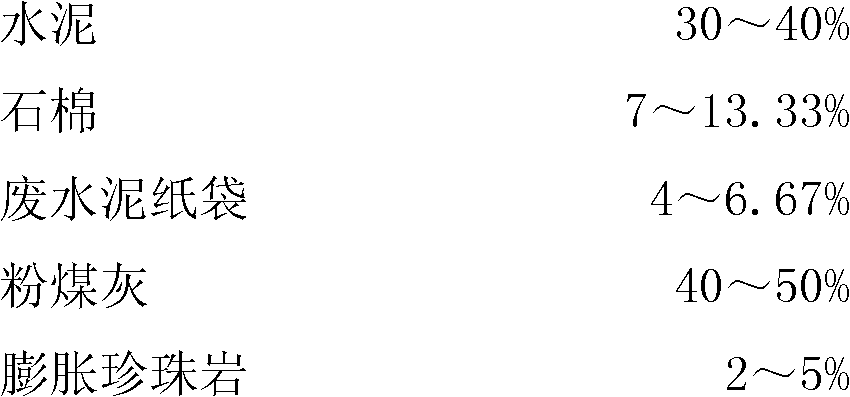

Fiber-reinforced fly ash pressure plate and manufacturing method

The invention relates to a fiber-reinforced fly ash pressure plate and its manufacturing method. Composed of cement, asbestos, waste cement paper bag, fly ash, and expanded perlite, the fly ash pressure plate is prepared by the processes of: pulping, releasing, beating, pulp storage, pulp discharge, pulp flow, vacuum pumping, molding, cold pressing pressurization, precuring, demoulding, autoclaving, drying, sanding, edging and chamfering. The invention provides the fiber-reinforced fly ash pressure plate with the advantages of rich raw material sources, low cost, environment friendliness, high density, great nail-holding power, good strength as well as good processability and its preparation method.

Owner:江苏康辉硅酸钙板有限公司

Method for improving mechanical properties of gypsum-based material

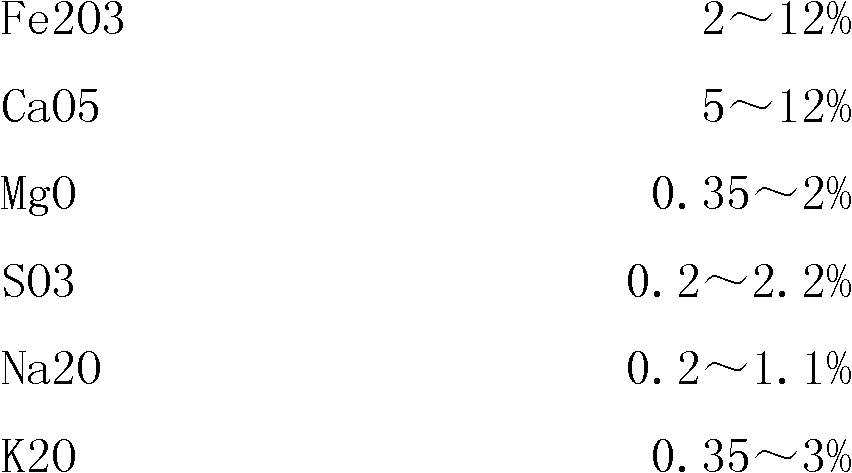

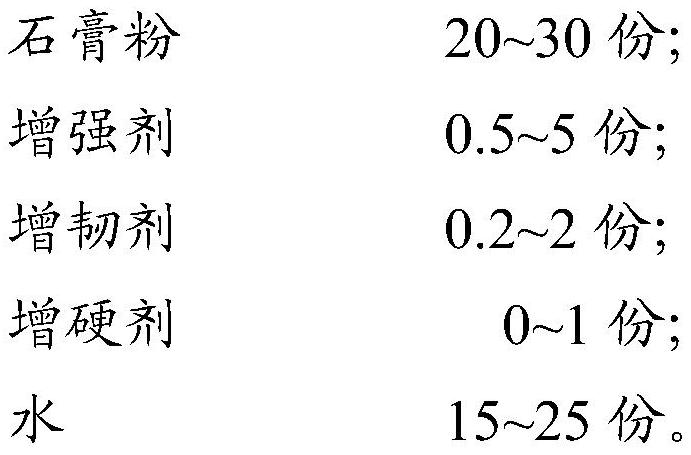

ActiveCN112408936AImprove mechanical propertiesHigh flexural strengthSolid waste managementSodium silicateAcrylic acid

The invention belongs to the field of building materials, and relates to a method for improving the mechanical property of a gypsum-based material. The method comprises the following steps that: a) gypsum powder, a reinforcing agent, a toughening agent, a hardening agent and water are mixed to obtain gypsum slurry, wherein the reinforcing agent comprises an acrylic polymer, polyisocyanate polyester, polyalkyd resin and the like, wherein the toughening agent comprises glass fibers, paper fibers and wood fibers, and the hardening agent comprises sodium silicate, quartz powder and sand; and b) solidifying and molding the gypsum slurry, and then performing drying to obtain the high-strength gypsum-based material. According to the method provided by the invention, the reinforcing agent, the toughening agent and the hardening agent of specific types are doped into the gypsum, so that the breaking strength, hardness and shearing strength of the gypsum-based material are greatly improved. Withthe method adopted, the problem of poorer mechanical property of a traditional gypsum-based material can be solved; the mechanical strength and nail-holding power of the prepared gypsum-based material can be comparable with those of a blockboard, and the gypsum-based material has a higher fireproof grade than the blockboard.

Owner:TAISHAN GYPSUM CO LTD

Chlorosulfonated polyethylene rubber/biomass composite plate and making method thereof

InactiveCN106398264AImprove the phenomenon of easy separation and agglomeration with rubberImprove mechanical propertiesPolymer scienceN-Propyl alcohol

The invention discloses a chlorosulfonated polyethylene rubber / biomass composite plate. The chlorosulfonated polyethylene rubber / biomass composite plate is characterized by being made from the following raw materials: rice straw, wheat straw, a sodium hydroxide solution, n-propyl alcohol, maleic anhydride, azodiisobutyronitrile, acetone, styrene, N,N-dimethyl-4-pyridylamine, montmorillonoid, sodium hexametaphosphate, cocamidopropyl betaine, vinyl triethoxysilane, chlorosulfonated polyethylene rubber, zinc oxide, dipentamethylenethiura tetrasulfide, imarcaptoacetate dioctyltin, a proper amount of hydrochloric acid solution and a proper amount of deionized water. The made chlorosulfonated polyethylene rubber / biomass composite plate has the advantages of stable size, wear resistance, corrosion resistance, nailing, sawing and pivoting properties, waterproofness, mold resistance, worm damage resistance, wide application and the like.

Owner:凤台县双利生物科技有限公司

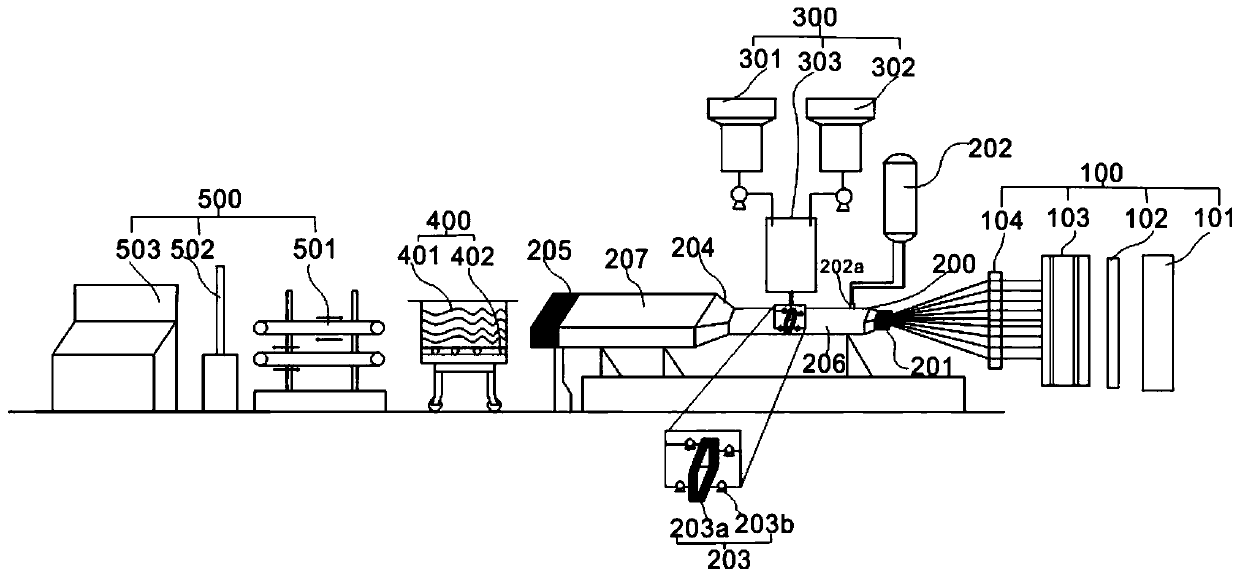

Continuous glass fiber reinforced polyurethane microporous foaming profile pultrusion process and product and pultrusion system thereof

The invention discloses a continuous glass fiber reinforced polyurethane microporous foaming profile pultrusion process and a product and a pultrusion system thereof. The continuous glass fiber reinforced polyurethane microporous foaming profile comprises the following components of, in parts by mass, 70-80 parts of polyether polyol, 15-20 parts of polyester polyol, 1-3 parts of crosslinking agent, 0.5-1.5 parts of catalyst, 1-3 parts of surfactant, 1-4 parts of microcrystalline cellulose, 0.2-3 parts guanidine oligomer and 95-105 parts of isocyanate; and the reinforcing material adopts continuous glass fiber after surface activation pretreatment. According to the continuous glass fiber reinforced polyurethane microporous foaming profile pultrusion process and the product and the pultrusion system thereof, the problem of high-speed curing polyurethane glue dipping is solved, the polyurethane is fully foamed under the pressure-free state to obtain the microporous foaming polyurethane profile which is light, high in strength, high in toughness, high in holding nail force and capable of be permanently flame-retardant, antibacterial, mildew-proof and corrosion-proof, the profile can beused for high-speed railway sleepers, and the process is the only technology capable of realizing continuous fiber reinforced polyurethane pultrusion microporous foaming.

Owner:NANJING RONGSHIJING COMPOSITE MATERIAL +1

Compression molding fibre-reinforced straw plastic combined cabinet slab and preparation method thereof

The invention discloses a compression molding fibre-reinforced straw plastic combined cabinet slab which is prepared from the following raw materials according to parts by weight: 0.2-0.6 part of modified crop straw fibre or straw fibre wood powder thereof, 0.1-0.2 part of PET or nylon waste silk, 0.05-0.2 part of melamine, 0.05-0.2 part of modified talcum powder, 0.01-0.05 part of chemical assistant and 0.3-0.6 part of polyolefin thermoplastic resin. The invention also discloses a preparation method thereof. The cabinet slab of the invention is formaldehyde-free environment-protection material and has wood texture and handling characteristics, and the machinery mechanics strength thereof exceeds that of good-quality solid-wood slabs; and in addition, the cabinet slab does not adsorb water and has the functions of low coefficient of thermal expansion, moisture prevention, mildew prevention, aging prevention, combustion prevention, reuse and the like and is an ideal cabinet slab wood replacing material.

Owner:绍兴一普塑业有限公司

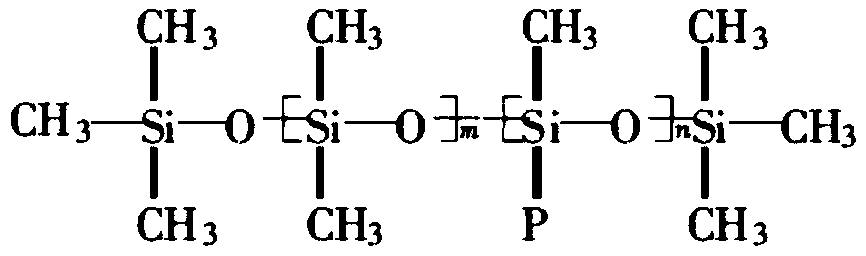

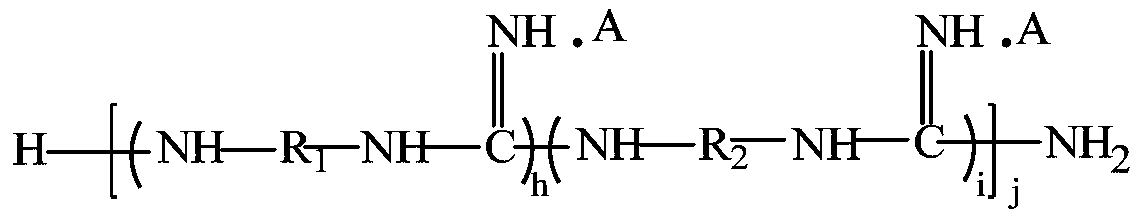

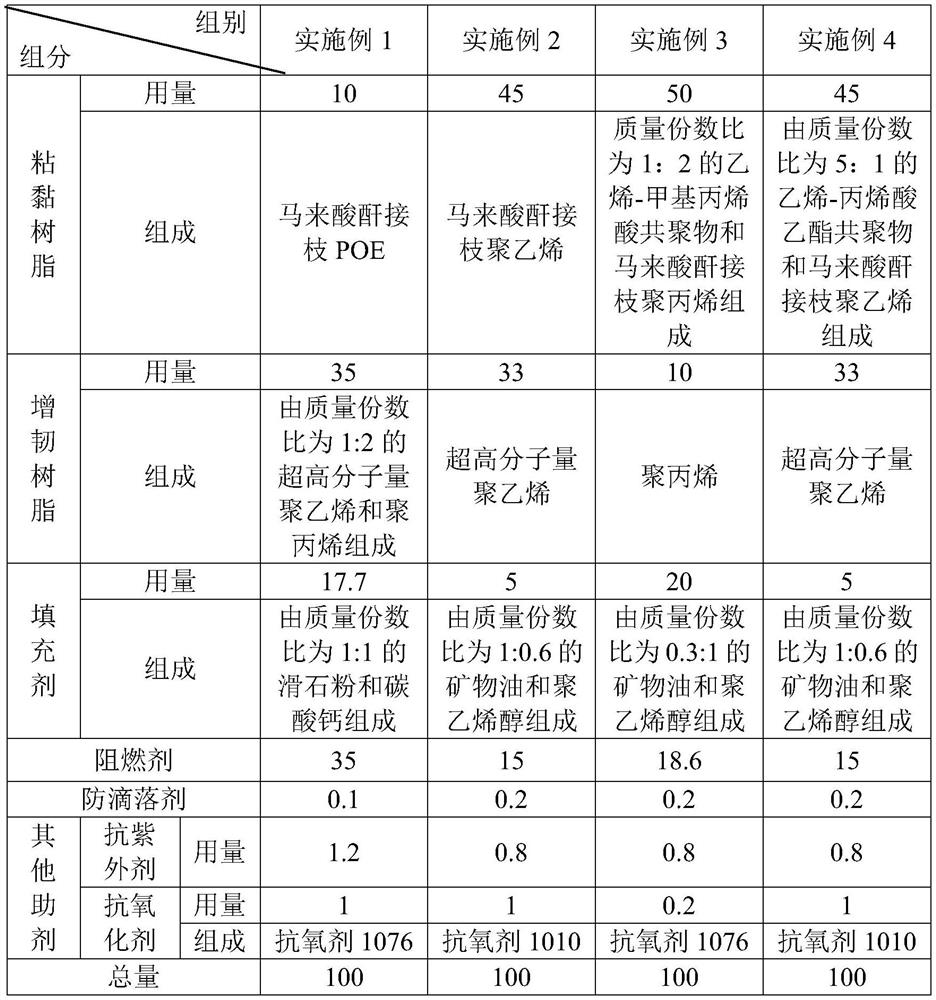

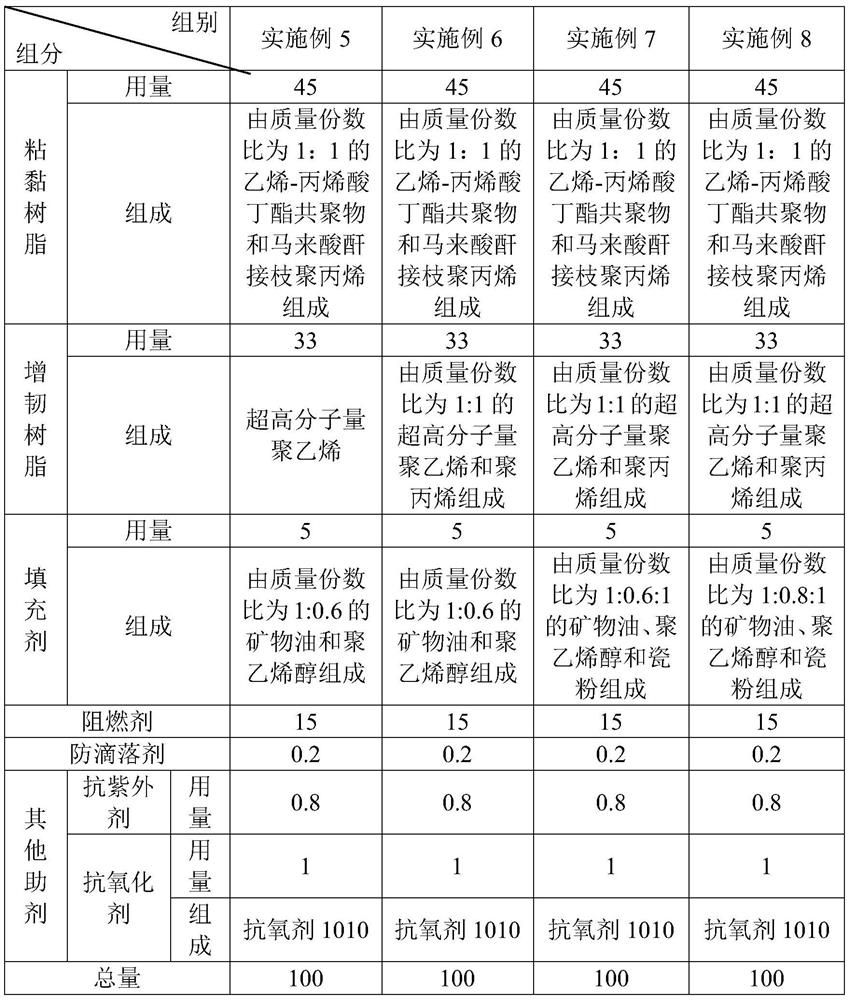

Wood-like flame-retardant plastic-coated aluminum profile and preparation method thereof

The invention relates to the field of plastic-coated aluminum profiles, and particularly discloses a wood-like flame-retardant plastic-coated aluminum profile and a preparation method thereof. The wood-like flame-retardant plastic-coated aluminum profile is composed of an aluminum profile and a coating layer outside the aluminum profile, wherein the coating layer is composed of the following components in percentage by weight: 10-50% of adhesive resin, 10-35% of toughening resin, 5-20% of a filler, 15-35% of a flame retardant, 0.1-1% of an anti-dripping agent and 0.4-2.3% of other auxiliary agents, wherein the adhesive resin is at least one selected from a polyethylene copolymer and maleic anhydride-grafted polyolefin; and the toughening resin is at least one selected from ultra-high-molecular-weight polyethylene and polypropylene. The plastic-coated aluminum profile has the advantages that bonding force between the coating layer and the aluminum profile is improved, and therefore, thenail-holding force of the overall structural strength of the plastic-coated aluminum profile is improved.

Owner:NINGBO HELONG NEW MATERIAL

Mulberry fiber composite board

ActiveCN103612314ASufficient supplyEasy to collectFlat articlesDomestic articlesPolymer scienceAdhesive

The invention relates to the board technology, in particular to a mulberry fiber composite board. The mulberry fiber composite board comprises a mulberry fiber base plate and a face plate fixed on the mulberry fiber base plate. The mulberry fiber base plate comprises mulberry fibers and sheet-shaped mulberry trunks, and the mulberry fibers and the sheet-shaped mulberry trunks are in hot press molding through adhesives. The production method comprises the steps that (1) peeling is carried out, so that mulberry bark and a mulberry trunk are obtained; (2) smashing is carried out, so that the mulberry fibers and the sheet-shaped mulberry trunks are obtained; (3) ungrease treatment, washing, filtering and drying are conducted; (4) mixing is carried out in a rolling mode, acrylic emulsion is added, preheating is conducted, and then an anti-caking modifying agent and a curing agent are added; (5) modularization forming is achieved to obtain the mulberry fiber base plate; (6) the mulberry fiber base plate and the face plate are subjected to sizing treatment and then are molded in a hot press mode. According to the mulberry fiber composite board, raw material supply of goods is sufficient, collecting is convenient, cost is low, the processing technology is simple, and the mulberry fiber base plate and the face plate are combined. Compared with a single fiber plate, the nail-holding ability and the bending strength are improved substantially, the moistureproof performance is obviously improved, and the surface of the board is also flatter and more smooth.

Owner:HUZHOU YOULUO NEW MATERIAL TECH

Bamboo charcoal plate and manufacturing method thereof

InactiveCN105647219AStrong ability to adsorb formaldehydeImprove nail holding powerBamboo charcoalMaterials science

The invention provides a bamboo charcoal plate and a manufacturing method thereof. The bamboo charcoal plate is prepared from the following raw materials in parts by mass: 30 to 100 parts of absorbing substrates formed by mixing charcoal powder and bamboo fine fiber powder, and 10 to 130 parts of resin base materials. The bamboo charcoal plate provided by the invention comprises raw materials of bamboo fine fiber powder; the bamboo charcoal has high formaldehyde absorbing capability; in addition, a certain degradation effect is also achieved on formaldehyde, so that the absorbing effect of the bamboo charcoal plate on harmful gas is improved; when 50 to 100g of bamboo charcoal is put into per cubic meter of space, the adsorption rate on the formaldehyde within 12 hours can reach 33 percent. In addition, the nail-holding power and the toughness effect can be improved by the bamboo charcoal.

Owner:赵星安

Glass mat gypsum board and preparation method thereof

The invention discloses a glass mat gypsum board. The glass mat gypsum board comprises a board core and a glass mat, wherein the glass mat wraps the board core; the board core is prepared from a gypsum clinker, an anionic surfactant, cellulose ether, chopped glass fibers, a modified emulsion, a mildew preventive, a water reducing agent and water; and in the preparation process of the glass mat gypsum board, the chopped glass fibers are uniformly mixed with the anionic surfactant, the cellulose ether and the water at first. The gypsum board provided by the invention does not need starch as an adhesive, so the possibility of mildew of the gypsum board is greatly reduced. A glass fiber mat is good in air permeability, so moisture is more volatile in the drying process, drying time in the production process of the board is shortened, energy consumption is reduced, and production efficiency is improved. In addition, the gypsum board is high in strength, good in toughness, resistant to water, fire and mildew, small in damp deformation and high in weather resistance, and can be used in a humid environment and a building outer wall.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

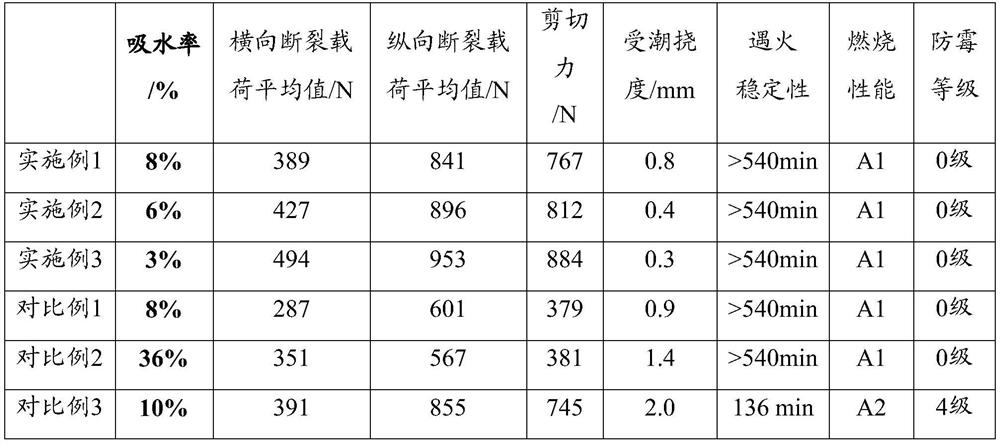

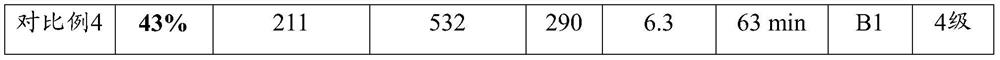

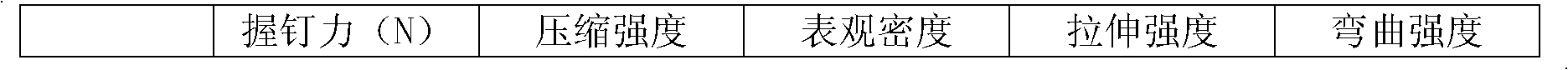

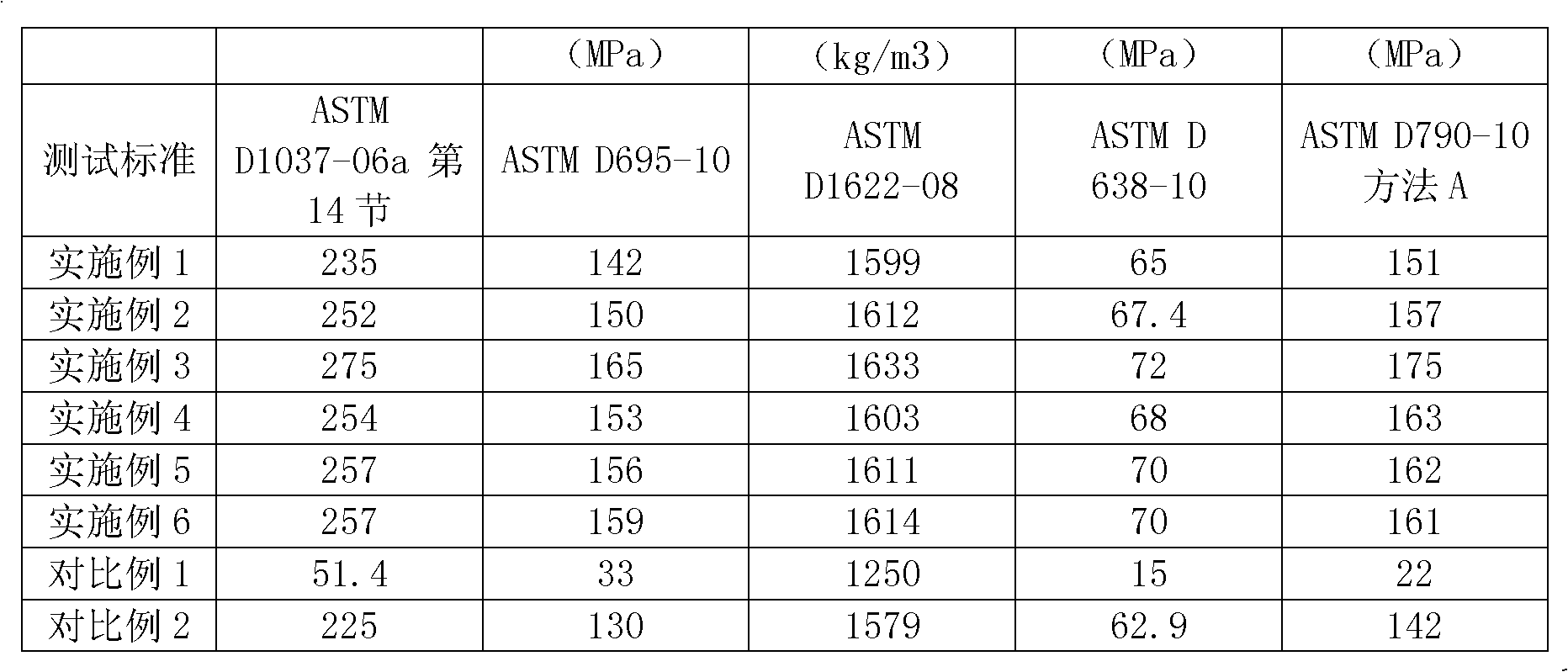

High-strength non-combustible decoration plate and preparation method thereof

InactiveCN102423931AHigh strengthImprove nail holding powerSynthetic resin layered productsPaper/cardboard layered productsApparent densityFlexural strength

The invention discloses a high-strength non-combustible decoration plate. A preparation method comprises the following steps of: impregnating kraft paper into phenolic resin, alternately superposing the kraft paper and a substrate to form a sandwich structure, and performing hot-press forming by using a hot press. The properties such as nail-holding power, compression strength, tensile strength, bending strength and the like of the high-strength non-combustible decoration plate are obviously improved, the decoration plate has high compactness, and the apparent density is improved by over 25 percent.

Owner:宁波奥尔迪装饰材料有限公司

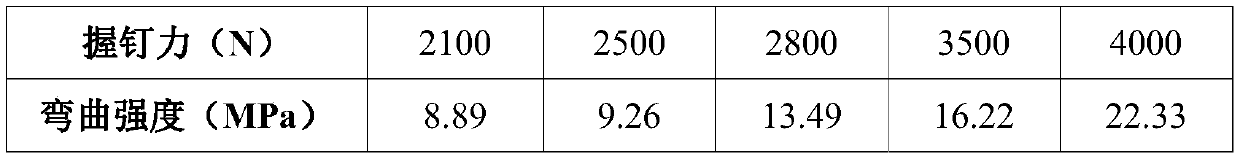

High-strength rigid foam core board and preparation method thereof

The invention discloses a high-strength rigid foam core board and a preparation method thereof. The preparation method of the high-strength rigid foam core board comprises the following steps that (1)a forming mold is manufactured, fiber felts are fixed to the bottom and the top of the mold, and a stereoscopic fiber skeleton is arranged in the mold; and (2) a polyurethane base material and a foaming agent are injected into the forming mold after mixing evenly, and the mold is closed for foam forming. The high-strength rigid foam core board is large in nail holding force, high in strength, less in mass and good in heat preservation and sound insulation effects, the density of a foam layer is small, the preparation process is simple, and the high-strength rigid foam core board can directlyreplace wooden boards, plastic plates and metal plates after being bonded with surface layer materials.

Owner:广州粤齐复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com