Wood-like flame-retardant plastic-coated aluminum profile and preparation method thereof

A technology of plastic-clad aluminum and aluminum profiles, applied in the direction of coating, etc., can solve the problems of separation between cladding layer and aluminum profile, poor adhesion between aluminum profile and cladding layer, affecting appearance and use, and achieve the goal of reducing separation Possibility, taking into account the imitation wood texture, the effect of light weight and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

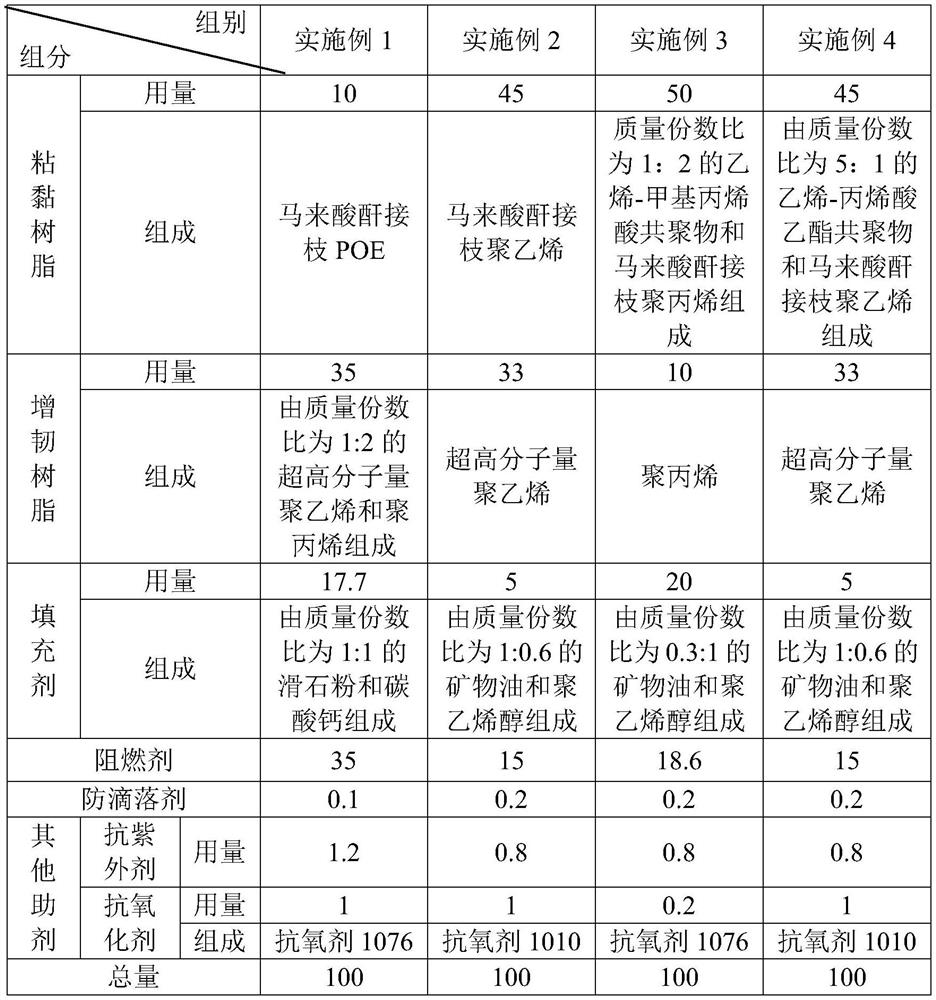

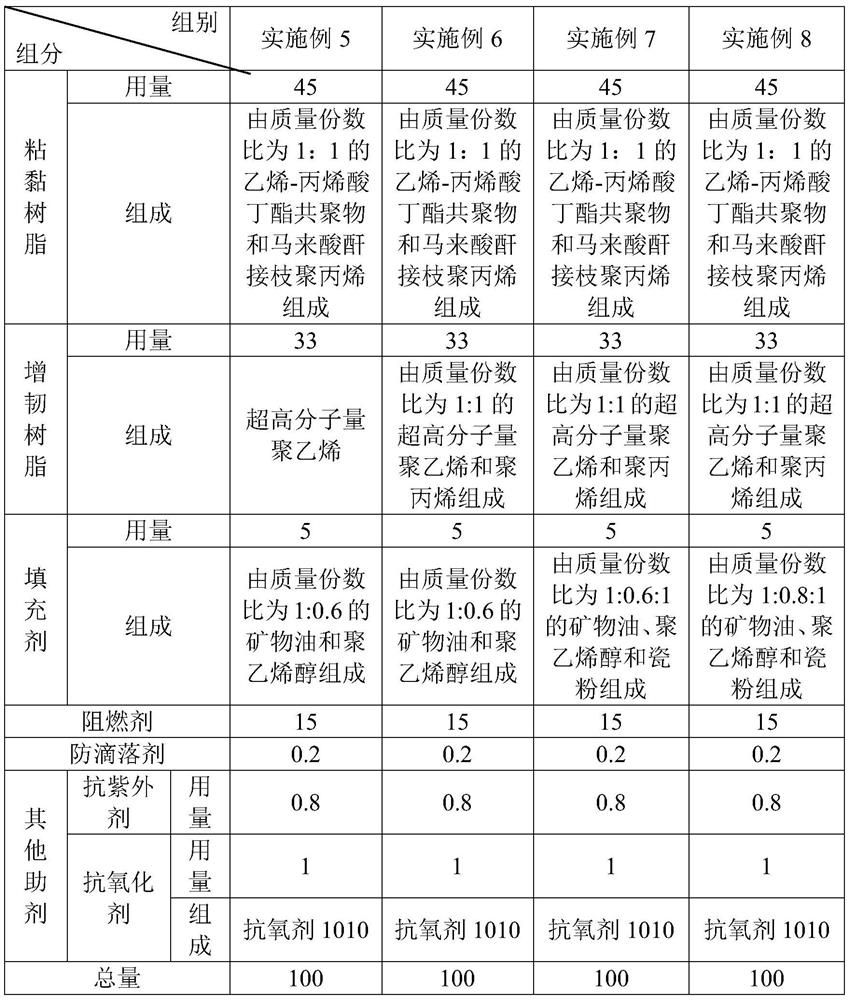

[0039] Embodiment 1-8: A wood-like flame-retardant plastic-clad aluminum profile, which is composed of an aluminum profile and an external cladding layer. The components, specific composition and corresponding quality included in the coating layer in Examples 1-4 are shown in Table 1.1; the components, specific composition and corresponding quality included in the coating layer in Examples 5-8 are shown in Table 1.2, and prepared by the following steps:

[0040] Examples 1-6 Filler preparation: put all the raw materials into a stirred tank, and stir for 10 min at 30° C. at a stirring speed of 100 r / min to obtain a filler.

Embodiment 7-8

[0041] Example 7-8 Filler preparation: add mineral oil and polyvinyl alcohol to the stirring tank at 30°C, stir for 5 minutes at a stirring speed of 100r / min, then add porcelain powder, and stir at a stirring speed of 500r / min After 10 minutes, the filler was obtained.

[0042] S1: Add adhesive resin, toughening resin, flame retardant and other additives to the stirring tank at 25±2°C, stir for 5 minutes under the condition of 30r / min, then add filler, continue stirring for 10 minutes, and then put it into The granulation equipment is granulated to obtain the coating material, which is used for later use;

[0043] S2: Add the cladding material to the co-extrusion hopper, the screw extrusion is divided into five heating sections, the temperature is 150°C-170°C-190°C-200°C-220°C, the aluminum profile is heated to 120°C, and the The auxiliary material is melted and extruded to the outer surface of the heated aluminum profile to obtain a plastic-clad aluminum profile.

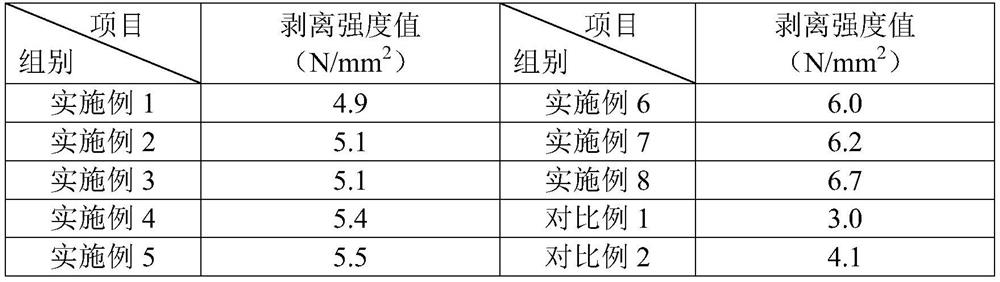

[0044] T...

Embodiment 9

[0051] Embodiment 9: A method for preparing wood-like flame-retardant plastic-clad aluminum profiles, comprising the following steps:

[0052] Examples 1-6 Filler preparation: put all the raw materials into a stirred tank, and stir for 10 min at 30° C. at a stirring speed of 100 r / min to obtain a filler.

[0053] Example 7-8 Filler preparation: add mineral oil and polyvinyl alcohol to the stirring tank at 30°C, stir for 5 minutes at a stirring speed of 100r / min, then add porcelain powder, and stir at a stirring speed of 500r / min After 10 minutes, the filler was obtained.

[0054] S1: Add adhesive resin, toughening resin, flame retardant and other additives to the stirring tank at 25±2°C, stir for 5 minutes under the condition of 30r / min, then add filler, continue stirring for 10 minutes, and put it into the mixing tank. The granulation equipment is granulated to obtain the coating material, which is set aside;

[0055] S2: Add the cladding material to the co-extrusion hopper, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com