Technology for manufacturing glulam

A preparation process and glulam technology, applied in the pretreatment of molding materials, manufacturing tools, wood processing equipment, etc., can solve the problems of waste of resources, complicated production process, and difficult to guarantee dimensional tolerances, so as to improve the utilization rate of wood, high Strong nail holding power and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

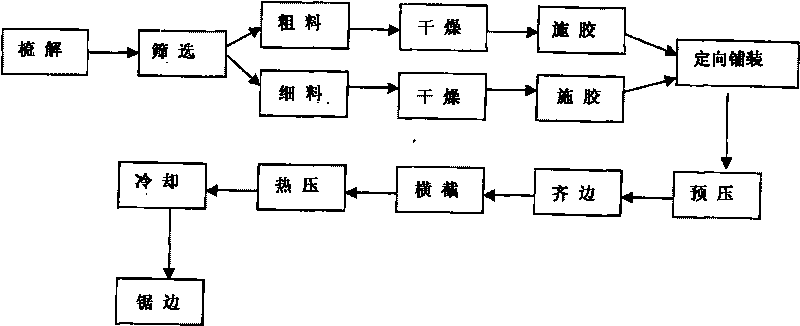

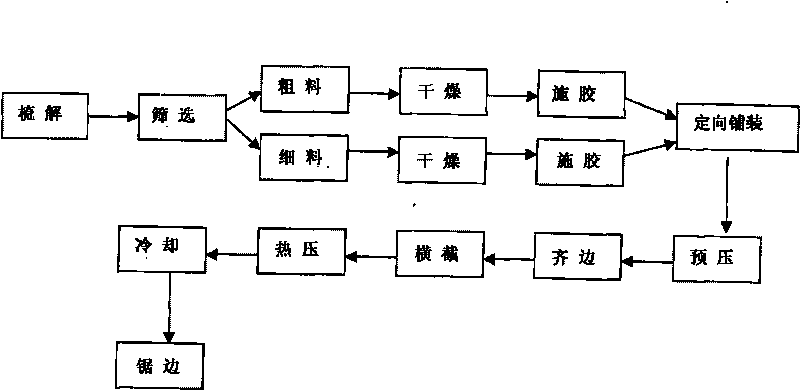

Image

Examples

Embodiment

[0018] Embodiment: a kind of preparation technology of glulam, comprises the following steps:

[0019] (1) Combing, first feed the waste wood scraps into the roller press for proper radial pressure, make them radially cracked, and initially separate into larger pieces and a network structure that is mutually adhered but not separated. The body is sent to the carding machine and then combed along the grain, so that the direction of the comb teeth is basically consistent with the direction of the wood fiber. There are a number of fixed-distance comb rulers on the carding machine, and the network structure is combed along the grain by the frequent action of the comb teeth. solution, forcing the adhesion part to separate, so that the separated wood bundle is basically in the shape of a single wood bundle, and the size of the wood bundle after the combing process is 90mm in length and the thickness is below 5mm;

[0020] (2) Screening, the wood bundle strips that will be combed are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com