High-strength rigid foam core board and preparation method thereof

A rigid foam, high-strength technology, applied in the field of high-strength rigid foam core board and its preparation, can solve the problem of low nail holding force, and achieve the effect of high nail holding force, good effect and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

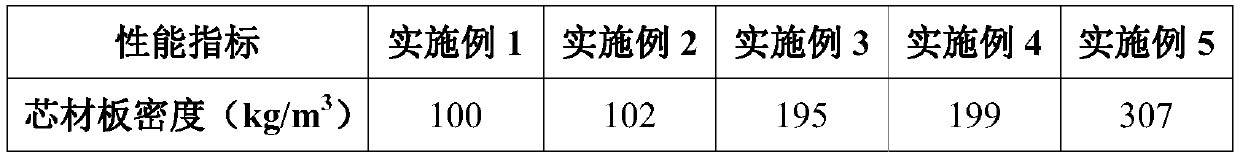

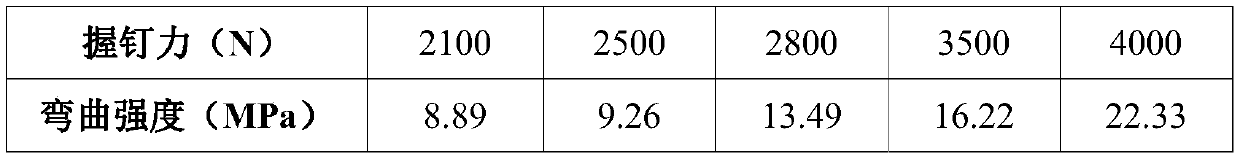

Examples

Embodiment 1

[0024] A high-strength rigid foam core board, the preparation method of which comprises the following steps:

[0025] 1) Make a forming mold (specification: 100cm×50cm×6cm), and then place the fiber felt (mass per unit area: 40g / m 2 ) is fixed on the bottom and top of the mold, and a three-dimensional fiber skeleton (consisting of mesh glass fibers and three-dimensional crimped nylon fibers; the mass per unit area of mesh glass fibers is 120g / m 2 , the mesh size is 4mm×4mm);

[0026] 2) The polyurethane base material and n-pentane were mixed evenly according to the mass ratio of 1:0.005, then injected into the molding mold, closed, and foamed at 40°C for 50 minutes to obtain a high-strength rigid foam core board.

Embodiment 2

[0028] A high-strength rigid foam core board, the preparation method of which comprises the following steps:

[0029] 1) Make a forming mold (specification: 100cm×50cm×6cm), and then place the fiber felt (mass per unit area: 35g / m 2 ) is fixed on the bottom and top of the mold, and a three-dimensional fiber skeleton (consisting of mesh glass fibers and three-dimensional crimped aramid fibers; the mass per unit area of mesh glass fibers is 80g / m 2 , the mesh specification is 6mm×6mm);

[0030] 2) The polyurethane base material and n-pentane were mixed evenly according to the mass ratio of 1:0.008, then injected into the molding mold, closed, and foamed at 60°C for 40 minutes to obtain a high-strength rigid foam core board.

Embodiment 3

[0032] A high-strength rigid foam core board, the preparation method of which comprises the following steps:

[0033] 1) Make a forming mold (specification: 100cm×50cm×3cm), and then place the fiber felt (mass per unit area: 60g / m 2 ) is fixed on the bottom and top of the mold, and a three-dimensional fiber skeleton (consisting of mesh glass fibers and three-dimensional crimped cotton fibers; the mass per unit area of mesh glass fibers is 50g / m 2 , the mesh size is 8mm×8mm);

[0034] 2) The polyurethane base material and n-butane were mixed evenly according to the mass ratio of 1:0.012, and then injected into the molding mold, closed, and foamed at 60°C for 60 minutes to obtain a high-strength rigid foam core board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com