Continuous glass fiber reinforced polyurethane microporous foaming profile pultrusion process and product and pultrusion system thereof

A continuous glass fiber and microporous foaming technology, applied in the field of polyurethane composite material preparation, can solve the problems of no super-tough wood, lack of toughness, poor interface bonding, etc., to overcome poor interface bonding, long service life, high grip nail force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

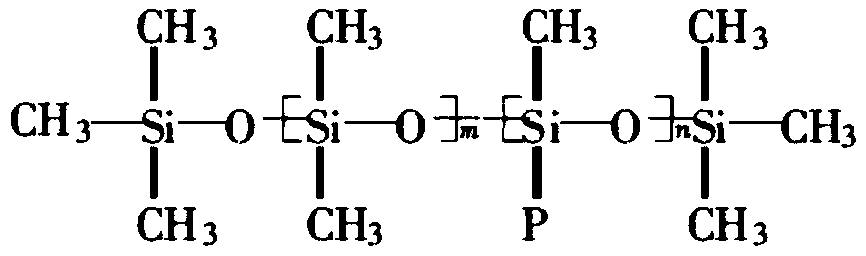

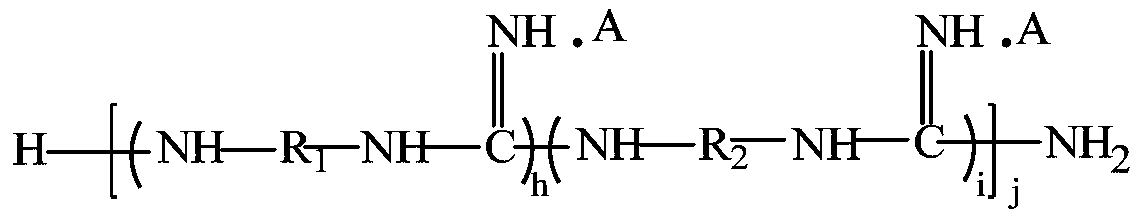

[0043] (1) Preparation of matrix raw materials: In terms of parts by weight of each raw material in the foaming system, the combined polyether is prepared according to the following ratio, and after being fully mixed, it is added to the storage tank,

[0044]

[0045] At the same time, isocyanate is added in storage tank B, wherein isocyanate is 110 parts of diphenylmethane diisocyanate (MDI)

[0046] (2) Reinforcement material: the continuous glass fiber filament whose surface is pretreated with KH792 silane coupling agent, and the weight ratio of the matrix material to the reinforcement material is 5:5.

[0047] (3) Forming process:

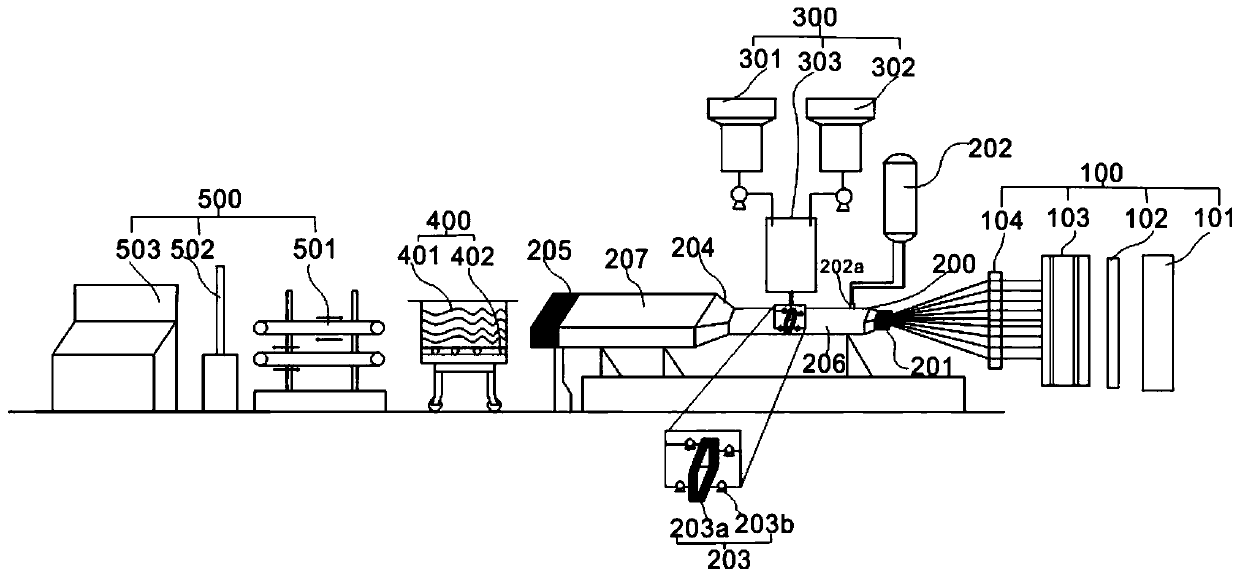

[0048] figure 1 It is a diagram of the continuous glass fiber reinforced polyurethane microcellular foamed profile pultrusion system of Example 1 of the present invention. The continuous glass fiber reinforced polyurethane microcellular foamed profile pultrusion system of the present invention includes:

[0049] The glass fiber pretreatmen...

Embodiment 2

[0068] Also adopt KH792 silane coupling agent to carry out the continuous glass fiber filament that surface is pretreated as reinforcement material, the ratio of matrix material and reinforcement material is 5:5, and isocyanate is changed to toluene diisocyanate (TDI), and addition is identical with embodiment 1 , Determination of its main mechanical properties, the results are shown in Table 2.

Embodiment 3

[0070] Also use KH792 silane coupling agent to pretreat the surface of continuous glass fiber as a reinforcing material, the ratio of matrix material to reinforcing material is 5:5, the isocyanate is changed to hexamethylene diisocyanate (HDI), the amount of addition and implementation Same as Example 1, its main mechanical properties were measured, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com