Door/window auxiliary frame and application method thereof

A technology of attaching frames and doors and windows, applied in the direction of base frame, window/door, frame fixing, etc., can solve the problems of time-consuming and labor-intensive, poor sealing performance, poor thermal insulation, etc., and achieve the effect of improving connection strength, strengthening bonding force, and enhancing sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

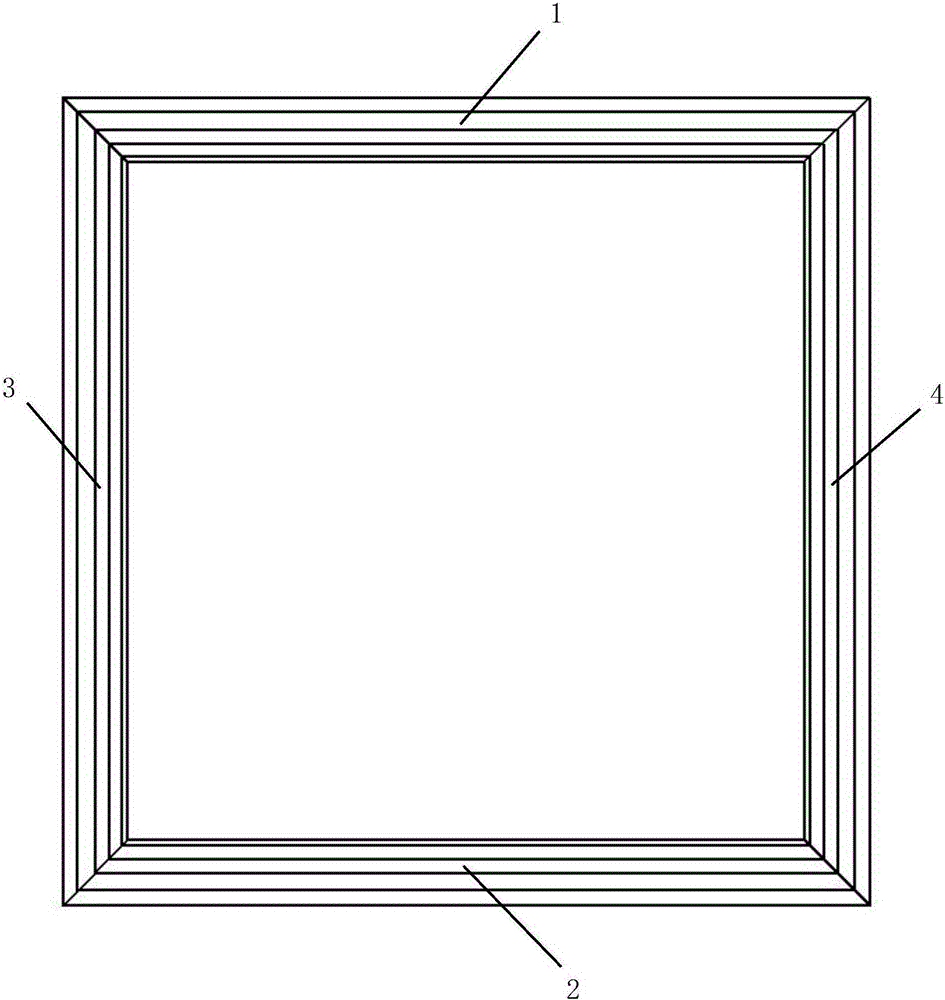

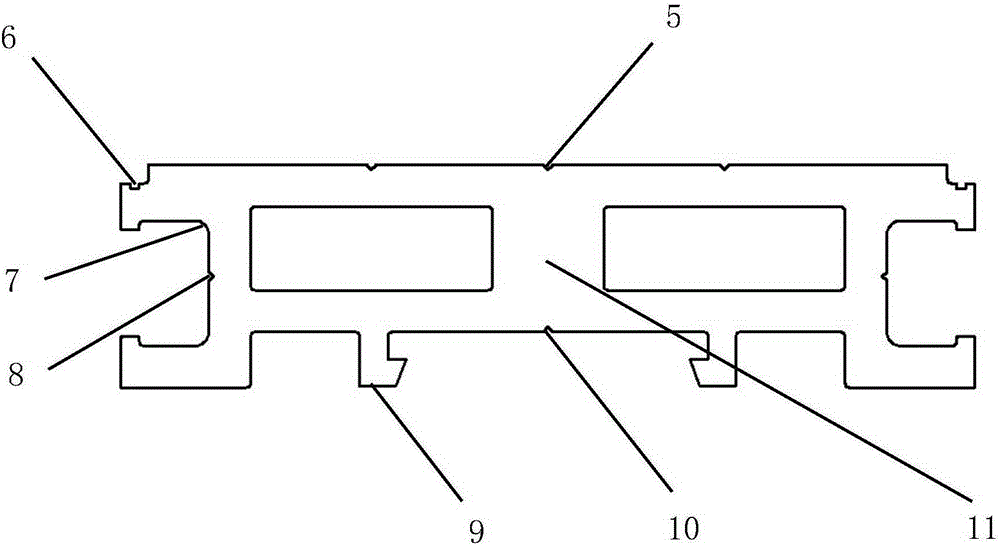

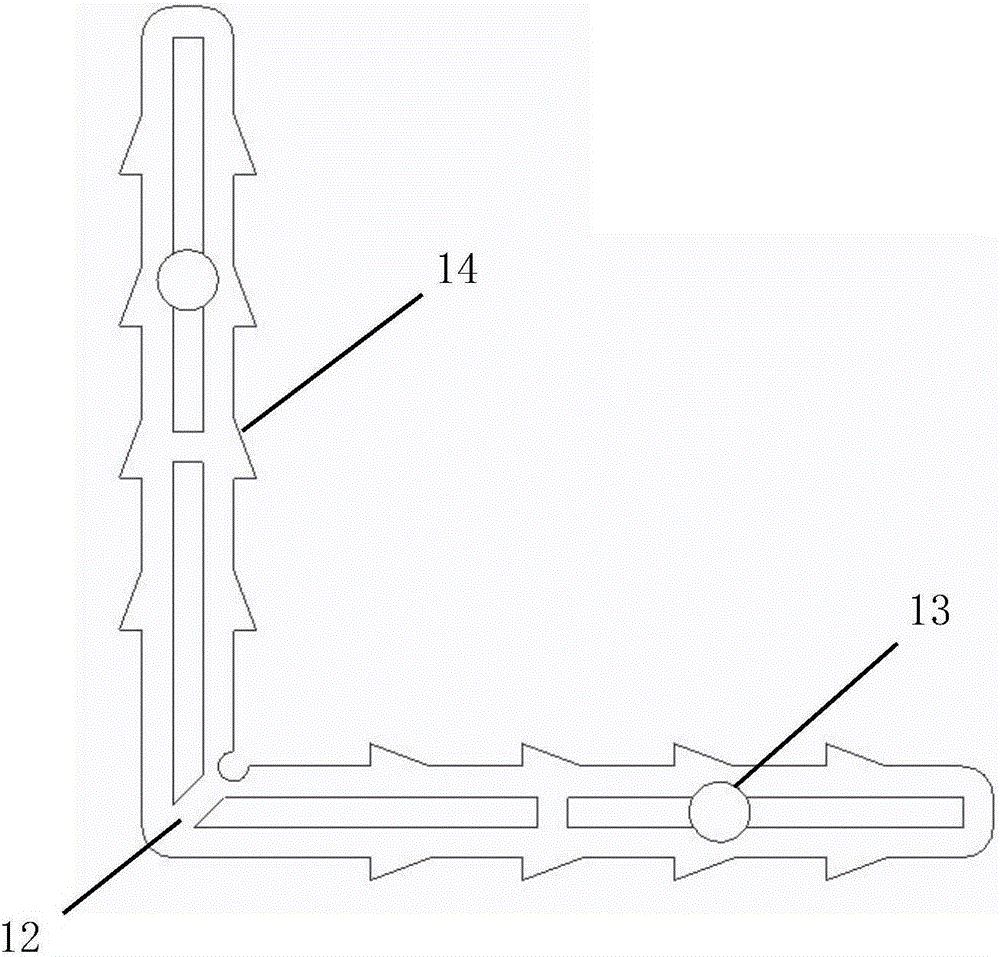

[0030] like figure 1 , figure 2 As shown, the attached frame of the present invention is a rectangular box, and the main body is composed of an upper frame plate 1, a lower frame plate 2, a left frame plate 3, and a right frame plate 4. Both ends of each plate are cut into angles of 45 degrees. Bevel angle; each frame plate has the same cross section, the upper side of the cross section is designed with the first screw positioning line 5 and the glue injection groove 6, and the left and right sides of the cross section are designed with the fixing groove 7 and the second screw positioning line 8, Buckles 9 and third screw positioning lines 10 are designed on the lower side of the cross section, and reinforcing ribs 11 are designed on the inner side of the cross section. The outer surface of the attached frame of the present invention has been sandblasted and has an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com