Glass mat gypsum board and preparation method thereof

A technology for gypsum board and thin felt, which is applied to building components, buildings, building materials, etc., can solve the problems of not proposing process parameters and preparation methods, the overall strength of the board is not greatly improved, and the gypsum board is easy to absorb moisture and mildew. Achieve the effect of improving breaking load and nail holding force, improving mechanical properties and application range, and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

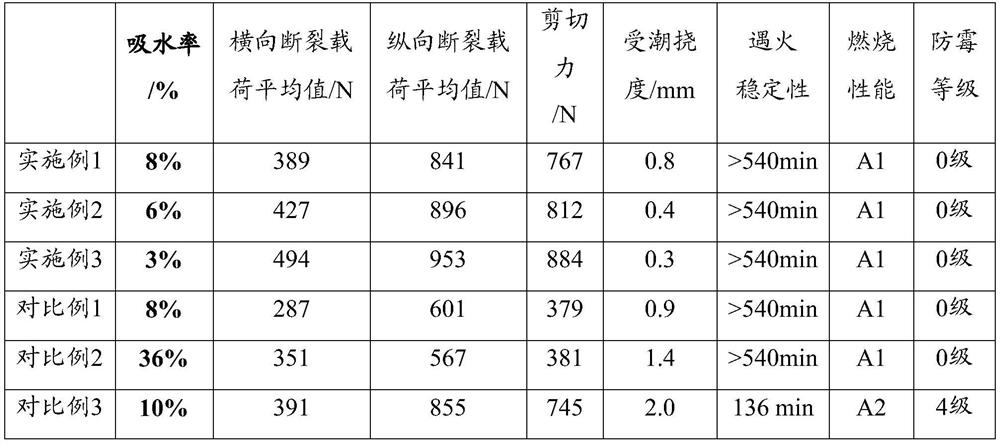

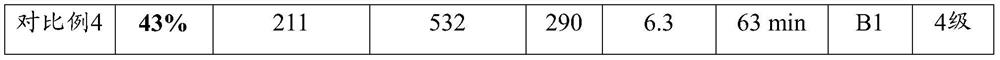

Examples

preparation example Construction

[0050] In the embodiment of the present application, optionally, the preparation method of the silicone modified emulsion includes the following steps:

[0051] 1) Dissolve the emulsifier in water, and mix it evenly with the silicone and the emulsion (stir vigorously for 20-40min,) to obtain a pre-emulsion; the quality of the emulsifier, the water, the silicone and the emulsion The ratio is (1 to 4):(40 to 80):(1 to 5):(30 to 40);

[0052] 2) Take (1-50) wt.% of the pre-emulsion described in step 1) and (1-50) wt.% of the initiator, mix evenly and heat up;

[0053] 3) Slowly add the rest of the pre-emulsion and the initiator, and keep warm to maintain the reaction;

[0054] 4) cooling the mixture obtained after the reaction in step 3) to 30°C to 40°C, and adjusting the pH value to 7-10 to obtain the modified emulsion;

[0055] In the embodiment of the present application, optionally, the organosilicon is selected from vinyltriethoxysilane, vinyltrimethoxysilane, octamethylcy...

Embodiment 1

[0067] This embodiment provides a kind of glass thin felt high-strength waterproof gypsum board, and described gypsum board comprises the following components: 100 parts by weight of gypsum powder, 0.1 part by weight of anionic surfactant sodium dodecylbenzene sulfonate, 0.2 part by weight of formazan Base cellulose ether, 0.2 weight part chopped glass fiber, 0.5 weight part modified emulsion, 0.1 weight part antifungal agent dichlorophen, 0.4 weight part polycarboxylate water reducer, 67 weight part water.

[0068] In the embodiment of the present application, the modified emulsion is a silicone acrylic emulsion.

[0069] The specific surface area of the gypsum clinker is 257m 2 / kg, the particle size is 43 μm, and the specific surface area is Blaine’s specific surface area. The density of described glass felt is 280g / m 2 , the thickness is 0.5mm. The chopped glass fibers have a diameter of 15 μm and a length of 7 mm.

[0070] The silicone acrylic emulsion was purchased...

Embodiment 2

[0077] This embodiment provides a glass thin felt high-strength waterproof gypsum board, the gypsum board includes the following components: 100 parts by weight of gypsum powder, 0.4 parts by weight of anionic surfactant sodium lauryl sulfate, and 0.8 parts by weight of cellulose ether Hydroxypropyl methylcellulose, 0.4 parts by weight of chopped glass fibers, 1.5 parts by weight of modified emulsion, 0.2 parts by weight of antifungal agent, 0.6 parts by weight of water reducer, and 73 parts by weight of water.

[0078] In the embodiment of the present application, the modified emulsion is a silicone-modified acrylate emulsion.

[0079] The preparation method of organosilicon modified acrylate emulsion comprises the steps:

[0080] 1) Dissolve octylphenol polyoxyethylene ether OP-10 in water, and mix it with vinyltriethoxysilane and acrylate emulsion to obtain a pre-emulsion; the emulsifier, the water, the organic The mass ratio of silicon and the emulsion is 1:40:1:30;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com