Method for producing composite non-woven cloth material from irradiated ultrahigh molecular weight polyethylene fiber

A technology of ultra-high molecular weight and polyethylene fiber, which is applied in the direction of fiber type, fiber treatment, non-woven fabrics, etc., can solve the problems of large ratio of resin glue to fiber, heavy weight, poor adhesion between fiber and resin matrix, etc., and achieve reduction Surface density, reduced dosage, and improved interfacial bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

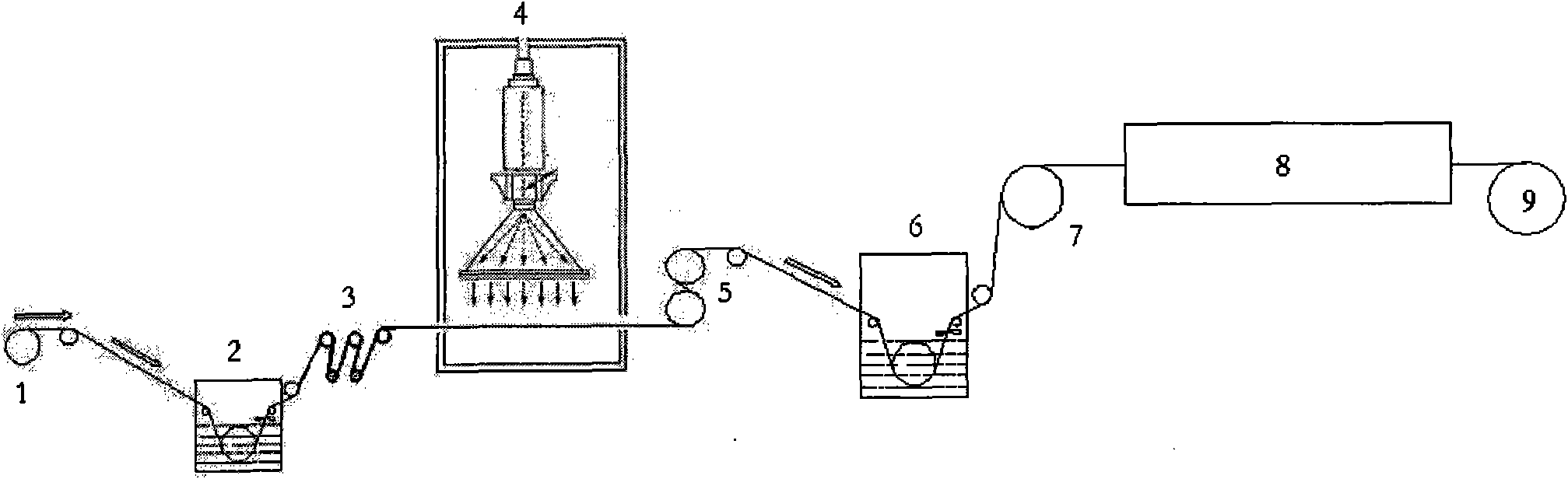

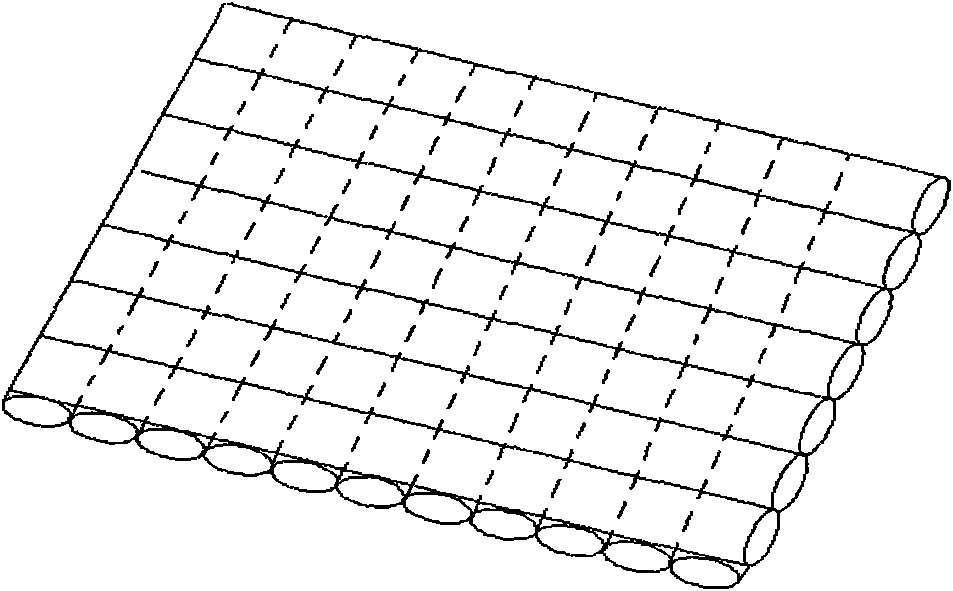

[0026] Such as Figure 1-2 As shown, a method for making ultra-high molecular weight polyethylene fiber composite non-weft cloth sheet, multiple strands of ultra-high molecular weight polyethylene fibers are bundled through a bundle guide roller 1 and spread in parallel to control the laying of ultra-high molecular weight polyethylene fibers Speed is 5m / min, by grafting liquid tank 2, the grafting liquid in this grafting liquid tank 2 is made of deionized water, acrylic acid, trichloroethylene, CuSO 4 Composition, based on deionized water, the concentration of acrylic acid is 6mol / L, the concentration of trichlorethylene is 1mol / L, CuSO 4 The concentration is 0.002mol / L. Using JJ-2 electrostatic accelerator, at room temperature, N 2 The ultra-high molecular weight polyethylene fiber impregnated with the above-mentioned grafting solution is introduced into the electron beam irradiation device 4 through the pulling roller 3 under the atmosphere for irradiation, and the avera...

Embodiment 2

[0028] A method for making ultra-high molecular weight polyethylene fiber composite non-weft cloth sheets, the method first controls the laying speed of ultra-high molecular weight polyethylene fibers to be 8m / min, passes through a grafting liquid tank, and the grafting liquid tank is formed by removing Ionized water, methacrylic acid, dichloroethane, CuSO 4 composition. Based on deionized water, the concentration of methacrylic acid is 10mol / L, the concentration of dichloroethane is 2.5mol / L, CuSO 4 The concentration is 0.01mol / L. Using JJ-2 electrostatic accelerator, at room temperature, N 2 The ultra-high molecular weight polyethylene fibers impregnated with the above-mentioned grafting solution were irradiated under the atmosphere, and the average dose rate was 40KGy / S. The irradiated fiber enters the dipping tank, the adhesive is EEA, the concentration is 22%. After the dipping, the tow containing the adhesive is treated with a parallel scraper on both sides, and then ...

Embodiment 3

[0030] A method for making ultra-high molecular weight polyethylene fiber composite non-weft cloth sheets, the method first controls the laying speed of ultra-high molecular weight polyethylene fibers to be 10m / min, passes through a grafting liquid tank, and the grafting liquid tank is formed by removing Ionized water, methyl acrylate, trichloroethylene, CuSO 4 composition. Based on deionized water, the concentration of methyl acrylate is 15mol / L, the concentration of trichlorethylene is 4.2mol / L, CuSO 4The concentration is 0.05mol / L. JJ-2 type electrostatic accelerator was used to irradiate the ultra-high molecular weight polyethylene fiber impregnated with the above grafting liquid at room temperature and Ar atmosphere, with an average dose rate of 60KGy / S. The irradiated fiber enters the dipping tank, the adhesive is EVA, the concentration is 20%, and the fiber / adhesive weight ratio in the unidirectional non-woven fabric is 85:15.

[0031] Then unwind the first layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com