Treatment method of enhancing wood performance by quick dense carbonization

A processing method and technology of wood, applied in the direction of wood processing, wood processing details, wood heating, etc., can solve the problem of wood density, flexural strength, impact toughness and nail-holding force reduction, affecting the performance of wood, poor dimensional stability of wood, etc. problems, to achieve the effect of improving anti-corrosion and antibacterial properties, realizing compression and densification, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

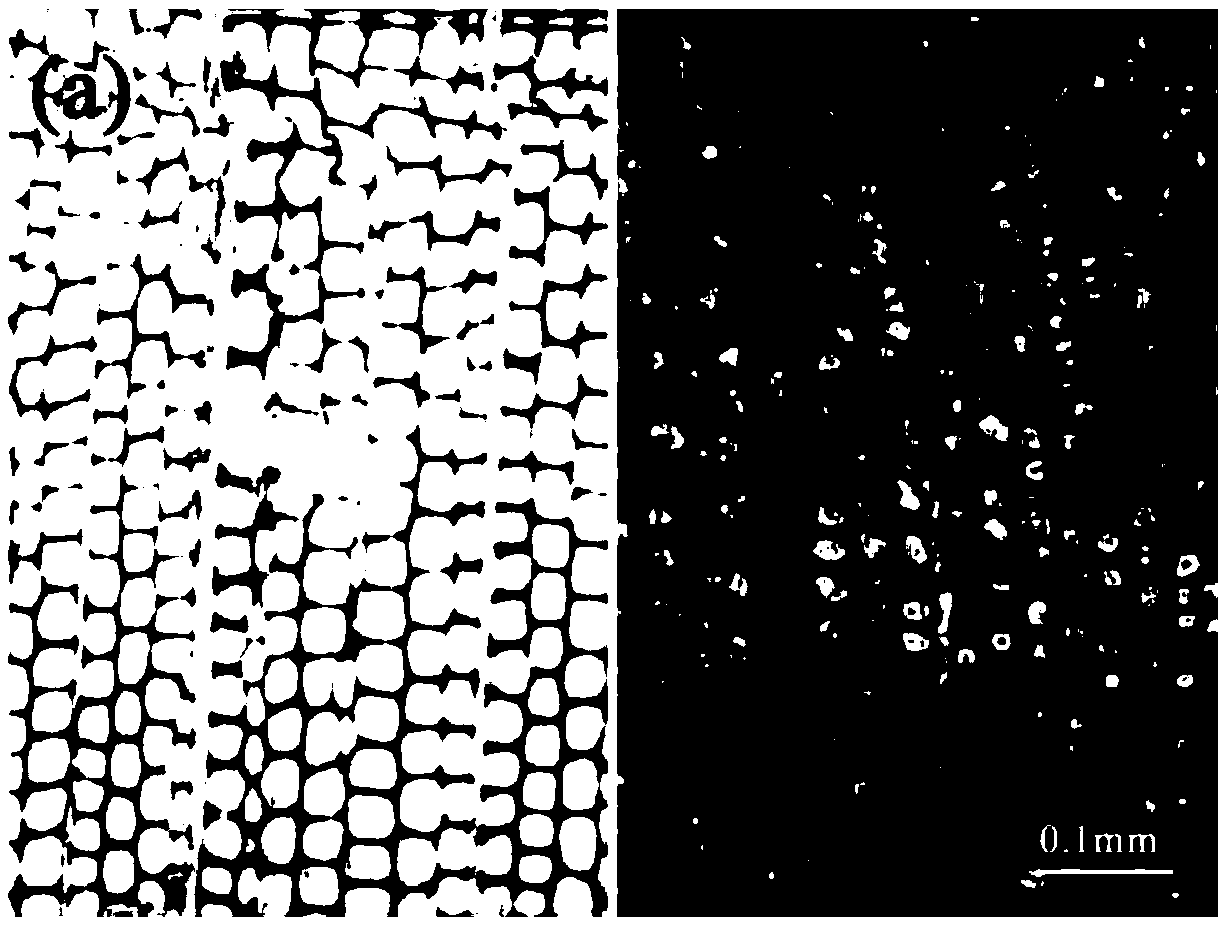

Image

Examples

Embodiment 1

[0030] A kind of processing method of fast dense carbonization of the present invention strengthens wood performance, concrete steps are as follows:

[0031] (1) Wood sawing is processed into the size required for use, and natural drying controls the moisture content of the wood to 20%;

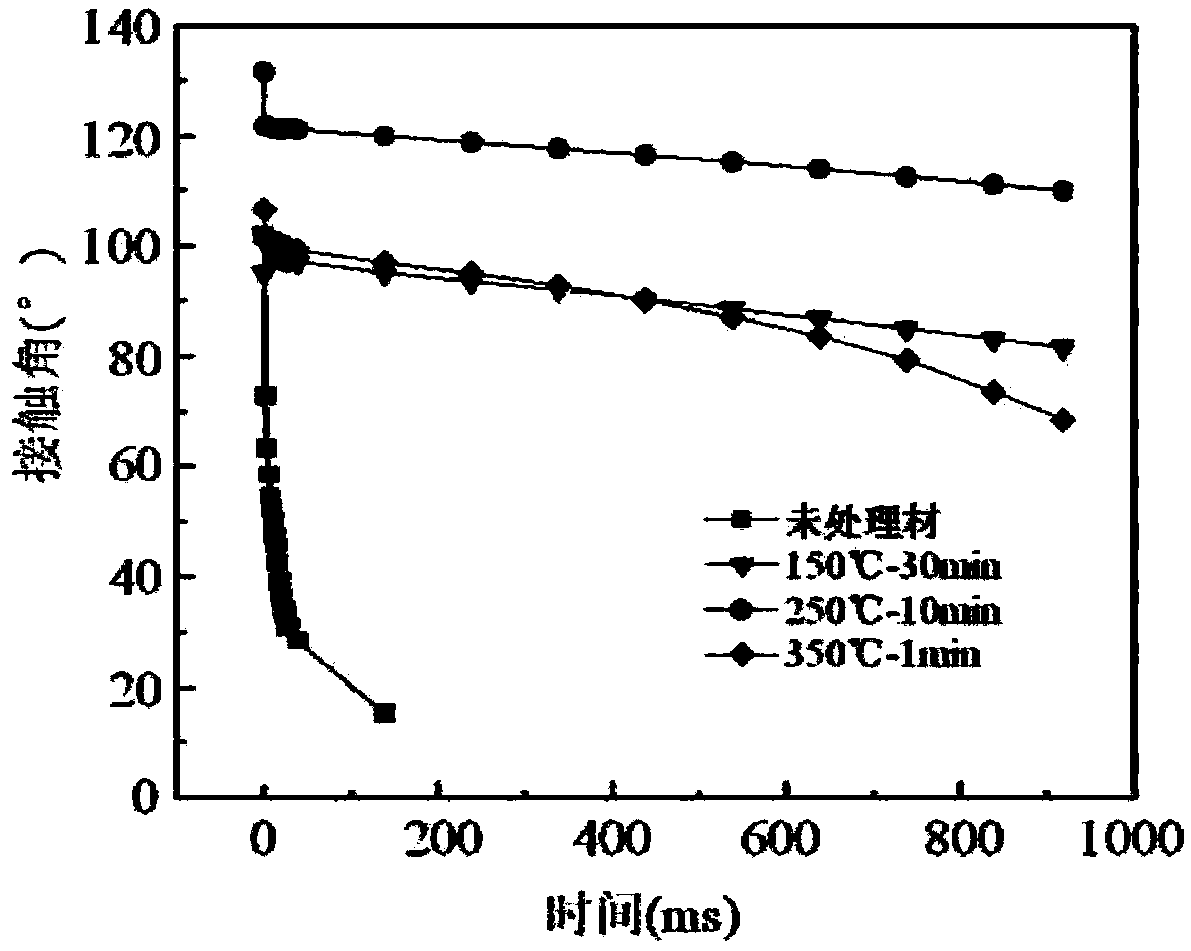

[0032] (2) Heat the stainless steel electric heating plate to the set temperature of 150°C, then put the wood of the same thickness batch on the stainless steel electric heating plate, and place a perforated metal plate between the wood and the pressure plate to adjust the heat treatment Water vapor in the process; the pressure plate (the pressure plate is not energized and heated) pressurizes the wood so that the wood compression rate is controlled to 25% (use a thickness gauge to control the thickness of the treated wood, and the closing time of wood compression to the thickness gauge is 5min );

[0033] (3) After the wood is continuously treated for 30 minutes under compression and heatin...

Embodiment 2

[0039] A kind of processing method of fast dense carbonization of the present invention strengthens wood performance, concrete steps are as follows:

[0040] (1) Wood sawing is processed into the size required for use, and the drying kiln is dried to control the moisture content of the wood to 15%;

[0041](2) Heat the stainless steel heater to the set temperature of 250°C, then put the wood of the same thickness batch on the stainless steel electric heating plate, and place a perforated metal plate between the wood and the pressure plate to adjust the heat treatment process Water vapor in the medium; the pressure plate (the pressure plate is not heated) pressurizes the wood so that the wood compression rate is controlled to 15% (the thickness of the wood is controlled by a thickness gauge, and the closing time of the wood compression to the thickness gauge is 2.5min) ;

[0042] (3) After the wood is continuously processed under compression and heating for 10 minutes, turn on...

Embodiment 3

[0048] A kind of processing method of fast dense carbonization of the present invention strengthens wood performance, comprises the following steps:

[0049] (1) Saw the wood into the size required for use, and dry it naturally until the moisture content of the wood is 9%;

[0050] (2) Heat the stainless steel to a set temperature of 350°C, then place the same batch of wood on a stainless steel electric heating plate for heating, and place a perforated metal plate between the wood and the pressure plate to adjust the heat treatment process Water vapor in the medium; the pressure plate (the pressure plate is not heated) pressurizes the wood so that the wood compression rate is controlled to 6% (the thickness of the wood is controlled by a thickness gauge, and the closing time of the wood compression to the thickness gauge is 0.5min) ;

[0051] (3) After the wood is continuously processed under compression and heating for 1 min, turn on the water cooling system under the stainl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com